Combating Voids: Mechanisms, Mitigation, and Analysis of Internal Void Formation in Extrusion-Based Polymer Processing for Biomedical Applications

This article provides a comprehensive analysis of internal void formation mechanisms in material extrusion (MatEx) polymer processing, a critical concern for biomedical device fabrication and drug delivery system development.

Combating Voids: Mechanisms, Mitigation, and Analysis of Internal Void Formation in Extrusion-Based Polymer Processing for Biomedical Applications

Abstract

This article provides a comprehensive analysis of internal void formation mechanisms in material extrusion (MatEx) polymer processing, a critical concern for biomedical device fabrication and drug delivery system development. We explore the fundamental physics behind void nucleation, including gas entrapment, moisture volatilization, and thermal-induced cavitation. Methodological approaches for characterizing voids via micro-CT, SEM, and ultrasound are detailed, alongside process parameter optimization strategies for Fused Deposition Modeling (FDM) and direct ink writing (DIW) of biocompatible polymers. The review further compares mitigation techniques—encompassing drying protocols, vacuum-assisted printing, and parameter tuning—and validates their efficacy through case studies on mechanical integrity and drug release kinetics. Targeted at researchers and pharmaceutical scientists, this work establishes a framework for troubleshooting void-related defects to enhance the reliability of printed biomedical constructs.

The Genesis of Emptiness: Unraveling Core Mechanisms of Void Formation in Extrusion-Based Additive Manufacturing

Within the context of a broader thesis on internal void formation mechanisms in material extrusion (MatEx) polymer processing, the presence and characteristics of internal voids constitute a critical, multi-faceted problem. These voids, inherent to or intentionally designed within fabricated structures, profoundly influence the end-use performance of components in biomedical and pharmaceutical applications. This technical guide synthesizes current research to delineate the systematic impact of void morphology—size, distribution, fraction, and interconnectivity—on three interdependent domains: mechanical integrity, biological response, and controlled drug release.

The Tripartite Impact of Internal Voids: A Data-Driven Analysis

Impact on Mechanical Properties

Internal voids act as stress concentrators, significantly altering the structural response of MatEx-fabricated parts, especially those using biodegradable polymers like PCL, PLA, and their composites.

Table 1: Quantitative Impact of Void Fraction on Mechanical Properties

| Material System | Void Fraction (%) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Strain at Break (%) | Reference Key |

|---|---|---|---|---|---|

| PCL Scaffold | ~5 (controlled) | 12.3 ± 1.5 | 0.21 ± 0.03 | 380 ± 45 | [Study A, 2023] |

| PCL Scaffold | ~25 (controlled) | 4.1 ± 0.8 | 0.08 ± 0.02 | 510 ± 60 | [Study A, 2023] |

| PLA Bone Implant | <2 (defect) | 58 ± 3 | 3.2 ± 0.2 | 5.2 ± 0.6 | [Study B, 2024] |

| PLA Bone Implant | ~10 (defect) | 41 ± 4 | 2.4 ± 0.3 | 3.1 ± 0.5 | [Study B, 2024] |

| PLGA Microparticle | 15 (porous) | N/A | N/A | N/A | [Study C, 2023] |

Experimental Protocol for Mechanical Characterization (ASTM-based):

- Sample Fabrication: Fabricate test specimens (e.g., ASTM D638 Type V) using a calibrated MatEx system. Key parameters: Nozzle diameter (D), layer height (h), print speed, and infill pattern (e.g., rectilinear, gyroid) are varied to induce specific void fractions (Φ_v).

- Void Quantification: Micro-CT scan specimens at a resolution ≤ (D/10). Reconstruct 3D volumes. Using image analysis software (e.g., ImageJ, Avizo), apply a global threshold to segment voids. Calculate Φ_v = (Volume of Voids / Total Apparent Volume) * 100.

- Tensile Testing: Condition specimens at standard atmosphere (e.g., 23°C, 50% RH). Perform uniaxial tensile test using a universal testing machine with a 1 kN load cell and an extensometer. Crosshead speed: 1 mm/min until failure. Record stress-strain curves.

- Data Analysis: Extract ultimate tensile strength, Young's modulus (from linear elastic region), and strain at break. Correlate mechanically derived properties with micro-CT derived Φ_v via linear or power-law regression models.

Impact on Biological Properties

Void architecture dictates the biological microenvironment, affecting cell-scaffold interactions, tissue ingrowth, and vascularization.

Table 2: Influence of Void Architecture on In Vitro Biological Response

| Cell Type | Scaffold Material | Void Feature | Key Biological Outcome | Measurement | Reference Key |

|---|---|---|---|---|---|

| Human Mesenchymal Stem Cells (hMSCs) | PCL-β-TCP Composite | Interconnected, 300-400 μm pores | Osteogenic differentiation ↑ 2.5x vs. non-porous control | Alkaline Phosphatase Activity (Day 21) | [Study D, 2023] |

| NIH/3T3 Fibroblasts | PLGA | Random, sub-50 μm pores (from phase separation) | Cell adhesion density ↓ 40% vs. smooth surface | Fluorescence (Actin/DAPI) Count (Day 3) | [Study E, 2023] |

| Endothelial Cells (HUVECs) | GelMA Hydrogel | Channel-like voids (Bioprinted) | Capillary network length ↑ 300% | Total tubule length (Confocal, Day 7) | [Study F, 2024] |

Experimental Protocol for Evaluating Cell Invasion and Viability in 3D Porous Structures:

- Scaffold Preparation & Sterilization: Fabricate porous 3D scaffolds via MatEx. Ethanol wash (70%, 2 hrs) followed by UV irradiation per side (30 min). Pre-wet in culture medium overnight.

- Cell Seeding: Use dynamic seeding method. Prepare cell suspension (e.g., 1x10^6 cells/mL). Place scaffold in low-attachment well, slowly pipette suspension onto scaffold. Place on orbital shaker (25 rpm, 2 hrs) for uniform distribution. Transfer to static culture.

- Analysis of Cell Infiltration & Viability:

- Live/Dead Staining (Day 1, 3, 7): Incubate in Calcein-AM (2 μM, live/green) and Ethidium homodimer-1 (4 μM, dead/red) for 45 min. Image via confocal microscopy at multiple depths (Z-stack). Calculate viability (%) and infiltration depth (μm).

- Metabolic Activity (MTT Assay, Day 1, 3, 7): Incubate with MTT reagent (0.5 mg/mL) for 4 hrs. Dissolve formazan crystals in DMSO. Measure absorbance at 570 nm (reference 670 nm). Normalize to scaffold-only control.

- Histology (Day 14): Fix in 4% PFA, dehydrate, paraffin embed. Section (5-10 μm) and stain with H&E or for specific markers (e.g., collagen via Masson's Trichrome).

Impact on Drug Release Properties

Voids influence drug loading capacity, release kinetics, and stability, critical for implantable or injectable depot systems.

Table 3: Void Characteristics and Drug Release Kinetics

| Drug/Carrier System | Void Creation Method | Avg. Pore Size | Drug Loading Efficiency (%) | Release Profile (Key Model Fit) | t_50 (days) | Reference Key |

|---|---|---|---|---|---|---|

| Doxorubicin / PLA Microparticles | Emulsion-Solvent Evaporation | 5-15 μm | 85.2 ± 3.1 | Biphasic: Initial burst (30% in 1d), then sustained (Higuchi) | 12.5 | [Study G, 2023] |

| Vancomycin / PCL 3D Printed Scaffold | MatEx Infill Control (Rectilinear) | 200-500 μm (macro) | 92.7 ± 2.4 | Sustained, zero-order for ~28 days | >40 | [Study H, 2024] |

| BSA (Model Protein) / PLGA Microspheres | Double Emulsion (W/O/W) | 1-5 μm | 65.8 ± 5.0 | Triphasic: Burst, lag, secondary release (inc. pore rupture) | Variable | [Study I, 2023] |

Experimental Protocol for Drug Loading and Release from Porous MatEx Scaffolds:

- Drug-Loaded Scaffold Fabrication: Two primary methods:

- Post-printing Infusion: Fabricate porous scaffold. Immerse in concentrated drug solution (e.g., 10 mg/mL in ethanol/water). Apply vacuum (0.1 bar, 30 min) to remove air from pores, then release to atmospheric pressure for infusion. Dry under vacuum.

- Co-extrusion: Prepare drug-polymer composite filament via hot-melt extrusion. Use this filament directly in MatEx process.

- Drug Loading Quantification: Precisely weigh drug-loaded scaffold (Wloaded). Dissolve scaffold completely in organic solvent (e.g., DCM for PCL/PLA). Dilute with release-simulating buffer (e.g., PBS). Use HPLC or UV-Vis spectroscopy against a standard curve to determine total drug mass (Mdrug). Loading Efficiency (%) = (M_drug / Theoretical Max Drug) * 100.

- In Vitro Release Study: Immerse scaffold in release medium (e.g., PBS, pH 7.4, 37°C) under sink conditions (volume ≥ 10x saturation volume). Place in an incubator shaker (50 rpm). At predetermined time points, withdraw and replace the entire medium aliquot. Analyze drug concentration via HPLC/UV-Vis. Plot cumulative release (%) vs. time. Fit data to models (Zero-order, First-order, Higuchi, Korsmeyer-Peppas) to elucidate release mechanisms.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Void Characterization and Functional Testing

| Item / Reagent | Function / Application | Key Consideration |

|---|---|---|

| Micro-CT System (e.g., SkyScan, µCT) | Non-destructive 3D imaging for quantifying void fraction, size distribution, and interconnectivity. | Resolution must be significantly smaller than feature size. Use contrasting agents (e.g., iodine) for low-density polymers. |

| Poly(D,L-lactide-co-glycolide) (PLGA) | A benchmark biodegradable polymer for drug delivery studies; degradation rate tunable via LA:GA ratio. | Inherently forms porous structures via phase separation. Supplier (e.g., Evonik, Lactel) dictates reproducible MW and dispersity. |

| Poly(ε-caprolactone) (PCL) | Semi-crystalline, slow-degrading polymer for long-term implants and mechanical testing scaffolds. | Low melting point (~60°C) enables low-temperature MatEx, reducing thermal degradation of bioactives. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard release medium for in vitro drug elution and degradation studies. | Must contain antimicrobial agents (e.g., 0.02% sodium azide) for long-term studies; may require surfactants (e.g., 0.1% Tween 80) for hydrophobic drugs. |

| AlamarBlue or MTT Assay Kit | Colorimetric/fluorometric metabolic assays for quantifying cell viability and proliferation in 3D scaffolds. | Ensure reagent penetration into scaffold pores; may require extended incubation times or scaffold sectioning. |

| Fluorescently-tagged Phalloidin & DAPI | Stains F-actin cytoskeletons (green/red) and nuclei (blue) for visualizing cell adhesion, morphology, and infiltration in voids. | Critical for confocal imaging of cell distribution relative to 3D void architecture. |

| MatEx-Compatible Bioinks (e.g., GelMA, Alginate) | For creating controlled channel-like voids (perfusable) in hydrogel constructs for vascularization studies. | Gelation mechanism (UV, ionic) must be compatible with void preservation post-printing. |

Visualizing Relationships and Workflows

Title: Interdependency of Voids and Functional Properties

Title: Workflow for Assessing Cell-Void Interaction

Within the broader investigation of Internal Void Formation Mechanisms in Material Extrusion Polymer Processing, the primary mechanism of gas entrapment and volatile evolution is a critical determinant of final part quality. This whitepaper details the sub-mechanisms by which gases are introduced, transported, and stabilized as voids during the filament-based additive manufacturing process, with direct implications for the mechanical integrity, dimensional accuracy, and functional performance of printed constructs—a paramount concern in research and high-stakes applications such as pharmaceutical device development.

Core Physical-Chemical Mechanisms

The formation of internal voids during the melt extrusion and deposition sequence is governed by a cascade of interrelated phenomena:

- Initial Gas Entrapment: Air and moisture physically trapped within the porous structure of the feedstock filament, or at the inter-filament contact points (the "road-to-road" interface).

- Volatile Generation: Thermal degradation of polymer chains or evaporation of low-molecular-weight components (e.g., plasticizers, residual solvents, absorbed water) within the melt zone of the hot-end.

- Supersaturation and Nucleation: Dissolved gases and volatiles exceed solubility limits in the polymer melt upon heating, leading to heterogeneous nucleation at impurity sites or filament interfaces.

- Bubble Dynamics: Nucleated bubbles undergo growth (via diffusion and pressure reduction), coalescence, and transport within the shear flow of the melt.

- Stabilization and Trapping: Rapid cooling (quenching) during deposition solidifies the polymer matrix, trapping bubbles as permanent voids before they can escape to the free surface.

Table 1: Key Process Parameters Influencing Void Formation

| Parameter | Typical Range Studied | Effect on Void Fraction | Key Finding (Source) |

|---|---|---|---|

| Nozzle Temperature | 180°C - 280°C | 0.5% - 15% | Peak void fraction at intermediate temps (~220°C) due to balance of melt viscosity and degradation rate. |

| Chamber/Enclosure Temp | 25°C - 90°C | 1% - 8% | Elevated chamber temperature reduces void content by 60% due to slower cooling and increased bubble escape time. |

| Print Speed | 10 mm/s - 150 mm/s | 2% - 12% | High speed (>100 mm/s) correlates with 3-5x increase in void content from enhanced shear and reduced relaxation time. |

| Filament Drying Time | 0 hrs - 24 hrs | 15% -> 2% | Drying (80°C, 12h) reduces moisture-induced void content in hygroscopic polymers (e.g., PLA, PA) by >85%. |

| Layer Height / Nozzle Gap | 0.1 - 0.3 mm | 3% - 9% | Smaller layer height increases road compaction, reducing interfacial void volume by up to 70%. |

| Volatile Content (Initial) | 0.05 wt% - 0.5 wt% | Linear Increase | Direct linear correlation (R²=0.96) between initial moisture content and final void percentage in ABS. |

Table 2: Measured Void Characteristics by Analytical Technique

| Technique | Void Size Range Detectable | Measured Metric | Example Data (PLA) |

|---|---|---|---|

| X-ray Micro-CT | 1 µm - 500 µm | Volume Fraction, Sphericity | Avg. Void Diameter: 45 ± 22 µm; Anisotropy Ratio (Z/X): 1.8 |

| Optical Microscopy (cross-section) | 5 µm - 1 mm | Areal Fraction, Distribution | Inter-road voids: ~100 x 50 µm (elongated); Intra-road voids: ~20 µm (spherical). |

| Archimedes' Density | N/A | Bulk Density, % Theoretical Density | Measured Density: 1.21 g/cm³; Theoretical: 1.24 g/cm³; Porosity: 2.4%. |

| Pycnometry (Gas) | N/A | True Density, Open/Closed Porosity | Closed Porosity: 1.8%; Open Porosity: 0.7%. |

Experimental Protocols for Investigation

Protocol 1: In-situ Volatile Detection via Thermogravimetric Analysis-Mass Spectrometry (TGA-MS)

- Objective: Quantify the temperature-dependent evolution of specific volatile species (H₂O, CO₂, monomers) from filament samples.

- Procedure:

- Cut 10-20 mg of filament into small pieces.

- Load into a platinum TGA crucible.

- Heat from 30°C to 500°C at a rate of 10°C/min under a constant nitrogen purge (50 mL/min).

- The evolved gas stream is transferred via a heated capillary to a mass spectrometer.

- MS monitors specific mass-to-charge ratios (m/z) corresponding to target volatiles (e.g., m/z 18 for H₂O, m/z 44 for CO₂).

- Data Analysis: Correlate weight loss steps (from TGA) with peaks in MS ion current to identify degradation products and their evolution temperatures.

Protocol 2: Ex-situ Void Characterization via X-ray Micro-Computed Tomography (μCT)

- Objective: Obtain 3D quantification of void size, distribution, and morphology in a printed sample.

- Procedure:

- Print a standardized test cube (e.g., 10 x 10 x 10 mm) with defined parameters.

- Mount the sample on a rotary stage within the μCT chamber.

- Set scanning parameters (e.g., 80 kV source voltage, 10W power, 0.5 mm aluminum filter).

- Acquire a series of 2D radiographic projections over a 360° rotation (e.g., 2000 projections).

- Reconstruct the 3D volume using a filtered back-projection algorithm.

- Data Analysis: Apply image processing (thresholding, segmentation) to isolate voids. Calculate metrics like void volume fraction, size distribution, and sphericity using software (e.g., Avizo, ImageJ).

Protocol 3: Controlled Printing for Interfacial Void Analysis

- Objective: Isolate the effect of deposition parameters on gas entrapment at road-to-road interfaces.

- Procedure:

- Utilize a single-layer, multi-road printing pattern on a heated bed.

- Systematically vary one parameter: nozzle height (e.g., 80%, 100%, 120% of filament diameter).

- Hold all other parameters constant (temperature, speed, cooling).

- Immediately after deposition, quench the sample to preserve the melt state morphology.

- Prepare polished cross-sections perpendicular to the print direction.

- Image using optical or scanning electron microscopy.

- Data Analysis: Measure the cross-sectional area of gaps/voids at the interface between adjacent roads and calculate the percentage of incomplete contact area.

Diagrams

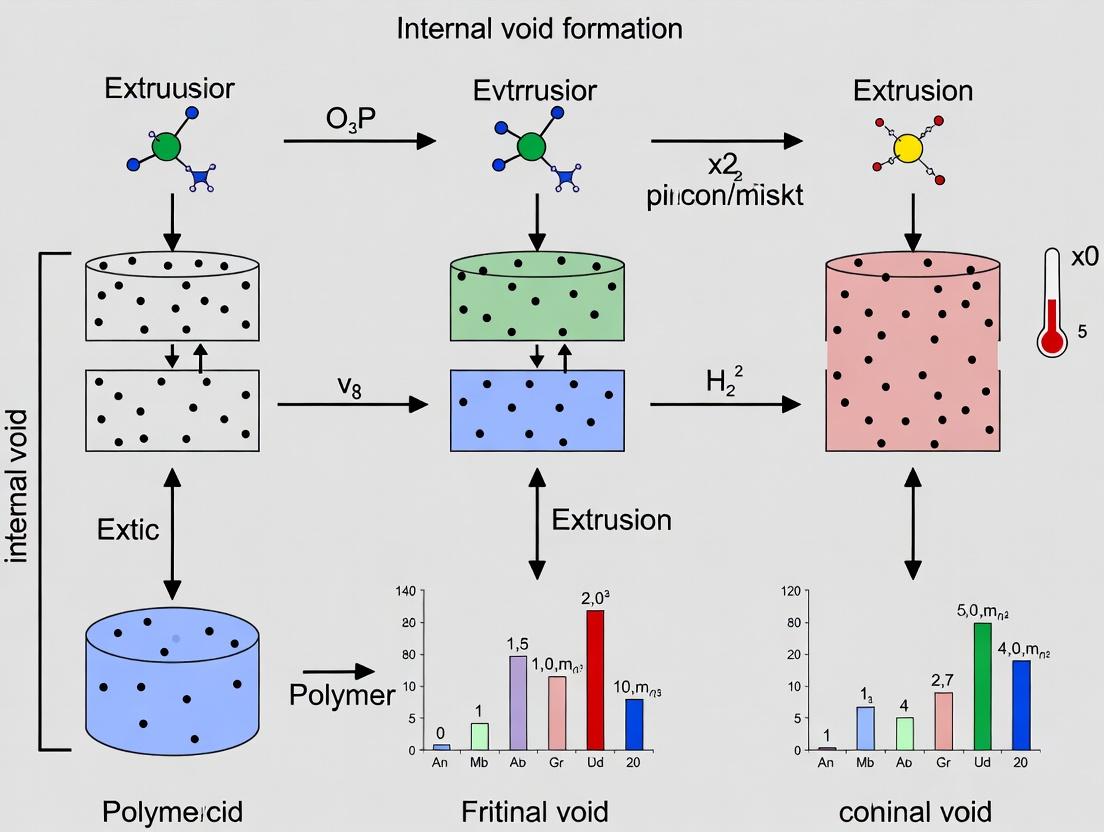

Diagram 1: Pathway of Void Formation in MEX.

Diagram 2: Research Workflow for Void Analysis.

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

| Item | Function & Relevance to Void Research | Example Specification / Note |

|---|---|---|

| Hygroscopic Polymer Filaments | Primary test material; intrinsic moisture absorption drives volatile-induced void formation. | PLA, ABS, Nylon 6; Pre-dry and store in desiccated conditions. |

| Desiccant Dryer / Oven | To standardize initial volatile content by removing absorbed water from feedstock. | Capable of maintaining 70-80°C with <10% RH airflow for >12 hours. |

| High-Resolution Nozzle | To study size effects on shear and pressure drop, influencing bubble dynamics. | Tungsten carbide nozzles, diameters from 0.1 mm to 0.6 mm. |

| In-line Melt Pressure & Temperature Sensor | For real-time monitoring of process conditions that govern gas solubility and viscosity. | Integrated near the nozzle to capture actual melt state data. |

| Sealed Printing Enclosure with Climate Control | To isolate and control ambient humidity and temperature, key external variables. | Enables studies at fixed relative humidity (e.g., 10%, 50%, 90% RH). |

| Thermogravimetric Analyzer with Mass Spectrometry (TGA-MS) | To identify and quantify the specific chemical species of evolved volatiles. | Critical for linking mass loss events to gas species (H₂O vs. CO₂ vs. organics). |

| Micro-CT Scanner (Benchtop) | For non-destructive 3D quantification of void architecture within printed parts. | Resolution < 5 µm/voxel required for resolving typical intra-road voids. |

| Image Analysis Software | To segment, quantify, and statistically analyze void data from microscopy/CT. | Avizo, ImageJ/Fiji, or commercial packages with robust segmentation tools. |

| Computational Fluid Dynamics (CFD) Software | To model multiphase flow (polymer melt + bubbles) within the nozzle and melt pool. | ANSYS Fluent, COMSOL with customized viscoelastic and multiphase models. |

Within the broader research on Internal void formation mechanisms in material extrusion polymer processing, moisture-induced vaporization and degradation represent a critical, secondary mechanism that compromises structural integrity and functional performance. For hygroscopic biomedical polymers—such as poly(lactic-co-glycolic acid) (PLGA), polycaprolactone (PCL), and polyvinyl alcohol (PVA)—residual or absorbed water acts as a volatile plasticizer. During high-temperature extrusion processes (e.g., in fused filament fabrication or hot-melt extrusion), this moisture rapidly vaporizes, generating micro- and nano-scale voids. Concurrent thermal-hydrolytic degradation cleaves polymer chains, altering melt viscosity and crystallization kinetics, which further exacerbates void formation and leads to unpredictable drug release profiles and reduced mechanical strength in final devices.

Core Physicochemical Pathways

The mechanism operates through two intertwined pathways:

- Physical Vaporization: Absorbed water, upon heating above its boiling point at processing pressures, undergoes a phase change to steam. The resulting expansion generates internal pressure, forming pores and delamination at weak interlayer boundaries.

- Chemical Hydrolytic Degradation: Water molecules catalyze ester bond cleavage (in polyesters like PLGA) via hydrolysis, significantly accelerated at extrusion temperatures. This reduces molecular weight, increases oligomer content, and modifies viscoelastic properties, making the melt more susceptible to cavity formation and coalescence.

Table 1: Hygroscopicity and Degradation Kinetics of Common Biomedical Polymers

| Polymer | Equilibrium Moisture Uptake (% w/w, 25°C/60% RH) | Glass Transition Temp, Tg (°C) | Extrusion Temp Range (°C) | Hydrolysis Rate Constant (k, x10⁻³ day⁻¹) at 37°C | Key Degradation Product |

|---|---|---|---|---|---|

| PLGA (50:50) | 0.5 - 1.2 | 45-50 | 160-220 | 8.2 - 12.5 | Lactic/Glycolic Acid |

| PCL | < 0.3 | (-60) - (-65) | 60-100 | ~0.3 | Caproic Acid |

| PVA | 20 - 35 (Fully hydrolyzed) | 75-85 | 180-230 | Varies with hydrolysis degree | Water-Soluble Fragments |

| Polyethylene Glycol (PEG) | High (Hygroscopic) | (-65) - (-10) | 50-80 | - | - |

Table 2: Impact of Moisture Content on Void Formation in Extruded Filaments

| Initial Moisture Content (% w/w) | Avg. Void Diameter (µm) | Void Volume Fraction (%) | Resultant Tensile Strength (MPa) | % Drug Release Burst (24h) |

|---|---|---|---|---|

| < 0.05 (Dry) | 1.2 ± 0.5 | 0.15 ± 0.05 | 58.7 ± 2.1 | 12 ± 3 |

| 0.1 | 5.5 ± 1.8 | 0.8 ± 0.2 | 52.1 ± 3.3 | 18 ± 4 |

| 0.3 | 18.3 ± 6.4 | 3.5 ± 0.9 | 41.6 ± 4.8 | 35 ± 7 |

| 0.5 | Coalesced voids >100 | 8.2 ± 1.5 | 22.4 ± 5.2 | 65 ± 10 |

Experimental Protocols for Characterization

Protocol 1: Quantifying Moisture Uptake and Critical Void-Forming Content

- Objective: Determine the kinetics of moisture sorption and the critical moisture level leading to significant void formation.

- Materials: Dried polymer pellets, controlled humidity chambers, microbalance, TGA, micro-CT scanner.

- Method:

- Dry polymer samples to constant weight in a vacuum oven at 40°C.

- Expose samples to controlled relative humidity (e.g., 30%, 60%, 90% RH) at 25°C.

- Record weight gain at intervals using a microbalance until equilibrium.

- Process moisture-laden samples via a laboratory-scale single-screw extruder with standardized parameters.

- Analyze extrudates using micro-CT to quantify void volume fraction and distribution.

- Correlate initial moisture content with void metrics to identify the critical threshold.

Protocol 2: In-Situ Rheology During Thermal-Hydrolytic Degradation

- Objective: Characterize changes in complex viscosity and shear modulus due to moisture-induced degradation during processing.

- Materials: Parallel-plate rheometer with environmental hood, pre-humidified polymer samples.

- Method:

- Prepare samples with precisely controlled moisture content (e.g., 0.05%, 0.2%, 0.4% w/w).

- Load sample into the rheometer pre-heated to a standard extrusion temperature (e.g., 180°C for PLGA).

- Perform time-sweep oscillatory tests at a constant strain and frequency.

- Monitor the decay of complex viscosity (η*) and storage modulus (G') over 20-30 minutes.

- Fit the viscosity decay curve to a first-order kinetic model to derive an effective degradation rate constant for the melt state.

Protocol 3: Chromatographic Analysis of Hydrolytic Byproducts

- Objective: Identify and quantify degradation products (e.g., lactic acid, glycolic acid) post-extrusion.

- Materials: High-Performance Liquid Chromatography (HPLC) system with refractive index/UV detector, extraction solvents.

- Method:

- Grind extruded polymer samples into powder.

- Extract degradation products using a suitable solvent (e.g., acetonitrile/water mix) under agitation.

- Filter extracts through a 0.22 µm membrane.

- Inject into HPLC equipped with a reversed-phase C18 column.

- Use an isocratic or gradient elution method (e.g., 0.1% aqueous phosphoric acid mobile phase).

- Quantify acid concentrations against calibrated standards.

Diagrams of Mechanisms and Workflows

Diagram 1: Moisture-Driven Void Formation Pathway

Diagram 2: Experimental Protocol for Void Analysis

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Investigating Moisture-Induced Degradation

| Item | Function/Benefit | Example (for illustration) |

|---|---|---|

| Vacuum Oven with Drying Gas Inlet | Removes residual moisture from polymers prior to experimentation; critical for establishing baseline "dry" state. | Memmert VO series |

| Dynamic Vapor Sorption (DVS) Analyzer | Precisely measures moisture uptake/loss kinetics as a function of %RH at isothermal conditions. | Surface Measurement Systems DVS Intrinsic |

| Humidity-Controlled Environmental Chamber | Conditions polymer samples to specific, reproducible moisture content levels for extrusion studies. | ESPEC BPL series |

| Twin-Screw Micro-Compounder | Allows for small-batch, highly controlled polymer processing with precise temperature and shear history. | Xplore MC 15 |

| Benchtop Micro-CT Scanner | Non-destructively images internal void structure, size, and spatial distribution in 3D. | Bruker SkyScan 1272 |

| High-Temperature Humidity Chamber for Rheometer | Enables in-situ rheological testing under controlled humidity at processing temperatures. | Anton Paar CTD 450 HCR |

| HPLC with RI/UV Detector and C18 Column | Separates, identifies, and quantifies low molecular weight acidic degradation products. | Agilent 1260 Infinity II |

| Simultaneous Thermal Analyzer (STA: TGA-DSC) | Quantifies moisture content (via TGA weight loss) and observes thermal transitions (DSC) in one experiment. | Netzsch STA 449 F5 |

Within the comprehensive research framework of internal void formation mechanisms in material extrusion (MatEx) polymer processing, Primary Mechanism III addresses a triad of interrelated, process-governed phenomena. This mechanism is distinct from material degradation or trapped-gas voids, focusing instead on geometric and topological defects arising from the programmed deposition process. Inadequate interlayer adhesion, suboptimal road cross-sectional contour, and the strategic placement of deposition paths collectively create a network of interconnected or isolated pores that critically compromise part density, mechanical anisotropy, and, in biomedical or drug delivery applications, predictable release kinetics and structural integrity.

Mechanistic Breakdown and Quantitative Analysis

Inadequate Layer Adhesion

Poor fusion between successively deposited roads (intralayer) and layers (interlayer) creates planar voids. The primary driver is insufficient thermal energy at the interface, governed by the temperature difference between the deposited road and the substrate layer.

Key Governing Equation:

The healing degree (D) at the interface can be modeled by the reptation theory-based equation:

D(t) ∝ (t/τ)^(1/4)

where t is the contact time and τ is the reptation time, highly sensitive to temperature via the Williams-Landel-Ferry (WLF) equation.

Quantitative Data Summary:

Table 1: Impact of Process Parameters on Interlayer Adhesion Strength (Representative Data)

| Polymer | Nozzle Temp (°C) | Bed Temp (°C) | Layer Height (mm) | Measured Interlayer Strength (MPa) | % of Bulk Strength |

|---|---|---|---|---|---|

| ABS | 230 | 110 | 0.20 | 28.5 | 85% |

| ABS | 230 | 110 | 0.30 | 22.1 | 66% |

| ABS | 210 | 110 | 0.20 | 18.7 | 56% |

| PLA | 220 | 60 | 0.15 | 32.8 | 92% |

| PLA | 200 | 60 | 0.15 | 25.4 | 71% |

| PEEK | 400 | 150 | 0.20 | 72.3 | 78% |

| PEEK | 400 | 250 | 0.20 | 89.5 | 96% |

Road Contour and Deformation

The ideal circular road cross-section is rarely achieved. Squashing (low standoff) leads to excessive width and potential overflow, while rounding (high standoff) reduces contact area, creating inter-road channels.

Quantitative Data Summary:

Table 2: Road Geometry vs. Process Parameters for a 0.4mm Nozzle (PLA)

| Layer Height (mm) | Extrusion Width (mm) | Theoretical Area (mm²) | Measured Area (mm²) | Form Factor (Area Ratio) | Observed Contour |

|---|---|---|---|---|---|

| 0.10 | 0.48 | 0.048 | 0.038 | 0.79 | Over-compressed, elliptical |

| 0.20 | 0.48 | 0.096 | 0.088 | 0.92 | Near-elliptical, optimal |

| 0.30 | 0.48 | 0.144 | 0.121 | 0.84 | Rounded, under-compressed |

| 0.20 | 0.60 | 0.120 | 0.115 | 0.96 | Wide, well-fused |

Nozzle-Path Induced Porosity

The programmed toolpath inherently creates geometric voids. In rectilinear infill, pores are formed at the intersections of perpendicular roads. The size and connectivity are direct functions of road width and the infill pattern/ density.

Quantitative Data Summary:

Table 3: Theoretical Void Fraction from Rectilinear Infill Patterns

| Infill Density (%) | Road Width (mm) | Layer Height (mm) | Theoretical Pore Area per Unit Cell (mm²) | Calculated Porosity (%) |

|---|---|---|---|---|

| 50 | 0.40 | 0.20 | 0.0080 | ~12.5 |

| 75 | 0.40 | 0.20 | 0.0027 | ~4.2 |

| 100 (solid, aligned) | 0.40 | 0.20 | 0.0000 | 0.0* |

| 100 (solid, staggered) | 0.40 | 0.20 | ~0.0016 | ~2.0 |

*Assumes perfect adhesion and contour.

Experimental Protocols for Investigation

Protocol 3.1: Quantifying Interlayer Adhesion

Objective: Measure the intrinsic fracture toughness of the interlayer bond. Materials: See "The Scientist's Toolkit" below. Method:

- Specimen Fabrication: Print standardized Double Cantilever Beam (DCB) or Tapered Double Cantilever Beam (TDCB) specimens with a pre-crack layer oriented to propagate along the interlayer plane (Z-direction). Use a polished plate inserted mid-print to seed the crack.

- Conditioning: Anneal specimens in a vacuum oven at Tg-10°C for 4 hours to relieve residual stress without promoting further healing.

- Testing: Perform a Mode I fracture test on a universal testing machine at a constant crosshead speed (e.g., 1 mm/min). Record load-displacement data.

- Analysis: Calculate the critical strain energy release rate (GIc) using compliance calibration or standard beam theory methods. Correlate GIc with in-situ thermal history data from IR thermography.

Protocol 3.2: Road Contour and Pore Morphology Analysis

Objective: Characterize the true cross-sectional geometry and resulting pore network. Method:

- Sample Preparation: Print a multi-road, single-layer specimen onto a glass substrate. Rapidly quench to freeze the morphology. Embed in epoxy resin and carefully polish transversely to the road direction.

- Imaging: Use optical microscopy or scanning electron microscopy (SEM) to image the cross-section. Apply a high-contrast stain if necessary.

- Image Analysis: Binarize the image to distinguish polymer from void/pore space. Use software (e.g., ImageJ, AutoCAD) to measure:

- Road area, perimeter, and form factor.

- Pore area and equivalent circular diameter.

- Inter-road contact length as a percentage of road perimeter.

- 3D Tomography: For volumetric analysis, perform micro-computed tomography (μCT) scanning. Reconstruct and segment the 3D volume to quantify void volume fraction, connectivity, and pore size distribution.

Protocol 3.3: Toolpath-Dependent Porosity Prediction and Validation

Objective: Predict and validate porosity from G-code toolpath geometry. Method:

- Theoretical Modeling: Develop a geometric model that, given nozzle diameter, layer height, and toolpath (G-code), predicts the theoretical void space. Assume idealized road contours.

- Simulation: Use finite element analysis (FEA) or computational fluid dynamics (CFD) to simulate road deposition, incorporating viscous sintering and surface tension to predict final contour and pore closure.

- Experimental Correlation: Print parts with varied infill patterns (rectilinear, grid, concentric). Analyze them via μCT (Protocol 3.2). Compare measured porosity with the geometric and simulated predictions.

Visualization of Mechanisms and Workflows

Diagram Title: Causal Pathways of Mechanism III Porosity

Diagram Title: Porosity Characterization Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials and Tools for Investigating Mechanism III

| Item / Reagent | Function / Rationale |

|---|---|

| High-Temperature MatEx Printer | Equipped with heated chamber and bed; essential for processing engineering polymers (e.g., PEEK, PEI) to study adhesion. |

| In-situ IR Thermocamera | Non-contact measurement of road and layer surface temperature during deposition; critical for quantifying thermal history. |

| Micro-Computed Tomography (µCT) System | Non-destructive 3D imaging of internal pore structure, connectivity, and volumetric porosity. |

| Universal Testing Machine (UTM) | For conducting standardized mechanical tests (tensile, fracture) to quantify interlayer adhesion strength. |

| Embedding Epoxy Resin | For preparing polished cross-sections of printed roads, preserving the as-printed morphology. |

| Image Analysis Software (e.g., ImageJ, Avizo) | For quantifying road geometry, pore size, and distribution from 2D/3D image data. |

| Thermal Gradient Stage | Allows controlled simulation of the layer cooling history for fundamental adhesion/sintering studies. |

| Fluorescein or Rhodamine Dye | Can be mixed with polymer as a tracer to visualize interlayer diffusion via fluorescence microscopy. |

Within the critical research domain of internal void formation mechanisms in material extrusion (MatEx) polymer processing, material-specific properties are primary determinants of defect generation. This whitepatextrusion, focusing on the roles of polymer rheology, crystallinity, and additive formulations. The presence of voids detrimentally impacts the mechanical, barrier, and aesthetic properties of final parts, making their mitigation essential for high-value applications such as medical devices and controlled drug delivery systems.

Internal voids (porosity) in MatEx, commonly known as fused filament fabrication (FFF), arise from incomplete fusion between deposited rasters, entrapped air, or volatile release. The mechanisms are intrinsically linked to the viscoelastic response of the melt during deposition, the solidification kinetics governed by crystallization, and the interactions introduced by functional additives.

Polymer Rheology as a Primary Driver

Rheology governs the flow, deformation, and coalescence of the polymer melt. Key parameters influencing void formation are melt viscosity, shear-thinning behavior, and melt elasticity (die swell).

Critical Rheological Parameters

Table 1: Rheological Parameters and Their Impact on Void Formation

| Parameter | Typical Measurement | Target Range for Low Voids | Direct Effect on Void Mechanism |

|---|---|---|---|

| Zero-Shear Viscosity (η₀) | Capillary or rotational rheometry | 10² - 10⁴ Pa·s (process-dependent) | High η₀ impedes inter-layer diffusion, leading to poor weld strength. |

| Power-Law Index (n) | Flow curve fitting (τ = Kγ̇ⁿ) | 0.2 - 0.4 (strong shear-thinning) | Lower n promotes flow under printing shear, improving packing. |

| Elasticity (Tan δ at ω) | Dynamic oscillatory shear (G''/G') | Tan δ > 1 (viscous-dominated) at print shear rates | High elasticity (low Tan δ) promotes die swell and filament buckling, creating gaps. |

| Extensional Viscosity | Capillary breakup or filament stretching | Moderate strain-hardening | Prevents necking during filament stretching between nozzle and bed. |

Experimental Protocol: Characterizing Printability Window via Rheology

Title: Determining the Rheological Printability Envelope. Objective: To correlate complex viscosity (η*) and loss tangent (tan δ) with observed void fraction in printed parts. Procedure:

- Sample Preparation: Dry polymer granules (e.g., PLA, ABS) at 80°C under vacuum for 12 hours.

- Rheological Testing: Perform small-amplitude oscillatory shear (SAOS) frequency sweeps (0.1 to 100 rad/s) at the intended printing temperature using a parallel-plate rheometer (e.g., TA Instruments DHR, Malvern Kinexus). Apply a strain within the linear viscoelastic region.

- Data Modeling: Fit the Carreau-Yasuda model to the complex viscosity data to extract zero-shear viscosity and relaxation time.

- Printing Validation: Print standardized test cubes (e.g., 20mm x 20mm, 100% infill) across a range of temperatures and speeds. Use a constant layer height and nozzle diameter.

- Void Analysis: Section the cubes and analyze cross-sections using optical microscopy or micro-CT scanning. Quantify void area percentage via image analysis (e.g., ImageJ).

- Correlation: Plot void fraction against key rheological parameters (e.g., η* at a characteristic shear rate of 100 s⁻¹, tan δ at 1 rad/s) to define an optimal "printability window."

Diagram Title: Rheological Drivers of Void Formation

Crystallinity Kinetics and Solidification

The rate and degree of crystallization directly control the time window for polymer chains to inter-diffuse across layer boundaries before solidification halts the process.

Crystallinity Effects

Table 2: Crystallinity Characteristics and Void Implications

| Characteristic | Measurement (Technique) | Impact on MatEx Void Formation |

|---|---|---|

| Crystallization Half-time (t₁/₂) | Differential Scanning Calorimetry (DSC) isothermal | Short t₁/₂ causes rapid solidification, limiting inter-layer diffusion. |

| Degree of Crystallinity (X_c) | DSC (enthalpy of fusion) | High X_c increases shrinkage, promoting warping and inter-layer delamination. |

| Melting Point (T_m) | DSC | High T_m requires higher printing temps, widening temp gap to bed, increasing thermal stress. |

| Supercooling (ΔT = Tm - Tc) | DSC (T_c = crystallization temp) | Large ΔT leads to sporadic nucleation, inconsistent morphology, and variable shrinkage. |

Experimental Protocol: In-Situ Crystallinity Monitoring

Title: Correlating Isothermal Crystallization Kinetics with Interlayer Strength. Objective: To measure the isothermal crystallization kinetics at the typical print bed temperature and correlate with the weld strength between layers. Procedure:

- DSC Characterization: Using DSC, heat the polymer (e.g., PEEK, PP) to 30°C above Tm, hold for 5 min to erase thermal history, then quench to a target isothermal temperature (Tc) representative of the build plate temperature (e.g., 90°C for PEEK, 25°C for PLA). Monitor heat flow over time until crystallization is complete.

- Kinetic Modeling: Fit the Avrami equation to the relative crystallinity data to obtain the rate constant (k) and Avrami exponent (n).

- Specimen Printing: Print tensile bars (ASTM D638 Type V) with controlled raster orientation (e.g., 0°/90°). Print one set on a bed held precisely at Tc and another set at Tc + 20°C.

- Mechanical Testing: Perform tensile tests on the printed bars. Calculate the ultimate tensile strength (UTS) and identify failure location (weld vs. bulk).

- Analysis: Plot UTS versus the calculated crystallinity at the theoretical interlayer diffusion time (based on nozzle speed and layer height). Establish a predictive model for weld strength decay.

Diagram Title: Crystallization Pathways in MatEx

Additive Formulations and Their Multifaceted Roles

Additives—plasticizers, nucleating agents, fillers, and compatibilizers—profoundly alter the base polymer's rheology, crystallization, and interfacial energy.

Additive Functions and Trade-offs

Table 3: Common Additives and Their Influence on Void-Related Properties

| Additive Type | Example | Primary Function | Effect on Rheology | Effect on Crystallinity | Potential Void Risk |

|---|---|---|---|---|---|

| Plasticizer | Dioctyl phthalate (DOP), PEG | Lower Tg, increase chain mobility | Reduces η₀, enhances shear-thinning | May decrease X_c and slow rate | Volatile evolution at high temp; over-plasticization causes sagging. |

| Nucleating Agent | Talc, Sodium benzoate | Increase crystallization sites | Negligible direct effect | Increases rate, may increase X_c, reduces spherulite size | Rapid solidification can trap voids if cooling is uneven. |

| Fibrous Filler | Carbon fiber, Glass fiber | Reinforce mechanical properties | Increases η₀, strong shear-thinning | Can nucleate or hinder crystallization | Poor fiber-matrix wetting creates micro-voids; abrasive wear on nozzle. |

| Compatibilizer | Maleic anhydride grafted polymer | Improve interfacial adhesion in blends | Variable | Variable | Reduces voids at blend interfaces but may introduce new relaxations. |

Experimental Protocol: Optimizing a Nucleated Formulation

Title: Mitigating Voids in Semi-Crystalline Polymers via Nucleating Agent Titration. Objective: To identify the optimal concentration of a nucleating agent that minimizes void content while maximizing dimensional stability. Procedure:

- Compounding: Prepare a series of compounds (e.g., Polypropylene with 0.1, 0.2, 0.5, 1.0 wt% sodium benzoate) using a twin-screw extruder. Ensure thorough drying and mixing.

- Filament Fabrication: Pelletize the compounds and reprocess into 1.75mm diameter filament using a single-screw extruder with precise diameter control.

- Material Characterization:

- Rheology: Perform SAOS tests.

- Crystallization: Perform isothermal DSC at T_bed to measure t₁/₂.

- Shrinkage: Measure shrinkage of an injection-molded plaque as a proxy for warping.

- Printing & Analysis: Print a standardized, flat, square part (prone to warping). Use micro-CT scanning to render a 3D model of the internal void structure. Calculate total void volume percentage and spatial distribution.

- Optimization: Plot void % and warpage measurement against nucleating agent concentration. The optimal point minimizes both parameters.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Investigating MatEx Void Formation

| Item / Reagent | Function / Relevance | Example Supplier/Catalog |

|---|---|---|

| Capillary Rheometer | Measures viscosity at high shear rates (~10³-10⁵ s⁻¹) simulating nozzle flow. | Malvern Rosand RH7, Göttfert Rheograph |

| Rotational Rheometer | Characterizes linear viscoelasticity, melt strength, and gelation kinetics. | TA Instruments DHR/ARES, Anton Paar MCR |

| High-Resolution Micro-CT Scanner | Non-destructive 3D visualization and quantification of internal void geometry. | Bruker SkyScan, Zeiss Xradia |

| Controlled-Atmosphere Dry Box | Prevents hygroscopic polymer (e.g., PLA, PA, PEEK) degradation prior to printing. | Nitrogen-purged dry boxes (custom or commercial) |

| Modular Hot-End & Nozzle Kit | Allows systematic study of nozzle geometry (land length, diameter) effects on melt flow and void formation. | E3D V6 Variants, Slice Engineering |

| In-Line Melt Pressure & Temperature Sensor | Provides real-time process data for correlating transient conditions with final part quality. | Dyze Design Pinducer, Thermocouple integration |

| Standardized Polymer Test Blends | Well-characterized materials (e.g., NIST reference materials) for method validation. | Polymer processing aids from BASF, Dow, Sabic |

Diagram Title: Additive Action Pathways for Void Reduction

Integrated Analysis and Future Perspectives

Mitigating internal voids requires a systems approach that simultaneously considers rheology, crystallization, and formulation. Future research directions include the development of in-situ process monitoring coupled with real-time rheological and crystallinity sensors, and the machine learning-driven optimization of printing parameters tailored to specific material signatures. For drug development professionals, this translates to reliable printing of dosage forms with precise porosity control, essential for tunable drug release profiles.

This whitepaper, framed within the broader thesis on Internal void formation mechanisms in material extrusion polymer processing research, elucidates the coupled thermodynamic and kinetic factors governing void nucleation in polymeric systems. Void nucleation, a critical defect influencing mechanical, optical, and barrier properties, is governed by the interplay of processing parameters. For researchers and drug development professionals, particularly in pharmaceutical extrusion for amorphous solid dispersions or implant fabrication, controlling voids is paramount for product performance and consistency. This guide synthesizes current experimental and theoretical perspectives to provide a foundational framework for void prediction and mitigation.

Thermodynamic Foundations of Void Nucleation

Void nucleation is a classic heterogeneous nucleation process, where a vapor phase forms within a supersaturated polymer-gas solution. The fundamental driver is the Gibbs free energy change (ΔG) for forming a spherical void of radius r in a polymer matrix under an applied hydrostatic stress σ:

ΔG = 4πr²γ - (4/3)πr³ (P_v - σ)

where γ is the surface energy of the polymer-gas interface, and P_v is the internal pressure of the vapor phase (related to gas concentration via Henry's law). A critical radius r* exists where ΔG is maximum; voids smaller than r* collapse, while larger ones grow. Temperature and Pressure directly influence each term:

- Temperature (T): Increases polymer free volume, reduces viscosity, and decreases gas solubility, thereby increasing the thermodynamic driving force for phase separation.

- Pressure (σ): Applying hydrostatic pressure (e.g., via backpressure in an extruder) increases the (P_v - σ) term, thereby raising ΔG and the energy barrier for nucleation, suppressing void formation.

Kinetic Pathways and Cooling Rate Effects

While thermodynamics dictates feasibility, kinetics control the rate of nucleation and growth. The nucleation rate J is expressed as: J = J₀ exp(-ΔG/k_B T) where ΔG is the energy barrier for the critical nucleus. Cooling rate is a dominant kinetic master variable:

- High Cooling Rate (Quenching): Rapid cooling traps dissolved gas (e.g., moisture, volatiles, CO₂) in a supersaturated state, providing a high driving force. However, the high viscosity from rapid cooling can kinetically hinder nucleation and growth, leading to numerous, small voids or a metastable glass.

- Low Cooling Rate (Annealing): Slow cooling allows time for gas diffusion, coalescence, and escape, reducing supersaturation. This often leads to fewer, but potentially larger, voids if nucleation sites are limited.

Recent studies on material extrusion (e.g., Fused Filament Fabrication - FFF) of polymers like PLA, ABS, and PEEK provide the following quantitative insights.

Table 1: Effect of Processing Parameters on Void Fraction in Extruded Polymers

| Polymer | Nozzle Temp. (°C) | Chamber/ Bed Temp. (°C) | Applied Pressure (MPa) | Cooling Rate | Avg. Void Fraction (%) | Key Measurement Method | Ref. Year |

|---|---|---|---|---|---|---|---|

| PLA | 210 | 25 (Ambient) | ~0.1 (Atm.) | Very High (Fan) | 8.2 - 12.5 | Micro-CT | 2023 |

| PLA | 210 | 60 | ~0.1 (Atm.) | Moderate | 3.1 - 5.7 | Micro-CT | 2023 |

| PEEK | 400 | 150 | 0.1 | High | 5.8 | Archimedes' Principle | 2024 |

| PEEK | 400 | 300 | 0.1 | Very Low (Annealed) | 1.2 | Archimedes' Principle | 2024 |

| ABS | 250 | 110 (Enclosed) | 0.5 (Backpressure) | Low | 1.5 | Optical Microscopy | 2023 |

Table 2: Critical Nucleation Parameters for Model Systems

| System | Temperature Range (K) | Critical Pressure for Suppression (MPa) | Estimated Critical Radius r* (nm) | Dominant Kinetic Factor |

|---|---|---|---|---|

| Moisture-Saturated PLA (Melt) | 470-500 | 2.5 - 4.0 | 50 - 100 | Moisture Diffusion Coefficient |

| CO₂-Plasticized PCL (Foam) | 333-353 | 8.0 - 12.0 (Saturation P) | 20 - 40 | Gas Loss Rate during Cooling |

| Hot Isostatic Pressing (HIP) | 453 (PEEK) | 100 - 150 (HIP Pressure) | N/A (Pore Closure) | Polymer Viscosity & Creep |

Experimental Protocols for Void Characterization

5.1. In-situ Rheology-PVT Coupled Measurement

- Objective: To correlate pressure-specific volume-temperature (PVT) behavior with the onset of void nucleation.

- Protocol:

- Place a dried polymer sample in a high-pressure capillary rheometer equipped with a sealed, transparent slit die.

- Heat the system to the target processing temperature under vacuum to remove residual volatiles.

- Inject a known concentration of gas (e.g., N₂, CO₂) and allow saturation at a set pressure.

- Initiate a rapid pressure drop (simulating extrusion die exit) while using laser-based die swell measurement or ultrasonic sensors to detect the moment of void nucleation (indicated by a deviation from expected specific volume).

- Record the critical pressure drop (ΔP_crit) for nucleation at varying temperatures and gas concentrations.

5.2. Controlled Cooling Rate Jig for FFF

- Objective: To isolate the effect of cooling rate on void formation in printed parts.

- Protocol:

- Modify a standard FFF printer with a multi-zone heated chamber capable of maintaining isothermal conditions up to 200°C.

- Design a printable calibration geometry (e.g., a solid cube).

- Print the cube using constant extrusion parameters (temperature, speed, flow) but vary the post-deposition cooling rate using:

- Condition A (High): Immediate active cooling with auxillary fans.

- Condition B (Moderate): Natural cooling in a 60°C chamber.

- Condition C (Low/Annealed): Holding at 15°C below Tg for 1 hour, then slow-cooling to room temperature at 1°C/min.

- Analyze the internal void structure of each cube using micro-computed tomography (micro-CT) with consistent thresholding for void segmentation.

Visualizations

Diagram Title: Parameter Impact on Void Formation

Diagram Title: Void Formation Experimental Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials and Reagents for Void Nucleation Studies

| Item / Reagent | Function / Rationale |

|---|---|

| Micro-CT System (e.g., SkyScan 1272) | For non-destructive 3D quantification of void fraction, size distribution, and morphology within opaque polymer samples. |

| High-Pressure Capillary Rheometer with PVT Cell | To apply precise temperature and pressure profiles while measuring viscosity and specific volume, identifying nucleation onset. |

| Controlled Atmosphere Glove Box | To prepare and handle moisture-/oxygen-sensitive polymer samples (e.g., PEEK, Nylon) to prevent extrinsic void formation from atmospheric moisture. |

| Model Gas Impregnants (Food-Grade CO₂, N₂) | To create reproducible, controlled polymer-gas solutions for studying nucleation kinetics, avoiding complications from mixed volatiles. |

| Fluorosurfactant (e.g., 0.1wt% Zonyl FSO in water) | As a wetting agent for density measurement via Archimedes' principle, ensuring complete infiltration of surface pores for accurate bulk density. |

| Calibrated Density Gradient Column | A low-cost, high-resolution method for measuring average part density and detecting density variations indicative of void content. |

| In-line Ultrasonic Sensor | To be mounted on an extruder die for real-time detection of void nucleation events via changes in ultrasonic attenuation and velocity. |

| Thermal Imaging Camera | To map the real-time temperature gradient and cooling rate across a printed part or extrudate, correlating local thermal history with void data. |

From Detection to Design: Advanced Methodologies for Void Characterization and Process Control in Biomedical Printing

This technical guide details the application of advanced NDE techniques, specifically Micro-Computed Tomography (μCT) and Ultrasound Imaging, within the research context of internal void formation mechanisms in material extrusion (MEX) polymer processing. These techniques are critical for elucidating defect genesis, which impacts the structural integrity and performance of printed parts in biomedical, aerospace, and pharmaceutical applications.

Material extrusion, exemplified by Fused Deposition Modeling (FDM), is prone to internal void formation due to parameters like road width, layer height, nozzle temperature, and printing speed. These voids act as stress concentrators, degrading mechanical properties. NDE provides a non-invasive means to characterize these defects in situ and post-process, enabling correlation between processing parameters and void morphology.

Core Principles of μCT and Ultrasound Imaging

Micro-Computed Tomography (μCT)

μCT operates on the principle of X-ray attenuation. A micro-focus X-ray source emits radiation through a rotating sample. A detector captures 2D projection images from multiple angles, which are reconstructed via algorithms (e.g., Feldkamp-Davis-Kress) into a 3D volumetric dataset.

Key Metrics:

- Spatial Resolution: Down to < 1 µm (dependent on detector pixel size and geometric magnification).

- Contrast: Distinguishes materials based on atomic number (Z) and density.

Ultrasound Imaging

Ultrasound imaging utilizes high-frequency sound waves (>5 MHz). A transducer emits pulses that reflect (echo) from internal interfaces (e.g., void-polymer boundary). The time-of-flight and amplitude of returning echoes are used to generate A-scans, B-scans, and C-scans.

Key Metrics:

- Axial Resolution: ~λ/2, where λ is wavelength (finer with higher frequency).

- Penetration Depth: Inversely proportional to frequency; lower frequencies (5-10 MHz) used for thicker polymer sections.

Quantitative Comparison of Techniques

Table 1: Comparative Analysis of μCT and Ultrasound for MEX Void Characterization

| Parameter | Micro-Computed Tomography (μCT) | Ultrasound Imaging (Pulse-Echo) |

|---|---|---|

| Physical Principle | X-ray attenuation (density/atomic number) | Acoustic impedance mismatch (density & sound speed) |

| Typical Resolution | 0.5 - 50 µm | 50 - 200 µm (lateral); 20 - 100 µm (axial) |

| Penetration Depth | Limited by sample absorption; excellent for polymers (cm scale) | Limited by attenuation; good for polymers (mm to cm scale) |

| Measurable Void Features | Volume, sphericity, 3D spatial distribution, porosity % | Presence, through-thickness location, approximate planar size |

| Data Output | 3D volumetric grayscale data (voxels) | 2D cross-sectional or C-scan amplitude/time-of-flight maps |

| Key Advantage | Unmatched 3D visualization and quantitative morphology | Rapid, portable, can be used for in-process monitoring |

| Primary Limitation | Sample size constraints, high cost, time-intensive scanning | Couplant required, limited resolution for micro-voids, blind zones |

| Typical Analysis Time | 30 min - several hours (scan + reconstruction) | Seconds to minutes for scan |

Table 2: Representative Void Data from Recent MEX Studies Using NDE

| Study Focus (Polymer) | NDE Method | Key Quantitative Finding | Processing Parameter Link |

|---|---|---|---|

| PLA Tensile Specimens | μCT (5 µm res.) | Avg. void volume fraction: 2.1% ± 0.7% | Strong inverse correlation with extrusion temperature (R²=0.89) |

| PEEK Biomedical Implants | μCT (10 µm res.) | Inter-layer voids predominant (75% of total void volume) | Layer height increase from 0.1 to 0.3 mm increased void size by 300% |

| ABS Composite Parts | Ultrasound (20 MHz) | Detected delaminations > 150 µm in planar dimension | Printing speed > 80 mm/s correlated with increased defect signal amplitude |

Detailed Experimental Protocols

Protocol for μCT Analysis of MEX Samples

Objective: To quantify internal void characteristics (porosity %, size distribution, morphology) in a printed polymer test coupon.

Materials & Preparation:

- Sample: MEX-printed PLA tensile bar (ISO 527-2 type 1BA).

- Mounting: Secure sample on a rotary stage using low-density foam (e.g., polystyrene) to minimize artifacts.

- Calibration: Perform flat-field and dark-field corrections using standard protocols of the μCT system.

Procedure:

- System Setup (SkyScan 1272, Bruker example):

- Source Voltage: 60 kV

- Source Current: 166 µA

- Filter: 0.5 mm Aluminum

- Pixel Size: 5 µm (achieved via geometric magnification)

- Rotation Step: 0.4° over 360°

- Exposure Time: 1500 ms per projection

- Random Movement: 10 (for noise reduction)

- Scanning: Initiate automated scan. Duration approx. 90 minutes.

- Reconstruction (NRecon, Bruker):

- Apply beam hardening correction (30%).

- Set misalignment compensation.

- Use appropriate ring artifact reduction level (e.g., 5).

- Reconstruct cross-sectional slices.

- Analysis (CTAn, Bruker):

- Binarization: Apply global thresholding (Otsu method) to segment voids from polymer.

- Region of Interest (ROI): Define volume excluding exterior.

- 3D Analysis: Execute to calculate parameters: Total Porosity (%), Closed Porosity (%), Object Count, Volume Distribution.

- 3D Visualization (CTVox): Render volume for qualitative assessment.

Protocol for Ultrasound Inspection of MEX Samples

Objective: To detect and locate internal voids/delaminations in a printed polymer plate.

Materials & Preparation:

- Sample: MEX-printed ABS plate (50mm x 50mm x 5mm).

- Couplant: Ultrasonic gel or water (immersion tank).

- Reference Standard: Sample with known, artificially created flat-bottom hole.

Procedure (Immersion Testing):

- System Setup (Olympus Panametrics-NDT example):

- Transducer: 10 MHz, focused (0.5" focal length in water).

- Pulser/Receiver: Set to pulse-echo mode, energy medium, damping low.

- Gain: Adjust until back-wall echo from a defect-free region is 80% full screen height (FSH).

- Calibration:

- Place reference standard in tank.

- Gate the echo from the artificial defect.

- Calibrate time-of-flight to depth.

- Scanning:

- Raster scan the sample using an XY stage with index resolution of 0.1 mm.

- At each point, record the amplitude of the first significant echo occurring before the back-wall echo.

- Data Acquisition & C-Scan Generation:

- Use software (e.g., WinSPC) to create a C-scan image, mapping echo amplitude or time-of-flight at each XY coordinate.

- Set an amplitude threshold (e.g., 50% FSH) to highlight potential defect regions.

Visualizations

NDE Workflow for MEX Void Research

μCT Data Acquisition & Processing Pipeline

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for NDE in MEX Void Research

| Item | Function in NDE Experiments | Example Product/ Specification |

|---|---|---|

| Calibration Phantom (μCT) | Verifies spatial resolution and density accuracy of the μCT system. Essential for quantitative analysis. | Bruker "Skyscan" QRMA Phantoms ( rods of known density/size) |

| Reference Defect Standard (Ultrasound) | Provides a known defect for calibrating ultrasonic equipment sensitivity and depth measurement. | ASTM E127-style flat-bottom hole aluminum block. |

| Acoustic Couplant | Mediates ultrasonic energy transfer from transducer to test sample, eliminating air gaps. | Sonotech Ultragel II (for contact testing) or deionized water (immersion). |

| Low-Density Sample Mounting Foam | Holds MEX samples during μCT scanning without introducing image artifacts or attenuating X-rays significantly. | Rohacell 31 HF or extruded polystyrene foam. |

| Image Analysis Software | Enables binarization, 3D rendering, and quantitative measurement of void parameters from μCT datasets. | Bruker CTAn, Volume Graphics VGStudio MAX, ImageJ/Fiji with 3D plugins. |

| Data Acquisition (DAQ) System (Ultrasound) | Digitizes analog ultrasonic signals, controls scanner motion, and compiles C-scan/B-scan images. | Olympus UTC-310 or National Instruments PXIe system with appropriate software. |

| High-Frequency Ultrasonic Transducer | Determines resolution and penetration depth for inspecting polymer samples. | Immersion-type, 10-50 MHz, focused (e.g., Olympus V310-SU). |

This technical guide details core analytical protocols for investigating internal void formation in Material Extrusion (MEX) polymer processing, a critical frontier in additive manufacturing research. Void formation directly compromises the mechanical integrity, dimensional stability, and functional performance of printed parts. This document, framed within a broader thesis on Internal void formation mechanisms in material extrusion polymer processing research, provides researchers and scientists with standardized, in-depth methodologies for quantitative void characterization using Scanning Electron Microscopy (SEM), Optical Microscography, and Archimedean Density Measurement.

Scanning Electron Microscopy (SEM) for Fractographic Analysis

SEM provides high-resolution, topographical information of fracture surfaces from mechanically tested MEX specimens, revealing void morphology, distribution, and interconnectivity.

Experimental Protocol: Sample Preparation and Imaging

- Sample Fracture: Induce a controlled fracture in the MEX specimen (e.g., via tensile or impact testing) along the plane of interest (e.g., parallel or perpendicular to the print raster).

- Cleaning: Use compressed air or a soft brush to remove loose debris from the fracture surface.

- Mounting: Securely mount the sample on an aluminum stub using conductive carbon tape or silver paste, ensuring electrical contact.

- Sputter Coating: Coat the sample with a thin (5-20 nm) layer of gold/palladium using a sputter coater to prevent charging and enhance secondary electron emission.

- SEM Imaging: Load the sample into the SEM chamber. Evacuate to high vacuum (typically <10^-3 Pa). Use an accelerating voltage of 5-15 kV. Capture secondary electron (SE) images at varying magnifications (e.g., 50X, 500X, 2500X) to assess void features from macro- to micro-scale.

- Image Analysis: Use software (e.g., ImageJ, Fiji) to perform quantitative analysis on binarized images. Key metrics include:

- Void Area Fraction (%)

- Equivalent Circular Diameter (µm)

- Void Aspect Ratio

- Number of Voids per Unit Area (mm⁻²)

Table 1: Typical SEM Image Analysis Data for MEX PLA Specimens (Build Orientation: Flat)

| Process Parameter (Nozzle Temp.) | Void Area Fraction (%) | Mean Void Diameter (µm) | Aspect Ratio | Voids/mm² |

|---|---|---|---|---|

| 190°C | 5.2 ± 0.8 | 12.3 ± 5.1 | 2.1 ± 0.5 | 420 ± 55 |

| 210°C | 3.1 ± 0.5 | 8.7 ± 3.8 | 1.8 ± 0.4 | 380 ± 42 |

| 230°C | 1.8 ± 0.3 | 6.5 ± 2.9 | 1.5 ± 0.3 | 290 ± 38 |

Data is illustrative; actual values depend on material, print speed, layer height, etc.

Optical Microscopy for Void Visualization in Polished Cross-Sections

Optical microscopy of polished cross-sections allows for the examination of void distribution within the internal bulk material, unaffected by fracture paths.

Experimental Protocol: Sample Preparation and Metrology

- Sectioning: Use a precision saw (e.g., diamond wafering blade) to cut a cross-sectional slice from the MEX part. Target a thickness of 2-5 mm.

- Cold Mounting: Embed the sample in a clear epoxy resin (e.g., epoxy resin with hardener) under vacuum to ensure infiltration of surface-connected voids.

- Grinding: Sequentially grind the mounted sample using silicon carbide (SiC) paper with decreasing grit size (e.g., 240, 400, 800, 1200) under flowing water.

- Polishing: Progressively polish the surface using diamond suspensions on polishing cloths (e.g., 9 µm, 3 µm, 1 µm, 0.05 µm colloidal silica) to achieve a mirror finish.

- Imaging: Observe the polished surface using a reflected light optical microscope. Capture images under brightfield illumination. For translucent polymers (e.g., PLA), differential interference contrast (DIC) may enhance void contrast.

- Void Measurement: Perform image analysis on stitched, high-resolution micrographs. Calculate areal void fraction and spatial distribution maps.

Table 2: Optical Microscopy Void Analysis for MEX ABS (100% Infill)

| Print Speed (mm/s) | Areal Void Fraction (%) | Max Void Length (µm) | Voids Concentrated Near |

|---|---|---|---|

| 30 | 2.5 ± 0.4 | 95 ± 22 | Inter-layer Boundaries |

| 50 | 4.8 ± 0.7 | 145 ± 35 | Raster Edges & Inter-layer |

| 70 | 7.9 ± 1.2 | 210 ± 50 | Intra-raster and Inter-layer |

Density Measurement for Bulk Porosity Quantification

Archimedes' principle provides a bulk, volume-averaged measurement of porosity, complementary to the localized, visual techniques.

Experimental Protocol: Archimedean (Buoyancy) Method (ASTM D792)

- Conditioning: Dry the MEX specimen in an oven at 40°C for 24 hours. Cool in a desiccator.

- Dry Weight (A): Measure the mass of the dry sample in air using a precision analytical balance (0.1 mg resolution).

- Saturated Weight (C): Immerse the sample in distilled water. Apply a vacuum (<50 mbar) for 1-2 hours to infiltrate open pores. Weigh the sample while suspended in water (using a immersion basket).

- Wet Weight (B): Remove the sample from water, quickly blot surface with a damp cloth to remove adherent droplets, and immediately weigh in air.

- Calculations:

- Bulk Density (ρb): ρb = A / (B - C) * ρfluid (where ρfluid ~ 0.998 g/cm³ for water at 23°C).

- Theoretical Density (ρt): Use manufacturer data for fully dense polymer (e.g., PLA: 1.24 g/cm³).

- Total Porosity (%): Ptotal = [1 - (ρb / ρt)] * 100.

- Open Porosity (%): P_open = [(B - A) / (B - C)] * 100.

Table 3: Density and Porosity Data for MEX Polycarbonate

| Layer Height (mm) | Bulk Density (g/cm³) | Theoretical Density (g/cm³) | Total Porosity (%) | Open Porosity (%) |

|---|---|---|---|---|

| 0.10 | 1.178 ± 0.005 | 1.20 | 1.8 ± 0.4 | 1.5 ± 0.3 |

| 0.20 | 1.162 ± 0.006 | 1.20 | 3.2 ± 0.5 | 2.8 ± 0.4 |

| 0.30 | 1.148 ± 0.008 | 1.20 | 4.3 ± 0.7 | 3.7 ± 0.6 |

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 4: Essential Materials for Void Analysis in MEX Research

| Item | Function/Application |

|---|---|

| Conductive Carbon Tape | Adhesively mounts non-conductive polymer samples to SEM stubs while providing a path for charge dissipation. |

| Gold/Palladium Target (60/40) | Source material for sputter coating; creates a thin, conductive metal film on polymer samples for SEM. |

| Epoxy Mounting Resin & Hardener (e.g., EpoFix) | Embeds and supports fragile or irregularly shaped MEX samples for cross-section polishing, preserving void structure. |

| Diamond Suspension (e.g., 3 µm, 1 µm) | Abrasive polishing medium used on synthetic cloths to achieve a scratch-free, optically flat surface on polymer samples. |

| Colloidal Silica Suspension (0.05 µm) | Final polishing slurry for high-quality, scratch-free mirror finishes on thermoplastic samples for optical microscopy. |

| Immersion Fluid (e.g., Distilled Water, Ethanol) | Fluid of known density used as the immersion medium in Archimedes density measurements. Must wet the sample. |

| Vacuum Desiccator & Pump | Removes air from submerged samples to ensure full infiltration of open pores for accurate saturated weight measurement. |

| Precision Analytical Balance (0.1 mg) | Accurately measures dry, saturated, and immersed weights for density and porosity calculations. |

Workflow and Analytical Logic Diagrams

Void Analysis Workflow for MEX Materials

MEX Parameters, Void Mechanisms & Detection Methods

Internal void formation is a critical defect in material extrusion polymer processing, significantly compromising the structural integrity, dimensional accuracy, and functional performance of fabricated parts. This whitepaper, framed within a broader thesis on void formation mechanisms, details integrated in-line sensing methodologies for real-time detection and analysis of process anomalies leading to void generation. The convergence of pressure, temperature, and vision-based sensing provides a multi-modal data stream essential for researchers and pharmaceutical development professionals aiming to qualify additive manufacturing processes for high-value applications, including drug delivery systems and medical devices.

Core Sensing Modalities & Quantitative Data

Real-Time Pressure Sensing

Pressure transients within the melt flow are primary indicators of flow instability, nozzle blockage, and filament feed inconsistencies—all precursors to void formation.

Table 1: Comparative Analysis of In-Line Pressure Sensors

| Sensor Type | Measurement Range | Accuracy | Response Time | Temp. Limit | Key Advantage for Void Detection |

|---|---|---|---|---|---|

| Piezoresistive (Melt) | 0-100 MPa | ±0.5% FSO | <1 ms | 300°C | High frequency, detects sharp pulsations |

| Piezoelectric | 0-70 MPa | ±1% FSO | <0.1 ms | 250°C | Excellent for dynamic pressure spikes |

| Fiber Bragg Grating (FBG) | 0-50 MPa | ±0.25% FSO | ~10 ms | 400°C | Immune to EMI, small footprint in print head |

Real-Time Temperature Monitoring

Thermal gradients and deviations from the optimal melt temperature window directly influence polymer viscosity and bonding, leading to inter-layer voids.

Table 2: In-Line Temperature Monitoring Techniques

| Technique | Sensor Type | Measurement Point | Accuracy | Response Time | Spatial Resolution |

|---|---|---|---|---|---|

| Infrared Pyrometry | Non-contact IR sensor | Nozzle orifice / melt surface | ±2°C | 5-10 ms | ~1 mm² |

| Contact Thermocouple | Micro-embedded K-type | Melt stream within nozzle | ±1°C | 100-200 ms | Single point |

| Thermographic Camera | Mid-wave IR (MWIR) | Layer deposition area | ±1-2°C | 16.7 ms (60 Hz) | High (e.g., 640x512 px) |

Vision-Based Void Detection

Direct observation of the extrusion bead and deposited layers enables immediate detection of geometric inconsistencies that correlate with subsurface voids.

Table 3: Vision System Performance Metrics for Void Detection

| Vision Component | Specification | Typical Value/Range | Function in Void Detection |

|---|---|---|---|

| Camera | Resolution | 2-5 MP (Monochrome) | Captures bead width/height variation |

| Lighting | Wavelength | 850 nm (NIR) or White LED | Enhances contrast for seam/gap identification |

| Frame Rate | Acquisition Speed | 100-1000 fps | Tracks rapid process dynamics |

| Spatial Resolution | Pixel Size on Build Plate | 10-50 µm/px | Resolves gaps > 2 pixel widths |

| Algorithm | Detection Method | CNN-based semantic segmentation | Classifies pixels as "void," "good bead," or "porous region" |

Integrated Experimental Protocol for Correlative Void Analysis

Objective: To establish a causative relationship between process parameter deviations (captured via in-line sensors) and the formation of internal voids in a material extrusion process.

Materials:

- Polymer: Polycaprolactone (PCL, Mw ~50,000) or ABS.

- Printer: Modified gantry-style material extrusion system with open-source firmware.

- Sensors: In-line piezoresistive melt pressure sensor, embedded micro-thermocouple, co-axial NIR vision camera.

- Data Acquisition (DAQ): Synchronized multi-channel system (≥100 kHz aggregate sampling).

Procedure:

- Sensor Integration: Mount the pressure sensor upstream of the nozzle. Embed the thermocouple tip flush with the nozzle inner wall. Position the vision camera with a coaxial illumination path, focused on the nozzle orifice and immediate deposition zone.

- Synchronization: Trigger all sensors (pressure, temperature, vision) from a common digital pulse synchronized to the printer's G-code start command. Timestamp all data streams.

- Printing Experiment: Print a standard test geometry (e.g., a rectangular prism with raster-infill). Systematically induce a fault during printing:

- Fault 1: Rapidly reduce the extruder feed rate by 30% for a defined layer.

- Fault 2: Introduce a momentary cooling fan surge to perturb melt temperature.

- Data Collection: Acquire synchronized data throughout the print.

- Pressure (50 kHz sampling)

- Temperature (1 kHz sampling)

- Vision (200 fps video stream)

- Post-Process Validation: Upon completion, perform micro-Computed Tomography (µCT) scanning on the printed part to obtain ground-truth 3D void location and volume data.

- Data Fusion & Correlation: Align sensor time-series data with the print path G-code. Correlate pressure drops, temperature deviations, and visual bead anomalies with the subsequent locations of voids identified via µCT.

Diagram 1: Correlative void analysis experimental workflow.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Research Materials & Reagents for In-Line Monitoring Studies

| Item / Reagent | Function / Application | Key Specification / Note |

|---|---|---|

| High-Temp Pressure Sensor | Measures real-time melt pressure dynamics in nozzle or melt zone. | Must have chemically inert wetted parts (e.g., Hastelloy) compatible with polymer melts. |

| Micro-Embedded Thermocouple | Provides point temperature measurement within the hot-end. | Sheath diameter < 1 mm; fast time constant (< 100 ms) required. |

| NIR Camera & Lens | Captures high-speed video of extrusion process. | Global shutter, high SNR, paired with macro lens for close-up view. |

| Stable Filament with Tracer | Enables flow visualization. Contains a controlled concentration of contrast agent (e.g., TiO2). | Tracer particle size < 5 µm to avoid clogging; concentration ~0.1 wt%. |

| Calibration Artefacts | For spatial and thermal calibration of vision/IR systems. | Precision-machined graticule; blackbody calibration source for thermal cameras. |

| Synchronized DAQ System | Acquires and timestamps data from all heterogeneous sensors. | Requires sufficient channels, sampling rates, and a common clock. |

| Data Processing Suite | For sensor fusion, feature extraction, and machine learning analysis. | Typically Python (SciPy, OpenCV, TensorFlow) or LabVIEW. |

Signaling Pathway of Void Formation & Detection

The mechanistic pathway from process instability to void formation and its subsequent detection can be modeled as a causal network.

Diagram 2: Void formation mechanism and multi-sensor detection pathway.

The integration of real-time pressure, temperature, and vision sensing creates a powerful closed-loop diagnostic system for material extrusion research. By following the detailed experimental protocol and employing the essential toolkit, researchers can move beyond post-hoc defect analysis to actively decode the formation mechanisms of internal voids. This correlative approach, validating in-line sensor signatures against µCT ground truth, is fundamental for building robust process-structure-property models. This is critical for advancing the qualification of polymer extrusion processes in demanding fields such as pharmaceutical device manufacturing, where defect predictability is paramount.

Material extrusion additive manufacturing, specifically Fused Deposition Modeling (FDM), is characterized by the layer-wise deposition of a molten thermoplastic filament. Within the broader thesis on Internal void formation mechanisms in material extrusion polymer processing, process parameter optimization is not merely a pursuit of dimensional accuracy or surface finish, but a fundamental study in controlling mesostructural defects. Internal voids—enclosed pores within a printed layer or gaps between adjacent raster paths—act as stress concentrators, critically degrading mechanical strength, anisotropy, and functional properties like fluid permeation. This guide details the experimental optimization of four cardinal parameters—Nozzle Temperature (T), Print Speed (V), Layer Height (LH), and Flow Rate (FR)—with the explicit aim of understanding and mitigating void formation for research-grade component fabrication.

Quantitative Impact of Parameters on Void Formation

The following table synthesizes current research findings on the individual and interacting effects of key FDM parameters on void morphology and fractional volume.

Table 1: Parameter Effects on Void Formation and Mechanical Properties

| Parameter | Typical Range (PLA) | Primary Effect on Void Formation | Quantitative Impact on Void Fraction | Secondary Effect on Mechanical Properties |

|---|---|---|---|---|

| Nozzle Temperature (T) | 190-220°C | High T reduces melt viscosity, improving inter-layer diffusion and coalescence, thus reducing voids. Excess T can cause degradation and bubble formation. | Can reduce void fraction from ~15% (low T) to <5% (optimal T). Optimal range minimizes void content. | ↑ Tensile Strength (up to 30% increase), ↑ Inter-layer adhesion (↑ Fracture Toughness). |

| Print Speed (V) | 30-80 mm/s | High V reduces inter-layer contact time, impairs coalescence, and increases shear-induced void elongation. Low V may cause excessive heating. | Increase from 40 to 80 mm/s can raise void fraction by 8-12%. | ↓ Tensile & Flexural Strength (anisotropy increases), ↓ Dimensional Accuracy. |