ANSYS Polyflow Simulation for Polymer Extrusion: Advanced Modeling Techniques for Biomedical Device Development

This article provides a comprehensive guide to leveraging ANSYS Polyflow for simulating polymer extrusion processes, with a specific focus on applications in biomedical and pharmaceutical device manufacturing.

ANSYS Polyflow Simulation for Polymer Extrusion: Advanced Modeling Techniques for Biomedical Device Development

Abstract

This article provides a comprehensive guide to leveraging ANSYS Polyflow for simulating polymer extrusion processes, with a specific focus on applications in biomedical and pharmaceutical device manufacturing. We explore foundational non-Newtonian fluid dynamics, detail practical methodologies for modeling screws, dies, and co-extrusion, address critical troubleshooting for defects like die swell and melt fracture, and discuss validation against experimental data. Aimed at researchers and development professionals, this guide bridges simulation theory with practical optimization for creating drug delivery systems, lab-on-a-chip devices, and implantable polymer components.

Mastering the Fundamentals: Non-Newtonian Flow and Polymer Rheology in ANSYS Polyflow

Application Notes: Polymer Extrusion in Medical Device Fabrication

Polymer extrusion is a foundational, continuous manufacturing process for producing a wide array of biomedical devices, including catheters, tubing, fibers for tissue engineering scaffolds, and filament for 3D printing of implants. The process involves melting polymer pellets (e.g., PLGA, PCL, PU, medical-grade PVC) in a heated barrel and forcing the viscous melt through a die to create a continuous profile with a defined cross-section. Precision control over thermal and shear history is critical to ensure the final device meets stringent requirements for biocompatibility, mechanical properties, and dimensional accuracy.

The integration of ANSYS Polyflow simulation into research and development provides a powerful tool for virtual prototyping. It enables researchers to model complex non-Newtonian fluid dynamics, predict velocity/temperature fields, shear stress, and pressure drop, and optimize die design before physical trials. This significantly reduces material waste, accelerates development cycles, and enhances understanding of process-structure-property relationships critical for regulatory submissions.

Table 1: Common Biomedical Polymers and Key Extrusion Parameters

| Polymer | Typical Medical Application | Recommended Melt Temp (°C) | Key Extrusion Challenge | ANSYS Polyflow Relevance |

|---|---|---|---|---|

| PLGA (85:15) | Bioresorbable sutures, scaffolds | 180-220 | Hydrolysis/degradation if moisture present | Modeling thermal degradation kinetics |

| PCL | Long-term implantable devices, drug delivery | 60-100 | Low melt strength, difficult to draw | Viscoelastic flow simulation for draw-down |

| Medical-Grade PVC | Flexible tubing, blood bags | 170-190 | Thermal stabilizer leaching | Predicting thermal history to minimize degradation |

| Polyurethane (TPU) | Vascular grafts, cardiac leads | 190-220 | Melt fracture at high shear rates | Analyzing wall shear stress to eliminate defects |

| UHMWPE | Orthopedic bearing surfaces | 200-250 | Extremely high viscosity, non-Newtonian | Accurate shear-thinning power-law modeling |

Table 2: Critical Quality Attributes (CQAs) for Extruded Medical Devices

| CQA | Target Range (Example) | Influential Extrusion Parameter | Measured Via |

|---|---|---|---|

| Outer Diameter | 2.00 mm ± 0.05 mm | Die swell, haul-off speed | Laser micrometer |

| Wall Thickness Uniformity | < ±5% variation | Die centering, melt homogeneity | Optical Coherence Tomography |

| Tensile Strength | > 20 MPa | Molecular orientation (draw ratio) | Instron Tensile Tester |

| Surface Roughness (Ra) | < 0.8 µm | Melt fracture, cooling rate | Profilometry/AFM |

| Residual Stress | Minimized | Cooling profile, draw-down | Photoelasticity or simulated |

Experimental Protocols

Protocol 1: Single-Screw Extrusion of PLGA Monofilament for Surgical Sutures

Objective: To produce a consistent, high-strength, bioresorbable PLGA monofilament with a target diameter of 0.3 mm.

Materials & Pre-processing:

- PLGA (85:15) pellets (Purac Biomaterials).

- Vacuum oven for drying (12 hrs at 50°C, <0.02% moisture).

- Laboratory-scale single-screw extruder (e.g., Thermo Scientific Haake MiniLab) with a 2 mm diameter rod die.

- Calibrated haul-off unit and spooler.

- Three-zone temperature-controlled water bath for cooling.

Procedure:

- Material Preparation: Dry PLGA pellets in a vacuum oven per manufacturer specifications. Store in a desiccator until use.

- Extruder Setup: Configure the extruder with a 2 mm circular die. Set the temperature profile along the three heating zones: Zone 1 (Feed): 160°C, Zone 2 (Transition): 180°C, Zone 3 (Metering/Die): 190°C. Allow system to equilibrate for 30 minutes.

- Purging & Priming: Purge the barrel with a lower-temperature polymer (e.g., PLA) if needed. Feed dried PLGA pellets manually until a clean melt extrudes.

- Steady-State Operation: Run the extruder at a screw speed of 20 rpm. Allow 15 minutes for steady-state conditions.

- Drawing & Quenching: Gently guide the extrudate through a 40°C water bath placed 5 cm from the die exit. Attach the filament to the haul-off unit set at a speed of 15 m/min to achieve the desired draw-down ratio (~10:1).

- Collection: Spool the finalized monofilament under constant tension. Label and store in a desiccated, UV-light-free environment.

- Process Monitoring: Record actual barrel temperatures, screw speed, melt pressure, and haul-off speed.

Protocol 2: Tubular Extrusion of PU for Vascular Conduit Prototyping

Objective: To co-extrude a two-layer tubular structure mimicking a vascular graft, with an inner diameter of 4 mm and a wall thickness of 0.5 mm.

Materials:

- Medical-grade thermoplastic polyurethane (TPU) pellets (e.g., Tecothane) – two colors or grades for layer distinction.

- Co-axial tubular die with mandrel and spider legs.

- Dual-stream single-screw extruder or two synchronized extruders.

- Precision peristaltic pump for lumen pressurization (optional).

- Laser gauge for diameter measurement.

Procedure:

- Die Design & Setup: Install a co-axial die with independent melt channels for inner and outer layers. Set mandrel to target 4 mm ID.

- Temperature Profiling: Set a balanced temperature profile for both TPU streams, ramping from 180°C (feed) to 210°C (die).

- Co-extrusion Initiation: Start both extruders at low speed (10 rpm). Introduce internal air pressure (0.5 Bar) via the mandrel to prevent tube collapse.

- Haul-off & Sizing: Guide the soft tube through a calibrated sizing sleeve and into a 10°C water bath placed 20 cm downstream. Engage the haul-off unit.

- Layer Ratio Control: Adjust the relative screw speeds of the two extruders to achieve the desired inner/outer layer thickness ratio (e.g., 1:1).

- Process Optimization: Use in-line laser micrometry for real-time OD feedback to adjust haul-off speed or internal pressure dynamically.

- Collection: Cut samples for characterization and spool the remainder.

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Key Materials & Reagents for Biomedical Polymer Extrusion Research

| Item Name/Class | Example Product/Chemical | Primary Function in Research |

|---|---|---|

| Bioresorbable Polymer | PLGA (Lactel Absorbable Polymers) | Raw material for temporary implants; study degradation kinetics vs. extrusion history. |

| Thermoplastic Elastomer | ChronoFlex C (AdvanaSource) | Material for flexible, implantable devices; study melt fracture limits and compliance. |

| Medical-Grade Masterbatch | Colorant Masterbatch (Colorite) | Adds traceable color for layer distinction or UV stabilization without compromising biocompatibility. |

| Processing Stabilizer | Irganox 1010 (BASF) | Antioxidant added to prevent thermal-oxidative degradation during processing. |

| Plasticizer (for rigid polymers) | Acetyl Tributyl Citrate (ATBC) | Increases flexibility and processability of polymers like PVC; study leaching potential. |

| In-line Rheometer | Goettfert RheoTester | Attached to die, provides real-time viscosity & shear rate data for model validation. |

| ANSYS Polyflow Software | ANSYS Academic Research | Finite Element Analysis software for simulating extrusion, die swell, and mixing. |

| Characterization: DSC | TA Instruments Q20 | Determines thermal transitions (Tg, Tm, crystallinity) affected by extrusion thermal history. |

| Characterization: GPC/SEC | Agilent InfinityLab | Measures molecular weight distribution to quantify shear-induced chain scission. |

Visualization: Experimental and Simulation Workflows

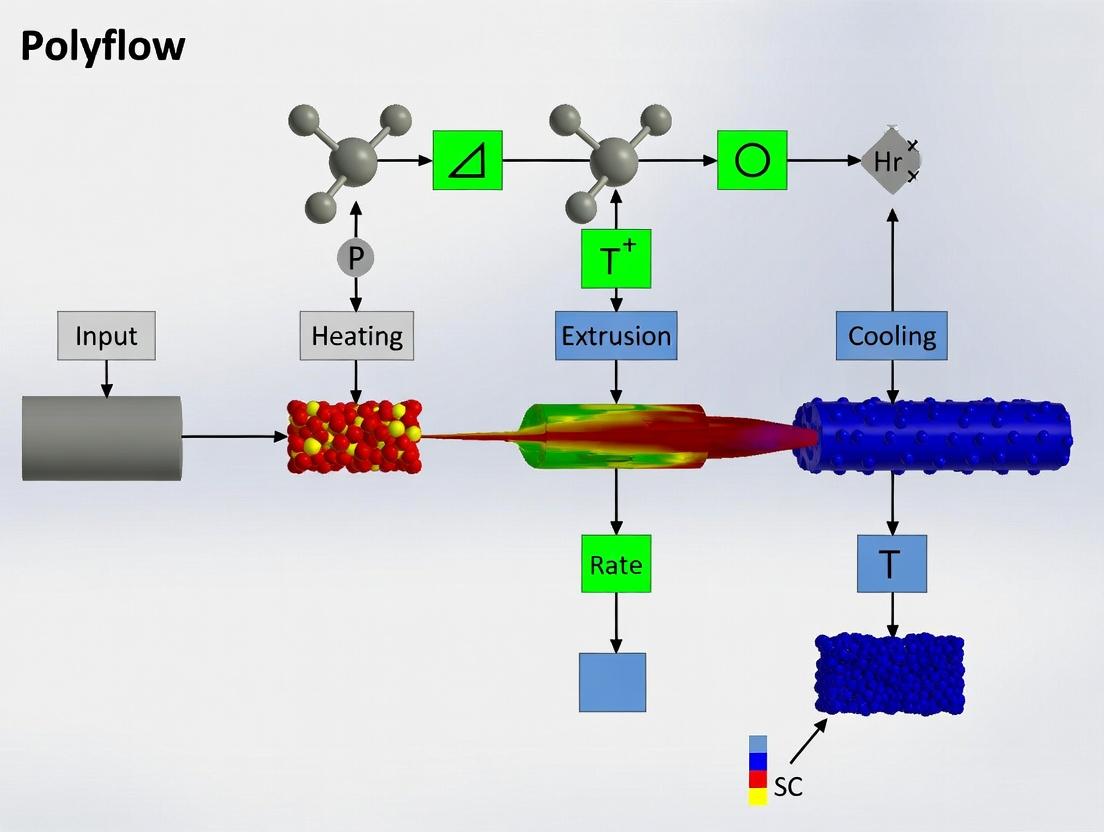

Diagram Title: Integrated Simulation-Experimental Workflow for Extrusion Optimization

Diagram Title: Cause-Effect Map of Extrusion Parameters on Final Device Quality

Application Notes: Rheological Models for Polymer Extrusion Simulation

The accurate simulation of polymer extrusion in ANSYS Polyflow hinges on selecting an appropriate constitutive model that captures both viscoelastic stress relaxation and shear-thinning viscosity. The following models are critical for predicting flow instabilities, die swell, and final product morphology.

Quantitative Comparison of Common Constitutive Models

Table 1: Key Rheological Models for Polymer Melt Simulation in ANSYS Polyflow

| Model Name | Type | Key Parameters (Typical Units) | Best For | Limitations |

|---|---|---|---|---|

| Generalized Newtonian (Power Law) | Viscosity-only | ( K ) (Pa·sⁿ), ( n ) (-), ( \dot{\gamma}_0 ) (1/s) | High shear, dominant viscous flows. | Cannot predict viscoelastic effects like normal stresses. |

| Carreau-Yasuda | Viscosity-only | ( \eta0 ) (Pa·s), ( \eta\infty ) (Pa·s), ( \lambda ) (s), ( a ) (-), ( n ) (-) | Capturing zero-shear plateau and shear-thinning. | Purely viscous, no elasticity. |

| Upper-Convected Maxwell (UCM) | Viscoelastic | ( \eta ) (Pa·s), ( \lambda ) (s) | Basic stress relaxation, theoretical analysis. | No shear-thinning, excessive strain hardening. |

| Giesekus | Viscoelastic | ( \eta ) (Pa·s), ( \lambda ) (s), ( \alpha ) (-) | Shear-thinning, normal stresses, polymer anisotropy. | More complex parameter fitting. |

| Phan-Thien Tanner (PTT) | Viscoelastic | ( \eta ) (Pa·s), ( \lambda ) (s), ( \epsilon ) (-), ( \xi ) (-) | Elongational flows, strain softening, die swell. | Multiple parameters require extensive data. |

Note: ( \eta_0 ): zero-shear viscosity; ( \eta_\infty ): infinite-shear viscosity; ( \lambda ): relaxation time; ( K ): consistency index; ( n ): power-law index; ( \alpha, \epsilon, \xi ): model-specific nonlinear parameters.

Protocol: Determination of Model Parameters from Rheometry Data

Objective: To experimentally obtain parameters for the Giesekus model using small-amplitude oscillatory shear (SAOS) and steady shear measurements.

Materials & Equipment:

- Strain-controlled rotational rheometer (e.g., TA Instruments ARES-G2, Malvern Kinexus).

- Parallel plate geometry (8-25 mm diameter).

- Polymer sample disks, compression-molded.

- Environmental test chamber for temperature control.

Procedure:

Sample Loading & Temperature Equilibrium:

- Preheat rheometer plates to target processing temperature (e.g., 200°C).

- Load polymer disk onto the lower plate.

- Lower the upper plate to a defined gap (typically 1.0 mm). Trim excess material.

- Allow sample to thermally equilibrate for 10 minutes under a nitrogen blanket to prevent degradation.

Small-Amplitude Oscillatory Shear (SAOS) - Linear Viscoelasticity:

- Perform a strain sweep (0.1-10% strain) at a fixed angular frequency (ω = 10 rad/s) to determine the linear viscoelastic region (LVR).

- Execute a frequency sweep (e.g., 0.1 to 100 rad/s) within the LVR (typically 1% strain).

- Record storage modulus ((G')), loss modulus ((G'')), and complex viscosity ((|\eta^*|)).

- Data Fitting (Part 1): Fit the discrete relaxation spectrum ({gi, \lambdai}) to the (G') and (G'') master curves using the TA Instruments TRIOS software or equivalent. A single-mode Giesekus model can be initialized using the dominant relaxation time (( \lambda{max} )) and plateau modulus (( GN^0 = \sum g_i )).

Steady Shear - Nonlinear Viscosity & Normal Stress:

- Conduct steady shear rate sweeps from low shear (0.01 1/s) to high shear (1000 1/s).

- Record steady-state shear viscosity ((\eta)) and first normal stress difference ((N_1)) if measurable.

- Data Fitting (Part 2): In ANSYS Polyflow's material property fitting module or external software (e.g., MATLAB), fit the Giesekus model parameters ((\eta0, \lambda, \alpha)) simultaneously to:

- The complex viscosity (|\eta^|)(ω) data (using the Cox-Merz rule: (|\eta^|)(ω) ≈ (\eta(\dot{\gamma})) for ω = (\dot{\gamma})).

- The steady shear viscosity (\eta(\dot{\gamma})) data.

- The (N1) vs (\dot{\gamma}) data (if available).

Validation:

- Use the fitted parameters in a simple 2D axisymmetric die flow simulation in ANSYS Polyflow.

- Compare simulated pressure drop and die swell ratio with a bench-scale extrusion experiment.

Protocol: Coupled Extrusion & Swell Simulation in ANSYS Polyflow

Objective: To simulate the non-isothermal, viscoelastic flow of a shear-thinning polymer through an extrusion die and predict the post-die swell.

Workflow:

Diagram Title: ANSYS Polyflow Extrusion Simulation Workflow

Detailed Steps:

Geometry & Mesh:

- Create a 2D axisymmetric or 3D model of the die flow region in ANSYS DesignModeler or SpaceClaim. Include an extended domain beyond the die exit to capture swell.

- Import geometry into ANSYS Meshing. Generate a hybrid mesh (quadrilaterals in the main flow, triangles in swell region). Ensure high mesh density (boundary layers) near the die walls and exit.

Material Model Definition:

- In Polyflow, select "Generalized Newtonian" or "Viscoelastic" fluid.

- For shear-thinning without elasticity: Select the Carreau-Yasuda model. Input parameters ((\eta_0, \lambda, a, n)) from Table 1.

- For viscoelastic + shear-thinning: Select the Giesekus or PTT model. Input the parameters ((\eta_0, \lambda, \alpha) or (\epsilon, \xi)) obtained from Protocol 1.2.

Boundary Conditions & Solver Setup:

- Inlet: Volume flow rate (or average velocity).

- Walls: No-slip condition. Set a fixed temperature (e.g., 200°C).

- Outlet (Free Surface): Use the "Remeshing" technique with the Spine method. Apply normal stress = 0 (atmospheric pressure).

- Solver: Choose "Segregated" solver for viscoelastic flows. Enable "Free Surface Tracking." Set appropriate convergence criteria for stresses (e.g., 1E-4).

Post-Processing:

- Calculate the die swell ratio = (extrudate diameter at equilibrium) / (die diameter).

- Analyze pressure drop along the die length.

- Visualize shear rate, viscosity, and first normal stress difference fields to identify regions of high stress or excessive thinning.

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Materials for Polymer Rheology & Extrusion Research

| Item | Function/Description | Example/Supplier |

|---|---|---|

| Model Polymer Resins | Well-characterized, standard materials for method validation. | Polystyrene (PS) NIST 706, Polypropylene (PP), Polyethylene (PE). |

| Stabilized Polymer Pellets | Prevent oxidative degradation during high-temperature rheology. | Pellets with added BHT or phosphite stabilizers (e.g., from Sigma-Aldrich). |

| Compression Molding Press | To prepare uniform, bubble-free disks for rheometry. | Carver Laboratory Press with heated platens. |

| Parallel Plate & Cone-Plate Geometry | Rheometer fixtures for measuring viscous and elastic properties. | Stainless steel or quartz, 8-25 mm diameter (TA Instruments, Anton Paar). |

| ANSYS Polyflow License | Finite Element software for simulating viscoelastic, non-Newtonian flows. | Academic or commercial license from ANSYS Inc. |

| High-Performance Computing (HPC) Cluster | For running large, transient 3D viscoelastic simulations. | Local university cluster or cloud-based HPC (AWS, Azure). |

| Capillary Rheometer | Measures viscosity at very high shear rates relevant to extrusion (>1000 1/s). | Rosand RH7/Dynisco LCR. |

| Laboratory-Scale Twin-Screw Extruder | For validating simulation predictions (swell, pressure) under real conditions. | Thermo Scientific Process 11, Xplore MC15. |

Application Notes: Core Polyflow Modules for Extrusion

Polymer extrusion research within ANSYS Workbench leverages specialized Polyflow modules integrated into a unified simulation environment. The following table summarizes the key quantitative data and functional roles of the primary modules.

Table 1: Key ANSYS Polyflow Modules for Extrusion Simulation

| Module Name | Primary Function | Key Quantitative Outputs | Integration within Workbench |

|---|---|---|---|

| Polydata | Pre-processor for defining geometry, mesh, and physics. | Mesh metrics (elements, skewness), Boundary condition IDs, Material zone definitions. | Accessed as the "Setup" cell; feeds data to the Polyflow solver. |

| Polyflow Solver | Finite-element solver for viscoelastic & generalized Newtonian flows. | Pressure drop (Pa), Flow rate (kg/s), Shear rate (1/s), Temperature (K), Velocity field. | Core solver engine; configured via Polydata and controlled by Workbench. |

| CFD-Post | Advanced post-processor for visualization and data extraction. | Extrudate swell (%), Die pressure (MPa), Velocity profile plots, Mixing index. | Standard post-processing module within the ANSYS ecosystem. |

| Anisotropic Diffusion | Models fiber orientation in filled polymers. | Orientation tensor components, Principal direction angles. | Add-on physics activated within the Polydata pre-processor. |

| Remeshing (ALE) | Manages mesh deformation for free surface flows (e.g., swell). | Mesh quality over time, Node displacement thresholds. | Critical sub-module for transient extrusion simulations. |

Experimental Protocols for Extrusion Simulation

Protocol 2.1: Steady-State 2D Axisymmetric Die Flow Analysis

Objective: To predict pressure drop and velocity profile for a capillary die.

- Workbench Project Setup: Launch ANSYS Workbench. Drag a "Polyflow" component system into the Project Schematic.

- Geometry: In the "Geometry" cell, create or import a 2D axisymmetric representation of the die flow region.

- Mesh: Generate a high-resolution mesh near the die walls using inflation layers. Target skewness < 0.9.

- Polydata Setup: Double-click "Setup" to launch Polydata.

- Subtask: Create a "New task" → "F.E.M. task 1".

- Material Model: Define a generalized Newtonian model (e.g., Carreau). Input parameters: Zero-shear viscosity (η₀), Power-law index (n), Time constant (λ).

- Boundary Conditions: Specify Inlet (volumetric flow rate), Walls (no-slip), Axis of symmetry, and Outlet (atmospheric pressure).

- Numerical Parameters: Select "Steady-state" analysis and "U/P formulation".

- Solution: In Workbench, run the "Solution" cell. Monitor residuals for convergence (< 10⁻⁴).

- Post-Processing: Open "Results" in CFD-Post. Create contour plots for pressure and velocity. Plot velocity profile at the die exit.

Protocol 2.2: Transient 3D Extrudate Swell Simulation

Objective: To simulate the time-dependent swelling of a polymer after exiting a die.

- Follow Steps 1-3 from Protocol 2.1 for a 3D die geometry.

- Polydata Setup:

- Subtask: "New task" → "3D extrusion task".

- Free Surface: Activate the "Remeshing" technique with the "ALE" method. Define the initial free surface location at the die exit.

- Transient Settings: Define time step and total simulation time based on characteristic flow time.

- Material Model: Use a viscoelastic model (e.g., Giesekus) if necessary. Input parameters: Solvent viscosity, polymer viscosity, relaxation time, mobility parameter.

- Solution: Execute the transient solver. Monitor mesh quality and remeshing triggers.

- Post-Processing: Animate the free surface deformation. Quantify the steady-state swell ratio as (Final Diameter / Die Diameter) * 100%.

Visualization Diagrams

Title: Polyflow Workbench Simulation Workflow

Title: Polydata Pre-processing Logic Flow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials & Digital Tools for Polyflow Extrusion Research

| Item Name | Category | Function in Research |

|---|---|---|

| Carreau Model Parameters | Material Data | Describe shear-thinning behavior of polymers; critical for accurate viscosity prediction. |

| Giesekus Model Parameters | Material Data | Define viscoelastic stress response for simulating extrudate swell and normal stresses. |

| High-Resolution Mesh | Digital Tool | Enables resolution of high shear rate gradients near die walls; foundation of solution accuracy. |

| Remeshing (ALE) Controls | Solver Setting | Manages mesh distortion during free surface flow, allowing for stable transient swell simulation. |

| User-Defined Function (UDF) | Custom Code | Allows implementation of proprietary material models or complex boundary conditions. |

| Mixing Index Calculator | Post-Processing Script | Quantifies distributive mixing efficiency in static mixers or extruder sections. |

Within a broader thesis utilizing ANSYS Polyflow for polymer extrusion research—particularly relevant to pharmaceutical hot-melt extrusion (HME) for amorphous solid dispersions—the accurate definition of non-Newtonian fluid behavior is paramount. The selection and calibration of appropriate rheological models (Power Law, Carreau, Cross) directly dictate the fidelity of simulations predicting flow, pressure drop, shear heating, mixing, and ultimately, product quality. This document provides application notes and protocols for this critical pre-processing step.

Rheological Model Definitions and Data Fitting

The generalized Newtonian fluid models relate the shear stress (τ) to the shear rate (γ̇) via the apparent viscosity (η). The model parameters are typically determined by fitting to experimental rotational or capillary rheometry data.

Table 1: Rheological Model Equations and Parameter Descriptions

| Model | Equation | Key Parameters | Physical Interpretation |

|---|---|---|---|

| Power Law | η = K γ̇^(n-1) | K: Consistency Index (Pa·sⁿ). n: Power Law Index. |

n<1: Shear-thinning. n=1: Newtonian. Simple, limited range. |

| Carreau | η(γ̇) = η∞ + (η₀ - η∞)[1 + (λγ̇)²]^((n-1)/2) | η₀: Zero-shear viscosity (Pa·s). η∞: Infinite-shear viscosity (Pa·s). λ: Time constant (s). n: Power Law Index. |

Captures Newtonian plateaus at low/high shear, transition region. |

| Cross | η(γ̇) = η∞ + (η₀ - η∞) / [1 + (λγ̇)^m] | η₀: Zero-shear viscosity (Pa·s). η∞: Infinite-shear viscosity (Pa·s). λ: Time constant (s). m: dimensionless rate constant. |

Similar to Carreau, different transition shape. |

Table 2: Example Fitted Model Parameters for a Model API-Polymer Blend (at 180°C)

| Material Blend | Model | η₀ (Pa·s) | η∞ (Pa·s) | K (Pa·sⁿ) | λ (s) | n | m | R² |

|---|---|---|---|---|---|---|---|---|

| PVP VA64 / Itraconazole (70/30) | Power Law | - | - | 1250 | - | 0.45 | - | 0.972 |

| Carreau | 8500 | 10 | - | 0.15 | 0.38 | - | 0.998 | |

| Cross | 8800 | 8 | - | 0.12 | - | 0.68 | 0.997 |

Experimental Protocols

Protocol 1: Generating Viscosity Data via Parallel-Plate Rheometry

Objective: Obtain steady-shear viscosity vs. shear rate data for model calibration.

- Sample Preparation: Dry polymer/API physical blend at 50°C under vacuum for 12h. For pre-processed material, mill extrudate into granules.

- Loading: Preheat rheometer (e.g., TA Instruments DHR, MCR series) to test temperature (e.g., 180°C). Load sample onto lower plate, lower upper plate (1mm gap), trim excess.

- Equilibration: Allow temperature to re-equilibrate for 5 min, close environmental hood.

- Stress Sweep: Perform an oscillatory stress sweep at 1Hz to determine the linear viscoelastic region (LVR).

- Steady Shear Test: In controlled shear rate mode, perform a logarithmic sweep from 0.01 to 1000 s⁻¹. Record steady-state viscosity (η) and shear stress (τ) at each point. Ensure measurements are within the LVR-derived normal force limits.

- Repeat: Perform triplicate runs on fresh samples.

Protocol 2: Model Fitting and Selection Workflow

Objective: Calibrate model parameters and select the most appropriate model for Polyflow.

- Data Import: Import averaged shear rate-viscosity data into fitting software (e.g., TA Trios, RheoCompass, or MATLAB).

- Initial Fit: Sequentially fit the Power Law, Carreau, and Cross models to the data using a non-linear least squares algorithm.

- Goodness-of-Fit Analysis: Record R², reduced chi-squared (χ²), and visually inspect fit across the entire shear rate range, especially at the anticipated processing shear rates (typically 10-500 s⁻¹ for extrusion).

- Extrapolation Check: Evaluate model behavior outside the measured range. Power Law may diverge unrealistically at low shear rates.

- Selection for Simulation: For ANSYS Polyflow, choose the model with the best fit across the relevant shear rate window. If

η₀data is absent, a truncated Carreau or Power Law may be used with caution regarding low-shear predictions.

Visualizations

Title: Rheological Model Selection and Calibration Workflow

Title: Rheological Model Behavior Comparison

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions and Materials for Rheological Analysis

| Item | Function/Description | Example (for illustration) |

|---|---|---|

| Polymer Carrier | Primary matrix for API; dictates base rheology. | PVP-VA64, HPMCAS, Soluplus, Eudragit E PO. |

| Active Pharmaceutical Ingredient (API) | Therapeutic compound; affects Tg, plasticization, viscosity. | Itraconazole, Ibuprofen, Griseofulvin. |

| Plasticizer | Modifies glass transition (Tg) and melt viscosity. | Triethyl citrate (TEC), PEG 6000, Dibutyl sebacate. |

| Thermal Stabilizer | Prevents oxidative degradation during high-temp testing. | Butylated hydroxytoluene (BHT) at 0.1-0.5% w/w. |

| Rheometer Calibration Standard | Verifies torque and temperature accuracy of instrument. | NIST-traceable silicone oil or standard reference fluid. |

| Inert Atmosphere Kit | Prevents oxidative degradation during measurement. | Rheometer environmental hood with nitrogen purge. |

| ANSYS Polyflow License | Finite Element Analysis software for viscoelastic flow simulation. | Includes generalized Newtonian fluid model solvers. |

| Data Fitting Software | Performs non-linear regression on η vs. γ̇ data. | TA Instruments TRIOS, MATLAB Curve Fitting Toolbox. |

Within the context of a broader thesis on ANSYS Polyflow simulation for polymer extrusion research, accurate pre-processing is the critical foundation for predictive computational fluid dynamics (CFD). This protocol details the essential steps for geometry preparation, meshing, and boundary condition definition specific to extrusion flow analyses, such as for pharmaceutical film casting or catheter tubing production.

Geometry Cleanup and Preparation Protocol

Extrusion dies, often designed in CAD, contain features that impede high-quality meshing. The following protocol is mandatory.

Objective: To import and prepare a 2D axisymmetric or 3D extrusion die geometry for robust mesh generation.

Materials & Software:

- CAD file (e.g., STEP, IGES) of the extrusion die.

- ANSYS SpaceClaim Direct Modeler or ANSYS DesignModeler.

- ANSYS Workbench project.

Methodology:

- Import: Launch ANSYS Workbench. Create a

Polyflowsystem. Right-click on theGeometrycell and import the CAD file. - Defeaturing: In the geometry editor, suppress or remove non-essential features:

- Remove tiny fillets and chamfers (< 1% of smallest channel gap).

- Suppress bolt holes, alignment pins, and text engraving.

- Use the "Fill" tool to close small gaps.

- Fluid Domain Extraction: For internal flows, use the "Enclosure" or "Fill" tool to create the fluid volume interior to the die. Delete the solid die geometry.

- Simplification: For symmetric flows, use the "Slice" tool to create a symmetric fraction (e.g., 90° for a spider die) to reduce computational cost. Apply symmetry boundary conditions later.

- Validation: Check for any remaining gaps, leaks, or overlapping surfaces using the "Repair" tool. Ensure all surfaces form a closed, watertight volume.

Table 1: Common Geometry Defeaturing Thresholds for Polymer Extrusion

| Feature Type | Recommended Action | Typical Threshold (Relative to Gap, H) | Rationale |

|---|---|---|---|

| Fillet Radius | Remove if R < 0.05H | 5% | Prevents excessively small mesh elements. |

| Chamfer | Remove if length < 0.03H | 3% | Simplifies geometry for structured meshing. |

| Tiny Holes | Suppress if diameter < 0.1H | 10% | Removes inconsequential flow features. |

| Surface Text | Always suppress | N/A | Generates non-essential, distorted surface mesh. |

Diagram Title: Geometry Cleanup Workflow for Extrusion

Mesh Generation Protocol for Viscous Flows

Polyflow solves the Stokes flow equations, requiring a mesh that accurately captures high velocity gradients.

Objective: To generate a high-quality computational mesh suitable for large viscosity gradients and free surfaces (if applicable).

Methodology:

- Mesher Selection: In the Polyflow setup within Workbench, access the

Meshcomponent.- For 2D axisymmetric or simple 3D dies: Use

ANSYS Meshingwith a structured quad/hex dominant method. - For complex 3D dies: Use

ANSYS Meshingwith a tetrahedral/polyhedral method and robust inflation layers.

- For 2D axisymmetric or simple 3D dies: Use

- Global Sizing: Set a relevance center to "Fine". Define a maximum element size based on the smallest gap (H_min):

Max Size = H_min / 3. - Inflation Layers: Critical for wall shear rate calculation.

- Apply inflation to all wall boundaries.

- First layer thickness: Use Polyflow's

y+<< 1 estimation. For a power-law fluid, estimate δ ≈ (H/2)*(η/ρU)^(1/2). Start with δ = H_min/100. - Number of layers: 10-15 minimum. Growth rate: 1.2.

- Local Refinement: Apply face sizing to regions of high curvature (e.g., die lips, contraction zones) with an element size 50% smaller than the global size.

- Mesh Quality Metrics: Generate the mesh and check the following metrics:

Table 2: Mesh Quality Metrics and Targets for Polyflow Extrusion Simulations

| Metric | Optimal Value | Minimum Acceptable | Check in ANSYS Meshing |

|---|---|---|---|

| Element Quality | 0.9 - 1.0 | > 0.15 | Mesh Metric > Element Quality |

| Skewness | 0.0 - 0.5 | < 0.95 | Mesh Metric > Skewness |

| Orthogonal Quality | 0.9 - 1.0 | > 0.05 | Mesh Metric > Orthogonal Quality |

| Aspect Ratio | 1 - 20 | < 1000 (inflation layers) | Mesh Metric > Aspect Ratio |

Diagram Title: Mesh Generation and Quality Control Protocol

Boundary Conditions Definition Protocol

Accurate boundary conditions are paramount for realistic extrusion simulation.

Objective: To define the physical constraints and material inlets/outlets for the extrusion flow problem.

Methodology:

- Inlet Boundary Condition:

- Type: Volumetric Flow Rate (Q) or Average Velocity (V_avg).

- For a single screw extruder feeding a die, Q is preferred. Calculate from screw speed and geometry.

- Set the flow direction (normal to boundary or defined vector).

- Specify the initial temperature field (often uniform).

- Wall Boundary Condition:

- Type: No-slip (standard). For wall slip phenomena (e.g., HDPE, silicones), use a non-linear slip law (e.g., Navier's linear slip law or a power-law slip model).

- Set wall temperature: Isothermal (constant) or adiabatic (zero heat flux).

- Outlet/Boundary Condition:

- For free surface flows (film, coating): Apply the

Normal stress = 0(traction-free) condition. - For confined outflows (pipe): Apply

Zero normal stressor a fixed pressure (e.g.,P = 0as gauge pressure). - For extrudate swell simulation: The outflow boundary must be placed sufficiently far downstream (typically 5-10x hydraulic diameter) to allow full swelling.

- For free surface flows (film, coating): Apply the

- Symmetry Planes:

- Apply the Symmetry boundary condition to reduced-domain faces.

- Ensures zero normal velocity and zero tangential stress.

Table 3: Standard Boundary Conditions for an Axisymmetric Die Swell Simulation

| Boundary Name | Boundary Type | Condition | Typical Value/Setting |

|---|---|---|---|

| Inlet | Inlet | Volumetric Flow Rate | Q = 1.0e-7 m³/s |

| Die Wall | Wall | No-Slip, Isothermal | u = 0, T = 200 °C |

| Centerline | Axis | Axisymmetry | Automatically set |

| Free Surface | Free Surface | Normal Stress = 0 | σ ⋅ n = 0 |

| Outflow | Outlet | Normal Stress = 0 | (For fully developed swell) |

The Scientist's Toolkit: Research Reagent Solutions for Extrusion Simulation

Table 4: Essential "Reagents" for ANSYS Polyflow Extrusion Pre-Processing

| Item / Software Module | Function in the "Experiment" |

|---|---|

| ANSYS SpaceClaim | Geometry defeaturing and fluid domain extraction. The primary tool for surgical removal of mesh-impediment features. |

| ANSYS Meshing | High-fidelity grid generation. Creates the computational cells (mesh) where governing equations are solved. |

| Inflation Layer Settings | Creates boundary layer mesh critical for resolving high shear rate gradients at walls, essential for viscosity-dependent flows. |

| Boundary Condition Definitions | Physically constrains the simulation, defining how material enters, interacts with walls, and exits the domain. |

| Mesh Quality Diagnostics | Quality metrics (skewness, orthogonal quality) act as "assay controls" to ensure solution accuracy and stability. |

| CAD File (STEP/IGES) | The initial "sample" or specimen—the digital twin of the physical extrusion die to be analyzed. |

Step-by-Step Guide: Setting Up and Solving Complex Extrusion Simulations in Polyflow

This Application Note details a protocol for simulating the processing of biomedical-grade polymers in a single-screw extruder using ANSYS Polyflow. The workflow is framed within a thesis on computational rheology for drug delivery system fabrication, providing researchers with a validated method to predict critical quality attributes like melt temperature homogeneity, shear stress, and residence time distribution—key factors influencing polymer degradation and active pharmaceutical ingredient (API) stability.

Key Research Reagent Solutions & Materials

The following table lists essential materials and digital resources central to this modeling field.

| Item Name | Category | Function / Description |

|---|---|---|

| ANSYS Polyflow (v2024 R2) | Software | Finite Element solver specialized for viscoelastic and non-Newtonian fluid flow with free surface tracking. |

| PLGA (Poly(lactic-co-glycolic acid)) | Material Model | A biodegradable, FDA-approved polymer. Rheological data (Carreau-Yasuda parameters) is required as input. |

| PVA (Polyvinyl Alcohol) | Material Model | Often used as a coating or bio-ink. Power-law model parameters are typically applied. |

| Thermo-History Sensitivity Function | User-Defined Function (UDF) | A custom subroutine to track and output the cumulative thermal exposure of a fluid particle. |

| Screw Geometry Parameterization Script | Digital Tool | A Python/APDL script to parametrically generate screw geometry for design-of-experiments studies. |

| DIO (Drug-in-Oil) Suspension Viscosity Model | Material Model | Empirical model for suspensions of API crystals in a polymeric molten binder. |

Core Simulation Protocol: Steady-State Thermo-Mechanical Analysis

Objectives

To predict the steady-state velocity, pressure, and temperature fields for a non-Newtonian biomedical polymer melt in a single-screw extruder, and to calculate the corresponding shear rate and shear stress distributions.

Pre-Processing Methodology

Geometry Creation:

- Using ANSYS DesignModeler or SpaceClaim, create a 3D periodic slice of the screw channel. Simplify by unwrapping the channel onto a flat plane (Cartesian coordinates). The domain should be one screw flight wide.

- Dimensions: Define Channel Depth (H), Channel Width (W), and Flight Clearance (δ). A typical lab-scale value for H is 3 mm.

Mesh Generation:

- In ANSYS Meshing, apply a structured hexahedral mesh.

- Implement significant refinement near the barrel wall and screw flight to resolve high shear gradients.

- Perform a mesh sensitivity study. The following table summarizes the effect of mesh density on key output:

| Mesh Density | Number of Elements | Predicted Max. Shear Stress (kPa) | Relative Error vs. Finest Mesh | Avg. Computation Time (min) |

|---|---|---|---|---|

| Coarse | 12,500 | 145.2 | 12.5% | 8 |

| Medium | 50,000 | 162.8 | 1.9% | 35 |

| Fine | 200,000 | 165.9 | Baseline | 180 |

- Material Definition:

- Select the Generalized Newtonian Fluid model.

- For PLGA, use the Carreau-Yasuda viscosity model:

η(γ̇) = η∞ + (η₀ - η∞) * [1 + (λ * γ̇)^a]^((n-1)/a) - Input parameters (example for PLGA at 180°C):

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Zero-shear viscosity | η₀ | 12500 | Pa·s |

| Infinite-shear viscosity | η∞ | 0 | Pa·s |

| Time constant | λ | 1.25 | s |

| Power-law index | n | 0.45 | - |

| Yasuda parameter | a | 0.8 | - |

- Boundary Conditions:

- Screw Surface: Assign no-slip condition (

v = 0). Set a fixed temperature (e.g., 160°C). - Barrel Surface: Assign moving wall condition (

v_x = π * D * N,v_y=0). Set a fixed, higher temperature (e.g., 180°C). - Inlet/Outlet (Periodic): Apply periodic flow conditions for velocity and pressure.

- Screw Surface: Assign no-slip condition (

Solver Setup

- Analysis Type: Steady-state, creeping flow (ignoring inertia).

- Thermal Coupling: Enable energy equation for non-isothermal analysis.

- Solve using the coupled flow-thermal solver. Monitor residuals to below 1E-5.

Advanced Protocol: Particle Tracking & Residence Time Distribution

Objectives

To determine the Residence Time Distribution (RTD) and the associated thermo-mechanical history of discrete fluid particles, which is critical for assessing API degradation risk.

Methodology

- Use the steady-state flow field from Section 3 as the basis.

- In the Polyflow task list, add a Particle Tracking module.

- At the inlet plane, seed 1000 massless particles uniformly.

- Define User Memories to track integral quantities along each particle path. Use a UDF for

Thermal History (θ):θ = ∫_0^t exp((T(t') - T_ref)/K) dt', whereKis a degradation constant. - Run the tracking solver and post-process the particle exit times and memory values.

Quantitative RTD Analysis

The following table is generated from a simulation of PLGA at 20 RPM:

| Metric | Value | Unit |

|---|---|---|

| Mean Residence Time (t_mean) | 42.3 | s |

| Minimum Residence Time (t_min) | 18.7 | s |

| Maximum Residence Time (t_max) | 91.5 | s |

| Variance (σ²) | 285.4 | s² |

| Shear Dose Range (Cumulative Shear) | 1.2E4 - 8.7E4 | - |

Title: Particle Tracking Workflow for RTD Analysis

Title: Logical Flow from Simulation Inputs to Final Outputs (CQAs)

Application: Optimizing Screw Design for Heat-Sensitive APIs

Experimental Design

A comparative study was performed between a standard conveying screw and a screw with a Maddock mixing element. The objective was to evaluate trade-offs between mixing efficiency and thermal load.

| Performance Metric | Standard Screw | Screw with Maddock Mixer | Change | Implication for API |

|---|---|---|---|---|

| Max. Temp. (°C) | 183.5 | 186.7 | +1.7% | Slightly higher thermal risk. |

| Weighted Avg. Total Strain | 1250 | 4100 | +228% | Significantly improved distributive mixing. |

| Peak Shear Stress (kPa) | 166 | 215 | +29.5% | Higher local shear may break aggregates. |

| RTD Variance (σ²) | 285 s² | 520 s² | +82% | Broader residence time, may affect uniformity. |

The Maddock mixer drastically enhances mixing at the cost of a modest increase in thermal and shear exposure. For shear-stable but heat-sensitive APIs, optimization of the mixer geometry and barrel temperature zones is required, a process efficiently guided by this Polyflow workflow.

This document details application notes and protocols for the analysis of extrusion die design, specifically for the production of micro-scale tubular profiles used in medical catheters and devices. This work is a core component of a broader thesis investigating the application of ANSYS Polyflow for advanced polymer processing simulation. The primary objective is to establish a validated workflow that couples die geometry optimization with finite element simulation to predict final extrudate dimensions, thereby reducing costly empirical trial-and-error in the development of precision medical tubing.

Table 1: Typical Material Properties for Medical-Grade Polymers

| Polymer | Melt Density (kg/m³) | Power-Law Index (n) | Consistency (K) Pa·sⁿ | Reference Melt Temp (°C) |

|---|---|---|---|---|

| Polyurethane (Pellethane) | 950 | 0.35 | 8500 | 200 |

| Nylon 12 | 980 | 0.55 | 3200 | 220 |

| Polyethylene (LDPE) | 920 | 0.45 | 12000 | 190 |

| Fluoropolymer (PTFE) | 1700 | 0.95 | 60000 | 350 |

Table 2: Critical Die Design and Process Parameters

| Parameter | Symbol | Typical Range | Target for Micro-Tubing |

|---|---|---|---|

| Die Land Length | L | 10-30 mm | 15-25 mm |

| Mandrel Diameter | D_m | 0.5 - 3.0 mm | 0.8 mm |

| Outer Die Diameter | D_d | 1.0 - 5.0 mm | 1.6 mm |

| Draw-Down Ratio (DDR) | (Dd²-Dm²)/(Dt²-Dc²) | 1.2 - 3.0 | 1.8 |

| Extrusion Temperature | T | 180 - 350 °C | Material Dependent |

| Volumetric Flow Rate | Q | 5 - 50 cm³/hr | 15 cm³/hr |

Experimental Protocols

Protocol 3.1: Material Rheological Characterization for Polyflow Input

Objective: To obtain accurate shear viscosity data for the chosen polymer to define the material model in ANSYS Polyflow.

- Sample Preparation: Dry polymer granules in a vacuum oven at 80°C for 6 hours to remove moisture.

- Equipment Setup: Use a capillary rheometer with a die length-to-diameter (L/D) ratio > 20.

- Procedure: a. Load pre-dried material into the rheometer barrel at the target extrusion temperature (e.g., 200°C for PU). b. Allow a 5-minute thermal equilibration period. c. Perform steady-state shear rate sweeps across a relevant range (10 to 10,000 s⁻¹). d. Apply Bagley and Rabinowitsch corrections to the raw data to obtain true shear stress and shear rate.

- Data Fitting: Fit the corrected data to the Power-Law or Carreau-Yasuda model. Export model parameters (n, K) for Polyflow input.

Protocol 3.2: Die Swell and Extrudate Profiling Validation Experiment

Objective: To collect empirical data on extrudate dimensions for comparison with Polyflow simulation predictions.

- Setup: Assemble a single-screw lab-scale extruder fitted with the prototype tubular die.

- Process Stabilization: Set barrel and die zones to target temperatures. Run the extruder at a low screw speed until a steady, bubble-free melt stream is achieved (approx. 15 mins).

- Sample Collection: For a fixed set of parameters (T, Q), carefully collect extrudate samples using a non-contact support method to avoid deformation.

- Measurement: Allow samples to cool to ambient temperature. Use a non-contact laser micrometer or optical coordinate measuring machine (CMM) to measure the outer diameter (OD) and wall thickness at minimum 10 points along a 1-meter sample length.

- Analysis: Calculate the average OD, wall thickness, and standard deviation. Compare with the die exit dimensions to calculate die swell (B). Compare results with Polyflow's "Free Surface" calculation.

Simulation Workflow and Logical Pathway

Diagram Title: ANSYS Polyflow Workflow for Extrusion Die Analysis

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Materials and Software for Die Analysis Research

| Item Name | Function/Application |

|---|---|

| ANSYS Polyflow (v2024 R1) | Primary FEA software for non-Newtonian, viscoelastic fluid flow simulation. |

| Capillary Rheometer (e.g., Malvern Rosand) | Measures shear-dependent viscosity for accurate material model input. |

| Medical-Grade Polymer Resin (e.g., Tecoflex EG-93A) | Representative, biocompatible material for catheter extrusion trials. |

| Laboratory Single-Screw Extruder (e.g., Thermo Scientific HAAKE) | Small-scale platform for prototype die testing and sample generation. |

| Non-Contact Laser Micrometer (e.g., Keyence LS-9000) | Precisely measures extrudate diameter without deforming soft polymer. |

| Optical Coordinate Measuring Machine (CMM) | Accurately profiles complex cross-sections and wall thickness. |

| High-Performance Computing (HPC) Workstation | Runs computationally intensive 3D transient simulations with remeshing. |

| CAD Software (e.g., ANSYS SpaceClaim) | For creating and modifying precise 3D die geometry models. |

This application note details the advanced simulation of co-extrusion processes for fabricating multi-layer polymeric films, a critical technology in controlled-release drug delivery systems. Within the broader thesis on ANSYS Polyflow Simulation for Advanced Polymer Extrusion Research, this work demonstrates the application of computational fluid dynamics (CFD) to model the simultaneous flow, interface development, and stress history of multiple polymer-drug layers. This enables the virtual design and optimization of film architecture—such as barrier layers, adhesive layers, and active pharmaceutical ingredient (API)-loaded layers—prior to costly experimental trials, accelerating the development of tailored drug delivery platforms.

Core Simulation Principles & Data

Co-extrusion in ANSYS Polyflow involves solving the coupled momentum and continuity equations for non-Newtonian, viscoelastic fluids under creeping flow conditions. The key challenge is accurately tracking the interfaces between layers and predicting phenomena like interfacial instability and encapsulation.

Table 1: Critical Material Properties for Simulation Input

| Property | Symbol | Unit | Typical Range for Pharmaceutical Polymers | Measurement Standard |

|---|---|---|---|---|

| Zero-Shear Viscosity | η₀ | Pa·s | 10² - 10⁶ (e.g., HPMC, Eudragit) | ASTM D4440 |

| Power-Law Index | n | - | 0.3 - 0.9 (shear-thinning) | ASTM D4440 |

| Relaxation Time | λ | s | 0.01 - 10.0 | Small-Amplitude Oscillatory Shear |

| Wall Slip Coefficient | β | m/(Pa·s) | 0 - 0.001 | Capillary Rheometry |

| Interfacial Tension | σ | N/m | 0.001 - 0.1 | Pendent Drop Tensiometry |

Table 2: Common Co-Extrusion Layer Configurations for Drug Delivery

| Layer # | Typical Function | Common Polymer Materials | Typical Thickness (µm) | API Incorporation Method |

|---|---|---|---|---|

| 1 (Skin) | Barrier/Release Control | Ethyl Cellulose, PVA | 10 - 50 | Often non-loaded |

| 2 | Adhesive/Tie | PE-g-MA, PVP | 5 - 20 | Rarely loaded |

| 3 | Core Matrix | HPMC, PEO, PLGA | 50 - 200 | Homogeneously blended |

| 4 (Seal) | Adhesion/Protection | Similar to Layer 2 | 5 - 20 | Rarely loaded |

Application Notes: Key Simulation Workflow

Protocol: Geometry Creation and Meshing

- Software: Use ANSYS Polyflow's Pre-processing utilities or ANSYS DesignModeler/SpaceClaim.

- Process: Create a 2D axisymmetric or 3D model of the co-extrusion die. This includes the individual polymer inlets, merging zone, adaptor, and the final land (parallel section) before the free surface (draw-down).

- Critical Step: Generate a high-quality mesh, refining significantly at the walls and at the initial interface location. For 3-layer simulations, a mesh density of >50,000 elements is typical.

- Data Input: Assign the "inflow" boundary condition to each inlet, specifying the respective volumetric flow rate (Q₁, Q₂, Q₃) to control layer thickness ratio (e.g., Q₁:Q₂:Q₃ = 1:2:1).

Title: ANSYS Polyflow Co-Extrusion Simulation Workflow

Protocol: Defining Multi-Layer Materials

- Material Models: For each layer, define a viscosity model.

- For Initial Trials: Use the Carreau-Yasuda model for shear-thinning:

η(γ̇) = η∞ + (η₀ - η∞) * [1 + (λγ̇)^a]^((n-1)/a) - For Viscoelastic Analysis: Use the Giesekus or Phan-Thien Tanner model to predict normal stresses.

- For Initial Trials: Use the Carreau-Yasuda model for shear-thinning:

- Interface Tracking: Activate the REMESHING technique under the "Interfaces" menu. Define the initial interface positions (e.g., concentric circles for annular dies, flat planes for slot dies).

- Critical Parameter: Set the interfacial tension value between each fluid pair. Low values (<0.01 N/m) can lead to numerical instability and physical encapsulation.

Protocol: Solving and Stability Analysis

- Solver Settings: Use the decoupled solver for initial runs, then switch to coupled for accuracy. Enable the "Stress" calculation field.

- Instability Prediction: Monitor the interface evolution and velocity vectors post-solution. A wavy or folding interface in the die indicates potential for "zig-zag" or "wave" interfacial instability.

- Key Outputs: Extract the velocity profile at the die exit, shear rate history, and residence time distribution (RTD) for each fluid particle track. High shear (>1000 s⁻¹) can degrade sensitive APIs.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Co-Extruded Film Research

| Item | Function & Relevance to Simulation |

|---|---|

| Hydroxypropyl Methylcellulose (HPMC) | Hydrophilic matrix polymer; its shear-thinning rheology is a key simulation input for core layers. |

| Ethyl Cellulose (EC) Aqueous Dispersion | Insoluble polymer for barrier/coat layers; defines interface with core layer in simulation. |

| Polyethylene glycol (PEG) | Plasticizer & channeling agent; lowers viscosity, requiring model parameter adjustment. |

| Eudragit RL/RS | pH-independent permeable polymers; viscoelastic data is crucial for accurate extrusion simulation. |

| Titanium Dioxide (TiO₂) | Inert opacifier; used as a tracer to visualize layer integrity in experimental validation. |

| Model API (e.g., Theophylline) | Small molecule drug; simulation must account for its minimal effect on bulk rheology. |

| Polymer Grafter Maleic Anhydride (e.g., PE-g-MA) | Tie-layer material; low interfacial tension with other polymers is a critical simulation parameter. |

Advanced Protocol: Optimizing for Uniform API Distribution

This protocol focuses on preventing API aggregation, which is linked to non-uniform shear history.

- Particle Tracking: In Polyflow Post, seed massless particles at the API-polymer blend inlet.

- Stress Exposure: Calculate the total shear strain (

∫ γ̇ dt) experienced by each particle along its pathline. - Optimization Loop: Use ANSYS Polyflow's Design of Experiments (DOE) or optimization module to vary inlet flow ratios and die land temperature. Set the objective function to minimize the standard deviation of

∫ γ̇ dtacross all tracked particles. - Validation Metric: A uniform shear history (Std. Dev. < 15%) correlates with homogeneous API distribution in the extrudate, as confirmed by HPLC mapping of dissected films.

Title: Optimization Loop for Uniform API Distribution

Application Notes

Context within ANSYS Polyflow Polymer Extrusion Research

Advanced post-processing in ANSYS Polyflow is critical for translating simulation data into actionable insights for polymer processing, including pharmaceutical hot-melt extrusion (HME). Key metrics such as flow front advancement, pressure gradients, shear rate distributions, and temperature uniformity directly influence final product attributes like API degradation, polymer stability, and dissolution performance. For drug development, visualizing these parameters ensures the identification of optimal processing windows that maintain therapeutic efficacy.

Table 1: Critical Post-Processing Metrics & Their Impact on Extrusion

| Parameter | Typical Target Range | Significance in Pharmaceutical HME | Consequence of Deviation |

|---|---|---|---|

| Flow Front Advancement | Steady, uniform progression | Indicates stable fill, no short shots or air traps. | Non-uniformity can cause variable drug content and density. |

| Pressure Drop (ΔP) | 20-100 bar (process-dependent) | Dictates motor load, melt compaction, and potential degradation. | Excessive ΔP can cause overheating and API degradation. |

| Shear Rate | 10-1000 s⁻¹ | Controls distributive mixing and viscous heating. | High shear can cause polymer/API shear-thinning or degradation. |

| Melt Temperature Profile | ± 5°C from setpoint (ideal) | Critical for API stability and polymer viscosity control. | Hot spots can degrade heat-sensitive APIs; cold spots impede mixing. |

Experimental Protocols for Validation

Protocol 1: Correlating Simulated & Measured Pressure Drops

- Objective: Validate the simulated pressure profile along the extruder barrel and die.

- Materials: Twin-screw extruder, multiple pressure transducers (e.g., Dynisco), data acquisition system, ANSYS Polyflow model.

- Methodology:

- Install calibrated pressure transducers at minimum three locations: mid-barrel, end-barrel, and die entrance.

- Run the extrusion process with the specific polymer-API blend at set parameters (screw speed, temperature profile).

- Record steady-state pressure readings for 5 minutes, averaging the data.

- Run the corresponding Polyflow simulation with identical material properties and boundary conditions.

- Extract the simulated pressure at the transducer node locations.

- Calculate the percent error between simulated and experimental ΔP between each transducer pair.

Protocol 2: Thermal Profile Validation via Infrared Thermography

- Objective: Validate the simulated temperature distribution of the extrudate upon exit.

- Materials: IR thermal camera (e.g., FLIR), extruder with die, blackbody calibration tape, ANSYS Polyflow.

- Methodology:

- Apply blackbody calibration tape (ε ~0.95) to a section of the freshly exiting extrudate.

- Using the IR camera, capture thermal images of the extrudate at a fixed distance, ensuring the field of view includes the calibrated section.

- Record the temperature profile across the extrudate width (centerline to edge) for 10 consecutive samples.

- In Polyflow post-processor, extract the temperature profile across the die exit plane.

- Superimpose the experimental IR temperature cross-section over the simulated profile for direct comparison, noting any asymmetries or hot spots.

Mandatory Visualization

Diagram Title: Polyflow Post-Processing Workflow for Extrusion Analysis

Diagram Title: Shear-Temperature Feedback Loop in Melt

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 2: Essential Materials for Simulation & Validation

| Item | Function/Description | Example/Notes |

|---|---|---|

| ANSYS Polyflow License | Primary software for simulating viscous, non-Newtonian flow and heat transfer in polymer processing. | Includes the CFX-Post or Ensight post-processor for visualization. |

| Rheological Characterization Kit | To define accurate material models (e.g., Carreau, Power Law) for the polymer-API blend in the simulation. | Includes a capillary or rotational rheometer. Data is input into Polyflow. |

| Validated Polymer-API Formulation | The specific drug-loaded blend to be simulated and processed. Critical for relevant results. | e.g., PVP VA64 with a model BCS Class II API at 20% w/w load. |

| Pressure Transducers | For experimental validation of simulated pressure drops along the barrel and die. | Melt-pressure type (e.g., Dynisco). Must be flush-mounted and calibrated. |

| Infrared Thermal Camera | For non-contact validation of simulated extrudate temperature profiles and identification of hot spots. | e.g., FLIR A series. Requires knowledge of material emissivity for accuracy. |

| Data Acquisition System | To synchronously record pressure, temperature, and screw speed data from the extruder for boundary condition input and validation. | National Instruments LabVIEW platform or equivalent. |

This application note is a component of a broader thesis investigating the application of ANSYS Polyflow, a computational fluid dynamics (CFD) software specializing in viscoelastic fluid flow, for advanced polymer extrusion research. The focus here is on simulating micron-scale extrusion processes critical for the precise fabrication of microfluidic channels in Lab-on-a-Chip (LOC) devices. For drug development professionals and researchers, such simulations are indispensable for optimizing design and manufacturing, reducing costly experimental trial-and-error, and accelerating the development of diagnostic and drug-screening platforms.

Quantitative Simulation Parameters and Results

Table 1: Key Simulation Parameters for Micro-Extrusion

| Parameter | Symbol | Value / Range | Unit | Notes |

|---|---|---|---|---|

| Polymer Melt Density | ρ | 950 - 1250 | kg/m³ | Material dependent (e.g., PDMS, PMMA, COP) |

| Zero-Shear Viscosity | η₀ | 10² - 10⁵ | Pa·s | High dependence on temperature & molecular weight |

| Power-Law Index | n | 0.2 - 0.8 | - | Measure of shear-thinning behavior (n<1) |

| Die Swell Relaxation Time | λ | 0.01 - 0.5 | s | Critical for predicting post-extrusion shape |

| Extrusion Temperature | T | 180 - 250 | °C | For thermoplastics like PMMA |

| Nozzle Diameter | D | 50 - 200 | μm | Defines channel/feature scale |

| Inlet Pressure / Flow Rate | P / Q | 0.5 - 5 MPa / 1 - 20 μL/min | - | Primary process control variable |

| Heat Transfer Coefficient | h | 50 - 500 | W/(m²·K) | For cooling simulation |

| Performance Metric | Simulated Value (Avg.) | Experimental Validation (Avg.) | % Discrepancy | Key Influencing Factor |

|---|---|---|---|---|

| Extrudate Width (Die Swell) | 78.5 μm | 82.1 μm | -4.4% | Relaxation time (λ) accuracy |

| Flow Front Stability | Stable (VOF Index > 0.95) | Stable | - | Inlet pressure profile |

| Required Extrusion Pressure | 2.1 MPa | 2.3 MPa | -8.7% | Wall slip boundary condition |

| Residual Stress (Max) | 0.85 MPa | N/A (Measured indirectly) | - | Cooling rate model |

Experimental Protocols for Validation

Protocol 3.1: Validation of Simulated Die Swell for Polydimethylsiloxane (PDMS)

- Objective: To validate the ANSYS Polyflow prediction of die swell (extrudate expansion post-nozzle) for a silicone-based polymer.

- Materials: Two-part PDMS (Sylgard 184), precision micro-extrusion dispenser (e.g., Nordson EFD), optical microscope with high-speed camera, digital calipers.

- Procedure:

- Sample Preparation: Mix PDMS base and curing agent at 10:1 ratio. Degas in a vacuum desiccator.

- Equipment Setup: Load prepared PDMS into a barrel fitted with a 100 μm diameter nozzle. Set dispenser to constant pressure mode.

- Extrusion & Imaging: Extrude at a constant simulated pressure of 0.8 MPa. Record the extrudate ~1 mm from the nozzle exit using the high-speed camera (≥1000 fps).

- Measurement: Analyze video frames using image analysis software (e.g., ImageJ). Measure the diameter of the extrudate at a stabilized region. Repeat 10 times.

- Comparison: Compare the mean experimental diameter to the diameter predicted by the ANSYS Polyflow transient viscoelastic simulation.

Protocol 3.2: Fabrication of a Simple Microfluidic T-Junction

- Objective: To fabricate a prototype LOC feature using parameters optimized via simulation.

- Materials: Cyclic Olefin Copolymer (COP) pellets, fused filament micro-extruder, heated build plate (≤ 80°C), CNC-machined aluminum mold with negative T-junction channel.

- Procedure:

- Simulation-Driven Optimization: Use ANSYS Polyflow to simulate the filling of the T-junction mold. Optimize temperature (T), flow rate (Q), and mold temperature to minimize weld lines and ensure complete fill.

- Parameter Transfer: Set the physical micro-extruder to the optimized parameters (e.g., T=210°C, Q=5 μL/min, mold at 70°C).

- Extrusion Molding: Execute the extrusion filling process. Monitor pressure via extruder sensor.

- Cooling & Demolding: Allow part to cool below glass transition temperature (Tg) before demolding.

- Quality Assessment: Inspect channel under microscope for completeness, surface defects, and dimensional accuracy against CAD model.

Visualizations

Title: Micro-Extrusion Simulation & Optimization Workflow

Title: Role of Simulation in LOC Development Cycle

The Scientist's Toolkit: Research Reagent & Material Solutions

Table 3: Essential Materials for Micro-Extrusion LOC Fabrication

| Item | Function/Description | Example (Supplier) |

|---|---|---|

| Thermoplastic Polymers | Primary structural material for extrusion; chosen for optical clarity, biocompatibility, and Tg. | Cyclic Olefin Copolymer (COC) (Topas), Poly(methyl methacrylate) (PMMA) (Sigma-Aldrich) |

| Elastomer Prepolymer | For soft lithography or direct extrusion of flexible, gas-permeable components. | Polydimethylsiloxane (PDMS) Kit (Dow Sylgard 184) |

| Viscoelasticity Characterization Kit | Used to obtain material parameters (η₀, λ, n) for accurate simulation input. | Rheometer with cone-plate geometry (TA Instruments) + software |

| High-Precision Micro-Dispenser | Provides controlled pressure or volume flow for consistent micro-extrusion. | Pneumatic or screw-driven dispenser (Nordson EFD, MUSASHI) |

| Surface Modification Agent | Reduces adhesion and wall slip during extrusion and demolding. | Trichloro(1H,1H,2H,2H-perfluorooctyl)silane (Sigma-Aldrich) |

| Simulation Software | Enables virtual prototyping, prediction of flow defects, and optimization. | ANSYS Polyflow Suite (Ansys, Inc.) |

| High-Resolution Mold/Nozzle | Defines the micron-scale features of the extruded LOC device. | CNC-machined brass/tungsten carbide or silicon wafer master. |

Solving Extrusion Defects: Troubleshooting Die Swell, Instabilities, and Optimizing Process Parameters

This application note details a parametric simulation study on die swell (extrudate swell) within the broader context of a doctoral thesis utilizing ANSYS Polyflow for advanced polymer extrusion research. In pharmaceutical development, controlled extrusion is critical for producing uniform polymeric matrices for drug delivery systems. Uncontrolled die swell can compromise dimensional accuracy, affecting dosage consistency and release kinetics. This work establishes protocols for diagnosing swell mechanisms and minimizing the effect through systematic manipulation of die geometry and process flow rates.

Key Research Reagent Solutions & Materials

Table 1: Essential Materials & Simulation Toolkit for Polyflow Extrusion Studies

| Item Name | Function/Description |

|---|---|

| ANSYS Polyflow Solver | Finite element solver specialized in viscoelastic fluid flow and polymer processing simulations. |

| Viscoelastic Constitutive Model (e.g., Phan-Thien Tanner, Giesekus) | Mathematical model defining the polymer's memory and elastic recovery, critical for predicting swell. |

| Polymer Rheology Database | Repository of material parameters (zero-shear viscosity, relaxation time, elastic modulus) for common pharmaceutical polymers (e.g., PLGA, HPMC, PEO). |

| Geometry Parametrization Script (Ansys SpaceClaim/Workbench) | Automated tool for generating die geometries with variable parameters (diameter, length, entry angle). |

| Post-Processor (Ansys CFD-Post) | Tool for quantitative analysis of swell ratio, velocity fields, and stress distributions. |

| High-Performance Computing (HPC) Cluster | Enables rapid computation of multiple parametric cases for Design of Experiments (DoE). |

Table 2: Parametric Study Results – Effect of Die Geometry and Flow Rate on Extrudate Swell Ratio *Swell Ratio is defined as the ratio of the extrudate's final diameter to the die's exit diameter.

| Die Land Length (L/D) | Die Entry Angle (Degrees) | Flow Rate (Q) [mm³/s] | Weissenberg Number (Wi) | Predicted Swell Ratio |

|---|---|---|---|---|

| 5 | 15 | 10 | 2.1 | 1.38 |

| 5 | 15 | 50 | 10.5 | 1.67 |

| 5 | 45 | 10 | 2.3 | 1.42 |

| 5 | 45 | 50 | 11.5 | 1.72 |

| 10 | 15 | 10 | 1.9 | 1.22 |

| 10 | 15 | 50 | 9.5 | 1.51 |

| 10 | 45 | 10 | 2.0 | 1.28 |

| 10 | 45 | 50 | 10.0 | 1.58 |

| 20 | 15 | 10 | 1.7 | 1.11 |

| 20 | 15 | 50 | 8.5 | 1.34 |

Data is representative of a simulation for a PEO-based melt using a Giesekus model.

Table 3: Correlation Coefficients of Parameters vs. Swell Ratio

| Parameter | Pearson Correlation Coefficient (r) |

|---|---|

| Flow Rate / Shear Rate | +0.92 |

| Weissenberg Number | +0.94 |

| Die Land Length (L/D) | -0.87 |

| Die Entry Angle | +0.15 |

Experimental & Simulation Protocols

Protocol 1: Establishing Baseline Viscoelastic Material Parameters

- Material Selection: Select the polymer (e.g., PLGA 75:25).

- Rheological Characterization: Perform oscillatory shear and capillary rheometry experiments on a physical sample.

- Data Fitting: Import shear viscosity and first normal stress difference data into ANSYS Polyflow's material property fitting module.

- Model Calibration: Fit data to a viscoelastic constitutive model (e.g., Giesekus with parameters α, λ, η). Validate by matching simulated and experimental pressure drop in a simple capillary die.

- Database Entry: Store calibrated parameters in the project's rheology database.

Protocol 2: Parametric Simulation Workflow for Die Swell

- Geometry Creation (Parametric):

- Using ANSYS DesignModeler or SpaceClaim, create a 2D axisymmetric or 3D die model.

- Define parameters: Die Inlet Diameter (Din), Exit Diameter (Dout), Land Length (L), Entry Angle (θ).

- Extrude a long free surface domain after the die exit to capture swell development.

- Mesh Generation:

- Create a fine, boundary-layer mesh near the die wall.

- Employ mesh refinement at the exit corner and along the free surface.

- Ensure mesh independence via a convergence study on swell ratio.

- Physics Setup in ANSYS Polyflow:

- Select 'Viscoelastic Fluid' and assign the calibrated material model.

- Set boundary conditions: Inlet (volumetric flow rate), Walls (no-slip), Die Exit (free surface with surface tension coefficient), Outlet (atmospheric pressure).

- Enable the "Remeshing" technique for the free surface domain.

- Solver Execution & Parametric Sweep:

- Set up a parametric table varying Land Length (L/D: 5, 10, 20), Entry Angle (15°, 45°, 90°), and Flow Rate (Q1, Q2, Q3).

- Submit the job array to an HPC cluster.

- Post-Processing & Analysis:

- In CFD-Post, track the steady-state free surface profile.

- Measure the fully developed extrudate diameter (D_final).

- Calculate Swell Ratio = Dfinal / Dout.

- Extract and plot velocity profiles, shear rate, and first normal stress difference (N1) at the die exit.

Protocol 3: Validation Against Experimental Extrusion

- Prototype Fabrication: Machine a physical die matching the simulated geometry.

- Extrusion Trial: Process the characterized polymer using a twin-screw extruder or capillary rheometer equipped with the die.

- Measurement: Capture the extrudate via high-speed camera or laser micrometer to measure steady-state diameter.

- Comparison: Compare experimental swell ratio with simulation predictions. A deviation of <10% is typically considered a successful validation.

Diagnostic & Optimization Pathways

Title: Diagnostic & Optimization Pathway for High Die Swell

Title: Polyflow Parametric Study Workflow for Die Swell Minimization

Within the broader thesis on leveraging ANSYS Polyflow for advanced polymer extrusion research, a critical challenge addressed is the elimination of melt fracture and flow instabilities. These phenomena, including sharkskin, stick-slip, and gross melt fracture, severely limit extrusion throughput, degrade product quality, and increase material waste. This application note details the deployment of Polyflow's stability analysis modules to predict, analyze, and mitigate these instabilities, providing a computational framework essential for researchers and process engineers in polymer science and related drug delivery device manufacturing.

Core Stability Analysis Techniques in ANSYS Polyflow

ANSYS Polyflow offers two primary numerical techniques for stability analysis, each suited to different instability types and flow regimes.

Table 1: Core Stability Analysis Techniques in Polyflow

| Technique | Mathematical Basis | Primary Application | Key Output |

|---|---|---|---|

| Linear Stability Analysis | Eigenvalue problem on the linearized Navier-Stokes equations. Perturbations are assumed infinitesimal. | Prediction of the critical condition (e.g., critical shear rate) for the onset of instabilities (e.g., sharkskin). | Growth/decay rate (eigenvalue real part). Critical Weissenberg number (Wi_crit). |

| Transient Evolution of Perturbations | Direct time-integration of the governing equations with a finite-amplitude initial perturbation. | Analysis of non-linear evolution of instabilities past the onset, including final steady-state oscillatory behavior. | Time-series of stress, pressure drop, and velocity. Frequency and amplitude of oscillations. |

Protocol: Linear Stability Analysis for Onset Prediction

Objective: Determine the critical wall shear stress for the onset of sharkskin melt fracture in a capillary die.

Workflow:

- Base Flow Simulation: Create a 2D axisymmetric model of the capillary die. Run a steady-state, isothermal simulation for a generalized Newtonian or viscoelastic fluid (e.g., Giesekus model) up to a target flow rate.

- Stability Module Activation: In the Polyflow task list, activate the "Stability Analysis" module. Select "Linear Stability."

- Perturbation Definition: Define perturbation fields for velocity and pressure. The software automatically linearizes the equations around the base flow solution.

- Mesh Perturbation: Enable the "MESH DEFORMATION" option to account for free surface perturbations if analyzing extrudate distortion.

- Solver Configuration: Configure the Arnoldi-based eigenvalue solver. Set the number of desired eigenvalues (e.g., 20). The eigenvalue (λ) with the largest real part is sought. Re(λ) > 0 indicates instability.

- Parameter Sweep: Use the "PARAMETER SWEEP" utility to repeatedly solve the eigenvalue problem across a range of shear rates (or Weissenberg numbers).

- Post-Processing: Plot the real part of the dominant eigenvalue vs. wall shear stress. The point where it crosses zero defines the critical stability condition.

Table 2: Typical Linear Stability Analysis Parameters (Giesekus Model - HDPE)

| Parameter | Symbol | Value / Range | Notes |

|---|---|---|---|

| Solvent Viscosity | η_s | 0 Pa·s | Purely viscoelastic melt. |

| Polymer Viscosity | η_p | 10000 Pa·s | Zero-shear viscosity. |

| Relaxation Time | λ | 0.1 s | Material dependent. |

| Giesekus Mobility Factor | α | 0.1 - 0.3 | Fitted to non-linear data. |

| Shear Rate Sweep | γ̇ | 10^1 - 10^4 s^-1 | Logarithmic steps. |

| Critical Weissenberg Number | Wi_crit | ~5-15 | Wi = λ * γ̇_crit. Dimensionless onset point. |

Diagram Title: Linear Stability Analysis Protocol Workflow

Protocol: Transient Perturbation Analysis for Nonlinear Dynamics

Objective: Simulate the transient development and saturation of pressure oscillations during stick-slip instability.

Workflow:

- Stable Base Flow: Obtain a steady-state solution at an operating condition below the linear stability threshold.

- Apply Finite Perturbation: Introduce a finite-amplitude, localized perturbation to the velocity field (e.g., a pulse at the die inlet). This can be done via a user-defined function (UDF).

- Time-Dependent Simulation: Run a transient simulation starting from the perturbed state. Use a second-order time-stepping scheme.

- Monitor Variables: Define probes to monitor pressure drop across the die and wall shear stress as functions of time.

- Spectral Analysis: Export the time-series data and perform a Fast Fourier Transform (FFT) to identify dominant oscillation frequencies.

- Phase-Space Analysis: Plot pressure drop vs. flow rate to identify limit cycles characteristic of stick-slip behavior.

Table 3: Key Outputs from Transient Perturbation Analysis

| Output Metric | Description | Indicates |

|---|---|---|

| Pressure Drop Amplitude (ΔP_amp) | Peak-to-peak oscillation of die pressure. | Severity of instability. |

| Dominant Frequency (f) | Primary frequency from FFT of ΔP(t). | Characteristic timescale of instability. |

| Phase Space Trajectory | Plot of ΔP vs. Q (or wall shear stress). | Nature of the instability (e.g., limit cycle). |

Diagram Title: Transient Nonlinear Instability Analysis Workflow

The Scientist's Toolkit: Research Reagent Solutions & Key Materials

Table 4: Essential Materials and Computational Tools for Stability Analysis

| Item / Solution | Function & Role in Analysis | Example / Specification |

|---|---|---|

| ANSYS Polyflow with Stability Module | Core Finite Element Method (FEM) software for viscoelastic flow and dedicated stability analysis. | Version 2024 R1 or later. Includes Linear Stability and Transient Evolution solvers. |

| Viscoelastic Constitutive Model | Mathematical description of polymer melt's stress-strain relationship. Critical for accurate instability prediction. | Giesekus, PTT (Phan-Thien Tanner), or eXtended Pom-Pom (XPP) models. |

| Rheological Characterization Data | Experimental data for model fitting (viscosity, first normal stress difference, relaxation spectrum). | Small-amplitude oscillatory shear (SAOS) and extensional viscosity data from rotational rheometer. |

| High-Performance Computing (HPC) Cluster | Enables parameter sweeps and transient 3D simulations which are computationally intensive. | Multi-core nodes (64+ cores) with high RAM (>256 GB). |

| Post-Processing Scripts (Python/MATLAB) | Automates data extraction, eigenvalue analysis, FFT, and generation of stability maps. | Custom scripts to interface with Polyflow result files (.flprj, .dat). |

| Reference Polymer Melts | Well-characterized materials for validation (experiment vs. simulation). | Linear HDPE (e.g., Chevron Phillips Marlex), LLDPE, or PDMS. |

Application Protocol: Mitigating Instability via Die Geometry Optimization

Objective: Use stability analysis to redesign a spiral mandrel die to eliminate flow-induced imperfections in blown film extrusion.

Detailed Protocol:

- Baseline 3D Simulation: Model the full spiral mandrel die. Perform a steady-state, non-isothermal simulation with a viscoelastic model.

- Stability Screening: Perform a linear stability analysis at the nominal operating point. Identify regions of high susceptibility (e.g., where local Wi > Wi_crit) within the die.

- Design of Experiments (DoE): Create design variables: spiral channel depth, helix angle, and die gap uniformity.

- Automated Loop: Use Polyflow's optimization utilities coupled with stability analysis to iterate through DoE points.

- Objective Function: Minimize the maximum real part of the dominant eigenvalue (max(Re(λ))) across the die domain.

- Validation: Run a transient perturbation analysis on the optimized die geometry to confirm suppression of instability growth.

- Output: An optimized die geometry file (CAD) and a stability map showing a uniformly negative growth rate field.

Diagram Title: Die Geometry Optimization Loop for Stability

Optimizing Screw Design and Processing Parameters (Temperature, Speed) for Homogeneous Output

Within the scope of a thesis on ANSYS Polyflow simulation for polymer extrusion research, achieving homogeneous output in polymer processing is critical. This homogeneity directly impacts product quality in applications ranging from medical device components to drug delivery systems. This application note details a structured approach, integrating simulation and experimental validation, to optimize extruder screw design and key processing parameters—barrel temperature and screw speed—for consistent melt homogeneity.

Key Principles & Literature Synthesis