Biopolymer Batch Consistency: Strategies to Control Variability for Reliable Biomedical Applications

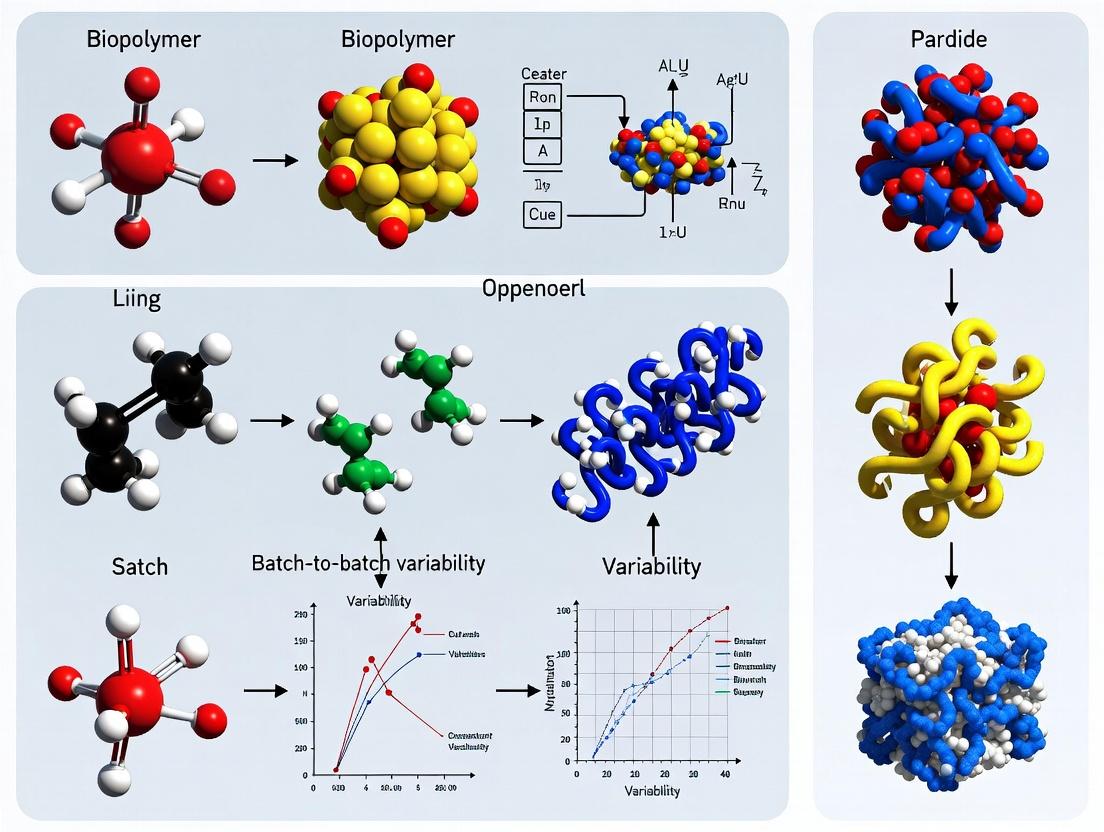

This article addresses the critical challenge of biopolymer batch-to-batch variability, a major hurdle in reproducible research and drug development.

Biopolymer Batch Consistency: Strategies to Control Variability for Reliable Biomedical Applications

Abstract

This article addresses the critical challenge of biopolymer batch-to-batch variability, a major hurdle in reproducible research and drug development. We explore the foundational sources of variability inherent to natural and recombinant biopolymers. The article provides a methodological framework for characterization and standardization, offers practical troubleshooting and mitigation strategies, and examines validation techniques and comparative analyses of different biopolymer classes. Designed for researchers and development professionals, this guide synthesizes current best practices to enhance experimental reliability and regulatory compliance.

Understanding the Roots of Variability: Why No Two Batches Are Alike

Technical Support Center

Frequently Asked Questions (FAQs)

Q1: My cell culture assay results are inconsistent between experiments. Could my extracellular matrix (ECM) hydrogel be the cause? A: Yes, batch-to-batch variability in biopolymer hydrogels (e.g., Matrigel, collagen, alginate) is a leading cause of irreproducibility. Key variable parameters include polymer concentration, growth factor/cytokine content, stiffness (elastic modulus), and gelation kinetics. These can alter cell signaling, proliferation, and differentiation. To troubleshoot, perform a new experiment side-by-side using your current batch and a new batch of the hydrogel, while keeping all other reagents constant. Characterize the lots using the protocols in the "Experimental Protocols" section.

Q2: How does variability in chitosan molecular weight affect my drug encapsulation and release study? A: Chitosan's molecular weight (MW) and degree of deacetylation (DDA) vary between batches, critically impacting nanoparticle formation, drug loading efficiency, and release profile. Higher MW chitosan typically produces larger nanoparticles with more sustained release. Request the Certificate of Analysis (CoA) for DDA and MW from your supplier. For critical studies, we recommend purchasing a large, single batch and characterizing it yourself using gel permeation chromatography (GPC) and NMR, as per the protocols below.

Q3: Why do my 3D bioprinted constructs have different mechanical properties when using the same bioink product code? A: Bioinks based on natural polymers like hyaluronic acid, fibrin, or agarose are susceptible to batch variations in polymer purity, chain length, and derivative substitution ratios. This affects the viscosity, crosslinking density, and final compressive modulus of printed constructs. Implement routine rheological testing of each new bioink batch before printing. Adjust printing parameters (pressure, speed) based on the measured viscosity to ensure consistency.

Q4: Our in vivo results from a disease model could not be replicated by a collaborator. We suspect the alginate used for encapsulation. What should we compare? A: Focus on the alginate's guluronic-to-mannuronic acid (G/M) ratio and impurity profile. The G/M ratio dictates the stiffness and porosity of calcium-crosslinked beads, affecting immune response and nutrient diffusion. Trace endotoxin or protein contaminants can cause uncontrolled inflammation. Share full characterization data (see Table 1) with your collaborator and consider switching to a clinical-grade, GMP-manufactured alginate source for translational studies.

Experimental Protocols

Protocol 1: Characterizing Hydrogel Stiffness via Rheology Objective: Quantify the storage modulus (G') of ECM hydrogels to assess batch consistency. Method:

- Sample Prep: Prepare hydrogel according to standard protocol. Load 150 µL onto the Peltier plate of a rotational rheometer.

- Tool: Use a 20-mm diameter parallel plate geometry. Set gap to 500 µm.

- Temperature Control: Set to 37°C. Maintain for 10 minutes for temperature equilibration and gelation.

- Oscillation Test: Perform a strain sweep (0.1-10% strain) at a constant frequency (1 Hz) to identify the linear viscoelastic region.

- Measurement: Perform a frequency sweep (0.1-10 Hz) at a constant strain within the linear region (e.g., 1%).

- Analysis: Record the average G' (storage modulus) at 1 Hz. Compare values between batches.

Protocol 2: Determining Chitosan Degree of Deacetylation (DDA) via Titration Objective: Measure the DDA, a key parameter influencing chitosan's charge and reactivity. Method:

- Dissolution: Precisely weigh 0.2 g of dry chitosan. Dissolve in 30 mL of 0.1 M HCl.

- Titration: Titrate the solution with standardized 0.1 M NaOH using a pH meter.

- Data Points: Record the volume of NaOH at the two equivalence points: the first (V1) corresponds to neutralization of excess HCl, the second (V2) corresponds to neutralization of ammonium groups from chitosan.

- Calculation: Calculate DDA using the formula: DDA (%) = [(V2 - V1) * MNaOH * 16] / msample * 100, where M is molarity and m is sample mass in grams.

Data Presentation

Table 1: Key Variability Parameters for Common Biopolymers

| Biopolymer | Key Variable Parameters | Typical Impact on Experiments | Recommended QC Test |

|---|---|---|---|

| Matrigel | Growth factor concentration, Total protein content, Polymerization time | Altered cell differentiation, angiogenesis, organoid formation | ELISA for VEGF/FGF, Total protein assay, Rheology |

| Type I Collagen | Concentration, pH, Fiber thickness/pore size | Variable matrix stiffness, cell adhesion, migration rate | SDS-PAGE, Amino acid analysis, SEM imaging |

| Alginate | G/M Ratio, Molecular weight, Endotoxin level | Changes in gel stiffness, porosity, immune response in vivo | NMR for G/M ratio, GPC, LAL assay |

| Chitosan | Degree of Deacetylation (DDA), Molecular weight, Ash content | Altered nanoparticle size, transfection efficiency, drug release kinetics | Titration/NMR for DDA, GPC, Viscosimetry |

| Hyaluronic Acid | Molecular weight, Sulfation level, Purity | Affects viscosity, receptor binding (CD44), wound healing response | GPC, Size-exclusion chromatography, ICP-MS for impurities |

Visualizations

Diagram 1: Batch Variability Impact Pathway

Diagram 2: Experimental QC Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Relevance to Batch Variability |

|---|---|

| Rotational Rheometer | Measures storage/loss modulus (G'/G") to quantify hydrogel mechanical stiffness, a critical batch-dependent property. |

| Gel Permeation Chromatography (GPC) | Determines the molecular weight distribution of polymer chains (e.g., chitosan, HA) to assess polydispersity between lots. |

| NMR Spectrometer | Gold-standard for quantifying chemical structure parameters like chitosan's Degree of Deacetylation (DDA) or alginate's G/M ratio. |

| Certificates of Analysis (CoA) | Supplier-provided documentation of key parameters for a specific lot. Always request and archive these. |

| Clinical/GMP-grade Materials | Biopolymers manufactured under stringent quality controls to minimize batch variability for translational research. |

| In-house Reference Standard | A large, well-characterized batch of material reserved for side-by-side comparison with new lots. |

| LAL Assay Kit | Quantifies endotoxin levels, a critical impurity in polysaccharide biopolymers (alginate, chitosan) for in vivo work. |

| ELISA Kits | Quantifies specific growth factor concentrations in complex mixtures like Matrigel. |

Troubleshooting & FAQ Center

Q1: Our chitosan batches show significant variability in Degree of Deacetylation (DDA) despite using the same supplier specification. What are the likely root causes and how can we verify? A: Variability often originates from inconsistent raw chitin sources (crab vs. shrimp shell, seasonal changes) and poorly controlled deacetylation reaction conditions (alkali concentration, temperature gradients, reaction time). To verify, implement these protocols:

- DDA Verification via Titration: Dissolve 0.2g dry chitosan in 30mL of 0.1M HCl. Titrate with 0.1M NaOH using an automatic titrator. Record the two inflection points. Calculate DDA using the formula: DDA (%) = [(V2 - V1) * M_NaOH * 0.016 / W] * 100, where V1 and V2 are the first and second equivalence point volumes (mL), M is NaOH molarity, and W is sample weight (g). Perform in triplicate.

- FTIR Cross-Check: Prepare a KBr pellet with 1% chitosan. Acquire spectrum from 4000-400 cm⁻¹. Calculate the absorbance ratio A₁₅₅₀/A₂₈₇₀ or A₁₆₅₅/A₃₄₅₀. Compare against a calibration curve from standards of known DDA.

Q2: During PLGA nanoparticle synthesis, we observe high PDI (>0.2) and inconsistent encapsulation efficiency. What synthesis and purification factors should we scrutinize? A: This points to inconsistencies in the emulsification and solvent removal steps. Follow this optimized single-emulsion (O/W) protocol:

- Organic Phase: Dissolve 50 mg PLGA and 5 mg API in 2 mL dichloromethane (DCM). Vortex until clear.

- Aqueous Phase: Add 4 mL of 2-5% PVA (w/v) solution (MW 30-70 kDa) to 20 mL deionized water.

- Primary Emulsion: Under high-speed vortexing (3000 rpm), add the organic phase to the aqueous phase dropwise over 60 seconds. Immediately probe sonicate (on ice, 40% amplitude, 30 seconds pulse on/off for 2 minutes total).

- Solvent Evaporation: Stir the emulsion at 800 rpm at room temperature for 3 hours to evaporate DCM.

- Purification: Centrifuge at 21,000 RCF for 30 minutes at 4°C. Wash pellet with DI water twice. Resuspend in buffer for characterization. Key Factors: Control room temperature, PVA lot viscosity, sonicator probe calibration, and DCM evaporation rate rigidly.

Q3: After purifying bacterial cellulose, its mechanical properties vary. Which purification steps are most critical for standardizing nanofibril integrity? A: Inadequate removal of microbial cells and metabolic byproducts is the primary culprit. Implement this stringent multi-step protocol:

- Alkali Treatment: Treat pellicles with 0.1M NaOH at 80°C for 90 minutes under gentle agitation. This lyses and dissolves cells.

- Neutralization Wash: Rinse with DI water until effluent pH is neutral (7.0 ± 0.2).

- Bleaching (Optional): For pure white material, treat with 1-3% H₂O₂ at 60°C for 60 min.

- Final Wash & Storage: Wash extensively with DI water. Store as hydrated gels at 4°C in 0.02% sodium azide solution, not dried, to prevent irreversible hydrogen bonding.

Experimental Data Summary

| Biopolymer | Key Analytical Metric | Typical Range (High-Quality Batch) | Acceptable Batch Variance (±) | Primary Test Method |

|---|---|---|---|---|

| Chitosan | Degree of Deacetylation (DDA) | 75% - 95% | 2.5% | Potentiometric Titration |

| PLGA Nanoparticles | Polydispersity Index (PDI) | 0.05 - 0.15 | 0.04 | Dynamic Light Scattering |

| Alginate | M/G Ratio | 0.8 - 2.0 | 0.15 | 1H-NMR Spectroscopy |

| Hyaluronic Acid | Molecular Weight (kDa) | 50 - 2000 | 10% of specified | Size Exclusion Chromatography |

| Bacterial Cellulose | Water Holding Capacity (g/g) | 60 - 100 | 15 | Centrifugation-Based Assay |

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function & Rationale for Standardization |

|---|---|

| Certified Reference Materials (CRMs) | For alginate M/G ratio, chitosan DDA, etc. Essential for calibrating in-house analytical methods and validating results. |

| Endotoxin-Removing Agents | Critical for in-vivo applications. Use validated endotoxin removal resins or detergents specific to your biopolymer (e.g., polymyxin B agarose for cationic polymers). |

| High-Purity, Low-MW PVA | For nanoparticle synthesis. Low molecular weight (30-70 kDa) and consistent hydrolysis degree (87-89%) ensure reproducible emulsification and coating. |

| Deuterated Solvents for NMR | D₂O, NaOD/D₂O for alginate/chitosan analysis. Use high-grade (99.9% D) solvents from a single lot for comparative batch analysis. |

| Calibrated Sonicator Probe | For nanoparticle synthesis. A probe with a calibrated amplitude output and consistent tip geometry is vital for reproducible energy input during emulsification. |

Visualizations

Diagram Title: Chitosan DDA Verification and Batch Release Workflow

Diagram Title: Root Cause Analysis for PLGA Synthesis Variability

Troubleshooting Guides & FAQs

FAQ: Understanding and Measuring Variability

Q1: What are the primary sources of batch-to-batch variability in natural biopolymers (e.g., collagen, alginate) versus recombinant ones (e.g., engineered spider silk, recombinant collagen)?

A1: Variability stems from fundamentally different sources.

- Natural Biopolymers: Source organism age/health, seasonal/environmental factors, extraction method inconsistencies, and inherent polymorphic sequences.

- Recombinant Biopolymers: Host-cell expression drift, fermentation condition fluctuations, purification yield inconsistencies, and post-translational modification (PTM) fidelity.

Q2: How can I quickly assess if a new batch of biopolymer is suitable for my experiment?

A2: Implement a tiered characterization protocol:

- Tier 1 (Rapid): Measure pH, osmolality, and concentration.

- Tier 2 (Structural): Run SDS-PAGE for purity/molecular weight, and use FTIR or CD spectroscopy for secondary structure.

- Tier 3 (Functional): Perform a pilot bioactivity assay (e.g., cell adhesion for ECM proteins).

Q3: My cell culture results are inconsistent when using different batches of recombinant hydrogel. What should I check?

A3: Focus on polymer assembly and presentation.

- Check cross-linking kinetics: Gelation time can vary with protein concentration and purity.

- Characterize mechanical properties: Use rheometry to measure storage (G') and loss (G") moduli. Batch variability often manifests here.

- Assess ligand density: For RGD-modified polymers, verify integrin-binding site availability via ELISA or mass spectrometry.

Troubleshooting Specific Experimental Issues

Issue: Inconsistent viscosity measurements for a natural polysaccharide.

- Cause: Variability in polymer chain length (polydispersity index, PDI) and degree of branching.

- Solution: Use Size-Exclusion Chromatography with Multi-Angle Light Scattering (SEC-MALS) to characterize molecular weight distribution for each batch. Correlate specific viscosity with weight-average molecular weight (Mw).

Issue: Recombinant protein polymer forms unexpected aggregates.

- Cause: Batch-specific misfolding or minor sequence errors due to codon mis-incorporation.

- Solution: Analyze via analytical ultracentrifugation (AUC) or dynamic light scattering (DLS). Increase stringency of purification (e.g., add a size-exclusion chromatography step) and validate folding with NMR or differential scanning calorimetry (DSC).

Issue: Poor reproducibility in drug release kinetics from biopolymer microspheres.

- Cause: Variability in polymer cross-link density or degradation profile.

- Solution: Standardize cross-linking reaction conditions precisely. Perform a bulk degradation study (mass loss over time in buffer) for each batch and correlate with release data.

Quantitative Data Comparison

Table 1: Typical Variability Ranges for Key Biopolymer Characteristics

| Characteristic | Natural Biopolymer (e.g., Type I Collagen) | Recombinant Biopolymer (e.g., Silk-Elastin Like Protein) |

|---|---|---|

| Molecular Weight PDI | 1.5 - 3.0 (High) | 1.01 - 1.2 (Low) |

| Amino Acid Sequence Consistency | Low (Polymorphic) | High (Defined) |

| Batch-to-Batch Bioactivity (CV*) | 15% - 35% | 5% - 15% |

| Endotoxin Level Range | 0.1 - 10 EU/mg | <0.1 - 1 EU/mg |

| Typical Residual Host Cell DNA | Not Applicable | < 10 pg/mg |

| Major Variability Driver | Source & Extraction | Expression & Purification |

*CV: Coefficient of Variation

Experimental Protocols

Protocol 1: Characterizing Batch-to-Batch Structural Variability via SEC-MALS Objective: Determine absolute molecular weight and PDI of biopolymer samples.

- Prepare polymer solution at 2 mg/mL in suitable filtered buffer.

- Filter sample through 0.22 μm syringe filter.

- Equilibrate SEC column (e.g., OHpak SB-806M HQ) with running buffer at 0.5 mL/min.

- Inject 100 μL of sample. Monitor with UV (280 nm), light scattering (LS), and refractive index (RI) detectors.

- Use Astra or equivalent software to calculate absolute Mw, Mn, and PDI using the Zimm plot method.

Protocol 2: Assessing Functional Variability in Cell-Adhesive Biopolymers Objective: Quantify cell attachment efficiency as a batch-sensitive bioassay.

- Coat 96-well plates with 50 μL of biopolymer solution (standardized concentration) per well. Incubate at 4°C overnight.

- Block with 1% BSA for 1 hour.

- Seed fluorescently labeled (e.g., Calcein AM) cells at a density of 10,000 cells/well.

- Incubate for 2 hours under standard culture conditions.

- Gently wash plates 3x with PBS to remove non-adherent cells.

- Measure fluorescence (Ex/Em ~494/517 nm). Calculate attachment percentage relative to a pre-wash reading.

Visualizations

Title: Biopolymer Variability Source Map

Title: Tiered Batch Acceptance Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Variability Analysis

| Item | Function in Variability Research |

|---|---|

| Size-Exclusion Chromatography (SEC) System with MALS/RI | Provides absolute molecular weight and polydispersity index (PDI), critical for quantifying polymer chain consistency. |

| Rheometer (e.g., rotational) | Measures viscoelastic properties (G', G") of hydrogels, directly assessing functional batch-to-batch consistency. |

| Circular Dichroism (CD) Spectrophotometer | Probes secondary structure (α-helix, β-sheet) of protein biopolymers, detecting folding variations. |

| Endotoxin Detection Kit (LAL) | Quantifies Gram-negative bacterial endotoxins, a key contaminant variable, especially in natural polymers. |

| Calorimeter (DSC/ITC) | Assesses thermal stability (Tm) and folding energetics, identifying subtle conformational batch differences. |

| Standardized Cell-Based Bioassay Kit | Provides a functional readout (e.g., adhesion, proliferation) to correlate physical data with biological performance. |

Technical Support Center: Troubleshooting & FAQs

Troubleshooting Guides

Issue 1: Inconsistent Molecular Weight (MW) Results from SEC-MALS

- Problem: Significant variation in reported weight-average molecular weight (Mw) between batches or runs.

- Potential Causes & Solutions:

- Column Degradation or Incompatibility: SEC columns can degrade or interact with specific biopolymers. Solution: Run column calibration standards. Consider using a column with different chemistry (e.g., switch from silica-based to polymer-based).

- Incomplete Solubilization or Aggregation: Sample not fully dissolved or forming aggregates mid-run. Solution: Ensure rigorous, validated dissolution protocols (specific solvent, temperature, duration, agitation). Always filter samples (e.g., 0.22 µm) immediately before injection. Include a denaturing agent if applicable.

- Inaccurate dn/dc Value: The refractive index increment (dn/dc) is critical for MALS calculation. Solution: Measure the dn/dc value for each new biopolymer or formulation buffer using a refractometer. Do not rely on literature values if buffer composition differs.

- Protocol: Determining dn/dc for SEC-MALS

- Prepare the biopolymer at five known concentrations (e.g., 0.5, 1.0, 1.5, 2.0, 2.5 mg/mL) in the exact mobile phase to be used.

- Using a differential refractometer, measure the refractive index of each solution against the blank mobile phase.

- Plot refractive index difference (Δn) vs. concentration (c). Perform linear regression.

- The slope of the linear fit is the dn/dc value. The R² should be >0.99.

Issue 2: High or Variable Polydispersity Index (PDI)

- Problem: PDI (Mw/Mn) is too high (>1.2 for polymers, often >1.0 for designed peptides/nucleic acids) or fluctuates batch-to-batch.

- Potential Causes & Solutions:

- Incomplete Polymerization or Cleavage (for synthetic polymers): Solution: Optimize and tightly control reaction time, temperature, and catalyst/initiator concentration. Implement a quenching step.

- Enzymatic or Hydrolytic Degradation (for natural biopolymers): Solution: Incorporate enzyme inhibitors (e.g., protease, nuclease inhibitors) in all processing buffers. Control pH and temperature to minimize hydrolysis. Use lyophilization for long-term storage.

- Inadequate Purification: Solution: Implement orthogonal purification methods (e.g., SEC followed by ion-exchange chromatography). Analyze fractions individually to assess PDI improvement.

Issue 3: Sequence Verification and Batch Consistency

- Problem: Mass spectrometry (MS) or sequencing data shows heterogeneity (truncations, deletions, modifications).

- Potential Causes & Solutions:

- Inefficient Coupling in Solid-Phase Synthesis (peptides/oligos): Solution: Monitor coupling efficiency after each step (e.g., Kaiser test). Implement double-coupling for difficult residues. Use high-quality, fresh reagents.

- Post-Translational Modifications (PTMs) or Degradation: Solution: Use LC-MS/MS for detailed characterization. Compare batches using peptide mapping. For unwanted PTMs, optimize expression system (e.g., cell line, bacterial strain) and purification conditions (e.g., include dephosphorylation inhibitors).

- Protocol: Peptide Mapping for Sequence Confirmation

- Denature and reduce the protein/biopolymer.

- Digest with a specific protease (e.g., trypsin) under controlled conditions (enzyme:substrate ratio, time, temperature, pH).

- Analyze the digest via LC-MS/MS (reverse-phase nanoLC coupled to a high-resolution tandem mass spectrometer).

- Identify fragments by searching against the expected sequence using software (e.g., Mascot, Sequest). Confirm >95% sequence coverage.

Frequently Asked Questions (FAQs)

Q1: What is the acceptable range for PDI in a therapeutic oligonucleotide or peptide? A: Acceptance criteria are product-specific. Generally, for well-defined biologics like synthetic oligonucleotides or peptides, PDI should be as close to 1.0 as possible, often with an upper specification limit of ≤1.1. For larger polymers (e.g., polysaccharides, PEGylated drugs), PDI ≤ 1.2 may be acceptable. Justification must be based on clinical relevance.

Q2: How do I choose between SEC-MALS and Mass Spectrometry for MW analysis? A: The techniques are complementary. Use this decision guide:

- SEC-MALS: Best for native state MW, detecting aggregates, and measuring PDI of complex or polydisperse samples in formulation buffer.

- Mass Spectrometry (ESI or MALDI-TOF): Best for exact mass, confirming primary sequence, identifying post-translational modifications, and analyzing purity of monodisperse samples.

Q3: Our biopolymer's activity varies between batches despite similar MW and PDI. What should we investigate next? A: This highlights that MW and PDI are not always predictive of function. Focus on sequence fidelity and higher-order structure:

- Perform detailed peptide mapping/N-terminal sequencing to check for sequence errors or truncations.

- Analyze secondary and tertiary structure using Circular Dichroism (CD) spectroscopy or intrinsic fluorescence.

- Check for chemical modifications (e.g., oxidation, deamidation) via targeted LC-MS/MS.

Q4: What are the key steps to minimize batch-to-batch variability from the start? A: Implement a Quality by Design (QbD) approach:

- Define Target Product Profile (TPP): Link CQAs (MW, PDI, Sequence) to clinical efficacy/safety.

- Identify Critical Process Parameters (CPPs): For synthesis/purification (e.g., temperature, pH, reagent stoichiometry, chromatography gradients) that impact your CQAs.

- Establish a Design Space: Use DOE (Design of Experiments) to model the relationship between CPPs and CQAs.

- Implement Process Analytical Technology (PAT): Use in-line or at-line monitoring (e.g., in-line UV/Vis during chromatography) for real-time control.

Table 1: Common Analytical Techniques for CQA Assessment

| CQA | Primary Technique | Typical Output | Key Metric | Acceptance Criteria Example |

|---|---|---|---|---|

| Molecular Weight | Size Exclusion Chromatography with Multi-Angle Light Scattering (SEC-MALS) | Weight-average MW (Mw), Number-average MW (Mn) | Mw (kDa or Da) | Mw = Target ± 5% |

| Polydispersity | SEC-MALS or SEC with Refractive Index (RI) | Polydispersity Index (PDI) | PDI = Mw / Mn | PDI ≤ 1.1 (for defined polymers) |

| Sequence | Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) | Amino Acid/Nucleotide Sequence, Coverage Map | % Sequence Coverage | Coverage ≥ 95% |

Table 2: Impact of Common Process Deviations on CQAs

| Process Deviation | Likely Effect on MW | Likely Effect on PDI | Likely Effect on Sequence |

|---|---|---|---|

| Incomplete polymerization/chain elongation | Lower than target Mw | Increases (broader distribution) | May cause truncations |

| Aggregation during purification | Higher than target Mw | Increases (secondary peak) | Typically unchanged |

| Enzyme contamination during harvest | Lower than target Mw | Increases | Cleavage, incorrect termini |

| Inefficient synthesis coupling step | Lower than target Mw | Increases | Point deletions/mutations |

Experimental Protocols

Protocol: Size Exclusion Chromatography with Multi-Angle Light Scattering (SEC-MALS)

- Column Equilibration: Equilibrate the SEC column (e.g., TSKgel SuperSW3000) with filtered (0.1 µm) and degassed mobile phase (e.g., PBS + 200 mM NaCl) at a constant flow rate (e.g., 0.35 mL/min) for at least 1 hour until a stable baseline is achieved.

- System Calibration: Normalize the MALS detector using a monodisperse protein standard (e.g., Bovine Serum Albumin). Verify system performance with a narrow MW distribution standard.

- Sample Preparation: Dissolve or dilute the biopolymer sample in the mobile phase to a target concentration of 1-5 mg/mL. Centrifuge at 14,000 x g for 10 minutes and filter through a 0.22 µm centrifugal filter.

- Injection & Run: Inject 50-100 µL of the filtered sample. Monitor signals from UV (280 nm or 260 nm), RI, and MALS (multiple angles).

- Data Analysis: Use the instrument software (e.g., ASTRA) to calculate Mw, Mn, and PDI using the Zimm or Debye model, inputting the correct dn/dc value.

Protocol: Determining PDI by SEC with RI Detection

- Follow the SEC-MALS protocol steps 1, 3, and 4, using only the RI detector.

- Generate a Calibration Curve: Run a series of monodisperse standards (e.g., polyethylene glycol, proteins) of known MW.

- Plot Log(MW) vs. Elution Volume and fit a polynomial regression.

- Analyze Sample: Convert the sample's RI chromatogram into a molecular weight distribution using the calibration curve.

- Calculate: The software will report Mw (Σ (Ni * Mi²) / Σ (Ni * Mi)), Mn (Σ (Ni * Mi) / Σ Ni), and PDI (Mw / Mn), where Ni is the polymer concentration at elution slice i, and Mi is the MW at that slice.

Visualizations

Diagram Title: CQA Testing in Batch Release Workflow

Diagram Title: Troubleshooting High Polydispersity Index (PDI)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for CQA Analysis of Biopolymers

| Item | Function | Example/Note |

|---|---|---|

| SEC-MALS Columns | High-resolution size-based separation of biopolymers. | TSKgel SuperSW series, Waters Acquity BEH. Choice depends on MW range. |

| Narrow MW Standards | Calibration of SEC system and verification of MALS detector. | Polyethylene oxide (PEO), proteins (BSA, thyroglobulin). |

| Differential Refractometer | Measures dn/dc value for absolute MW determination by MALS. | Essential for novel compounds or new buffer formulations. |

| Protease for Digestion | Enzymatic cleavage for peptide mapping/sequence analysis. | Trypsin (cleaves after Lys/Arg), Asp-N, Glu-C. Must be sequencing grade. |

| LC-MS/MS Grade Solvents | Low volatility, high purity solvents for sensitive MS detection. | Acetonitrile, water, and formic acid specifically labeled for LC-MS. |

| Solid-Phase Synthesis Reagents | High-purity monomers and activators for controlled polymerization. | Fmoc- or Boc-protected amino acids, phosphoramidites for oligonucleotides. |

| Stabilizers/Inhibitors | Prevent degradation during processing and storage. | Protease inhibitor cocktails, nuclease inhibitors, antioxidants. |

| 0.22 µm & 0.1 µm Filters | Removal of particulates and microbes from samples & mobile phases. | Use low protein-binding PVDF or PES membranes. Critical for SEC. |

Technical Support Center: Troubleshooting Batch Variability in Biopolymer Characterization

FAQs

Q1: Our biopolymer's SEC-MALS data shows a significant shift in molar mass between batches, causing our CQA specification to fail. What are the primary investigative steps? A: First, confirm the consistency of your sample preparation buffer and filtration (0.1 µm or 0.22 µm). Run the system with a fresh protein standard (e.g., BSA) to rule out instrument drift. If the issue persists, perform the following orthogonal analyses:

- Intrinsic Viscosity (IV): Determine if the conformational state has changed.

- Charge-based method (cIEF or imaged CE): Check for changes in charge isoforms.

- Advanced NMR (2D ¹H-¹³C HSQC): Probe for subtle differences in primary structure or glycosylation. Batch variability often originates from upstream processes. Review fermentation/purification logs for changes in pH, temperature, or raw material sources.

Q2: During forced degradation studies for an IND submission, we observe new fragments in CE-SDS not seen in previous batches. How should this be addressed? A: This indicates a potential change in degradation pathways. Proceed as follows:

- Identify the fragment: Use LC-MS/MS peptide mapping to pinpoint the cleavage site.

- Correlate with function: Assess if the new fragment population impacts the biological activity in a relevant bioassay (e.g., cell-based potency).

- Root cause: Investigate if a minor process change (e.g., hold time, filtration step) introduced a new protease or oxidative species. Document the characterization thoroughly. For the IND, propose updated, justified acceptance criteria for the CE-SDS method that account for this newly understood variability, demonstrating control strategies.

Q3: How should we present batch-to-batch variability data in the "Chemistry, Manufacturing, and Controls" (CMC) section of a BLA? A: Variability data is critical to demonstrate product consistency and process control. Present it using summary tables and trend analyses. For each Critical Quality Attribute (CQA), data from at least 5-10 clinical/commercial-scale batches should be included, showing the range, mean, and standard deviation against proposed acceptance criteria. Justify that the observed variability has no adverse impact on safety or efficacy, supported by non-clinical and clinical data.

Experimental Protocols

Protocol 1: Comprehensive Biopolymer Batch Comparability Workflow

Objective: To systematically identify and characterize the root cause of observed batch-to-batch variability in a therapeutic protein.

Materials: See "Research Reagent Solutions" table.

Methodology:

- Primary Structure Analysis:

- Perform peptide map analysis by digesting 100 µg of each batch with a site-specific protease (e.g., trypsin).

- Analyze via reversed-phase UHPLC coupled to a high-resolution mass spectrometer.

- Compare chromatographic profiles and deconvoluted spectra for modifications (oxidations, deamidations, glycations).

Higher-Order Structure (HOS) Analysis:

- Prepare samples at 1 mg/mL in formulation buffer.

- Acquire far-UV CD spectra (190-250 nm) to assess secondary structure.

- Acquire intrinsic fluorescence spectra (excitation 280 nm, emission 300-400 nm) to assess tertiary structure.

- Use orthogonal techniques like FTIR or HDX-MS for confirmation.

Functional Bioassay:

- Conduct a cell-based potency assay relevant to the mechanism of action (e.g., reporter gene assay, proliferation assay).

- Test each batch in a minimum of 3 independent experiments, each in triplicate.

- Calculate relative potency compared to the reference standard.

Data Integration & Reporting:

- Compile all data into a comparability table. Use statistical tools (e.g., equivalence testing, multivariate analysis) to determine if differences are significant.

Protocol 2: Forced Degradation Study for Variability Assessment

Objective: To evaluate the stability and degradation profile of different biopolymer batches under stress conditions.

Methodology:

- Thermal Stress: Incubate samples at 40°C for 1 and 2 weeks. Analyze by SE-HPLC and CE-SDS for aggregation and fragmentation.

- Oxidative Stress: Treat with 0.01% - 0.1% H₂O₂ for 1 hour at room temperature. Analyze by peptide mapping (targeting Met and Trp oxidation) and cIEF.

- pH Stress: Incubate at pH 3.0 and pH 10.0 for 1 hour at room temperature. Neutralize and analyze by SE-HPLC and visual inspection for particles.

- Mechanical Stress: Vortex samples for 5 minutes or perform repeated freeze-thaw cycles (5 cycles, -80°C to 25°C). Analyze by microflow imaging (MFI) for subvisible particles.

Data Presentation

Table 1: Batch Comparability Analysis for Drug Substance DS-001 to DS-005

| Critical Quality Attribute (CQA) | Analytical Method | Acceptance Criteria | DS-001 | DS-002 | DS-003 | DS-004 | DS-005 | Mean ± SD |

|---|---|---|---|---|---|---|---|---|

| Purity (%) | CE-SDS (Non-Reduced) | ≥95.0% | 98.2 | 97.8 | 96.5 | 98.1 | 97.9 | 97.7 ± 0.7 |

| Aggregates (%) | SE-HPLC | ≤2.0% | 0.8 | 1.2 | 1.9 | 0.9 | 1.1 | 1.2 ± 0.5 |

| Isoform Distribution (Main Peak %) | cIEF | ≥60.0% | 72.1 | 68.5 | 65.2* | 70.8 | 71.3 | 69.6 ± 2.9 |

| Potency (Relative %) | Cell-Based Bioassay | 80.0%-125.0% | 102 | 98 | 105 | 96 | 101 | 100.4 ± 3.6 |

| Endotoxin (EU/mg) | LAL Test | <1.0 | 0.12 | 0.25 | 0.18 | 0.10 | 0.15 | 0.16 ± 0.06 |

*Value slightly closer to specification limit; investigated and attributed to a known, controlled glycosylation microheterogeneity.

Table 2: Research Reagent Solutions Toolkit

| Item | Function & Rationale |

|---|---|

| NISTmAb Reference Material | An industry-standard monoclonal antibody for system suitability testing and cross-lab method qualification. |

| Stable, Site-Specific Protease (Trypsin/Lys-C) | Ensures reproducible digestion for peptide mapping, critical for identifying primary structure variants. |

| Monoclonal Antibody | An industry-standard monoclonal antibody for system suitability testing and cross-lab method qualification. |

| Charge Ladder Kit (for cIEF) | Provides isoelectric point (pI) markers for accurate peak identification and pl calibration in charge variant analysis. |

| SEC-MALS Calibration Standard (BSA or thyroglobulin) | Validates the proper functioning of the multi-angle light scattering detector for absolute molar mass determination. |

| Stressed Biopolymer Control Samples | Internally generated samples with known modifications (e.g., oxidized, deamidated) serve as positive controls in forced degradation studies. |

Mandatory Visualizations

From Analysis to Control: A Framework for Standardization and Consistency

Technical Support Center: Troubleshooting and FAQs

FAQs and Troubleshooting for HPLC Analysis of Biopolymers

- Q: My HPLC chromatogram shows peak broadening or splitting. What could be the cause?

- A: This is a common symptom of batch-to-batch variability. It can indicate partial degradation, aggregation, or changes in tertiary structure. First, check your mobile phase pH and composition for consistency. If the issue persists, use SEC-MALS to check for aggregation and MS to confirm primary structure integrity. Sample adsorption to the column can also cause this; consider adding a modifier like 0.1% TFA.

- Q: The retention time of my biopolymer peak is shifting between batches. How should I proceed?

- A: Retention time shifts directly suggest a change in chemical properties. For reversed-phase HPLC, this points to alterations in hydrophobicity. Verify column performance with standards. Then, use MS (ESI-TOF) to identify any changes in mass that could indicate post-translational modifications (e.g., glycosylation, oxidation) or sequence variants. Cross-reference with NMR to detect changes in the chemical environment of aromatic or aliphatic residues.

FAQs and Troubleshooting for SEC-MALS Analysis

- Q: My MALS-derived molar mass is significantly different from the expected theoretical mass. What does this mean?

- A: A consistent discrepancy across batches confirms inherent variability. A higher measured mass indicates aggregation or non-specific oligomerization. A lower mass may suggest degradation or fragments. Ensure your dn/dc value is correctly set for the specific biopolymer batch and buffer. Always use online MALS, not retention time calibration with globular standards, for accurate absolute mass.

- Q: The radius of gyration (Rg) vs. molar mass (Mw) plot shows a different slope for a new batch. How do I interpret this?

- A: The slope of this plot informs on conformation. A change in slope between batches indicates a structural difference—e.g., a more compact or more extended structure. This could be due to altered folding or changes in glycosylation patterns. Correlate this data with NMR structural fingerprints and HPLC purity profiles.

FAQs and Troubleshooting for NMR Spectroscopy

- Q: My 1D 1H-NMR spectrum shows broadened or missing peaks for a new biopolymer batch.

- A: Peak broadening often signifies aggregation, which is a key batch variability issue. Ensure sample conditions (buffer, pH, temperature) are identical. If aggregation is ruled out, consider increased conformational dynamics/flexibility. Use 2D experiments (e.g., 1H-15N HSQC) to assess if the structure is intact but more flexible, or if specific regions are unfolded.

- Q: How do I use NMR to quantify batch-to-batch differences?

- A: Perform a simple 1D 1H NMR comparative analysis. Key metrics are summarized in Table 1 below.

FAQs and Troubleshooting for Mass Spectrometry

- Q: My intact mass analysis shows a mass increase of +16 Da or multiples thereof. What is the likely cause?

- A: This is a strong indicator of oxidation (e.g., methionine or tryptophan), a common degradation product that varies between batches. Perform peptide mapping (LC-MS/MS after digestion) to localize the modification site. Compare the oxidation level between batches to establish a control threshold.

- Q: Deconvolution of my ESI-MS data shows multiple charge state distributions. How do I identify the correct species?

- A: Multiple charge state envelopes can indicate the presence of different conformers or stable aggregates. Use native MS conditions (volatile buffers like ammonium acetate) to preserve non-covalent interactions. Integrate SEC or HPLC online with MS to separate species prior to mass analysis.

Quantitative Data Summary

Table 1: Key NMR Metrics for Batch Comparability

| Metric | Method | Acceptable Batch Variation | Indication of Variability |

|---|---|---|---|

| Chemical Shift Δδ | 1H-15N HSQC | < 0.02 ppm (1H), < 0.2 ppm (15N) | Changes in local chemical environment/folding |

| Peak Intensity Ratio | 1D 1H NMR (Aromatic vs. Aliphatic) | ± 10% | Changes in concentration or presence of excipients |

| Peak Width at Half Height | 1D 1H NMR (Well-dispersed peak) | ± 15% | Changes in aggregation state or mobility |

Table 2: Common MS-Identified Modifications & Their Mass Shifts

| Modification | Mass Shift (Da) | Typical Cause | Impact on Biopolymer |

|---|---|---|---|

| Oxidation (Methionine) | +15.9949 | Storage, Process Stress | Potentially altered activity |

| Deamidation (Asparagine) | +0.9840 | pH, Temperature | Altered charge, stability |

| N-terminal Glu to Pyro-Glu | -17.0265 | Cyclization | Common, often acceptable |

| Glycation (Lysine) | +162.0528 | Reducing sugars in media | Can affect function & immunogenicity |

Experimental Protocols

Protocol 1: Integrated SEC-MALS-QTOF Workflow for Aggregation and Mass Analysis

- System Equilibration: Equilibrate an analytical SEC column (e.g., TSKgel SuperSW3000) in 50 mM sodium phosphate, 150 mM NaCl, pH 7.0 at 0.35 mL/min.

- Sample Preparation: Dilute biopolymer batches to 1 mg/mL in mobile phase. Centrifuge at 14,000 x g for 10 min at 4°C to remove particulates.

- Inline Analysis: Inject 50 µL onto the system configured in series: SEC → UV detector → MALS (18-angle) → Refractive Index (RI) detector → ESI-QTOF mass spectrometer.

- Data Acquisition & Analysis: Use ASTRA software to calculate absolute Mw and Rg from MALS/RI data. Use the QTOF data (deconvoluted using MaxEnt1 or similar) to confirm the monomer mass and identify co-eluting species.

Protocol 2: 1H-15N HSQC NMR for Fingerprinting Batch Conformity

- Sample Preparation: Prepare ~300 µL of 0.1-0.3 mM 15N-labeled biopolymer in 20 mM phosphate buffer (pH 6.8) in 90% H2O/10% D2O. Use a 3 mm NMR tube.

- Data Acquisition: On a 600 MHz spectrometer equipped with a cryoprobe, run a sensitivity-enhanced 1H-15N HSQC experiment at 25°C. Typical parameters: 2048 points in F2 (1H), 256 increments in F1 (15N), 16 scans.

- Processing & Analysis: Process with NMRPipe. Use Sparky or CCPNMR for analysis. Overlay spectra from different batches. Calculate chemical shift perturbations (CSP) for each resolved peak: CSP = √((ΔδH)² + (ΔδN/5)²). Batches with average CSP > 0.1 ppm warrant further investigation.

Visualizations

Title: HPLC Anomaly Diagnostic Workflow

Title: Analytical Toolkit Addresses Biopolymer Variability

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Addressing Batch Variability |

|---|---|

| Stable Isotope-labeled Amino Acids (15N, 13C) | Enables detailed 2D/3D NMR structural fingerprinting to detect conformational differences between batches. |

| Protease (e.g., Trypsin, Asp-N) | For peptide mapping protocols to digest biopolymers for LC-MS/MS analysis, locating site-specific modifications. |

| LC-MS Grade Solvents & Volatile Buffers (e.g., Ammonium Acetate, Formic Acid) | Essential for reproducible HPLC and high-sensitivity MS analysis, especially for native MS. |

| Certified SEC-MALS Standards (e.g., BSA, Monoclonal Antibody) | Required for regular system normalization and validation to ensure accurate molar mass and size measurements. |

| Stable, Well-Characterized Reference Biopolymer Batch | Serves as the essential gold standard for all comparative analytical assays (NMR, HPLC, MALS, MS). |

Implementing a Quality-by-Design (QbD) Approach for Biopolymer Production

Technical Support Center: Troubleshooting & FAQs

Troubleshooting Guides

Issue 1: High Batch-to-Batch Variability in Biopolymer Molecular Weight Symptom: Significant fluctuations in gel permeation chromatography (GPC) results for weight-average molecular weight (Mw) between production runs. Potential Causes & Solutions:

- Cause: Inconsistent monomer feed rate or purity.

- Solution: Implement inline spectroscopy (e.g., NIR) for real-time monomer concentration monitoring. Use high-performance liquid chromatography (HPLC) for rigorous incoming raw material qualification.

- Cause: Fluctuations in bioreactor environmental parameters (pH, dissolved oxygen, temperature).

- Solution: Utilize automated bioreactor control systems with redundant sensors. Establish tighter control ranges as part of the proven acceptable range (PAR) in your QbD design space.

- Cause: Enzyme or catalyst activity degradation.

- Solution: Establish a stability profile for the catalyst. Implement a standardized activity assay pre-run and adjust charge or reaction time accordingly.

Issue 2: Unacceptable Endotoxin Levels in Therapeutic-Grade Biopolymers Symptom: Limulus amebocyte lysate (LAL) assay failure post-purification. Potential Causes & Solutions:

- Cause: Biofilm formation in fermentation or downstream equipment.

- Solution: Enhance clean-in-place (CIP) and sterilize-in-place (SIP) protocols. Perform regular microbial monitoring of the production line.

- Cause: Leaching from chromatography resins or filters.

- Solution: Source resins certified for low endotoxin levels. Include a final, validated endotoxin removal step (e.g., tangential flow filtration with specific membranes).

- Cause: Contaminated water or buffer solutions.

- Solution: Use water for injection (WFI) and sterilize all buffers via validated autoclave or filtration processes.

Issue 3: Inconsistent Biopolymer Particle Size in Lyophilized Formulations Symptom: Poorly reproducible dynamic light scattering (DLS) or laser diffraction results after reconstitution. Potential Causes & Solutions:

- Cause: Uncontrolled freezing rate during lyophilization.

- Solution: Develop a controlled, ramped freezing protocol. Use lyophilizers with precise shelf temperature control.

- Cause: Variability in the primary polymer solution viscosity or concentration pre-lyo.

- Solution: Control the final ultrafiltration/diafiltration step to a precise concentration and viscosity range. Use a viscometer for in-process checks.

- Cause: Moisture content variability in the final cake.

- Solution: Extend secondary drying and use a calibrated, in-line moisture sensor (e.g., tunable diode laser absorption spectroscopy) to determine endpoint.

Frequently Asked Questions (FAQs)

Q1: How do I define the Quality Target Product Profile (QTPP) for a novel biopolymer in drug delivery? A: The QTPP is a prospective summary of the quality characteristics necessary for your biopolymer to perform its intended function. For a drug delivery vehicle, key QTPP elements include: Intended Use: Injectable sustained-release platform. Dosage Form: Lyophilized powder for reconstitution. Route of Administration: Subcutaneous. Critical Quality Attributes (CQAs): Molecular weight distribution, particle size post-reconstitution, endotoxin level, residual solvent content, drug loading capacity, and in vitro release profile.

Q2: What are the most critical process parameters (CPPs) to monitor during microbial fermentation for polyhydroxyalkanoate (PHA) production? A: Based on current research, the following CPPs significantly impact CQAs like yield, composition, and molecular weight:

- Carbon Source Feed Rate: Controls growth vs. polymer production phases.

- Dissolved Oxygen Tension: Affects metabolic pathway flux.

- Culture pH: Influences enzyme activity and cell health.

- Nitrogen Source Concentration: Its depletion often triggers polymer accumulation.

- Temperature: Impacts both cell growth and polymerase activity.

Q3: Which analytical techniques are essential for characterizing biopolymer CQAs? A: A robust analytical toolbox is required:

| Analytical Technique | Measured CQA | Typical QbD Application |

|---|---|---|

| Gel Permeation Chromatography (GPC) | Molecular Weight (Mw, Mn), Dispersity (Đ) | Links fermentation CPPs to polymer chain length. |

| Gas Chromatography (GC) / NMR | Monomer Composition, Purity | Correlates feedstock purity and ratios to polymer structure. |

| Dynamic Light Scattering (DLS) | Hydrodynamic Diameter, Polydispersity | Monitors nanoparticle formation consistency. |

| LC-MS / HPLC | Residual Monomers, Catalysts, Impurities | Sets limits for impurities in the final product. |

| Limulus Amebocyte Lysate (LAL) | Endotoxin Level | Critical safety attribute for injectables. |

| Differential Scanning Calorimetry (DSC) | Glass Transition Temp (Tg), Crystallinity | Relates to polymer stability and drug release kinetics. |

Q4: Can you provide a protocol for a Design of Experiment (DoE) to optimize fermentation yield? A: Title: DoE Protocol for Optimizing PHA Yield in Cupriavidus necator Fermentation. Objective: Determine the interaction between carbon source concentration, pH, and agitation speed on PHA yield and molecular weight. Method:

- Design: Use a Central Composite Design (CCD) with 3 factors at 5 levels (20 runs + 6 center points).

- Factors & Ranges:

- Factor A (Fructose): 15 g/L to 35 g/L.

- Factor B (pH): 6.5 to 7.5.

- Factor C (Agitation): 300 rpm to 500 rpm.

- Inoculation: Prepare a 48-hour seed culture in mineral salt medium. Inoculate 2L bioreactors at 10% (v/v).

- Process: Maintain temperature at 30°C. Dissolved oxygen is controlled via agitation/airflow cascade. Nitrogen limitation is induced after 24 hours.

- Harvest: Terminate fermentation at 72 hours.

- Analysis: Measure DCW (dry cell weight) gravimetrically. Extract PHA with chloroform and quantify via GC. Analyze PHA molecular weight via GPC.

- Modeling: Use statistical software (e.g., JMP, Design-Expert) to fit a quadratic model and identify the optimal operating space for maximizing yield while meeting Mw targets.

Visualization: Key Workflows & Pathways

Diagram 1: QbD Framework for Biopolymer Development

Diagram 2: Key Pathways in Microbial PHA Biosynthesis

Diagram 3: Experimental Workflow for QbD-Based Biopolymer Characterization

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in QbD for Biopolymers |

|---|---|

| Defined Minimal Salt Medium | Ensures consistent fermentation by eliminating variability from complex nutrients like yeast extract. Critical for DoE studies. |

| Certified Reference Standards (e.g., PHA, PLA) | Essential for calibrating GPC, GC, and DSC equipment to ensure accurate, reproducible CQA measurement across batches. |

| Endotoxin-Free Water & Buffers | Fundamental for producing therapeutic-grade biopolymers, directly impacting the critical safety attribute of endotoxin levels. |

| Stable Isotope-Labeled Substrates (e.g., ¹³C-Glucose) | Used in metabolic flux analysis to trace carbon pathways, linking CPPs (like feed rate) to polymer composition (CQA). |

| Activity-Calibrated Enzymes (e.g., Lipases, PHA Synthases) | For controlled polymerization or modification. Pre-calibrated activity allows for precise dosing, a key CPP. |

| Functionalized Monomers (e.g., Allyl Glycidyl Ether) | Used to introduce chemical handles into biopolymers for controlled drug conjugation. Purity is a key material attribute (CMA). |

| Low-Protein-Binding Filters & Columns | Minimize product loss during purification and prevent introduction of new impurities, affecting yield and purity CQAs. |

Standard Operating Procedures (SOPs) for Sourcing and Pre-processing

Technical Support Center & Troubleshooting FAQs

Q1: During initial biopolymer characterization, my Dynamic Light Scattering (DLS) results show multiple size populations. Is the material unusable? A: Not necessarily. Multiple peaks can indicate aggregation or contamination. Follow this protocol:

- Filter: Pass the solution through a sterile, low-protein-binding 0.22 µm syringe filter.

- Re-measure: Repeat DLS analysis on the filtered solution.

- Check Buffer: Ensure the dispersion buffer is freshly prepared and filtered (0.22 µm). Avoid phosphate buffers with certain alginates, as they can form precipitates.

- If peaks persist: This may indicate inherent polydispersity. Document the size distribution profile and proceed with downstream assays, monitoring for impact on biological activity. Consider using Asymmetrical Flow Field-Flow Fractionation (AF4) coupled to MALS for superior separation and characterization of polydisperse samples.

Q2: My cell viability assay shows high toxicity after switching to a new batch of chitosan. What are the likely causes? A: This is a common batch-variability issue. The primary culprits are degree of deacetylation (DDA) and molecular weight (MW).

- Troubleshooting Steps:

- Verify DDA: Request the supplier's Certificate of Analysis (CoA) for DDA (target >85% for most biocompatible applications). Consider validating via ¹H NMR.

- Test for Residuals: Dialyze the chitosan solution extensively (MWCO 3.5 kDa) against ultrapure water for 48 hours, changing water every 12 hours, to remove potential residual acids or contaminants.

- Dilution Test: Perform a dose-response viability assay. High toxicity at low concentrations suggests chemical contamination.

- Control Experiment: Run the assay with the previous, non-toxic batch side-by-side using the exact same protocol.

Q3: How should I pre-process natural-sourced alginate to minimize functional variability between batches? A: Implement a stringent purification and characterization cascade.

- Standard Purification Protocol:

- Dissolution: Dissolve crude alginate (1% w/v) in 50 mM MES buffer, pH 6.5.

- Filtration: Sequentially filter through 5.0 µm and 0.45 µm membranes.

- Precipitation: Precipitate with 2 volumes of ice-cold isopropanol. Re-dissolve in deionized water.

- Dialyze: Dialyze (MWCO 12-14 kDa) against deionized water for 72 hours.

- Lyophilize: Freeze at -80°C and lyophilize to a constant weight.

- Characterize: Determine M/G ratio via FT-IR or NMR and molecular weight via SEC-MALS for each batch. Only batches with M/G ratios within ±0.2 of your target should be used for critical experiments.

Q4: My collagen hydrogel polymerization kinetics are inconsistent. What factors should I control? A: Polymerization is highly sensitive to pH, ionic strength, and temperature.

- Critical Control Parameters:

- Neutralization: Precisely follow the supplier's neutralization protocol. Use chilled, sterile buffers and keep the collagen solution on ice until use.

- Buffer Consistency: Use the same batch of 10X PBS and 0.1N NaOH for neutralization across all experiments.

- Temperature: Perform polymerization in a temperature-controlled incubator or water bath at 37°C. Do not move the gel during the first 30 minutes.

- Document: Record the exact time from neutralization to placement in the incubator (gelation initiation time).

Q5: After lyophilization, my hyaluronic acid (HA) shows poor rehydration and solubility. What went wrong? A: This indicates potential polymer degradation or collapse of structure during lyophilization.

- Optimized Lyophilization SOP:

- Pre-freezing: Snap-freeze the HA solution in a thin layer using a dry ice/ethanol bath or liquid nitrogen. Slow freezing leads to large ice crystals that damage polymer structure.

- Additive: Include a cryoprotectant (e.g., 5% w/v trehalose) in the HA solution prior to freezing.

- Primary Drying: Lyophilize at a shelf temperature of -40°C and pressure below 0.1 mBar for 48 hours.

- Secondary Drying: Gradually increase shelf temperature to 25°C over 12 hours for final moisture removal.

- Storage: Store lyophilized HA in a desiccator at -20°C. For rehydration, use cold buffer and allow gentle mixing on a roller bank for 24 hours at 4°C.

Summarized Data on Biopolymer Variability

Table 1: Key Variability Parameters and Analytical Methods for Common Biopolymers

| Biopolymer | Primary Variability Parameters | Recommended Analytical Method(s) | Acceptable Batch Range (Example) |

|---|---|---|---|

| Alginate | Mannuronate/Guluronate (M/G) Ratio, Molecular Weight (MW) | ¹H NMR, FT-IR, SEC-MALS | M/G: 1.5 ± 0.2; PDI: < 1.5 |

| Chitosan | Degree of Deacetylation (DDA), MW, Viscosity | ¹H NMR, SEC-MALS, Ubbelohde Viscometer | DDA: > 85% ± 2%; Ash Content: < 0.5% |

| Hyaluronic Acid | Molecular Weight, Protein Content, Heavy Metals | SEC-MALS, BCA Assay, ICP-MS | MW: Target kDa ± 10%; Protein: < 0.3 µg/mg |

| Collagen (Type I) | Source (bovine, rat-tail, recombinant), Concentration, pH | SDS-PAGE, Amino Acid Analysis, pH Meter | Concentration: Label ± 5%; pH of stock: 2.0 - 3.0 |

Experimental Protocols

Protocol 1: Determination of Chitosan Degree of Deacetylation (DDA) by ¹H NMR

- Sample Prep: Dissolve 5 mg of dried chitosan in 1 mL of D₂O containing 1% (v/v) DCl. Transfer to a 5 mm NMR tube.

- Acquisition: Acquire ¹H NMR spectrum at 70°C using a standard pulse sequence (e.g., zg30) on a 400 MHz spectrometer. Set number of scans to 64.

- Analysis: Identify peaks: HOD (~4.8 ppm), H-1 of GlcN (~4.5 ppm), H-2 of GlcNAc (~3.2 ppm), and acetyl methyl protons (~2.1 ppm).

- Calculation: Calculate DDA (%) = [1 - ( (ICH3 / 3) / (IH2 / 1) )] × 100, where ICH3 is the integral of the methyl peak and IH2 is the integral of the H-2 peak of GlcNAc.

Protocol 2: SEC-MALS for Molecular Weight Distribution

- System Setup: Use an HPLC system with size-exclusion column(s) (e.g., TSKgel GMPWxl), multi-angle light scattering (MALS) detector, and refractive index (RI) detector.

- Mobile Phase: Use 0.1 M NaNO₂ + 0.02% NaN₃, filtered (0.1 µm) and degassed. Flow rate: 0.5 mL/min.

- Calibration: Normalize detectors using a monodisperse standard (e.g., BSA).

- Sample Analysis: Filter sample (0.22 µm), inject 100 µL at 2-4 mg/mL concentration.

- Data Analysis: Use ASTRA or equivalent software to calculate absolute weight-average molecular weight (Mw), number-average molecular weight (Mn), and polydispersity index (PDI = Mw/Mn).

Visualizations

Biopolymer Sourcing & Pre-processing Workflow

Biopolymer Variability Impact on Cell Signaling

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function / Relevance to Batch Variability |

|---|---|

| 0.22 µm PES Syringe Filters | Sterile filtration of biopolymer solutions to remove aggregates and microbial contamination prior to use. |

| Dialysis Tubing (MWCO 3.5-14 kDa) | Purification to remove salts, solvents, and low-MW impurities that vary between supplier batches. |

| Size-Exclusion Chromatography (SEC) Columns | For fractionation to obtain a narrow molecular weight distribution from a polydisperse batch. |

| Lyophilizer with Programmable Cycle | Ensures consistent, gentle removal of solvent to produce stable, reproducible solid biopolymer forms. |

| Certified Reference Materials (CRMs) | (e.g., NIST HA standards) Essential for calibrating instrumentation (MALS, NMR) to enable cross-batch, cross-lab comparison. |

| Stable Cell Line with Reporter Gene | (e.g., NF-κB or AP-1 driven luciferase) Functional QC tool to test batch-specific bioactivity (e.g., immunomodulation). |

| Rheometer with Peltier Plate | Quantifies mechanical property variability (gelation time, modulus) critical for hydrogel reproducibility. |

Technical Support Center: Troubleshooting & FAQs

Troubleshooting Guide: Common Experimental Issues

Issue 1: High Polydispersity Index (PDI) in Purified HA Batches

- Potential Cause: Incomplete enzymatic degradation of protein impurities or inconsistent precipitation conditions.

- Solution: Verify activity of protease (e.g., Pronase) via a control assay. Standardize precipitation by ensuring slow, dropwise addition of ethanol (at least 3x volume) at a consistent temperature (4°C) with uniform stirring speed.

Issue 2: Inconsistent Intrinsic Viscosity Measurements

- Potential Cause: Variations in sample dissolution time, temperature control of the viscometer bath, or presence of micro-bubbles.

- Solution: Implement a strict dissolution protocol (e.g., 24-hour gentle rotation at 4°C in 0.15M NaCl). Use a degassing step prior to analysis. Calibrate the viscometer bath temperature to ±0.1°C.

Issue 3: Variability in Gel Filtration Chromatography Profiles

- Potential Cause: Column degradation, inconsistent sample loading volume, or fluctuations in mobile phase ionic strength.

- Solution: Regularly run a standard HA molecular weight marker set. Enforce a fixed sample load volume (±2% tolerance). Monitor and adjust the buffer preparation protocol using conductivity measurements.

Frequently Asked Questions (FAQs)

Q1: What is the most critical parameter to control during HA extraction to minimize batch variability? A1: The enzyme digestion step is paramount. Inconsistent incubation time, temperature, or protease-to-tissue ratio leads to variable protein contamination and chain cleavage. Standardize using a highly purified, activity-quantified enzyme lot and a fixed, validated digestion endpoint assay (e.g., BCA protein assay on supernatant).

Q2: How can we rapidly screen HA molecular weight between purification runs? A2: Implement Size-Exclusion Chromatography with Multi-Angle Light Scattering (SEC-MALS) as a QC checkpoint. While intrinsic viscosity is the gold standard, SEC-MALS provides an absolute molecular weight distribution quickly (within 1 hour) and uses minimal sample.

Q3: Our rheological data shows inconsistent viscoelastic properties. What should we check? A3: Focus on sample preparation and test conditions. Ensure consistent pre-shearing of samples to erase loading history. Control and report the exact gap geometry, temperature equilibration time, and strain amplitude used for oscillatory frequency sweeps. Even small deviations can significantly impact G' and G'' values.

Q4: Which stability-indicating assay is best for detecting HA degradation in formulated viscosupplements? A4: A combination of hyaluronidase digestion rate kinetics and high-performance liquid chromatography (HPLC) analysis for disaccharide content is recommended. The enzymatic kinetics detect subtle changes in polymer structure, while HPLC quantifies the extent of depolymerization over time.

Table 1: Impact of Digestion Parameters on HA Purity and Molecular Weight

| Digestion Parameter | Tested Range | Optimal Value | Resulting HA Purity (%) | Resulting Weight-Avg MW (kDa) | PDI |

|---|---|---|---|---|---|

| Protease Incubation Time | 2-24 hours | 18 hours | 99.5 ± 0.2 | 1,250 ± 50 | 1.12 ± 0.05 |

| Temperature | 37-60°C | 50°C | 99.3 ± 0.3 | 1,200 ± 70 | 1.15 ± 0.07 |

| pH | 6.5-8.0 | 7.4 | 99.6 ± 0.1 | 1,270 ± 30 | 1.10 ± 0.03 |

Table 2: Key Physicochemical Specifications for Standardized HA

| Specification | Target Value | Analytical Method | Acceptance Criteria |

|---|---|---|---|

| Molecular Weight (Mw) | 1,200 - 1,400 kDa | SEC-MALS / Intrinsic Viscosity | 1,150 - 1,450 kDa |

| Polydispersity Index (PDI) | ≤ 1.20 | SEC-MALS | ≤ 1.25 |

| Protein Content | ≤ 0.1% w/w | Micro BCA Assay | ≤ 0.15% w/w |

| Intrinsic Viscosity | 3.5 - 4.2 dL/g | Capillary Viscometry (0.15M NaCl) | 3.3 - 4.4 dL/g |

| Dynamic Viscosity (1% soln, 1/s) | 50 - 70 Pa·s | Rotational Rheometry | 45 - 75 Pa·s |

Experimental Protocols

Protocol 1: Standardized HA Purification from Bacterial Fermentation

- Fermentation Halt & Cell Separation: Terminate Streptococcus zooepidemicus culture at late-log phase. Centrifuge at 12,000 x g for 45 min at 4°C. Retain supernatant.

- Protein Digestion: Adjust supernatant to pH 7.4 with 1M NaOH. Add Pronase (≥5 units/mg of estimated protein). Incubate at 50°C for 18 hours with gentle stirring.

- Precipitation: Cool digest to 4°C. Slowly add 3 volumes of cold 95% ethanol with constant stirring. Allow HA fibrous precipitate to form for ≥2 hours.

- Recovery & Washing: Spool precipitate onto a glass rod. Redissolve in 0.15M NaCl. Reprecipitate with 3 volumes ethanol. Wash final precipitate with 70% ethanol and absolute ethanol.

- Drying: Lyophilize the washed precipitate to constant weight. Store desiccated at -20°C.

Protocol 2: Intrinsic Viscosity Determination via Capillary Viscometry

- Solution Preparation: Precisely dissolve lyophilized HA in 0.15M NaCl containing 0.02% NaN3 to a concentration of 0.5 mg/mL. Stir gently at 4°C for 24 hours to ensure complete dissolution without shear degradation.

- Viscometer Calibration: Use purified water (η = 0.8904 cP at 25°C) to determine the viscometer constant (C) in an Ubbelohde-type viscometer immersed in a thermostated bath at 25.00°C ± 0.05°C.

- Measurement: Load 10 mL of sample. Measure flow time (t) five times. Repeat for the pure solvent (t0).

- Calculation: Calculate relative viscosity (ηrel = t/t0). Use the Huggins equation: ηsp/c = [η] + kH[η]²c, where ηsp = ηrel - 1. Plot ηsp/c vs. concentration (c). The y-intercept from a linear regression is the intrinsic viscosity [η].

Visualizations

Workflow for HA Standardization & QC

Quality Control Analysis Decision Path

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for HA Standardization Research

| Item | Function & Relevance to Standardization |

|---|---|

| Pronase (from Streptomyces griseus) | A broad-spectrum protease for consistent and complete removal of protein impurities, critical for achieving reproducible purity (>99%). |

| Certified Hyaluronan MW Standards | A set of narrow-distribution HA standards (e.g., 100 kDa, 500 kDa, 1.5 MDa) for accurate calibration of SEC-MALS systems and molecular weight determination. |

| SEC-MALS System | The primary analytical instrument for absolute molecular weight (Mw, Mn) and PDI determination without column calibration dependencies. |

| Ubbelohde Capillary Viscometer | The gold-standard apparatus for determining intrinsic viscosity, a key parameter directly related to HA molecular weight and conformation in solution. |

| Hyaluronidase (from bovine testes) | A standardized enzyme preparation used in stability and bio-activity assays to monitor degradation kinetics and compare batch performance. |

| Rotational Rheometer with Peltier Plate | Essential for characterizing viscoelastic properties (G', G'', complex viscosity) under simulated shear conditions, predicting in-vivo performance. |

Digital Batch Records and Data Tracking for Enhanced Traceability

This technical support center is designed for researchers and drug development professionals investigating biopolymer batch-to-batch variability. A digital batch record (DBR) system is critical for ensuring data integrity, traceability, and reproducibility in this research. The following guides and FAQs address common technical challenges encountered when implementing and using DBR platforms for tracking biopolymer synthesis and characterization data.

Troubleshooting Guides & FAQs

Q1: After updating a synthesis parameter in the digital batch record, why are the associated analytical results (e.g., SEC chromatograms) not automatically re-linked? A: This is typically a permissions or workflow state issue. The DBR likely prevents automatic linkage to historical data once a batch is "Signed" or "Under Review" to maintain audit integrity.

- Troubleshooting Steps:

- Check the batch's status. If it is

SignedorLocked, you must create a new version of the batch record to make changes. - Verify you have "Edit" permissions for the specific batch and its associated analytical data sets.

- Manually re-link the files using the "Associate Data" function, ensuring the file UUIDs or unique identifiers are correctly referenced in the DBR metadata table.

- Check the batch's status. If it is

Q2: How do I resolve an "Invalid Data Format" error when uploading rheology data from a .csv export? A: The DBR system's parser requires a strict column structure for time-series viscosity and modulus data.

- Troubleshooting Steps:

- Template Validation: Download the system's official rheology template and reformat your .csv to match its header exactly (e.g.,

Time_s,Strain_percent,Complex_Viscosity_Pa_s). - Null Values: Replace any

#N/Aor∞entries with a standard null indicator likeNAor a blank cell. - Protocol Step: Ensure the DBR's "Material Characterization" step is active before initiating the upload. The system will not parse files uploaded to a "Not Started" protocol section.

- Template Validation: Download the system's official rheology template and reformat your .csv to match its header exactly (e.g.,

Q3: Why can't I perform a trend analysis across 10 batches of my chitosan derivative using the DBR's analytics dashboard? A: The most common cause is inconsistent metadata tagging, which prevents the system from recognizing the batches as a comparable set.

- Troubleshooting Steps:

- Audit Metadata: Confirm all 10 batches use the identical Material ID (e.g.,

CS-TMA-01) in the "Polymer Design" section. Variants likeCS-TMA-01.1will be excluded. - Check Critical Parameters: The analytics module filters by key synthesis parameters. Verify that the

Deacetylation DegreeandMolecular Weight Targetfields are populated with numerical values, not text ranges (e.g., use85, not80-90). - Unlock Data: Ensure your query includes batches in all workflow states (

Draft,Reviewed,Signed). The default filter may only showSignedbatches.

- Audit Metadata: Confirm all 10 batches use the identical Material ID (e.g.,

Experimental Protocol: Characterizing Batch-to-Batch Variability in Alginate Hydrogels

Objective: To systematically quantify the impact of raw alginate batch variability on resultant hydrogel mechanical properties using a Digital Batch Record framework.

Materials: See "Research Reagent Solutions" table.

Methodology:

- DBR Creation: In the digital platform, initiate a new "Hydrogel Study" batch record. Input the source alginate

Lot #andSupplier Certificate of Analysis (COA)PDF. - Solution Preparation: Log the precise mass of alginate, solvent volume (deionized water), buffer type, and ionic strength. The DBR will calculate and record the final concentration (e.g., 2.0% w/v).

- Cross-linking & Gelation:

- Document the cross-linker (e.g., CaCl₂) solution concentration and gelling ion molarity.

- Follow the standardized

Alginate_Gelation_v2.1protocol embedded in the DBR, which timestamps the start of gelation.

- Rheological Analysis:

- After 24-hour incubation, perform oscillatory frequency sweep (0.1-10 Hz) using a parallel-plate rheometer.

- Upload the raw .csv data file directly to the "Analytical Results" section of the DBR. The system will automatically extract

G' at 1 HzandG'' at 1 Hz.

- Data Consolidation: The DBR compiles all process parameters and results into a summary table (see below). Perform statistical analysis (e.g., Coefficient of Variation, CV%) on the

Storage Modulus (G')across multiple alginate source batches.

Table 1: Impact of Alginate Source Batch on Hydrogel Stiffness (n=5 gels per batch)

| Alginate Batch ID | Supplier | [G'] at 1 Hz (kPa) Mean ± SD | [G''] at 1 Hz (kPa) Mean ± SD | Gelation Time (min) | Cross-linker Molarity (mM) |

|---|---|---|---|---|---|

| ALG-B237 | Supplier A | 12.5 ± 1.3 | 2.1 ± 0.3 | 18.5 | 100 |

| ALG-B238 | Supplier A | 9.8 ± 2.1 | 1.7 ± 0.5 | 22.0 | 100 |

| ALG-XR45 | Supplier B | 15.2 ± 0.9 | 2.4 ± 0.2 | 15.0 | 100 |

Visualizing the Digital Traceability Workflow

Diagram Title: Data Flow for Biopolymer Variability Research

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Biopolymer Hydrogel Variability Studies

| Item | Function | Critical Specification for Traceability |

|---|---|---|

| Source Biopolymer (e.g., Alginate, Chitosan) | Base material for hydrogel formation. | Lot/Batch Number from supplier. Record M_w, Dispersity (Đ), and residual impurity profile from COA. |

| Divalent Cross-linker (e.g., CaCl₂, ZnSO₄) | Induces ionic gelation of the polymer network. | Solution molarity and purity grade. Document preparation date and storage conditions in DBR. |

| Rheometer with Peltier Plate | Quantifies viscoelastic properties (G', G'') of formed hydrogels. | Calibration certificate date. Ensure data export format (.csv) is compatible with DBR upload parser. |

| Size Exclusion Chromatography (SEC) System | Determines molecular weight distribution of each biopolymer batch. | Column type and batch. Use primary reference standards for calibration. Link chromatogram file to DBR. |

| Digital Batch Record (DBR) Software | Centralized platform for logging all synthesis parameters, analytical data, and metadata. | Must support 21 CFR Part 11 compliance features: audit trails, electronic signatures, and data integrity checks. |

Mitigating Risk: Practical Strategies for Troubleshooting Variant Batches

Failed product specifications in biopolymer-based drug development often stem from inherent batch-to-batch variability. This guide provides a structured, step-by-step root cause analysis (RCA) framework for researchers to systematically investigate and resolve specification failures, ensuring robust and reproducible science.

Step-by-Step Root Cause Analysis Process

Step 1: Problem Definition & Data Collection

- Objective: Clearly define the specification failure with quantifiable metrics.

- Action: Gather all relevant batch records, QC data, and experimental conditions. Create a timeline of events from raw material receipt to final testing.

Step 2: Immediate Containment

- Objective: Prevent further impact.

- Action: Quarantine the affected batch(es) and any downstream products. Document all containment actions.

Step 3: Identify Potential Causes (The 5 Whys & Fishbone Diagram)

- Objective: Brainstorm all possible root causes across key categories.

- Action: Use a Fishbone (Ishikawa) diagram to map causes related to: Materials, Methods, Machines, Measurements, Personnel, and Environment.

Step 4: Data Analysis & Hypothesis Testing

- Objective: Correlate the failure with specific process variables.

- Action: Perform statistical analysis (e.g., PCA, regression) on historical batch data. Design controlled experiments to test the most likely hypotheses from Step 3.

Step 5: Implement & Verify Corrective Actions

- Objective: Address the root cause and confirm effectiveness.

- Action: Revise SOPs, qualify new material sources, or implement in-process controls. Verify through a new pilot batch that meets all specifications.

Step 6: Prevent Recurrence & Report

- Objective: Institutionalize learning.

- Action: Update quality systems, train staff, and document the RCA in a final report. Share findings with relevant stakeholders.

Technical Support Center: Troubleshooting Guides & FAQs

FAQs on Biopolymer Variability & Specifications

Q1: Our hyaluronic acid-based hydrogel shows significant batch-to-batch variation in rheological properties (G', G''). Where should we start our investigation? A: Focus first on the molecular weight distribution and degree of substitution (if chemically modified). Use SEC-MALS for precise Mw analysis and NMR for substitution confirmation. Recent studies (e.g., Journal of Pharmaceutical Sciences, 2023) highlight that even minor changes in purification salts can affect polymer entanglement and final viscoelasticity.

Q2: A batch of chitosan nanoparticles failed the drug encapsulation efficiency (EE%) specification. The synthesis protocol was unchanged. What are the most common root causes? A: Primary causes often relate to the source and characterization of the chitosan itself:

- Variability in Deacetylation Degree (DD%): This critically impacts charge density and encapsulation capability. Verify DD% for the new batch via potentiometric titration or FTIR.

- Viscosity/Molecular Weight Shift: Check the viscosity of the stock polymer solution.

- Trace Element Contamination: ICP-MS analysis can reveal differences in ash or heavy metal content from the new biopolymer lot that may interfere with nanoparticle self-assembly.

Q3: During scale-up, our PLGA microparticle formulation consistently fails the in vitro release specification after 7 days. The lab-scale batches passed. What process parameters are key? A: Scale-up failures often point to mixing dynamics and solvent removal rates. Investigate:

- Emulsion Homogenization: Shear rate and time must scale appropriately; droplet size distribution is critical.

- Solvent Evaporation Rate: Larger volumes change the kinetics. Monitor temperature and pressure profiles closely against your lab-scale process.

- Crystallinity of Polymer: Differences in the effective quenching rate can alter PLGA crystallinity, affecting release. Use DSC to compare batches.

Key Experimental Protocols for RCA

Protocol 1: Determining Deacetylation Degree (DD%) of Chitosan via Titration

- Purpose: To accurately quantify the DD%, a key source of variability affecting nanoparticle formation.

- Method:

- Dissolve 0.2 g dried chitosan in 30 mL of 0.1 M HCl.

- Titrate with 0.1 M NaOH using an automated titrator with pH probe.

- Record two equivalence points: (V1) for excess HCl neutralization and (V2) for amine group protonation.

- Calculate DD% using the formula:

DD% = [(V2 - V1) * M_NaOH * 16] / m_sample * 100, where m_sample is in mg.

- Key Reagents: High-purity HCl, NaOH, degassed DI water.

Protocol 2: Size Exclusion Chromatography with Multi-Angle Light Scattering (SEC-MALS) for Biopolymer Mw Distribution

- Purpose: To obtain absolute molecular weight and polydispersity index (PDI), critical for rheology and performance.

- Method:

- Prepare polymer solution at 2-4 mg/mL in the appropriate SEC solvent (e.g., 0.1 M NaNO3 with 0.02% NaN3).

- Filter through a 0.22 µm membrane (PVDF or similar).