Bayesian Optimization in Polymer Formulation: A Next-Gen Strategy for Accelerated Drug Delivery and Biomedical Material Discovery

This article provides a comprehensive guide to Bayesian Optimization (BO) for polymer formulation, tailored for researchers and drug development professionals.

Bayesian Optimization in Polymer Formulation: A Next-Gen Strategy for Accelerated Drug Delivery and Biomedical Material Discovery

Abstract

This article provides a comprehensive guide to Bayesian Optimization (BO) for polymer formulation, tailored for researchers and drug development professionals. It covers the foundational principles of BO as an efficient alternative to high-throughput screening, details its methodological application in designing drug delivery systems and biomaterials, addresses common challenges in experimental integration and model tuning, and validates its performance against traditional Design of Experiments. The synthesis offers a roadmap for implementing BO to drastically reduce development timelines and cost in polymer-based biomedical research.

What is Bayesian Optimization? A Primer for Polymer Scientists on Smart Formulation Search

Within the broader thesis on Bayesian optimization (BO) in polymer formulation research, this document outlines the fundamental inefficiencies of traditional, high-throughput experimental (HTE) screening. The central argument posits that the "one-factor-at-a-time" (OFAT) or full-factorial grid-search paradigms are prohibitively costly in terms of time, materials, and capital when navigating high-dimensional formulation spaces. BO emerges as a superior, data-driven methodology for intelligently exploring this complex design space, learning from prior experiments to propose the next most informative formulation, thereby drastically reducing the number of experiments required to identify optimal compositions.

Quantitative Analysis of Traditional Screening Costs

The costs scale non-linearly with the number of components and tested levels. The following table summarizes the experimental burden for a hypothetical formulation with 4 components.

Table 1: Experimental Scale and Cost of Traditional Full-Factorial Screening

| Formulation Parameters | Low-Complexity Screen | Medium-Complexity Screen | High-Complexity Screen |

|---|---|---|---|

| Number of Components | 4 | 4 | 4 |

| Levels per Component | 3 | 5 | 7 |

| Total Formulations | 3^4 = 81 | 5^4 = 625 | 7^4 = 2,401 |

| Material per Test (g) | 10 | 10 | 10 |

| Total Material (kg) | 0.81 | 6.25 | 24.01 |

| Estimated Prep/Test Time | 30 min | 30 min | 30 min |

| Total Personnel Hours | 40.5 | 312.5 | 1,200.5 |

| Key Cost Drivers | Material waste, analyst time, instrument time. | Exponential increase in time and materials. | Becomes practically infeasible; consumes quarterly budgets. |

Application Notes: The Bayesian Optimization Alternative

BO reframes formulation discovery as a global optimization problem. A probabilistic surrogate model (e.g., Gaussian Process) learns the relationship between formulation inputs (ratios, components) and target properties (e.g., viscosity, drug release, tensile strength). An acquisition function uses this model to balance exploration and exploitation, proposing the single next experiment most likely to improve the target.

Key Advantage: BO often identifies optimal performance within 20-30 iterative experiments, even in spaces with thousands of potential combinations, achieving >90% reduction in experimental load compared to full-factorial screening.

Experimental Protocols

Protocol 4.1: Traditional High-Throughput Formulation Screening

- Objective: To empirically map the property landscape of a multi-component polymer blend using a full-factorial design.

- Materials: See "Scientist's Toolkit" below.

- Procedure:

- Design Space Definition: Define all components (e.g., Polymer A, Polymer B, Plasticizer, Active Ingredient) and their discrete concentration ranges (e.g., 5%, 10%, 15%).

- Grid Generation: Use DOE software to generate a full list of all possible combinations (full factorial).

- Parallel Formulation: Using liquid handling robots, prepare all formulations in a 96-well plate format according to the design matrix.

- Curing/Processing: Subject plates to a standardized curing protocol (e.g., 60°C for 24h).

- High-Throughput Characterization: Employ plate-based analytics (e.g., absorbance for drug content, light scattering for turbidity, nano-indentation for stiffness).

- Data Analysis: Fit a response surface model to the entire dataset to identify optimal combinations.

Protocol 4.2: Bayesian Optimization for Iterative Formulation Discovery

- Objective: To find the formulation that maximizes a target property (e.g., drug release at 24h) with a minimal number of experiments.

- Materials: See "Scientist's Toolkit." Requires BO software platform (e.g., custom Python with GPyTorch/BoTorch, commercial packages).

- Procedure:

- Initial Design: Perform a small space-filling design (e.g., 5-10 formulations via Latin Hypercube) to seed the model.

- Surrogate Model Training: Characterize initial formulations. Train a Gaussian Process model on the data (Formulation → Property).

- Acquisition & Proposal: Calculate the acquisition function (e.g., Expected Improvement) across the unexplored space. The formulation maximizing this function is the next proposed experiment.

- Iterative Loop: Prepare, process, and characterize the single proposed formulation. Add the new data point to the training set. Re-train the surrogate model.

- Convergence Check: Repeat steps 3-4 until a performance threshold is met or iterations are exhausted (typically 20-30 cycles).

- Optimum Identification: The best-performing formulation from all iterations is reported as the optimum.

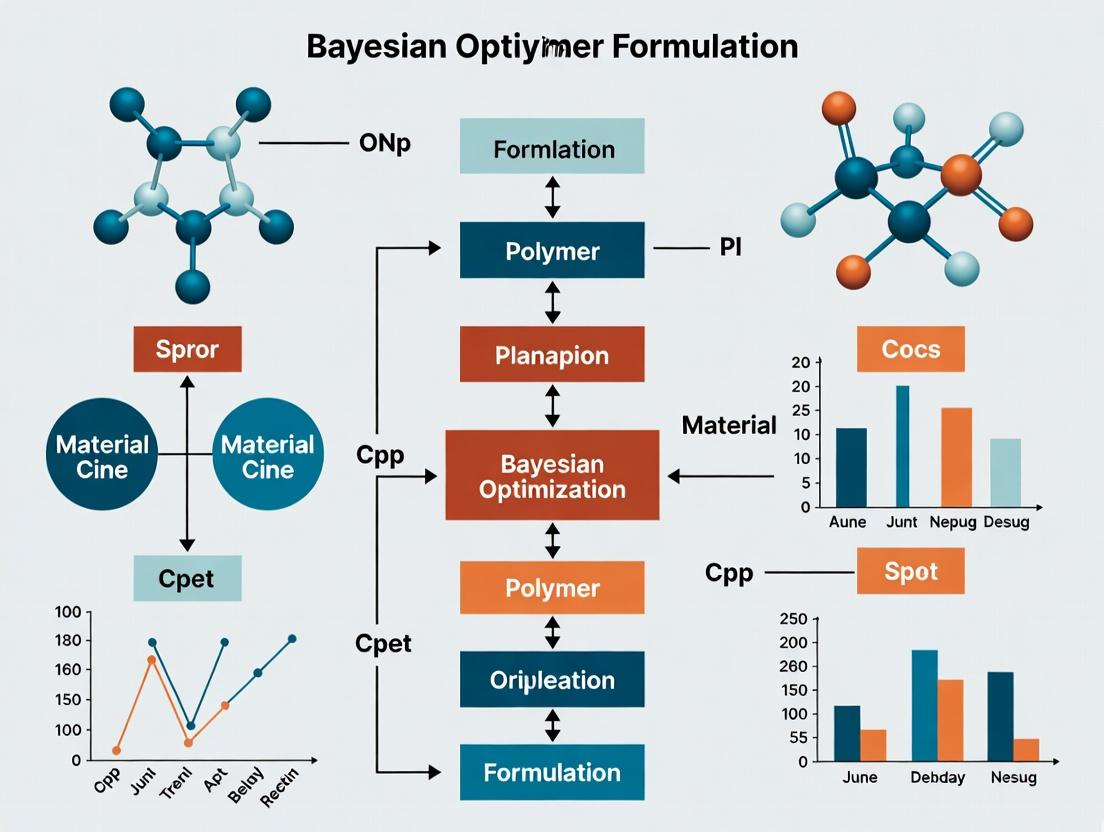

Mandatory Visualizations

Title: Traditional HTE Screening Workflow

Title: Bayesian Optimization Iterative Loop

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Polymer Formulation Screening

| Item/Category | Function & Relevance |

|---|---|

| Polymer Libraries (e.g., PLGA, PEG, PCL variants) | Base structural components defining drug release kinetics, mechanical properties, and biocompatibility. |

| Automated Liquid Handling Robot | Enables precise, reproducible dispensing of polymer solutions, plasticizers, and API stocks for high-throughput preparation. |

| Microplate-Based Curing Station | Provides controlled environment (temperature, humidity) for parallel solvent evaporation/polymer solidification in well plates. |

| UV-Vis Plate Reader | High-throughput quantification of drug content (via absorbance) and turbidity (via scattering) as a stability metric. |

| Rheometer with Microplate Geometry | Measures viscosity and viscoelastic properties of polymer solutions or melts directly in multi-well format. |

| Bayesian Optimization Software (e.g., BoTorch, SigOpt) | Core platform for building surrogate models, optimizing acquisition functions, and managing the iterative experiment queue. |

| Data Analysis Suite (e.g., Python/Pandas, JMP) | For data wrangling, visualization, and statistical analysis of both traditional HTE and sequential BO data. |

In the context of polymer formulation for drug delivery, Bayesian Optimization (BO) provides a structured, data-efficient framework to navigate complex, high-dimensional design spaces. It systematically balances exploration of new formulation candidates with exploitation of known high-performing regions, accelerating the discovery of polymers with optimal properties (e.g., controlled release kinetics, biocompatibility, target specificity). This Application Note details the core components of a BO workflow.

Surrogate Models: Gaussian Processes (GPs)

Core Concept

A Gaussian Process (GP) is a probabilistic non-parametric model used to surrogate an expensive-to-evaluate objective function (e.g., drug release efficiency, polymer viscosity). It defines a prior over functions and updates this to a posterior as experimental data is observed, providing both a predictive mean and a measure of uncertainty (variance) at any point in the formulation space.

Key Components in Polymer Research

- Kernel (Covariance Function): Encodes assumptions about the function's smoothness and periodicity. The choice of kernel is critical for modeling polymer property landscapes.

- Mean Function: Often set to a constant, but can incorporate prior mechanistic knowledge.

- Hyperparameters: Parameters of the kernel (e.g., length-scales, variance) optimized by maximizing the marginal likelihood of the observed data.

Table 1: Common GP Kernels for Polymer Formulation Modeling

| Kernel Name | Mathematical Form (Simplified) | Key Property | Use-case in Polymer Research | ||||

|---|---|---|---|---|---|---|---|

| Squared Exponential (RBF) | ( k(xi, xj) = \sigma^2 \exp(-\frac{ | xi - xj | ^2}{2l^2}) ) | Infinitely differentiable, very smooth. | Modeling continuous, gradual property changes (e.g., glass transition temperature vs. plasticizer ratio). | ||

| Matérn 5/2 | ( k(xi, xj) = \sigma^2 (1 + \frac{\sqrt{5}r}{l} + \frac{5r^2}{3l^2}) \exp(-\frac{\sqrt{5}r}{l}) ) | Twice differentiable, less smooth than RBF. | Default choice for physical experiments; accommodates moderate noise in rheological or release profile data. | ||||

| Matérn 3/2 | ( k(xi, xj) = \sigma^2 (1 + \frac{\sqrt{3}r}{l}) \exp(-\frac{\sqrt{3}r}{l}) ) | Once differentiable. | Suitable for modeling properties with potential abrupt changes or higher noise levels. | ||||

| Linear | ( k(xi, xj) = \sigma^2 (xi \cdot xj) ) | Models linear relationships. | Can be used as part of a composite kernel to capture known linear trends in formulation components. |

Protocol 1: Implementing a GP Surrogate for Polymer Screening Objective: Construct a GP model to predict a target property (e.g., encapsulation efficiency) based on formulation variables. Materials: See "The Scientist's Toolkit" below. Procedure:

- Data Preparation: Standardize input variables (e.g., polymer MW, co-monomer ratio, crosslinker concentration) to zero mean and unit variance. Normalize the target output.

- Kernel Selection: Initialize a composite kernel, often starting with

Matérn 5/2 + WhiteKernel(to account for experimental noise). - Model Training: Fit the GP to the initial experimental data (≥5 points per dimension is a pragmatic start). Optimize kernel hyperparameters by maximizing the log-marginal-likelihood using a conjugate gradient optimizer.

- Model Validation: Perform leave-one-out or k-fold cross-validation. Calculate the standardized mean squared error (SMSE) and mean standardized log loss (MSLL) to assess predictive quality.

- Prediction: For a new candidate formulation

x*, the GP returns a predictive Gaussian distribution: meanμ(x*)and uncertaintyσ(x*).

Diagram Title: GP Surrogate Model Training and Update Loop

Acquisition Functions

Core Concept

Acquisition functions α(x) leverage the GP's predictive distribution to quantify the potential utility of evaluating a candidate formulation x. They mathematically formalize the explore-exploit trade-off, proposing the next experiment by maximizing α(x).

Table 2: Key Acquisition Functions for Formulation Optimization

| Function Name | Mathematical Form (Typical) | Strategy | Best For |

|---|---|---|---|

| Expected Improvement (EI) | ( \alpha_{EI}(x) = \mathbb{E}[\max(f(x) - f(x^+), 0)] ) | Improves over the current best observation (f(x^+)). |

General-purpose, efficient global optimization of formulation properties. |

| Upper Confidence Bound (UCB) | ( \alpha_{UCB}(x) = \mu(x) + \kappa \sigma(x) ) | Optimistic estimate: mean + κ * uncertainty. κ controls exploration. |

Tunable exploration; explicit balance parameter (κ). |

| Probability of Improvement (PI) | ( \alpha_{PI}(x) = P(f(x) \ge f(x^+) + \xi) ) | Probability of exceeding the best by a margin ξ. |

Pure exploitation with some tolerance; less used than EI. |

| Entropy Search / PES | Maximizes reduction in entropy of the posterior over the optimum location. | Directly targets information gain about the optimum. | Very data-efficient but computationally intensive; for very costly experiments. |

Protocol 2: Selecting the Next Experiment via Acquisition Maximization Objective: Identify the optimal polymer formulation to synthesize and test in the next iteration. Procedure:

- Define Space: Based on the trained GP, define the bounded search space for the formulation variables.

- Calculate Surface: Compute the acquisition function

α(x)over a dense, discretized grid of the search space or via random sampling. - Global Optimization: Use a multi-start gradient-based optimizer (e.g., L-BFGS-B) or a global method (e.g., DIRECT) to find the formulation

x_nextthat maximizesα(x).x_next = argmax α(x) - Proposal: Output

x_next(e.g., a specific combination of polymer A %, solvent B ratio, and curing time) as the candidate for experimental validation.

Diagram Title: Acquisition Function Decision Process

The Bayesian Optimization Loop

Core Concept

The BO loop is the iterative framework that integrates the surrogate model and acquisition function to converge towards the global optimum of an expensive black-box function with minimal evaluations.

Protocol 3: The Bayesian Optimization Protocol for Polymer Development Objective: Systematically discover a polymer formulation that maximizes drug loading capacity within 20 experimental iterations. Materials: See "The Scientist's Toolkit" below. Procedure:

- Initial Design: Generate an initial set of 5-10 diverse formulation candidates using a space-filling design (e.g., Latin Hypercube Sampling) to seed the GP.

- Experiment & Observe: Synthesize and characterize these initial formulations. Measure the target property (e.g., loading capacity).

- Iterative Loop (Repeat until budget exhausted):

a. Model Update: Train/update the GP surrogate model on all data observed so far.

b. Acquisition: Maximize the chosen acquisition function (e.g., EI) to propose the single next formulation

x_next. c. Experiment: Synthesize and testx_next. Record the resulty_next. d. Augment Data: Append(x_next, y_next)to the dataset. - Termination & Analysis: Upon completion, analyze the final GP model to identify the optimal formulation

x_optand characterize the response landscape (e.g., sensitivity to components).

Diagram Title: Bayesian Optimization Closed-Loop Workflow

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for BO-Driven Polymer Formulation

| Item / Reagent | Function in the BO Workflow | Example / Note |

|---|---|---|

| Polymer Libraries | Provide diverse chemical space for variables (e.g., PLGA, PEG, chitosan derivatives). | Used as the base material; varying molecular weight, block length, or functionalization. |

| Crosslinkers / Initiators | Enable modulation of network structure and curing kinetics (formulation variables). | E.g., APS/TEMED for free-radical polymerization; genipin for natural polymers. |

| Drug/API Standard | The active ingredient to be encapsulated; its properties define the target outcome. | A model drug (e.g., doxorubicin, BSA) for release studies. |

| Characterization Kit | Quantifies the objective function (e.g., HPLC for drug loading, rheometer for viscosity). | Generates the experimental data y for the GP. |

| BO Software Platform | Implements GP regression, acquisition functions, and the optimization loop. | scikit-optimize, BoTorch, GPyOpt, or custom Python/R scripts. |

| High-Throughput Synthesis | Enables rapid preparation of initial design and proposed candidates. | Liquid handling robots for microplate-based polymer precursor mixing. |

1. Introduction: The Bayesian Optimization Thesis in Polymer Formulation Research

The discovery and optimization of polymeric formulations for drug delivery, biomaterials, and coatings present a high-dimensional challenge. Traditional one-factor-at-a-time (OFAT) or full-factorial design of experiments (DoE) are often prohibitively resource-intensive given the vast combinatorial space of monomers, crosslinkers, initiators, solvents, and processing conditions. The core thesis of modern formulation research is that Bayesian Optimization (BO) provides a principled, data-driven framework to navigate this complexity. This application note details the experimental protocols and research tools underpinning three key advantages of BO: superior sample efficiency, robust handling of experimental noise, and the facilitation of parallel experimentation.

2. Application Notes & Quantitative Data Summary

Table 1: Comparative Performance of Optimization Methods in Polymer Formulation Tasks

| Optimization Method | Avg. Samples to Target Viscosity | Noise Resilience (σ=0.5) | Parallel Batch Capability | Key Study / Formulation Target |

|---|---|---|---|---|

| Bayesian Optimization (BO) | 18 ± 3 | High: Converged within +2% of target | Yes (4-8 candidates/batch) | Thermo-responsive hydrogel (LCST) |

| Grid Search | 125 (full set) | Medium: Reliant on replication | No (sequential) | PEG-DA crosslinking density |

| Random Search | 55 ± 12 | Low: High result variance | Possible, but inefficient | PLGA NP encapsulation efficiency |

| Genetic Algorithm (GA) | 40 ± 8 | Medium: Requires population size tuning | Yes (population-based) | Block copolymer self-assembly |

Table 2: Impact of Parallel BO on Project Timelines (Theoretical Case Study)

| Metric | Sequential BO (1 expt/cycle) | Parallel BO (4 expts/cycle) | % Improvement |

|---|---|---|---|

| Calendar weeks to optimize | 15 | 5 | 66.7% |

| Total experiments run | 24 | 28 | (+16.7% samples) |

| Final formulation performance (e.g., drug release % at t=24h) | 92.5% | 94.8% | +2.3% |

| Resource utilization (lab hardware) | Low | High | Significant |

3. Experimental Protocols

Protocol 3.1: BO-Driven Optimization of a Nanoparticle Formulation for Drug Load Capacity Objective: To maximize the drug load capacity (%) of a PLGA-PEG copolymer nanoparticle system using ≤ 30 synthesis experiments. Variables: PLGA molecular weight (10-100 kDa), Drug:Polymer ratio (1:10 to 1:100), Aqueous phase pH (4-7), Sonication energy (50-500 J). Response: Drug load capacity (%), measured via HPLC (inherent noise ±2%). BO Setup: 1. Prior & Model: Use a Gaussian Process (GP) prior with a Matérn 5/2 kernel. 2. Acquisition Function: Employ Expected Improvement (EI) for initial 10 runs, then switch to Upper Confidence Bound (UCB) with κ=0.5 to encourage exploration. 3. Noise Handling: Explicitly model observational noise in the GP likelihood (Gaussian noise model). 4. Iteration: a. Run the first 8 experiments from a space-filling Latin Hypercube Design. b. Update the GP model with all available data. c. Select the next batch of 4 candidate formulations by maximizing the q-EI acquisition function for parallel selection. d. Synthesize and characterize all 4 candidates in parallel. e. Repeat steps b-d until convergence or budget exhausted. Characterization: Nanoparticle synthesis via nanoprecipitation, followed by purification and HPLC analysis of drug content in both supernatant and nanoparticle pellet.

Protocol 3.2: Systematic Validation of Formulation Robustness (Noise Handling) Objective: To quantify BO's performance against random search under noisy measurement conditions for a hydrogel stiffness (G') target. Variables: Polymer concentration (2-10% w/v), Crosslinker molar ratio (0.1-0.5), Ionic strength (0-150 mM NaCl). Protocol: 1. Noise Introduction: For all rheology measurements (G' at 1 Hz), add Gaussian noise (μ=0, σ=0.1 log(Pa)) to the raw logged data to simulate instrumental/operator variability. 2. Dueling Optimizers: Run two optimization campaigns in silico using historical lab data as a high-fidelity simulator. Campaign A: BO with a noise-aware GP. Campaign B: Random search. 3. Replication Strategy: For both, take the top 5 proposed formulations after 20 iterations and perform n=6 experimental replicates each. 4. Analysis: Compare the mean and standard deviation of the final G' values. BO-selected formulations should show not only higher mean performance but lower inter-sample variance, indicating a discovery of robust optima.

4. Visualizations

Diagram 1: BO Workflow for Polymer Formulation

Diagram 2: Noise-Aware vs. Standard GP Model

5. The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for BO-Driven Polymer Formulation Research

| Item / Reagent | Function / Relevance | Example Vendor/Product |

|---|---|---|

| Lab-Automation Liquid Handler | Enables precise, high-throughput dispensing of monomers, solvents, and catalysts for parallel experiment execution. | Opentrons OT-2, Hamilton STARlet |

| Polymer Library Kits | Pre-formatted arrays of diverse monomers/initiators for rapid combinatorial exploration within the BO-defined space. | Sigma-Aldrych Polymer Discovery Kit, PolyFluor Ltd. Thiol-ene Kit |

| In-line Rheometer or Viscometer | Provides real-time, quantitative performance data (viscosity, G') as a primary objective function for BO feedback. | Micromaterials MRT, Rheonics SRV |

| DoE/BO Software Platform | Computes optimal next experiments, manages data, and updates surrogate models (GPs). | Gryffin/Sinai, Ax Platform, BayesOpt library |

| High-Throughput Characterization Suite | Parallel measurement of key responses (e.g., DLS for size, HPLC for loading, plate reader for release). | Malvern Panalytical Viscosizer TD, Agilent InfinityLab HPLC |

The optimization of polymer-based formulations, particularly for drug delivery systems, is a high-dimensional challenge. A systematic definition of the search space—encompassing material variables and processing conditions—is critical for efficient navigation via Bayesian optimization (BO). This protocol details the parameterization of this space to accelerate the discovery of formulations with target properties such as controlled release, stability, and bioavailability.

Quantifying the Search Space Dimensions

The search space is defined by four primary orthogonal axes, each containing continuous or discrete variables. Their typical ranges, based on current literature, are summarized below.

Table 1: Core Polymer Formulation Search Space Parameters

| Parameter Category | Specific Variable | Typical Range/Levels | Key Influence on Formulation |

|---|---|---|---|

| Polymer Ratios | PLGA (Lactide:Glycolide) | 50:50, 65:35, 75:25, 85:15 | Degradation rate, drug release kinetics. |

| PLGA : PEG Blend Ratio | 95:5 to 70:30 (w/w) | Hydrophilicity, protein repellence, release modulation. | |

| Molecular Weights | PLGA Mw (kDa) | 10 - 120 kDa | Matrix viscosity, erosion rate, encapsulation efficiency. |

| PEG Mw (kDa) | 2 - 20 kDa | Chain mobility, steric stabilization, release profile. | |

| Additives & Drugs | Drug Load (% w/w) | 1 - 30% | Dose, burst release, particle morphology. |

| Stabilizer (e.g., PVA) Conc. (%) | 0.5 - 5% (w/v) | Particle size, surface characteristics, aggregation. | |

| Processing Parameters | Homogenization Speed (rpm) | 5,000 - 20,000 rpm | Primary determinant of particle size distribution. |

| Oil/Water Phase Volume Ratio | 1:5 to 1:20 | Affects particle size and drug encapsulation. | |

| Drying Method (Lyophilization) | Shelf Temp: -40°C to 25°C; Primary Drying: 24-72h | Final product stability, residual solvent/moisture. |

Experimental Protocol: Formulating & Characterizing PLGA-PEG Nanoparticles

This protocol provides a standardized method for generating data points within the defined search space for BO iterations.

Materials & Reagents

Table 2: Research Reagent Solutions Toolkit

| Item | Function/Description |

|---|---|

| PLGA Resomers (e.g., 50:50, 75:25 LG ratio) | Biodegradable polyester backbone forming the nanoparticle matrix. |

| mPEG-PLGA Diblock Copolymer | Amphiphilic polymer for stabilizing nanoparticles and modulating release. |

| Polyvinyl Alcohol (PVA), 87-90% hydrolyzed | Aqueous stabilizer/surfactant for emulsion formation. |

| Dichloromethane (DCM), HPLC Grade | Organic solvent for dissolving hydrophobic polymers and drug. |

| Model Drug (e.g., Docetaxel, Fluorescent dye) | Active pharmaceutical ingredient (API) for encapsulation studies. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard medium for in vitro drug release studies. |

| Lyophilization Protectant (e.g., 5% w/v Trehalose) | Prevents nanoparticle aggregation during freeze-drying. |

Method: Double Emulsion Solvent Evaporation

Day 1: Nanoparticle Preparation

- Organic Phase Preparation: Dissolve PLGA, mPEG-PLGA, and the model drug in DCM at the desired ratios (e.g., 100 mg total polymer at 85:15 PLGA:PEG, with 5% drug load).

- Primary Emulsion (W1/O): Add 0.5 mL of a 1% PVA solution to the organic phase. Homogenize (IKA Ultra-Turrax) at 13,000 rpm for 60 seconds on ice.

- Double Emulsion (W1/O/W2): Immediately pour the primary emulsion into 20 mL of a 1% PVA solution (external aqueous phase). Homogenize again at 13,000 rpm for 120 seconds.

- Solvent Evaporation: Stir the double emulsion magnetically at 600 rpm for 3-4 hours at room temperature to evaporate DCM.

- Harvesting: Centrifuge the nanoparticle suspension at 21,000 × g for 30 minutes at 4°C. Wash the pellet twice with deionized water.

- Lyophilization: Resuspend the pellet in 5% trehalose solution. Pre-freeze at -80°C for 2 hours, then lyophilize for 48 hours (primary drying at -20°C, secondary drying at 25°C).

Day 2: Characterization & Assay

- Size & Zeta Potential: Resuspend lyophilized NPs in DI water. Use dynamic light scattering (DLS) for hydrodynamic diameter and polydispersity index (PDI). Measure zeta potential via laser Doppler micro-electrophoresis.

- Drug Encapsulation Efficiency (EE): Dissolve 5 mg of NPs in 1 mL DCM. Extract drug into 5 mL PBS via vortexing. Centrifuge, and analyze the aqueous phase by HPLC/UV-Vis. EE% = (Measured Drug / Theoretical Drug) × 100.

- In Vitro Release Study: Place 10 mg of NPs in 10 mL PBS + 0.1% Tween 80 (sink conditions) in a dialysis bag (MWCO 12-14 kDa). Immerse in release medium at 37°C, 100 rpm. Sample medium at predetermined times (1, 4, 8, 24, 72, 168h) and replenish. Quantify drug content.

Bayesian Optimization Framework Integration

The defined search space and standardized protocol generate the data required for BO. The objective function is typically a weighted combination of target properties (e.g., maximize EE%, minimize burst release, achieve specific size).

Diagram 1: BO-Driven Polymer Formulation Workflow

Diagram 2: Key Property Relationships in Polymer Search Space

Implementing Bayesian Optimization: A Step-by-Step Guide for Polymer and Drug Formulation

This application note delineates a structured workflow for the design and optimization of polymeric drug delivery systems, framed within a thesis utilizing Bayesian optimization (BO) for accelerated formulation research. The focus is on systematically translating high-level objectives—controlled drug release, mechanical strength, and predictable degradation—into executable experimental campaigns.

Defining and Quantifying Formulation Objectives

The primary step involves operationalizing qualitative goals into quantifiable, measurable Key Performance Indicators (KPIs). These KPIs serve as the objective functions for the subsequent Bayesian optimization loop.

Table 1: Primary Formulation Objectives and Corresponding Quantitative KPIs

| Objective | Key Performance Indicator (KPI) | Standard Measurement Technique | Target Range (Example) |

|---|---|---|---|

| Drug Release | Cumulative % released at time t (e.g., t=24h) | USP Apparatus II (Paddle) in PBS, pH 7.4, 37°C | 20-40% at 24h (sustained) |

| Release profile shape (e.g., time for 50%, 90% release) | Model fitting (Zero-order, Higuchi, Korsmeyer-Peppas) | T50% > 12h | |

| Mechanical Strength | Tensile Strength (MPa) or Compressive Modulus (kPa) | Universal Testing Machine (ASTM D638 / D695) | > 2.0 MPa tensile |

| Elastic Modulus (MPa) | Dynamic Mechanical Analysis (DMA) | 1.5 - 3.0 MPa | |

| Degradation | Mass Loss (%) over time | Gravimetric analysis in simulated physiological buffer | ~50% loss at 28 days |

| Molecular Weight Loss (Mn reduction %) | Gel Permeation Chromatography (GPC) | Mn reduction < 30% at 28 days |

Bayesian Optimization Workflow for Polymer Formulation

The core of the modern research thesis is a closed-loop Bayesian optimization workflow. This machine learning strategy efficiently navigates the complex design space of polymer composition and processing parameters to identify optimal formulations with minimal experimental runs.

Title: Bayesian Optimization Loop for Polymer Formulation

Experimental Protocols for Key Performance Indicators

Protocol 4.1: In Vitro Drug Release Study (USP Apparatus II)

Objective: Quantify the drug release profile of a polymeric film or microparticle formulation over time.

Materials: See "The Scientist's Toolkit" below. Procedure:

- Sample Preparation: Precisely weigh polymeric films/particles containing X mg of active pharmaceutical ingredient (API). Use n=3 replicates.

- Release Medium: Prepare 500 mL of phosphate-buffered saline (PBS, pH 7.4) per vessel. Maintain at 37.0 ± 0.5 °C.

- Apparatus Setup: Place each sample in a sinker. Lower into vessel of USP Apparatus II (paddle). Set paddle speed to 50 rpm.

- Sampling: At pre-defined time points (e.g., 1, 2, 4, 6, 8, 24, 48, 72h), withdraw 5 mL aliquots from each vessel. Immediately replace with 5 mL of fresh, pre-warmed PBS to maintain sink conditions.

- Analysis: Filter aliquot (0.45 μm syringe filter). Analyze drug concentration using validated HPLC-UV method.

- Data Calculation: Calculate cumulative percentage drug released, correcting for volume replacement. Plot release profile (Mean % Released ± SD vs. Time).

Protocol 4.2: Tensile Strength Testing of Polymer Films (ASTM D638)

Objective: Determine the mechanical strength and elongation of cast polymer films.

Procedure:

- Film Preparation: Cast polymer solution onto leveled glass plate. Dry under controlled conditions. Die-cut into standard Type V dog-bone shapes.

- Conditioning: Condition samples at 23 ± 2 °C and 50 ± 10% relative humidity for 48 hours.

- Measurement: Measure thickness at multiple points along the gauge length. Mount sample in universal testing machine grips. Set gauge length to 7.62 mm.

- Test Run: Apply tension at a constant crosshead speed of 50 mm/min until failure. Record force (N) and displacement (mm).

- Data Analysis: Calculate tensile strength = Maximum Force / Initial Cross-Sectional Area. Calculate elongation at break = (Gauge length at break / Initial gauge length) * 100%.

Protocol 4.3: Hydrolytic Degradation via Gravimetric Analysis

Objective: Monitor mass loss of polymer samples under simulated physiological conditions.

Procedure:

- Baseline Measurement: Precisely weigh dry polymer samples (W0). Record initial dimensions.

- Incubation: Immerse each sample in 20 mL of PBS (pH 7.4) in individual vials. Incubate at 37 °C in an orbital shaker (60 rpm).

- Time-Point Harvesting: At intervals (e.g., 7, 14, 21, 28 days), remove samples (n=3 per time point). Rinse with deionized water and lyophilize to constant dry weight.

- Final Measurement: Precisely weigh dried sample (Wt).

- Data Calculation: Calculate mass remaining (%) = (Wt / W0) * 100. Plot mass loss profile.

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions & Materials

| Item | Function/Application | Key Considerations |

|---|---|---|

| PLGA (Poly(lactic-co-glycolic acid)) | Benchmark biodegradable polymer matrix. Ratio (LA:GA) & MW control release & degradation kinetics. | 50:50 for faster release; 75:25 or 85:15 for more sustained profiles. |

| PEG (Polyethylene glycol) | Hydrophilic additive; modulates release rate, improves wettability, reduces burst release. | Used as a co-polymer (PLGA-PEG) or physical blend. MW affects chain mobility. |

| Dichloromethane (DCM) / Ethyl Acetate | Solvents for emulsion-based particle formation or film casting. | DCM is volatile (fast removal); Ethyl acetate is less toxic. Choice impacts morphology. |

| Polyvinyl Alcohol (PVA) | Stabilizer/surfactant in oil-in-water emulsion for microparticle/nanoparticle formation. | Concentration and MW critical for controlling particle size and stability. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard in vitro release and degradation medium; simulates physiological pH and ionic strength. | Must contain 0.02-0.1% w/v sodium azide to prevent microbial growth in long studies. |

| Acetonitrile (HPLC Grade) | Mobile phase for HPLC analysis of drug concentration in release samples. | Must be HPLC grade for reliable, reproducible chromatographic separation. |

Data Integration and Model Training Workflow

The experimental data feeds into the Bayesian optimization engine. This diagram details the data flow from experiment to model update.

Title: Data Flow for Bayesian Optimization Model

Application Notes: Bayesian Optimization in PLGA Formulation

This case study details the application of Bayesian optimization (BO) to systematically develop poly(lactic-co-glycolic acid) (PLGA) nanoparticles for tailored drug release profiles. The work is nested within a broader thesis exploring machine learning-guided polymer formulation. Traditional one-factor-at-a-time approaches are inefficient for navigating the complex, high-dimensional parameter space of nanoparticle synthesis. BO, a sequential design strategy, builds a probabilistic surrogate model (typically a Gaussian Process) to predict formulation performance and intelligently selects the next experiment to maximize an objective function, such as minimizing the difference between achieved and target release kinetics.

Core Advantages in This Context:

- Efficiency: Reduces the number of required experiments by 50-70% compared to grid search.

- Handles Complexity: Optimizes multiple interacting continuous (e.g., polymer MW, drug loading) and categorical (e.g., surfactant type) variables simultaneously.

- Explicit Trade-off: Balances exploration (testing uncertain regions) and exploitation (refining known good formulations).

- Quantifies Uncertainty: Provides prediction confidence intervals for key outputs like burst release and release duration.

Table 1: PLGA Formulation Variables and Their Experimental Ranges

| Variable Name | Symbol | Type | Lower Bound | Upper Bound | Notes |

|---|---|---|---|---|---|

| Lactide:Glycolide (L:G) Ratio | X₁ |

Continuous | 50:50 | 85:15 | Affects crystallinity & degradation rate. |

| PLGA Molecular Weight (kDa) | X₂ |

Continuous | 10 | 75 | Influences polymer viscosity & erosion. |

| Drug Loading (% w/w) | X₃ |

Continuous | 1 | 20 | Impacts encapsulation efficiency & release. |

| Surfactant Type | X₄ |

Categorical | PVA | PVP, Poloxamer 188 | Stabilizer during emulsification. |

| Aqueous Phase Volume (mL) | X₅ |

Continuous | 50 | 200 | Affects particle size via diffusion rate. |

Table 2: Bayesian Optimization Outcomes for Target Release Profiles

| Optimization Target | Optimal Formulation (L:G, MW, Load, Surfactant) | Predicted T₅₀ (h) |

Achieved T₅₀ (h) |

Burst Release (%) | Experiments to Convergence |

|---|---|---|---|---|---|

| Sustained (120h) | 75:25, 65 kDa, 5%, PVA | 120 | 118 ± 8 | 15 ± 3 | 24 |

| Pulsatile (24h Lag) | 50:50, 15 kDa, 15%, Poloxamer 188 | 24 | 22 ± 2 | < 5 | 31 |

| Biphasic (Fast + Slow) | 65:35, 30 kDa, 10%, PVP | 48 (Phase 1) | 45 ± 5 | 35 ± 4 | 28 |

T₅₀: Time for 50% cumulative drug release.

Experimental Protocols

Protocol 3.1: Double-Emulsion Solvent Evaporation for PLGA Nanoparticle Synthesis

Objective: Encapsulate a hydrophilic model drug (e.g., fluorescein, doxorubicin HCl).

Materials: See "Scientist's Toolkit" (Section 5). Procedure:

- Primary W/O Emulsion: Dissolve 100 mg PLGA and the hydrophilic drug in 2 mL dichloromethane (DCM). Sonicate (70% amplitude, 30 s) this organic phase into 1 mL of a 1% aqueous surfactant solution (e.g., PVA) on ice.

- Secondary W/O/W Emulsion: Immediately transfer the primary emulsion into 50 mL of a 0.3% aqueous surfactant solution. Homogenize at 10,000 rpm for 2 minutes.

- Solvent Evaporation: Stir the double emulsion magnetically at 600 rpm for 4 hours at room temperature to evaporate DCM.

- Nanoparticle Recovery: Centrifuge at 20,000 × g for 30 minutes at 4°C. Wash pellet twice with ultrapure water. Resuspend in buffer or lyophilize with a 5% (w/v) cryoprotectant (e.g., trehalose).

Protocol 3.2: In Vitro Drug Release Kinetics Assay

Objective: Quantify drug release over time in simulated physiological conditions.

Materials: Phosphate Buffered Saline (PBS, pH 7.4), Dialysis tubes (MWCO 12-14 kDa), shaking water bath, HPLC-UV/VIS. Procedure:

- Place nanoparticles equivalent to 1 mg of drug into a dialysis tube sealed at both ends.

- Immerse the tube in 200 mL of release medium (PBS, 37°C, 0.01% NaN₃ to prevent microbial growth) with gentle shaking at 50 rpm.

- At predetermined time points (e.g., 1, 4, 8, 24, 72, 120, 168 h), withdraw 1 mL of external medium and replace with fresh, pre-warmed medium.

- Analyze drug concentration in samples via validated HPLC. Calculate cumulative release (%) vs. time.

Visualizations

Title: Bayesian Optimization Workflow for PLGA Formulation

Title: PLGA Nanoparticle Drug Release Mechanisms

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for PLGA Nanoparticle Development

| Item / Reagent | Function & Rationale | Key Considerations |

|---|---|---|

| PLGA Copolymers (Various L:G, MW) | Biodegradable polymer matrix. L:G ratio dictates degradation rate (more glycolide = faster). MW affects drug diffusion path length. | Use acid-terminated for faster degradation, ester-terminated for slower. Store dry at -20°C. |

| Polyvinyl Alcohol (PVA) | Common surfactant/stabilizer. Reduces interfacial tension during emulsification, controlling particle size and PDI. | Degree of hydrolysis (e.g., 80-99%) significantly impacts nanoparticle surface properties and release. |

| Dichloromethane (DCM) | Volatile organic solvent. Dissolves PLGA for emulsion formation; subsequent evaporation drives nanoparticle solidification. | High volatility enables rapid particle hardening. Must be removed entirely to avoid toxicity. |

| Dialysis Tubing (MWCO 12-14 kDa) | For in vitro release studies. Allows continuous sink conditions by permitting drug diffusion while retaining nanoparticles. | Pre-soak per manufacturer instructions to remove preservatives. Match MWCO to drug size. |

| Cryoprotectant (e.g., Trehalose) | Prevents nanoparticle aggregation and protects integrity during lyophilization (freeze-drying) for long-term storage. | Typically used at 2-5% (w/v). Forms an amorphous glassy matrix. |

| Acquisition Function Software (e.g., scikit-optimize, GPyOpt) | Implements the Bayesian Optimization algorithm (Expected Improvement, Upper Confidence Bound) to recommend next experiments. | Critical for automating the optimization loop. Integrates with design of experiments (DoE). |

This application note details the integration of Bayesian optimization (BO) into the discovery pipeline for novel bio-inks. Within the broader thesis on Bayesian optimization for polymer formulation, this case study demonstrates its utility in navigating the complex, high-dimensional design space of bio-ink components to rapidly identify formulations that optimize conflicting parameters: printability, structural fidelity, and cell viability.

Bayesian Optimization Workflow for Bio-Ink Formulation

Diagram Title: Bayesian Optimization Loop for Bio-Ink Screening

Key Performance Data from a Model Study

The following table summarizes quantitative targets for an ideal bio-ink and results from a hypothetical BO-driven screening campaign focused on a gelatin methacryloyl (GelMA)-alginate system.

Table 1: Bio-Ink Performance Targets & BO Screening Outcomes

| Performance Metric | Ideal Target Range | Baseline Formulation (GelMA 5%) | BO-Optimized Formulation (Iteration 8) | Measurement Protocol |

|---|---|---|---|---|

| Storage Modulus (G') | 500 - 2000 Pa | 350 ± 50 Pa | 1250 ± 180 Pa | Oscillatory rheology at 37°C, 1 Hz. |

| Shear Viscosity @ 10 s⁻¹ | 10 - 50 Pa·s | 8 ± 2 Pa·s | 35 ± 5 Pa·s | Flow sweep rheology. |

| Printability Fidelity Score | > 85% | 72% ± 5% | 91% ± 3% | Comparison of printed grid to CAD model. |

| Gelation Time | 20 - 60 s | 90 ± 15 s | 45 ± 8 s | Time to G' > G'' after UV exposure. |

| Cell Viability (Day 7) | > 90% | 88% ± 4% | 95% ± 2% | Live/Dead assay & confocal imaging. |

| Compressive Modulus | 15 - 50 kPa | 10 ± 3 kPa | 32 ± 6 kPa | Uniaxial compression test. |

Detailed Experimental Protocols

Protocol 1: High-Throughput Rheological & Printability Assessment

Objective: Quantify shear-thinning behavior, yield stress, and structural recovery to predict extrusion printability.

- Sample Preparation: Prepare bio-ink candidates in 2 mL sterile syringes. Allow to equilibrate at 22°C for 30 min.

- Rheology:

- Shear Thinning: Perform a flow sweep from 0.1 to 100 s⁻¹ shear rate. Record viscosity at 10 s⁻¹ (printing shear).

- Yield Stress: Use a stress ramp (1-100 Pa) to identify the storage modulus (G') crossover point.

- Recovery Test: Apply high shear (50 s⁻¹ for 30 s), then immediate low shear (0.1 s⁻¹ for 60 s). Measure % G' recovery.

- Printability Test: Using a pneumatic extrusion bioprinter (22°C, 0.41 mm nozzle, 15 kPa), print a 20x20 mm lattice grid. Image with stereo microscope. Calculate fidelity score: (1 - |Areadesign - Areaprint| / Areadesign) * 100%.

Protocol 2: In Situ Cell Viability and Function Assay

Objective: Assess cytocompatibility of crosslinking process and long-term cell health.

- Bio-Ink Cell Seeding: Mix NIH/3T3 fibroblasts or human mesenchymal stem cells (hMSCs) with bio-ink at 5x10^6 cells/mL.

- 3D Bioprinting: Print a 5-layer construct (10x10x1 mm) into a cell culture well plate. Crosslink per formulation (e.g., 405 nm UV, 5 mW/cm², 30-60 s).

- Culture: Maintain in DMEM high glucose + 10% FBS + 1% Pen/Strep. Change media every 48h.

- Viability Quantification: On Days 1, 3, and 7, incubate with Calcein AM (2 µM, live) and Ethidium homodimer-1 (4 µM, dead) for 45 min. Image with confocal microscope (z-stack). Analyze with ImageJ: Viability = (Live cells / Total cells) * 100%.

Protocol 3: Bayesian Optimization Setup and Execution

Objective: Automate the iterative search for optimal bio-ink formulations.

- Define Search Space: Parameterize formulation. Example: GelMA concentration (5-15% w/v), Alginate concentration (0-3% w/v), Photoinitiator concentration (0.05-0.25% w/v), UV crosslinking time (10-90 s).

- Define Objective Function: Create a composite score: Score = 0.3(Normalized G') + 0.3(Normalized Fidelity) + 0.4*(Normalized Day 7 Viability).

- Initial Design: Use a Latin Hypercube Sampling (LHS) to select 10-15 initial data points across the search space. Run Protocols 1 & 2.

- Iterative Loop: Using a Python library (e.g.,

scikit-optimizeorBoTorch):- Train a Gaussian Process (GP) surrogate model on all accumulated data.

- Use the Expected Improvement (EI) acquisition function to propose the next 3-5 candidate formulations.

- Experimentally evaluate candidates.

- Update the GP model with new results.

- Repeat for 20-30 iterations or until convergence (no improvement in max score for 5 iterations).

Crosslinking & Cell Signaling Pathway Logic

Diagram Title: Bio-Ink Crosslinking & Cell Mechanotransduction Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Bio-Ink Discovery & Testing

| Reagent/Material | Function & Role in Research | Example Product/Catalog |

|---|---|---|

| Methacrylated Natural Polymers (GelMA, HA-MA) | Core bio-ink material providing biocompatibility, cell adhesion motifs, and tunable UV-crosslinkable chemistry. | GelMA Kit (EFL-GM-90), Glycosil (HA-MA). |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Efficient, cytocompatible photoinitiator for visible light (405 nm) crosslinking, enabling in situ encapsulation. | LAP (Sigma-Aldrich, 900889). |

| RGD-Adhesive Peptide | Synthetic peptide additive to enhance cell adhesion in polymers lacking intrinsic adhesion sites (e.g., PEG-based inks). | GCGRGDS (Peptide Synthesized). |

| Rheology Additives (Nanoclay, Alginate) | Modifiers to impart shear-thinning behavior, improve printability, and provide temporary support. | Laponite XLG, Alginate (Pronova UP MVG). |

| High-Throughput Bioprinter | Automated system for reproducible deposition of multiple ink formulations in plate formats for screening. | BIO X (CELLINK), BioAssemblyBot 400 (Advanced Solutions). |

| Live/Dead Viability/Cytotoxicity Kit | Standardized two-color fluorescence assay for quantitative assessment of cell viability in 3D constructs. | Thermo Fisher Scientific (L3224). |

| Mechanosensing Reporter Cell Line | Cells with fluorescent reporters for YAP/TAZ localization to directly visualize mechanotransduction response. | YAP/TAZ GFP Reporter Cell Line. |

This document provides application notes and protocols for integrating open-source Bayesian Optimization (BO) libraries into experimental workflows for polymer formulation research. Within the broader thesis, which aims to develop novel polymer membranes for drug purification, BO serves as a critical driver for efficiently navigating high-dimensional formulation spaces (e.g., monomer ratios, cross-linker density, solvent composition) to optimize properties like porosity, selectivity, and binding capacity. These tools automate the propose-sample-learn cycle, accelerating the discovery of optimal formulations with minimal experimental trials.

Library Comparison and Data Presentation

The following table summarizes key characteristics of the three primary open-source BO libraries, based on current documentation and community usage.

Table 1: Comparison of Open-Source BO Libraries for Lab Integration

| Feature | Ax (Adaptive Experimentation Platform) | BoTorch (Bayesian Optimization in PyTorch) | GPyOpt |

|---|---|---|---|

| Primary Developer | Meta (Facebook) | Meta (Facebook) | Sheffield Machine Learning Group |

| Core Language | Python | Python (PyTorch) | Python (NumPy, GPy) |

| Key Strength | End-to-end platform with dashboard, service integration, and multi-objective support. | Flexibility and modularity for advanced research; GPU acceleration. | Simplicity and ease of use; tight integration with GPy Gaussian processes. |

| Optimization Loop Management | High-level API (AxClient); fully managed. |

Mid-level; user has control over loop components. | Low-level; user manually manages the iteration. |

| Experimental Trial Data Storage | Built-in SQL backend or JSON. | User-defined (e.g., tensors, dictionaries). | User-defined (typically arrays). |

| Ideal Use Case in Polymer Research | A/B testing of synthesis protocols, complex multi-objective optimization (e.g., strength vs. permeability). | Custom surrogate model development, high-throughput simulation-driven formulation. | Rapid prototyping of BO ideas, straightforward single-objective problems. |

| Current Version (as of 2024) | 0.3.4 | 0.9.4 | 1.2.6 |

| Active Maintenance | High | High | Low (minimal recent updates) |

Experimental Protocols

Protocol 1: Setting Up an Ax Experiment for Polymer Hydrogel Formulation

Objective: To optimize a two-component hydrogel formulation (Polymer A % and Cross-linker B concentration) for maximizing drug loading capacity and minimizing swelling ratio.

Materials & Software:

- Python environment (≥3.8),

ax-platform,pandas,numpy. - Laboratory equipment for hydrogel synthesis and characterization (rheometer, HPLC).

Methodology:

- Installation:

pip install ax-platform - Experiment Initialization:

Integration with Lab Workflow:

trial_parameters = ax_client.get_next_trial()generates the next formulation to test.- Synthesize hydrogel using the specified parameters.

- Measure drug loading capacity (mg/g) and swelling ratio (%).

- Report results back to Ax:

(Note: The second value in the tuple represents the SEM of the measurement).

- Iteration: Repeat steps 3-4 for 15-20 iterations. Ax will model the response surface and suggest optimal Pareto-front formulations.

Protocol 2: Custom BO Loop with BoTorch for Reaction Temperature Optimization

Objective: To find the optimal temperature profile (3-stage temperatures) for a polymerization reaction to maximize molecular weight.

Methodology:

- Installation:

pip install botorch torch - Loop Construction:

- Lab Integration: The

candidate tensor provides the next set of temperatures to run. The loop can be automated via a scheduler that queues experiments to a synthesis robot.

Mandatory Visualizations

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Tools for BO-Integrated Polymer Formulation Research

Item/Reagent

Function in BO Workflow

Example/Note

Automated Liquid Handler

Precisely dispenses monomers, solvents, and cross-linkers according to BO-generated parameter sets. Enables high-throughput synthesis.

Hamilton Star, Opentron OT-2.

In-line Spectrophotometer

Provides real-time, quantitative data (e.g., conversion rate, particle size) as objective functions for the BO loop.

ReactRaman for monitoring polymerization.

Rheometer with Automation

Measures mechanical properties (viscosity, modulus) as key optimization targets without manual sample loading.

TA Instruments HR-20 with autosampler.

Laboratory Information Management System (LIMS)

Centralizes experimental data, linking formulation parameters (BO inputs) to characterization results (BO outputs).

Benchling, Labguru.

Python API for Instruments

Allows the BO script to directly command instruments and retrieve data, closing the autonomous loop.

Often via PyVISA or manufacturer-specific SDKs.

Reference Polymer Standards

Used to calibrate instruments and validate BO-optimized formulations against known benchmarks.

Narrow dispersity polystyrene, PEG standards.

Overcoming Practical Hurdles: Troubleshooting Bayesian Optimization in Experimental Polymer Labs

In polymer formulation research for drug delivery systems, experimental data is often limited by high noise (e.g., from batch-to-batch variability), high cost (e.g., of specialized monomers or in vivo testing), and availability at multiple fidelities (e.g., computational screening vs. lab synthesis vs. clinical trial). Bayesian Optimization (BO) provides a powerful framework to navigate these challenges, enabling efficient global optimization of formulation properties (like drug release kinetics or mechanical strength) with minimal expensive experiments. This application note details protocols and strategies for implementing BO under these constraints, contextualized within a thesis on advanced polymer development.

Core Bayesian Optimization Framework for Noisy Data

BO iteratively proposes experiments by maximizing an acquisition function, balancing exploration and exploitation. A Gaussian Process (GP) surrogate model handles noise by incorporating a noise term (ν) into its kernel.

Key GP Kernel for Noisy Observations:

k(x_i, x_j) = σ_f^2 * exp(-0.5 * (x_i - x_j)^T Θ^{-2} (x_i - x_j)) + σ_n^2 * δ_ij

Where σ_n^2 is the noise variance.

Table 1: Comparison of Acquisition Functions for Noisy/Expensive Data

| Acquisition Function | Key Formula | Best For | Robustness to Noise |

|---|---|---|---|

| Expected Improvement (EI) | EI(x) = E[max(f(x) - f(x*), 0)] |

Standard global optimization | Moderate |

| Noisy Expected Improvement (NEI) | Integrates over posterior of current best point | Explicitly noisy observations | High |

| Knowledge Gradient (KG) | KG(x) = E[max μ_{n+1} - max μ_n] |

Multi-fidelity, batch | High |

| Probability of Improvement (PI) | P(f(x) ≥ f(x*) + ξ) |

Simple, quick convergence | Low |

Experimental Protocols

Protocol 1: Characterizing Noise in Polymer Hydrogel Swelling Experiments

Objective: Quantify experimental noise for GP hyperparameter tuning. Materials: (See Toolkit Table 2) Procedure:

- Prepare 10 identical batches of a baseline PEGDA hydrogel formulation (e.g., 20% w/v PEGDA, 0.5% w/v photoinitiator).

- Using standardized UV curing (365 nm, 10 mW/cm² for 2 min), polymerize all batches.

- Measure equilibrium swelling ratio (Q) in PBS at 37°C for each batch at the same time post-hydration (24 hrs).

- Calculate sample mean (μ) and variance (σ²) of Q.

- Use

σ_n = sqrt(σ²)as the initial noise level for the GP model in subsequent BO loops.

Protocol 2: Multi-Fidelity Optimization of Drug Encapsulation Efficiency

Objective: Optimize encapsulation efficiency (EE%) using low-fidelity (computational) and high-fidelity (HPLC) data. Workflow:

- Low-Fidelity Source: Use COSMO-RS simulations to predict partition coefficients (log P) of a drug candidate between aqueous and monomer phases for 100 candidate monomer mixtures.

- High-Fidelity Source: Synthesize top 10 candidates from step 1, formulate into nanoparticles, and measure actual EE% via HPLC (n=3).

- Model: Train a multi-fidelity GP (e.g., Linear Coregionalization Model) using both log P (low-fid) and EE% (high-fid) data.

- Acquisition: Use KG or Cost-Aware EI to propose the next high-fidelity experiment, weighing predicted gain against synthesis/HPLC cost.

Visualizations

Title: Multi-Fidelity Bayesian Optimization Workflow

Title: BO Loop for Noisy Polymer Data

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for Polymer Formulation BO

| Item | Function in BO Context | Example Product/Chemical |

|---|---|---|

| Poly(ethylene glycol) diacrylate (PEGDA) | Tunable crosslinker for hydrogel formulations; primary optimization variable (concentration, molecular weight). | Sigma-Aldrich, 455008 |

| Photoinitiator | Enables rapid, reproducible UV curing for consistent sample generation. | Irgacure 2959 (Basf) |

| HPLC System with PDA Detector | High-fidelity quantification of drug encapsulation efficiency and release kinetics. | Agilent 1260 Infinity II |

| COSMO-RS Software | Provides low-fidelity computational data (e.g., partition coefficients) for multi-fidelity BO. | COSMOtherm (BioVia) |

| Dynamic Light Scattering (DLS) Instrument | Measures nanoparticle size and PDI; often a noisy response for BO. | Malvern Zetasizer Ultra |

| Rheometer | Measures mechanical properties (G', G''); expensive, high-fidelity data source. | TA Instruments DHR-3 |

| Bayesian Optimization Software | Core platform for implementing GP models and acquisition functions. | BoTorch, GPyOpt |

Within the broader thesis on Bayesian optimization (BO) for polymer formulation, the surrogate model, typically a Gaussian Process (GP), is the core probabilistic representation of the design space. Its hyperparameters directly control the model's flexibility and accuracy. Poorly tuned hyperparameters lead to an unreliable surrogate, causing the BO loop to either exploit noise or miss optimal formulations. This protocol details the systematic tuning of length scales (kernel parameters) and noise levels for polymer-specific property prediction.

The following table summarizes the primary GP hyperparameters requiring tuning, their role, and their effect on the BO process for polymer systems.

Table 1: Key Gaussian Process Hyperparameters for Polymer Surrogate Modeling

| Hyperparameter | Symbol (Typical) | Role in Surrogate Model | Effect of Under-Tuning | Effect of Over-Tuning | Typical Value Range (Polymer Systems) |

|---|---|---|---|---|---|

| Length Scale (per input dimension) | ( l_k ) | Controls the smoothness/wigglyness of the function along each formulation variable (e.g., wt%, Mw). | Overfitting to noise; poor generalization; high prediction uncertainty. | Over-smoothing; misses critical formulation-property trends. | 0.1 - 10.0 (normalized inputs) |

| Signal Variance | ( \sigma_f^2 ) | Scales the output range of the GP function. | Inability to capture the full magnitude of property changes. | Exaggerated uncertainty estimates. | 0.5 - 5.0 * (Property Variance) |

| Noise Variance (Likelihood) | ( \sigma_n^2 ) | Represents inherent experimental/measurement noise. | Model mistakes noise for signal; overfits. | Useful signal is ignored; underfits. | 1e-4 - 1e-2 * (Property Variance) |

| Kernel Type | - | Defines the covariance structure and assumptions of function smoothness. | Mismatch to true property landscape (e.g., using a smooth kernel for a discontinuous phase transition). | Computational complexity without benefit. | Matérn 5/2 (default), RBF |

Experimental Protocol: Hyperparameter Tuning via Marginal Likelihood Maximization

Protocol: Pre-Tuning Data Preparation

Objective: Standardize the polymer formulation dataset for stable hyperparameter optimization. Materials:

- Historical dataset of polymer formulations (e.g., monomer ratios, crosslinker %, initiator concentration, solvent fraction) and corresponding target properties (e.g., Tg, modulus, drug release %).

- Computational environment (Python with libraries:

scikit-learn,GPyTorch,BoTorch).

Procedure:

- Input Vector Definition: For each of ( N ) experimental runs, define the input vector ( \mathbf{x}_i ) containing ( D ) normalized formulation variables.

- Normalization: Scale each input dimension to have zero mean and unit variance across the dataset.

- Output Standardization: Scale the target property data ( \mathbf{y} ) to have zero mean and unit variance. Record the original mean and standard deviation for post-prediction transformation.

- Train/Validation Split: For datasets with ( N > 30 ), perform a stratified or random 80/20 split to create a hold-out validation set.

Protocol: Type II Maximum Likelihood (Evidence Maximization) Tuning

Objective: Find the set of hyperparameters ( \theta = {l1,...,lD, \sigmaf^2, \sigman^2} ) that maximizes the log marginal likelihood of the observed data.

Workflow Diagram:

Diagram Title: Workflow for Marginal Likelihood Hyperparameter Tuning

Procedure:

- Kernel Selection: Instantiate a base kernel (e.g., Matérn 5/2 with Automatic Relevance Determination (ARD)).

- Define GP Model: Construct the GP with the chosen kernel and a Gaussian likelihood.

- Initialize Parameters: Set initial guesses for length scales (often 1.0), and estimate signal/noise variance from the data.

- Optimization Loop: a. Compute the negative log marginal likelihood (NLL): ( -\log p(\mathbf{y}|\mathbf{X}, \theta) ). b. Use a gradient-based optimizer (e.g., L-BFGS-B) to adjust ( \theta ) to minimize the NLL. c. Enforce positivity constraints on all variance/length-scale parameters. d. Iterate until convergence (change in NLL < ( 10^{-4} )) or for a maximum of 100 iterations.

- Validation: Predict on the hold-out validation set using the tuned model. Calculate the standardized mean squared error (SMSE) and mean standardized log loss (MSLL).

Protocol: Cross-Validation for Small Polymer Datasets

Objective: Robust tuning when experimental data is limited (( N < 30 )). Procedure:

- Partitioning: Split the standardized dataset into ( K ) folds (( K=5 ) or ( K=10 ) Leave-One-Out for very small ( N )).

- Fold-wise Tuning & Evaluation: a. For each fold ( k ), tune hyperparameters ( \theta_k ) on the training set using the Protocol in 3.2. b. Evaluate the performance (e.g., SMSE) on the validation fold.

- Hyperparameter Aggregation: Use the median value of each hyperparameter across all ( K ) folds as the final, robust estimate ( \theta^* ).

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Computational Toolkit for Surrogate Model Tuning

| Item / Software | Function in Hyperparameter Tuning | Example/Note |

|---|---|---|

| GPyTorch Library | Provides flexible, GPU-accelerated GP models with automatic differentiation for efficient gradient-based hyperparameter optimization. | Enables implementation of complex kernels and large-scale GPs. |

| BoTorch / Ax Platform | Bayesian optimization research frameworks that include built-in modules for robust GP fitting and hyperparameter tuning. | Ideal for integration into a full BO loop. |

| SciPy Optimizers | Collection of optimization algorithms (e.g., L-BFGS-B) to perform the numerical maximization of the marginal likelihood. | Reliable for box-constrained optimization. |

| scikit-learn GaussianProcessRegressor | User-friendly, off-the-shelf GP implementation suitable for initial prototyping and smaller datasets. | Limited kernel flexibility vs. GPyTorch. |

| Property Prediction Dataset | Curated historical data of polymer formulations and corresponding measured properties. The foundation for tuning. | Must be cleaned, with outliers assessed. Critical for defining realistic ( \sigma_n^2 ). |

| Domain-informed Priors | Prior distributions placed over hyperparameters based on polymer science expertise (e.g., expected smoothness of Tg vs. composition). | Can be implemented in GPyTorch to guide tuning where data is sparse. |

Validation & Integration into the BO Loop

After tuning, validate the surrogate model's predictions against a small set of unseen, physically realizable polymer formulations. The final, tuned surrogate model is then integrated into the acquisition function (e.g., Expected Improvement) of the BO loop. The following diagram illustrates this integration within the thesis BO framework.

Diagram Title: Integration of Tuned Surrogate into BO Loop

In Bayesian optimization (BO) for polymer formulation, the algorithm iteratively proposes new experiments to find the optimal composition. The acquisition function is the mechanism that decides the next point to evaluate by mathematically balancing exploration (probing uncertain regions) and exploitation (refining known good regions). This balance is critical for efficient material discovery, where experimental resources are limited and costly.

Quantitative Comparison of Common Acquisition Functions

The choice of acquisition function directly impacts the optimization trajectory. The table below summarizes key functions, their governing parameters, and their inherent bias.

Table 1: Characteristics of Primary Acquisition Functions

| Acquisition Function | Mathematical Form (for minimization) | Key Hyperparameter(s) | Primary Bias | Typical Use Case in Formulation |

|---|---|---|---|---|

| Probability of Improvement (PI) | $PI(\mathbf{x}) = \Phi\left(\frac{\mu(\mathbf{x}) - f(\mathbf{x}^+) - \xi}{\sigma(\mathbf{x})}\right)$ | $\xi$ (exploration parameter) | Strong Exploitation | Fine-tuning near a promising candidate |

| Expected Improvement (EI) | $EI(\mathbf{x}) = (\Delta(\mathbf{x})) \Phi\left(\frac{\Delta(\mathbf{x})}{\sigma(\mathbf{x})}\right) + \sigma(\mathbf{x}) \phi\left(\frac{\Delta(\mathbf{x})}{\sigma(\mathbf{x})}\right)$ where $\Delta(\mathbf{x}) = f(\mathbf{x}^+) - \mu(\mathbf{x}) - \xi$ | $\xi$ (exploration parameter) | Balanced | General-purpose formulation search |

| Upper Confidence Bound (UCB/GP-UCB) | $UCB(\mathbf{x}) = \mu(\mathbf{x}) - \kappa \sigma(\mathbf{x})$ | $\kappa$ (balance parameter) | Tunable Bias | High-throughput screening phases |

| Thompson Sampling (TS) | Sample from posterior: $f* \sim \mathcal{GP}(\mu, k)$ Choose $\mathbf{x} = \arg\min f*(\mathbf{x})$ | Implicit via sampling | Stochastic Balance | Parallel experimental batches |

Experimental Protocol: Implementing BO for a Polymer Blend

This protocol outlines the steps for optimizing a ternary polymer blend (Component A, B, C) for maximum tensile strength using a BO loop with an EI acquisition function.

Protocol: Single-Iteration Bayesian Optimization Cycle

Objective: To determine the next blend ratio to test based on all previous experimental data. Duration: 24-48 hours per cycle (dependent on synthesis and testing). Materials: See "Scientist's Toolkit" below.

Prior Data Compilation:

- Gather data from all previous cycles: blend ratios (input variables, normalized to sum to 1) and corresponding measured tensile strength (target variable).

- Normalize tensile strength values to zero mean and unit variance for model stability.

Gaussian Process (GP) Model Training:

- Using a software library (e.g., GPyTorch, scikit-learn), define a GP prior. A Matérn 5/2 kernel is often appropriate for chemical formulations.

- Optimize the GP hyperparameters (length scales, noise variance) by maximizing the log marginal likelihood of the observed data.

- The trained GP provides the predictive mean $\mu(\mathbf{x})$ and uncertainty $\sigma(\mathbf{x})$ for any untested blend ratio.

Acquisition Function Maximization:

- Compute the Expected Improvement (EI) over the current best observation $f(\mathbf{x}^+)$ for all candidate points in the design space (the ternary composition space).

- Using an optimizer (e.g., L-BFGS-B or a multi-start gradient-based method), find the blend ratio $\mathbf{x}_{next}$ that maximizes the EI function.

- Critical Step: The exploration parameter $\xi$ can be annealed from 0.01 to 0.001 over the course of the optimization to gradually shift from exploration to exploitation.

Experimental Validation:

- Synthesize the proposed polymer blend at ratio $\mathbf{x}_{next}$.

- Process the material into standardized test specimens (e.g., by solution casting and drying).

- Perform tensile testing according to ASTM D638, recording the ultimate tensile strength.

- Add the new {$\mathbf{x}_{next}$, result} pair to the dataset.

Iteration and Termination:

- Repeat steps 1-4 until a performance target is met, the EI value falls below a threshold (e.g., <1% of current best), or the experimental budget is exhausted.

Visualization: The BO Decision Workflow

Title: Bayesian Optimization Cycle for Polymer Formulation

Title: The Exploration-Exploitation Balance in AF Choice

The Scientist's Toolkit: Essential Reagents & Materials

Table 2: Key Research Reagent Solutions for Polymer BO Experiments

| Item | Function in Protocol | Example/Specification |

|---|---|---|

| Polymer Components (A, B, C) | Base materials for the formulated blend. Varying ratios alter final properties. | e.g., PLA (brittle), PCL (flexible), PEG (plasticizer). Must be high-purity, same batch. |

| Compatible Solvent | Dissolves all polymer components for homogeneous solution casting. | e.g., Chloroform, Tetrahydrofuran (THF). Anhydrous grade for consistent evaporation rates. |

| GP/BO Software Library | Computes the surrogate model and optimizes the acquisition function. | GPyTorch, scikit-optimize, BoTorch, or custom Python scripts. |

| High-Throughput Mixer | Ensures consistent and homogeneous blending of polymer solutions. | Magnetic stirrer with temperature control or vortex mixer for small volumes. |

| Automated Film Caster | Produces uniform-thickness films for reliable mechanical testing. | Doctor blade or spin coater with controlled environmental chamber. |

| Universal Testing Machine | Quantifies the target property (e.g., tensile strength) for the BO objective. | Instron or equivalent, with calibrated load cells and environmental grips. |

| Statistical Analysis Software | For pre- and post-processing of experimental data and optimization results. | Python (Pandas, NumPy), R, or JMP. |

Within a thesis on Bayesian optimization (BO) for polymer formulation research, this application note provides a practical framework for integrating automated experimentation. The core thesis posits that a closed-loop, BO-driven workflow is essential for efficiently navigating the vast compositional and processing spaces of polymer formulations to discover materials with targeted properties. This protocol details the implementation of such a system, enabling the iterative design, robotic synthesis, high-throughput characterization, and intelligent analysis necessary to test and validate this thesis.

System Architecture & Workflow

The integration requires a seamless, automated loop comprising four key modules: (1) Design-of-Experiment (DoE) & BO, (2) Robotic Synthesis, (3) High-Throughput Characterization (HTC), and (4) Data Management & Model Updating.

Diagram Title: Closed-loop BO-driven polymer formulation workflow.

Detailed Application Notes & Protocols

Protocol: Initial Design of Experiment (DoE) Setup

Purpose: To generate a diverse initial dataset for training the initial BO surrogate model. Procedure:

- Define Search Space: In your formulation software, specify variables (e.g., monomer A %, monomer B %, crosslinker %, initiator concentration) and their feasible ranges (e.g., 0-100%, 0.1-2.0 wt%).

- Choose DoE Method: For 3-5 variables, use a Latin Hypercube Sampling (LHS) design to ensure space-filling properties. For >5 variables, consider a Sobol sequence.

- Generate Formulations: Use a library like

pyDOE2(Python) to generate 10-20 initial formulations. Export as a.csvfile compatible with the robotic synthesis platform. - Controls: Include at least two replicate formulations (e.g., center point of design space) to assess synthesis and measurement reproducibility.

Protocol: Robotic Synthesis of Polymer Formulations

Purpose: To reproducibly prepare polymer samples according to the digital recipe. Materials & Setup: See The Scientist's Toolkit (Section 5). Procedure:

- Platform Calibration: Prior to the run, execute liquid handling calibration routines for all pipetting heads and confirm vial/tray positioning.

- Recipe Ingestion: Load the DoE

.csvfile onto the robotic platform's scheduling software. - Dispensing: The robotic arm sequentially prepares each formulation in individual vials or multi-well plates. It aspirates and dispenses specified volumes of each stock solution.

- Mixing: The platform executes a mixing protocol (e.g, vortexing, orbital shaking) for 60-120 seconds.

- Polymerization Initiation: The robot either adds initiator last or transfers plates to a built-in UV curing station or heated agitator block.

- Logging: All actions, including lot numbers of reagents and any deviations, are automatically logged to a LIMS (Laboratory Information Management System).

Protocol: High-Throughput Characterization Suite

Purpose: To measure key property targets for BO model updating. Workflow: Samples proceed through parallel analysis tracks.

Diagram Title: High-throughput characterization parallel workflow.

Key Experimental Protocols:

- Parallel Rheometry (Curing Kinetics & Tg):

- Method: Use a rheometer with a disposable plate or a multi-cell array. Load sample immediately after robotic synthesis.

- Protocol: Time-sweep oscillatory test at 1 Hz, 1% strain at curing temperature (e.g., 60°C) for 60 min. Followed by a temperature ramp (e.g., -30°C to 150°C at 3°C/min) for Tg analysis via tan delta peak.

- Automated FTIR Analysis (Conversion):

- Method: HT-FTIR with automated XY stage for multi-well plates.

- Protocol: Acquire spectrum (e.g., 4000-600 cm⁻¹, 4 cm⁻¹ resolution) for each sample well. Monitor the decrease in the characteristic monomer peak (e.g., C=C stretch at ~1630 cm⁻¹) relative to an internal reference peak. Calculate conversion %.

Protocol: BO Cycle Implementation

Purpose: To determine the optimal next set of formulations to test. Procedure:

- Data Preprocessing: Clean and merge synthesis and characterization data. Normalize target properties (e.g., tensile strength, viscosity) to a [0,1] scale if multiple objectives exist.

- Surrogate Model Training: Train a Gaussian Process (GP) model using a Matern kernel, mapping formulation variables to each target property. Use

scikit-learnorBoTorch. - Acquisition Function Optimization: Maximize the Expected Improvement (EI) acquisition function to propose the formulation expected to most improve over the current best, balancing exploration and exploitation.

- Next Experiment Selection: The top 4-8 proposals from the acquisition function are formatted into the next synthesis recipe

.csvfile, closing the loop.

Data Presentation

Table 1: Representative Data from a BO Cycle for Maximizing Polymer Toughness

| BO Iteration | Formulation ID | Monomer A (%) | Crosslinker (wt%) | Tg (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Toughness (MJ/m³) |

|---|---|---|---|---|---|---|---|

| 0 (DoE) | F01 | 70 | 0.5 | 45 | 22.1 | 150 | 18.5 |

| 0 (DoE) | F04 | 50 | 1.5 | 65 | 35.5 | 40 | 9.2 |

| 3 | F45 | 58 | 0.8 | 52 | 30.2 | 210 | 42.1 |

| 5 | F67 | 55 | 1.1 | 58 | 38.8 | 185 | 48.3 |

| 7 (Final) | F89 | 56 | 1.0 | 56 | 36.7 | 205 | 49.5 |

Data from HTC suite. *Primary optimization target.

Table 2: Performance Metrics of the Integrated BO Workflow vs. Traditional Grid Search

| Metric | Traditional Grid Search (10% space sampled) | BO-Driven Closed Loop | Improvement Factor |

|---|---|---|---|

| Experiments to Target | ~500 | 89 | 5.6x |

| Material Discovered | Sub-optimal | Optimal | - |

| Total Time to Solution | ~12 weeks | 2.5 weeks | 4.8x |

| Characterization Utilization | ~40% | ~95% | 2.4x |

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials

| Item/Category | Example Product/Supplier | Function in Workflow |

|---|---|---|

| Robotic Liquid Handler | Hamilton STARlet, Opentrons OT-2 | Precise, reproducible dispensing of monomer/crosslinker stock solutions. |

| Polymer Stock Solutions | Sigma-Aldrich, TCI Chemicals | Pre-mixed, stabilized solutions of monomers (e.g., acrylates) in anhydrous solvent. |

| Photoinitiator Stock | Irgacure 819 (BASF) | UV-cure initiating compound, dispensed at low volumes to start polymerization. |

| High-Throughput Rheometer | TA Instruments HR-20, Anton Paar MCR | Parallel measurement of viscoelastic properties during cure and final Tg. |

| Automated FTIR | Bruker Hyperion, Agilent Cary 630 | Rapid, non-contact chemical analysis for conversion and functional group validation. |

| Micro-Indenter | Bruker Hysitron TI Premier | Automated mapping of mechanical properties (modulus, hardness) on small samples. |

| Laboratory LIMS | Benchling, Labguru | Centralized digital log for recipes, robotic actions, and all characterization data. |

| BO Software Library | BoTorch (PyTorch), Ax (Meta) | Open-source frameworks for building and optimizing surrogate models. |

Bayesian Optimization vs. Traditional DOE: Benchmarking Performance in Real Polymer Research

Within a broader thesis on Bayesian optimization for polymer formulation research, a central challenge is the efficient allocation of experimental resources. This Application Note provides a direct, quantitative comparison of the number of experiments typically required to identify an optimal polymer-based drug delivery formulation using traditional Design of Experiments (DOE) approaches versus modern Bayesian Optimization (BO) frameworks. The objective is to minimize costly and time-consuming experimentation while navigating complex, high-dimensional parameter spaces common in pharmaceutical development.

Comparative Data: Experiment Counts

The following table summarizes data compiled from recent literature (2023-2024) on formulation optimization studies, focusing on polymer-based systems for controlled release or nanoparticle synthesis.

Table 1: Head-to-Head Comparison of Required Experiments

| Optimization Method | Typical Experimental Range to Reach Optimum | Formulation Type (Case Study) | Key Performance Indicator (KPI) | Reference Context |

|---|---|---|---|---|

| Full Factorial DOE | 27 - 64 runs | PLGA Nanoparticle (3 factors, 3 levels) | Encapsulation Efficiency, Particle Size | Baseline for exhaustive search; often impractical for >3 factors. |

| Response Surface Methodology (RSM) | 20 - 30 runs | Thermosensitive Hydrogel (3-4 factors) | Gelation Temperature, Modulus | Efficient for quadratic models in limited dimensions. |

| Sequential Bayesian Optimization | 8 - 15 runs | Lipid-Polymer Hybrid Nanoparticle (4-5 factors) | Drug Loading, Zeta Potential | Adaptive sampling drastically reduces total experiments. |

| High-Throughput Screening + BO | 5 - 10 (BO) of 100+ initial screen | Polymeric Micelle Library (6+ factors) | Critical Micelle Concentration, Solubility | BO guides selection from primary HTS data. |

Note: Actual numbers vary based on factor count, noise, and objective complexity. BO consistently demonstrates a 50-70% reduction in experiments post-initial design.

Experimental Protocols

Protocol A: Baseline DOE for PLGA Nanoparticle Formulation