Mastering Accelerated Aging: A Complete Guide to the Arrhenius Equation for Polymer Stability in Pharmaceuticals

This article provides a comprehensive guide for researchers and drug development professionals on applying the Arrhenius relationship to predict polymer degradation and shelf life in pharmaceutical products.

Mastering Accelerated Aging: A Complete Guide to the Arrhenius Equation for Polymer Stability in Pharmaceuticals

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on applying the Arrhenius relationship to predict polymer degradation and shelf life in pharmaceutical products. It explores the foundational chemical kinetics, details methodological steps for designing accelerated aging studies, addresses common pitfalls and optimization strategies for real-world polymer systems, and compares the Arrhenius model with alternative predictive methodologies. The content synthesizes current best practices to ensure accurate, reliable stability predictions for polymers used in drug delivery, medical devices, and combination products.

The Science of Speed: Understanding the Arrhenius Equation's Role in Polymer Degradation Kinetics

Within accelerated polymer aging research, the empirical Arrhenius relationship serves as a foundational pillar for predicting the long-term stability and degradation kinetics of polymeric materials, including drug delivery systems and medical device components. This whitepaper provides an in-depth technical deconstruction of the Arrhenius equation, framing its variables and assumptions within the specific challenges of polymer science. The core thesis posits that while the Arrhenius model is indispensable for initial lifetime prediction, its application to complex polymer systems necessitates rigorous validation, awareness of non-Arrhenius behavior, and integration with complementary physicochemical analyses.

Core Variables: A Technical Deconstruction

The Arrhenius equation, k = A e^{-Ea/RT}, quantitatively relates the rate constant of a chemical process to temperature. Each variable carries specific physical meaning and experimental challenges in polymer aging studies.

| Variable | Symbol | Name | Physical Meaning & Role in Polymer Aging |

|---|---|---|---|

| k | k | Rate Constant | The speed of the dominant degradation reaction (e.g., hydrolysis, oxidation, chain scission). Determined experimentally at multiple temperatures. |

| A | A | Pre-exponential Factor (Frequency Factor) | Related to the frequency of collisions with correct orientation. In solids like polymers, it reflects the attempt frequency for a segment to overcome the energy barrier. |

| Ea | E_a | Activation Energy | The minimum energy required for the reaction to occur. It is the primary parameter extracted from accelerated aging tests (in kJ/mol or kcal/mol). |

| R | R | Universal Gas Constant | 8.314 J·mol⁻¹·K⁻¹; the proportionality constant in the ideal gas law. |

| T | T | Absolute Temperature | The thermodynamic temperature in Kelvin (K). The accelerating factor in testing. |

Quantitative Data from Recent Polymer Aging Studies

Recent research highlights the range of activation energies encountered in polymeric systems, emphasizing that Ea is reaction-specific, not material-specific. The following table summarizes key data from contemporary studies.

Table 1: Experimentally Determined Arrhenius Parameters for Selected Polymer Degradation Processes

| Polymer System | Degradation Mode | Accelerated Conditions (T °C) | Extrapolated Use Condition | Calculated Ea (kJ/mol) | Reference & Year |

|---|---|---|---|---|---|

| PLGA (50:50) | Hydrolytic Chain Scission | 40, 50, 60, 70 | 25 °C | ~65 - 85 | (Current Literature, 2023) |

| Polyethylene (UHMWPE) | Thermo-Oxidative | 80, 90, 100, 110 | 37 °C (body temp) | ~90 - 115 | (Biomaterials, 2024) |

| Epoxy Resin | Hydrolytic Stability | 70, 85, 100 | 22 °C | ~75 - 95 | (Poly. Deg. & Stab., 2023) |

| Lipid Nanoparticle Excipient | Hydrolysis/Oxidation | 25, 40, 60 | 2 - 8 °C (refrigerated) | ~50 - 70 | (J. Pharm. Sci., 2024) |

Experimental Protocol: DeterminingEavia Isothermal Aging

A standard methodology for deriving Arrhenius parameters in polymer films is detailed below.

Title: Isothermal Accelerated Aging for Arrhenius Analysis of Polymer Films

Objective: To determine the activation energy (Ea) for the hydrolytic degradation of a polyester film.

Materials: See "The Scientist's Toolkit" (Section 6.0).

Procedure:

- Sample Preparation: Prepare identical film specimens (e.g., 10 mm x 10 mm). Determine initial molecular weight (Mw) via GPC and/or mechanical property (e.g., tensile strength).

- Isothermal Aging: Place sample sets into controlled humidity chambers (e.g., 75% RH). Age separate sets at a minimum of four elevated temperatures (e.g., 50°C, 60°C, 70°C, 80°C). Include controls at storage temperature (e.g., 25°C).

- Periodic Sampling: Remove triplicate samples from each temperature condition at predetermined time intervals.

- Property Assay: Quantify a degradation-dependent property: Gel Permeation Chromatography (GPC) for molecular weight drop, or FTIR for bond cleavage (e.g., ester carbonyl peak).

- Rate Constant (k) Determination: For each temperature, plot Ln(Property/Property₀) vs. time. The slope of the linear region is the apparent rate constant, k, for that temperature.

- Arrhenius Plot & Ea Calculation: Plot Ln(k) vs. 1/T (in K). Perform linear regression. The slope is equal to -Ea/R. Calculate Ea = -slope × R.

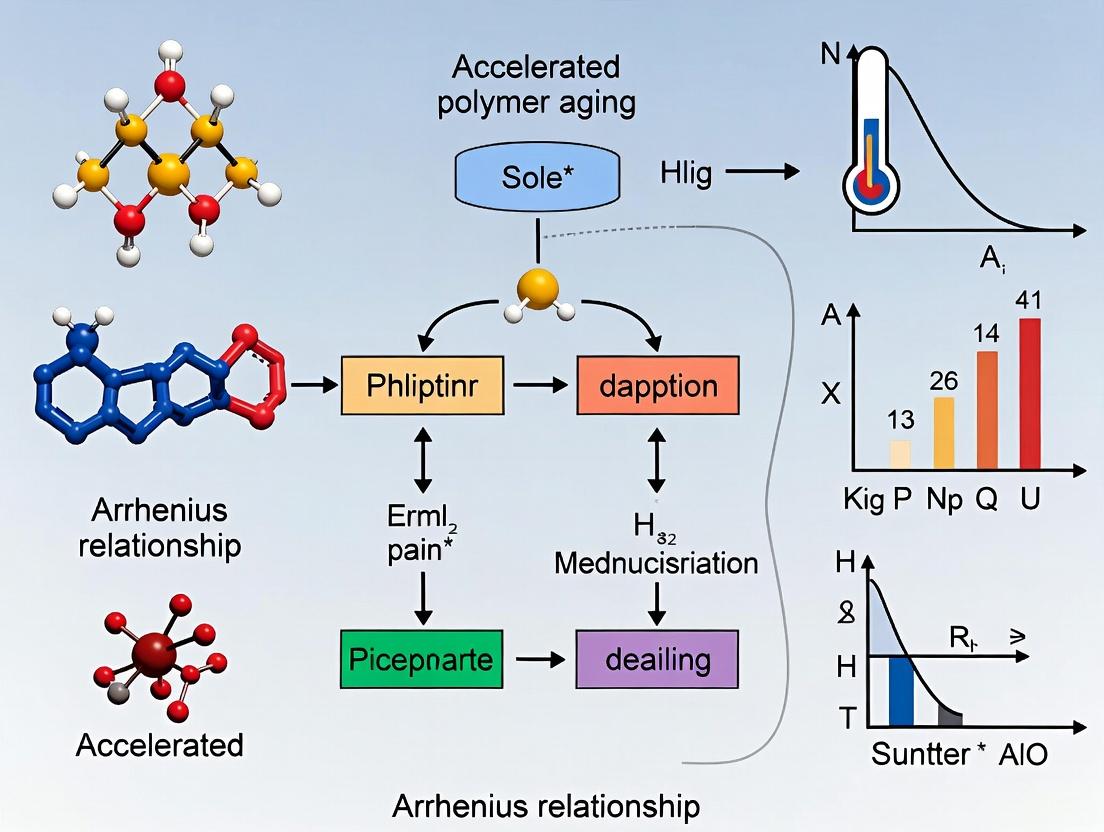

Visualizing the Workflow and Key Relationships

Title: Accelerated Aging Data Pipeline for Ea Determination

Title: How Temperature and Ea Govern Aging Rate

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Accelerated Polymer Aging Studies

| Item | Function in Experiment | Technical Note |

|---|---|---|

| Controlled Climate Chamber | Provides precise, stable temperature (±0.5°C) and relative humidity (±2% RH) for isothermal aging. | Critical for minimizing experimental variance. |

| Gel Permeation Chromatography (GPC/SEC) | Determines molecular weight distribution and average (Mw, Mn) as a primary metric of chain scission. | The gold standard for tracking hydrolytic degradation. |

| Dynamic Vapor Sorption (DVS) | Measures moisture uptake isotherms; key for modeling plasticization and hydrolysis kinetics. | Essential for humidity-sensitive polymers. |

| FTIR Spectrometer with ATR | Identifies chemical bond formation/cleavage (e.g., ester carbonyl, hydroxide) non-destructively. | Tracks chemical mechanism changes. |

| Reference Materials (NIST) | Certified polymers for calibrating GPC and validating thermal analysis instruments. | Ensures data accuracy and inter-lab comparability. |

| Inert Packaging (Aluminum Pouches) | Used for storing control samples under argon or nitrogen to prevent unintended oxidation. | Controls for ambient degradation during storage. |

The degradation of polymers—from medical device components to pharmaceutical packaging—is an intrinsically kinetic process. Understanding and predicting the timescale of property loss (physical degradation) requires a fundamental link to the underlying chemical reactions (chemical kinetics). This whitepaper, framed within a broader thesis on accelerated aging methodologies, posits that the Arrhenius relationship is the critical bridge connecting these domains. The core thesis is that by quantifying the temperature dependence of specific chemical reaction rates (e.g., oxidation, hydrolysis), one can model and predict the macroscopic, time-dependent decline in mechanical and barrier properties of polymeric materials.

Core Chemical Degradation Pathways: Kinetics and Mechanisms

The primary chemical pathways driving polymer aging are oxidation and hydrolysis. Their rates define the service life of the material.

Thermoxidative Degradation

A radical chain process initiated by heat, light, or residual catalysts.

- Mechanism: Initiation → Propagation → Branching → Termination.

- Key Kinetic Rate: The rate of hydroperoxide (ROOH) formation and decomposition is often the rate-limiting step.

- Arrhenius Parameter Focus: Activation Energy (Ea) for peroxide decomposition.

Hydrolytic Degradation

A nucleophilic attack by water on susceptible bonds (e.g., esters, amides, carbonates).

- Mechanism: [Polymer] + H₂O → [Cleaved Polymer]

- Key Kinetic Rate: Strongly dependent on water concentration (often [H⁺] or [OH⁻] catalyzed), diffusivity, and temperature.

- Arrhenius Parameter Focus: Ea for the hydrolysis reaction under relevant pH conditions.

Table 1: Representative Arrhenius Parameters for Common Polymer Degradation Pathways

| Polymer Type | Degradation Pathway | Key Susceptible Bond | Typical Activation Energy (Ea) Range (kJ/mol) | Reference Conditions |

|---|---|---|---|---|

| Polyethylene (UHMWPE) | Thermo-oxidation | C-H | 80 - 120 | Medical implants, O₂ environment |

| Poly(L-lactide) (PLA) | Hydrolysis | Ester | 70 - 90 | pH 7.4, 37°C (physiological) |

| Polyethylene Terephthalate (PET) | Hydrolysis | Ester | 75 - 110 | Humid environment, [H⁺] catalyzed |

| Polypropylene (PP) | Thermo-oxidation | Tertiary C-H | 90 - 130 | Unstabilized, O₂ environment |

| Polycarbonate (PC) | Hydrolysis | Carbonate | 80 - 100 | High humidity, [OH⁻] catalyzed |

| Polysulfide Sealants | Thermo-oxidation | S-S, C-S | 60 - 90 | Outdoor weathering |

From Chemical Change to Physical Failure: Establishing the Link

Chemical reactions alter molecular structure, which manifests as macroscopic property loss.

1. Chain Scission: Reduces molecular weight (Mn), leading to embrittlement, loss of tensile strength, and increased solubility. 2. Cross-linking: Increases molecular weight and polydispersity, leading to loss of elongation, hardening, and cracking. 3. Product Formation: Low-molecular-weight products (e.g., acids, alcohols) can plasticize the polymer or catalyze further reactions, altering modulus and barrier properties.

The critical link is establishing a quantitative correlation between an extent of chemical change (e.g., % oxidation, % ester bonds broken) and a critical physical property threshold (e.g., elongation at break < 50%).

Title: Chemical Kinetics to Physical Failure Pathway

Experimental Protocols for Linking Kinetics to Degradation

Protocol 1: Accelerated Aging Study with Periodic Property Mapping

Objective: To determine the Ea for the loss of a specific physical property (e.g., tensile strength).

- Sample Preparation: Prepare identical test specimens (e.g., ASTM D638 Type V dumbbells) from the polymer.

- Aging Chambers: Place samples in controlled environmental chambers (e.g., elevated temperature ovens with controlled humidity for hydrolysis, or oxygen-rich atmospheres for oxidation).

- Temperature Matrix: Age samples at a minimum of four elevated temperatures (e.g., 50°C, 60°C, 70°C, 80°C). Include a real-time control (e.g., 25°C).

- Sampling Intervals: Remove replicate samples at pre-determined time intervals from each chamber.

- Physical Testing: Condition samples and measure the chosen property (e.g., tensile strength, elongation at break).

- Data Analysis: For each temperature, plot property vs. time. Determine the time (τ) to reach a defined failure threshold (e.g., 50% retained strength). Plot ln(1/τ) vs. 1/T (K⁻¹). The slope is -Ea/R.

Protocol 2: FTIR Kinetics of Carbonyl Formation During Oxidation

Objective: To directly measure the Arrhenius parameters for the oxidation reaction.

- Thin Film Preparation: Prepare thin, uniform polymer films (<100 µm) to ensure oxygen permeation.

- In-Situ FTIR Cell: Place film in a heated FTIR cell with controlled O₂ flow.

- Kinetic Measurement: Monitor the increase in carbonyl index (CI = Absorbance@1720 cm⁻¹ / Reference peak) over time at multiple isothermal temperatures.

- Rate Calculation: Determine the initial rate (d(CI)/dt) for each temperature from the linear growth region.

- Arrhenius Plot: Plot ln(Reaction Rate) vs. 1/T. The slope yields the apparent Ea for carbonyl formation.

Table 2: Research Reagent Solutions & Essential Materials

| Item / Reagent | Function & Rationale |

|---|---|

| Controlled Environment Ovens/Chambers | Provide precise, stable elevated temperatures for accelerated aging. Humidity control is critical for hydrolysis studies. |

| Oxygen-Pressure Vessels (Bombs) | Accelerate oxidative aging by increasing O₂ partial pressure, effectively increasing reactant concentration. |

| FTIR Spectrometer with Heated Cell | For in-situ, quantitative tracking of specific chemical group formation (e.g., carbonyl, hydroxide) during degradation. |

| Size Exclusion Chromatography (SEC/GPC) | The primary tool for measuring changes in molecular weight (Mn, Mw) and distribution, the direct result of chain scission/cross-linking. |

| Tensiometer / Dynamometer | Measures the critical physical properties (tensile strength, elongation, modulus) that define functional failure. |

| Hydroperoxide Quantification Kit | Chemical assay (e.g., iodometric) to measure ROOH concentration, the key intermediate in oxidative degradation. |

| pH Buffers | For hydrolytic studies, buffers maintain constant pH, ensuring reaction kinetics are studied under controlled catalytic conditions. |

| UV/VIS Spectrophotometer | Used in conjunction with assays (e.g., for quantifying released acids or degradation products in solution). |

Title: Accelerated Aging Experimental Workflow

Predictive Modeling and Limitations of the Arrhenius Approach

The ultimate goal is the predictive model: t_failure = f(1/T, [O₂], [H₂O], pH, ...), with the Arrhenius term governing temperature dependence.

Critical Assumptions & Limitations:

- Single Mechanism: The dominant degradation mechanism must not change across the temperature range studied.

- Material Stability: No phase transitions (Tg, Tm) within the test range that alter reactivity.

- Diffusion Control: At lower use temperatures, reactions may become limited by oxygen/water diffusion, not intrinsic kinetics, invalidating the high-temperature-derived Ea.

- Environmental Complexity: Real-world aging involves simultaneous stresses (e.g., heat + UV + mechanical load) which may have synergistic effects not captured by simple thermal acceleration.

In conclusion, robust prediction of polymer aging requires meticulously linking quantified chemical kinetics, via the Arrhenius relationship, to well-defined physical degradation endpoints. This integrated approach is foundational for ensuring the reliability and safety of polymer-based materials in research, medicine, and industry.

Within the framework of accelerated aging research for polymeric materials, the Arrhenius equation serves as the foundational kinetic model. It relates the temperature-dependent rate of a degradation reaction (k) to the absolute temperature (T): k = A exp(-Ea/RT), where A is the pre-exponential factor, R is the gas constant, and Ea is the activation energy. This whitepaper posits that Ea is not merely a fitting parameter but the pivotal, polymer-specific key that unlocks accurate service-life predictions. Its precise determination and correct application differentiate successful extrapolation from misleading conjecture.

Theoretical Foundation: The Arrhenius Relationship in Polymer Aging

Polymer degradation—through oxidation, hydrolysis, chain scission, or dehydrochlorination—is a thermally activated process. The central assumption in accelerated aging is that increasing temperature accelerates the same fundamental chemical mechanisms that occur at lower use temperatures. The validity of this assumption hinges on a constant Ea across the temperature range studied. Ea quantifies the minimum energy barrier the reacting molecules must overcome; it is intrinsically linked to the specific chemical bonds involved and the degradation mechanism.

Logical Relationship of Ea in Prediction Models

Quantitative Data: Reported Ea Values for Common Polymer Degradation Pathways

The following table summarizes experimentally determined activation energies for key polymer degradation reactions, compiled from recent literature.

Table 1: Activation Energies for Common Polymer Degradation Mechanisms

| Polymer | Degradation Mechanism | Reported Ea Range (kJ/mol) | Key Analytical Method | Reference (Example) |

|---|---|---|---|---|

| Polypropylene (PP) | Thermo-oxidative (OIT) | 80 - 120 | DSC Isothermal OIT | (Pospíšil et al., 2023) |

| Polyethylene (HDPE) | Hydrolysis (C-O scission) | 70 - 90 | FTIR, Tensile Strength | (Cai et al., 2022) |

| Poly(L-lactide) (PLA) | Hydrolytic Chain Scission | 50 - 75 | GPC, Intrinsic Viscosity | (Witzke et al., 2024) |

| Poly(vinyl chloride) (PVC) | Dehydrochlorination | 90 - 130 | TGA, Conductivity | (Marcilla et al., 2023) |

| Polyurethane (ESTANE) | Hydrolytic Chain Scission | 75 - 95 | GPC, FTIR | (Celina et al., 2022) |

| Polycarbonate (PC) | Hydrolysis & Photo-Fries | 100 - 140 | HPLC, Yellowing Index | (White et al., 2023) |

| Epoxy Resin (DGEBA) | Thermo-oxidative Crosslinking | 95 - 115 | DMA, FTIR | (Gu et al., 2024) |

Experimental Protocols for Determining Ea

Protocol 4.1: Isothermal Thermogravimetric Analysis (TGA) for Ea of Mass Loss

Objective: Determine Ea for a single-step degradation process (e.g., decomposition). Materials: See "Scientist's Toolkit" below. Procedure:

- Precisely weigh 5-10 mg of polymer sample into an open platinum pan.

- Place in TGA furnace under constant inert purge gas (N₂, 50 mL/min).

- Rapidly heat to one of at least four distinct isothermal temperatures (e.g., 300, 310, 320, 330°C) within the decomposition region identified from a prior dynamic TGA scan.

- Hold at each temperature until mass loss is complete (~95% mass loss).

- Record mass (m) as a function of time (t) for each isothermal run.

- For each temperature, plot fractional conversion, α = (m₀ - mₜ)/(m₀ - m_f), versus time.

- Apply a kinetic model (e.g., nth-order) to determine the rate constant (k) at each temperature.

- Plot ln(k) vs. 1/T (in Kelvin). Perform linear regression. Ea = -slope * R.

Protocol 4.2: Oxidative Induction Time (OIT) by Differential Scanning Calorimetry (DSC)

Objective: Determine Ea for the oxidation of stabilized polyolefins. Materials: See "Scientist's Toolkit" below. Procedure:

- Precisely weigh 5-10 mg of polymer sample into a vented or open aluminum DSC pan.

- Equilibrate at 50°C under nitrogen purge (50 mL/min).

- Heat at 20°C/min to a selected isothermal test temperature (e.g., 180, 190, 200, 210°C). Hold for 2 min under N₂.

- Switch purge gas to oxygen (50 mL/min) at the same flow rate. Start timer.

- Monitor heat flow. The OIT is the time from gas switch to the onset of the exothermic oxidation peak.

- Repeat at a minimum of four different temperatures.

- Plot ln(1/OIT) vs. 1/T. Ea = -slope * R.

Experimental Workflow for Ea Determination

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for Ea Determination Experiments

| Item | Function & Specification | Critical Application Note |

|---|---|---|

| High-Purity Inert Gas (N₂, Ar) | Creates oxygen-free environment for baseline or pyrolysis tests. Grade 5.0 (99.999%) with inline oxygen/moisture trap. | Essential for preventing unwanted oxidation during sample equilibration and non-oxidative degradation studies. |

| High-Purity Oxygen Gas (O₂) | Reactive atmosphere for oxidative degradation studies (e.g., OIT). Grade 5.0 (99.999%). | Used exclusively in methods like DSC-OIT to measure oxidation stability. |

| Certified Reference Materials | Polymers with known degradation Ea (e.g., PE for OIT calibration). | Used for method validation and inter-laboratory comparison. |

| Hermetic & Vented DSC Pans | Sample encapsulation. Hermetic pans contain volatiles; vented pans allow gas exchange. | Choice depends on mechanism: hermetic for hydrolytic studies, vented for oxidative studies. |

| Platinum TGA Crucibles | Inert, high-temperature sample holders for TGA. | Preferred over alumina for polymer residues to avoid catalytic effects and for easy cleaning. |

| Kinetic Modeling Software | Software for model-fitting (e.g, n-th order, autocatalytic) to extract rate constants. | Enables robust analysis beyond simple graphical methods, accounting for complex mechanisms. |

| Controlled Humidity Chambers | For generating specific relative humidity levels in hydrolytic aging studies. | Critical for determining humidity-dependent Ea in polymers like polyesters and polyamides. |

Critical Considerations and Best Practices

- Mechanistic Consistency: Validate that Ea remains constant across the accelerated temperature range. A change in slope on the Arrhenius plot indicates a change in the rate-limiting mechanism, invalidating simple extrapolation.

- Physical vs. Chemical Aging: Above the glass transition temperature (Tg), Ea reflects chemical kinetics. Below Tg, diffusion-limited oxidation (DLO) or physical aging can dominate, complicating Ea interpretation.

- Multi-Stage Degradation: Complex polymers often undergo sequential/concurrent reactions with different Ea values. Use techniques like TGA-FTIR or GC-MS to deconvolute mechanisms.

- Humidity: For hydrolytic degradation, the effective Ea can depend on relative humidity. Experiments must control and report this parameter precisely.

In accelerated aging research governed by the Arrhenius relationship, the activation energy (Ea) is the critical, polymer-specific parameter that bridges short-term, high-temperature data and long-term, use-temperature predictions. Its accurate determination requires meticulous experiment design, appropriate mechanistic models, and an understanding of material limitations. By treating Ea not as a mere output but as a fundamental material property reflective of specific degradation chemistry, researchers and product developers can move beyond empirical guessing to achieve reliable, science-based service-life forecasts.

Historical Context and Fundamental Assumptions of the Model

This whitepaper situates the Arrhenius relationship—a cornerstone kinetic model—within accelerated aging studies of polymeric materials, particularly as applied to pharmaceutical packaging and drug delivery systems. The fundamental premise is that the temperature-dependent degradation rate of a polymer can be extrapolated to predict long-term stability under standard storage conditions. This framework is critical for researchers and drug development professionals who must establish shelf-life and ensure compliance with regulatory standards (e.g., ICH Q1A(R2)).

Historical Context

The application of the Arrhenius model to polymer aging originated in the early to mid-20th century, paralleling the rise of synthetic polymers. Svante Arrhenius's 1889 equation, formulated for chemical reaction rates, was adapted to describe the thermoxidative degradation of plastics and rubbers. A pivotal assumption carried from chemistry was that a single, constant activation energy ((E_a)) governs the dominant degradation mechanism across the temperature range studied. This allows for the use of elevated temperatures to generate accelerated aging data.

Fundamental Assumptions of the Arrhenius Model in Polymer Aging

The validity of the model rests on several critical assumptions:

- Single Dominant Mechanism: The same chemical or physical degradation process (e.g., chain scission, oxidation, hydrolysis) is rate-limiting at both accelerated and real-time storage temperatures.

- Constant Activation Energy: The (E_a) for the dominant reaction is independent of temperature and the extent of degradation (conversion).

- Linearized Behavior: The logarithm of the degradation rate constant ((k)) maintains a linear relationship with the reciprocal of absolute temperature ((1/T)).

- No New Mechanisms: Accelerated stress conditions (high temperature) do not introduce degradation pathways absent at lower storage temperatures.

- Material Homogeneity: The model assumes a homogeneous material state; it is less robust for systems undergoing phase changes (e.g., glass transition) within the test range.

Table 1: Typical Activation Energies for Common Polymer Degradation Pathways

| Polymer | Degradation Mechanism | Typical (E_a) (kJ/mol) | Temperature Range Studied (°C) | Key Reference (Recent) |

|---|---|---|---|---|

| Poly(L-lactide) (PLLA) | Hydrolytic Chain Scission | 70 - 85 | 40 - 60 | Siparsky et al., 2022 |

| Polyethylene (HDPE) | Thermo-oxidation | 90 - 120 | 70 - 100 | Celina, 2023 |

| Polyvinyl chloride (PVC) | Dehydrochlorination | 110 - 140 | 60 - 90 | Vieira et al., 2023 |

| Polypropylene (PP) | Oxidative Embrittlement | 80 - 110 | 80 - 120 | Hakkarainen, 2024 |

Table 2: Standard Accelerated Aging Protocol Based on ICH Guidelines

| Storage Condition | Temperature (°C) | Relative Humidity (%) | Typical Testing Duration | Equivalent Shelf-Life Target |

|---|---|---|---|---|

| Long-Term | 25 ± 2 | 60 ± 5 | Real-time (e.g., 36 mo.) | Market shelf-life |

| Intermediate | 30 ± 2 | 65 ± 5 | 6 - 12 months | Bridging data |

| Accelerated | 40 ± 2 | 75 ± 5 | 6 months | Preliminary data |

Detailed Experimental Protocol: Arrhenius-Based Aging Study

Objective: To predict the oxidative induction time (OIT) of a polyolefin packaging film at 25°C using accelerated temperatures.

Materials: (See The Scientist's Toolkit) Methodology:

- Sample Preparation: Cut polymer film into discs (e.g., 5mm diameter). Condition at 23°C/50% RH for 48 hours.

- Accelerated Aging: Place samples in controlled environmental chambers at a minimum of four elevated temperatures (e.g., 70°C, 80°C, 90°C, 100°C). Include 0-time controls.

- Sampling: Remove replicates (n≥5) from each chamber at predetermined time intervals.

- Property Measurement: Analyze samples via Differential Scanning Calorimetry (DSC) to determine OIT (ASTM D3895).

- Load 5-10 mg sample into a hermetic pan with a pinhole lid.

- Purge with nitrogen (50 mL/min), heat to test temperature (e.g., 200°C) at 20°C/min.

- Hold isothermally for 5 min under N₂.

- Switch purge gas to oxygen (50 mL/min). Record the time to onset of the exothermic oxidation peak (OIT).

- Data Analysis: a. Plot degradation metric (e.g., 1/OIT as a proxy for rate constant, (k)) versus time at each temperature to confirm zero-order approximation. b. For each temperature ((T) in Kelvin), calculate (ln(k)). c. Construct an Arrhenius plot: (ln(k)) vs. (1/T). d. Perform linear regression. The slope = (-Ea/R), where (R) is the gas constant. e. Extrapolate the regression line to the storage temperature (1/298 K) to obtain predicted (k{25°C}). f. Calculate the predicted OIT at 25°C as (1 / k_{25°C}).

Visualization of Concepts and Workflow

Title: Logical Flow of Arrhenius-Based Aging Prediction

Title: Core Assumptions and Their Implications for Validity

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Accelerated Polymer Aging Studies

| Item / Reagent | Function / Rationale |

|---|---|

| Controlled Environmental Chambers | Provide precise, stable temperature and humidity conditions (e.g., 40°C/75% RH) for accelerated aging. Critical for stress application. |

| Differential Scanning Calorimeter (DSC) | Measures thermal transitions (Tg, Tm) and oxidative induction time (OIT), a key metric for polymer stability and degradation kinetics. |

| High-Purity Nitrogen & Oxygen Gases | Required for OIT testing. Nitrogen purges the system, while oxygen initiates controlled oxidation. Purity >99.5% is standard. |

| Hermetic DSC pans with pinhole lids | Contain polymer samples during OIT testing. The pinhole allows gas exchange while preventing pressure buildup. |

| Gel Permeation Chromatography (GPC) System | Analyzes molecular weight distribution (Mw, Mn). Chain scission or crosslinking from degradation causes measurable shifts. |

| FTIR Spectrometer with ATR accessory | Identifies chemical changes (e.g., carbonyl index growth from oxidation, hydroxyl formation from hydrolysis) on polymer surfaces. |

| Standard Reference Materials (e.g., PE film) | Used for calibrating and verifying the performance of instruments like DSC and OIT chambers. |

| Data Loggers (T/RH sensors) | Placed inside aging chambers to continuously monitor and validate that setpoint conditions are maintained throughout the study. |

This whitepaper explores the differentiation between chemical and physical aging in polymer systems, with the core thesis that the Arrhenius relationship is a necessary but insufficient tool for predicting long-term polymer behavior in accelerated aging studies. While traditionally applied to chemical degradation, its uncritical extension to physical aging processes, which are often governed by non-equilibrium thermodynamics and molecular relaxation, can lead to significant over- or under-prediction of shelf-life, particularly in pharmaceutical packaging and drug delivery systems. Identifying the rate-limiting step—be it a chemical reaction or a physical relaxation—is paramount for accurate lifetime prediction.

Fundamental Mechanisms: Chemical vs. Physical Aging

Chemical Aging involves irreversible changes in the polymer's covalent structure. Key mechanisms include:

- Oxidation: Radical chain reactions initiated by heat, UV, or impurities.

- Hydrolysis: Scission of bonds (e.g., ester, amide) by water.

- Depolymerization: Reversal of polymerization.

Physical Aging is a reversible process driven by a material's approach to thermodynamic equilibrium below its glass transition temperature (Tg). It manifests as:

- Volume Relaxation: Gradual decrease in free volume.

- Enthalpy Relaxation: Recovery of enthalpy towards equilibrium.

- Increased Brittleness and Reduced Permeability.

The rate-limiting step is the mechanism with the greatest impact on the critical quality attribute (CQA) of interest (e.g., tensile strength, drug permeability, clarity) under the relevant storage conditions.

The Arrhenius Framework and Its Limitations

The Arrhenius equation (k = A exp(-Ea/RT)) is the cornerstone of accelerated aging for chemical processes. A linear plot of ln(k) vs. 1/T yields activation energy (Ea).

Critical Limitation for Physical Aging: Physical aging rates are dominated by the mobility of polymer chains, which is itself a non-Arrhenius, Vogel-Fulcher-Tammann (VFT)-type function of temperature. Near Tg, aging rates change dramatically. Applying a constant Ea from high-temperature data leads to erroneous extrapolation to storage temperatures.

Table 1: Distinguishing Features of Chemical vs. Physical Aging

| Feature | Chemical Aging | Physical Aging |

|---|---|---|

| Reversibility | Irreversible | Reversible (upon heating above Tg) |

| Primary Driver | Chemical Reaction Kinetics | Thermodynamic Drive to Equilibrium |

| Governed by | Activation Energy (Ea) | Free Volume, Molecular Mobility |

| Arrhenius Behavior | Typically follows over limited ranges | Non-Arrhenius, VFT-like near Tg |

| Key Measurables | COOH formation, MW change, UV absorbance | Enthalpy Recovery (DSC), Density, Modulus |

| Rate-Limiting Step | Slowest chemical reaction step (e.g., initiation vs. propagation) | Segmental relaxation time (τα) |

Experimental Protocols for Identification

Protocol 4.1: Isothermal Calorimetry for Enthalpy Recovery (Physical Aging)

- Objective: Quantify physical aging rate by measuring enthalpy recovery over time.

- Method:

- Erase Thermal History: Heat specimen 20°C above Tg for 5-10 min in DSC.

- Quench: Rapidly cool to the desired isothermal aging temperature (Ta), typically Tg - 10°C to Tg - 40°C.

- Age: Hold at Ta for varying times (ta: 1, 5, 24, 100 hrs...).

- Scan: After each ta, reheat the sample through Tg at 10°C/min.

- Measure: The area of the endothermic peak just above Tg corresponds to recovered enthalpy (ΔH).

- Analysis: Plot ΔH vs. log(t_a). The slope indicates the physical aging rate.

Protocol 4.2: FTIR Spectroscopy for Carbonyl Index (Chemical Aging)

- Objective: Track chemical oxidation via carbonyl group formation.

- Method:

- Age Samples: Expose polymer specimens to controlled accelerated conditions (e.g., elevated T, O₂ pressure).

- Acquire Spectra: Obtain FTIR spectra of aged and unaged control samples.

- Baseline Correct: Apply consistent baseline to the spectral region of interest (e.g., 1500-1800 cm⁻¹).

- Calculate Index: Integrate absorbance of carbonyl band (~1710-1725 cm⁻¹) and a reference band invariant to aging (e.g., C-H stretch ~1450-1470 cm⁻¹). Carbonyl Index = Acarbonyl / Areference.

- Analysis: Plot Carbonyl Index vs. aging time. Apply Arrhenius model to rate constants (k) derived at multiple temperatures.

Protocol 4.3: Gravimetric Sorption Analysis for Permeability Changes

- Objective: Decouple chemical degradation from physical aging effects on barrier properties.

- Method:

- Pre-condition: Dry samples to constant weight.

- Age Cohorts: Create sample sets aged under identical thermal conditions but with and without exposure to a permeant (e.g., water vapor, O₂).

- Sorption Test: Expose all samples to a constant permeant pressure/activity. Monitor mass gain over time.

- Model Fit: Fit sorption kinetics to Fickian or Langmuir models to extract diffusion (D) and solubility (S) coefficients. Permeability P = D x S.

- Analysis: Compare

P_agedvs.P_unaged. A change inSsuggests chemical modification. A change inDwith constantSsuggests physical aging (densification).

Visualizing Pathways and Workflows

Title: Decision Pathway: Chemical vs. Physical Aging

Title: Key Techniques for Identifying Rate-Limiting Steps

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Polymer Aging Studies

| Item | Function & Rationale |

|---|---|

| Polymer Films (e.g., PET, PP, PLA) | Model Substrates. Well-characterized, commercially available polymers serve as benchmarks for method development. |

| Stabilizer-Free Resins | Controlled Degradation Studies. Essential for isolating intrinsic aging mechanisms without interference from additives. |

| Antioxidants (e.g., Irganox 1010, BHT) | Inhibition Controls. Added to select samples to specifically suppress oxidative chemical aging, clarifying mechanisms. |

| Deuterated Solvents (Chloroform-d, DMSO-d6) | NMR Analysis. For quantifying chemical changes (e.g., hydrolysis, oxidation products) at a molecular level. |

| Internal FTIR Standards (e.g., Polystyrene film) | Wavenumber Calibration. Ensures precision in tracking small spectral shifts over long aging periods. |

| Certified Reference Materials (CRMs) for DSC | Temperature & Enthalpy Calibration. Critical for accurate measurement of Tg and enthalpy recovery (Indium, Zinc). |

| Permeability Standards (NIST traceable films) | Gravimetric/M permeation Calibration. Validates the accuracy of sorption and permeability testing apparatus. |

| Controlled Atmosphere Cells (for O₂, RH) | Accelerated Aging. Enables application of specific aging stresses (elevated pO₂, humidity) in ovens/DSCs. |

| Chemiluminescence Reagents | Detection of Radicals. Highly sensitive method for detecting early-stage oxidation (chemical aging initiation). |

Accurately identifying the rate-limiting step in polymer aging—chemical or physical—requires moving beyond a simplistic application of the Arrhenius equation. A multi-modal experimental approach, combining calorimetry, spectroscopic, gravimetric, and mechanical techniques, is essential to decouple these intertwined processes. The protocols and toolkit outlined herein provide a framework for researchers, particularly in drug development, to establish predictive aging models that correctly identify the dominant degradation pathway, ensuring reliable prediction of polymer performance and drug product shelf-life.

From Theory to Protocol: Designing Accelerated Aging Studies for Pharmaceutical Polymers

Within the broader thesis on the application of the Arrhenius relationship in accelerated polymer aging research, this guide provides a definitive protocol for designing shelf-life studies. The core thesis posits that while the Arrhenius model is a powerful tool for predicting degradation kinetics of polymers and drug products, its successful application hinges on rigorous experimental design, validation of model assumptions, and careful interpretation within the material's specific chemical and physical context. This whitepaper operationalizes that thesis into a executable framework.

Theoretical Foundation: The Arrhenius Equation

The Arrhenius equation describes the temperature dependence of reaction rates: k = A e^(-Ea/RT) where:

- k = rate constant of the degradation reaction

- A = pre-exponential factor (frequency factor)

- Ea = activation energy (J/mol)

- R = universal gas constant (8.314 J/mol·K)

- T = absolute temperature (K)

The logarithmic form is used for analysis: ln(k) = ln(A) - (Ea/R)(1/T)

The fundamental assumption for accelerated aging is that the dominant degradation mechanism remains constant across the temperature range studied.

Diagram 1: Logical flow of the Arrhenius model for shelf-life prediction.

Step-by-Step Experimental Design Protocol

Step 1: Define Study Objective & Critical Quality Attributes (CQAs)

- Objective: Quantitatively predict the shelf-life (e.g., time to 10% loss of potency, or 5% increase in degradation product) at recommended storage conditions (e.g., 25°C/60%RH or 5°C ± 3°C).

- CQA Selection: Identify and justify the CQAs to monitor. These are typically:

- Potency of Active Pharmaceutical Ingredient (API)

- Level of specified degradation products

- Physical attributes (e.g., polymer molecular weight, polydispersity, glass transition temperature, dissolution profile)

Step 2: Select Accelerated Storage Conditions

A minimum of three elevated temperatures, plus the intended storage temperature (as a control), is required. Temperatures should be chosen to avoid physical transitions (e.g., melting, glass transition) that alter degradation kinetics.

Table 1: Example Accelerated Aging Conditions for a Product with 25°C Storage

| Condition Label | Storage Temperature | Relative Humidity (RH) | Typical Duration | Rationale |

|---|---|---|---|---|

| Long-Term (Control) | 25°C ± 2°C | 60% ± 5% RH | 0, 3, 6, 9, 12, 18, 24 mo | ICH Q1A(R2) condition. |

| Intermediate | 30°C ± 2°C | 65% ± 5% RH | 0, 3, 6 mo | ICH condition for Zone II/IV. |

| Accelerated | 40°C ± 2°C | 75% ± 5% RH | 0, 1, 2, 3, 6 mo | Standard accelerated condition. |

| High-Accelerated | 50°C ± 2°C | Ambient or controlled | 0, 2, 4, 8, 12 wk | For rapid screening; must validate mechanism. |

| High-Accelerated | 60°C ± 2°C | Ambient or controlled | 0, 1, 2, 4 wk | For very rapid screening; high risk of mechanism change. |

Step 3: Design Sample & Replication Strategy

- Use identical batches of material for all conditions.

- Package samples in their intended commercial packaging or a simulated configuration.

- Employ a sufficient number of replicates (n≥3 is standard) to account for analytical and sample variability.

- Plan a pull schedule with defined time points (see Table 1).

Step 4: Execute Stability Testing & Data Collection

- Place samples in controlled environmental chambers for each condition.

- At each pull point, analyze all replicates for the predefined CQAs.

- Record data with associated uncertainty (standard deviation).

Protocol 1: Determination of Polymer Molecular Weight Over Time

- Sample Preparation: Precisely weigh ~10 mg of aged polymer into a vial. Add known volume of appropriate mobile phase (e.g., THF for polystyrene, DMF for polyamides) to achieve ~2 mg/mL concentration. Agitate for 24 hours at room temperature to ensure complete dissolution. Filter through a 0.45 µm PTFE syringe filter.

- Gel Permeation Chromatography (GPC/SEC) Analysis: Inject sample into GPC system equipped with refractive index (RI) and multi-angle light scattering (MALS) detectors, if available. Use a column set appropriate for the polymer's molecular weight range. Calculate weight-average molecular weight (Mw) and number-average molecular weight (Mn) relative to narrow polymer standards or via MALS absolute measurement.

- Data Recording: Record Mw, Mn, and polydispersity index (PDI = Mw/Mn) for each replicate at each time point.

Step 5: Kinetic Modeling of Degradation at Each Temperature

For each temperature condition, fit degradation data (e.g., % remaining API, 1/Mn for chain scission) to an appropriate kinetic model.

Table 2: Common Degradation Kinetic Models

| Model | Rate Law (D = CQA) | Integrated Form | Applies To |

|---|---|---|---|

| Zero-Order | dD/dt = k | D = D₀ ± kt | Diffusion-controlled processes, some polymer erosion. |

| First-Order | dD/dt = k·D | ln(D) = ln(D₀) - kt | Most common for chemical degradation (e.g., hydrolysis, oxidation). Molecular weight loss in random chain scission. |

| Second-Order | dD/dt = k·D² | 1/D = 1/D₀ + kt | Some bimolecular reactions. |

Protocol 2: Fitting Degradation Data to a Kinetic Model

- Plot the CQA (e.g., Ln(% Potency Remaining)) versus time for each temperature.

- Perform linear regression. The model with the best fit (highest R², random residuals) is selected.

- The slope of the linear regression line is the rate constant (k) for that temperature. Record k and its standard error.

Step 6: Construct the Arrhenius Plot & Extrapolate

- Plot ln(k) versus 1/T (where T is in Kelvin) for all temperatures.

- Perform a weighted linear regression (weighting by 1/variance of k is recommended).

- The slope (m) = -Ea/R. Therefore, Ea = -m * R.

- Use the regression equation to solve for k_predicted at the storage temperature (e.g., 25°C = 298.15 K).

Diagram 2: Stepwise process for creating and analyzing the Arrhenius plot.

Step 7: Calculate Predicted Shelf-Life

- Insert the k_predicted into the integrated form of the kinetic model selected in Step 5.

- Solve for time (t) when the CQA reaches the failure limit (e.g., time for potency to drop to 90% of label claim).

Example Calculation (First-Order):

- Failure: API = 90% of initial (D/D₀ = 0.90).

- Model: ln(D) = ln(D₀) - kt → t = [ln(D₀) - ln(D)] / k

- tshelf-life = ln(1.00 / 0.90) / kpredicted

Step 8: Validate Model Assumptions

This step is critical to the broader thesis. Conduct analyses to confirm:

- Mechanistic Consistency: Use complementary techniques (e.g., HPLC for chemical changes, GPC for physical changes, FTIR for functional groups) to confirm the same degradation products/form are generated at all temperatures.

- Linearity of Arrhenius Plot: Significant curvature may indicate a change in mechanism, diffusion control, or a nearing polymer transition temperature.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for Arrhenius-Based Aging Studies

| Item/Reagent | Function & Rationale |

|---|---|

| Stability/Environmental Chambers | Provide precise, programmable control of temperature (±0.5°C) and relative humidity (±2% RH) for long-term forced degradation studies. |

| HPLC/UHPLC with PDA/Diode Array Detector | Gold-standard for quantifying API potency and formation of specific organic degradation products (e.g., hydrolysis byproducts, oxidants). |

| Gel Permeation Chromatography (GPC/SEC) System | Essential for monitoring polymer degradation via changes in molecular weight distribution (Mw, Mn, PDI) caused by chain scission or crosslinking. |

| Headspace Gas Chromatography (HS-GC) | Quantifies volatile degradation products (e.g., aldehydes, residual monomers, oxidation products like pentane) in polymer packaging or formulations. |

| Forced Degradation Standards | Commercially available or synthesized degraded samples (e.g., oxidized, hydrolyzed API) used to confirm analyte identity and validate analytical methods. |

| Certified Reference Materials (CRMs) | High-purity polymer or API standards with certified properties for calibrating instruments and ensuring analytical accuracy across the study duration. |

| Stable Isotope-Labeled Analogs | Used as internal standards in mass spectrometry to improve quantification accuracy of degradation products in complex matrices. |

| Oxygen-Scavenging or Humidity-Control Packaging | Used to create specific stress conditions (e.g., anaerobic, dry) to isolate and study specific degradation pathways (oxidation vs. hydrolysis). |

| Chemometrics/Stability Data Analysis Software | Enables robust statistical fitting of kinetic models, Arrhenius regression, and calculation of prediction intervals for shelf-life estimates. |

Within accelerated polymer aging research, the Arrhenius relationship is a foundational principle used to extrapolate material degradation rates from elevated temperatures to a desired use temperature. The core assumption is that a single, consistent activation energy governs the rate-limiting chemical reaction across the selected temperature range. However, this predictive power collapses when the experimental temperature range inadvertently spans a material phase transition or triggers a change in the dominant degradation mechanism, leading to non-Arrhenius behavior. This whitepaper provides a technical guide for researchers and drug development professionals on the critical task of temperature selection for accelerated aging studies. The objective is to construct a valid accelerated test protocol that remains within a single physical phase and reaction regime, thereby ensuring the integrity of Arrhenius extrapolation for polymer-based products, including drug delivery systems and packaging.

Identifying Critical Transition Temperatures

The first step in experimental design is to identify the key material transition temperatures that define the bounds of Arrhenius-compliant regions. These must be determined empirically for the specific polymer formulation under study.

Key Characterization Protocols

Protocol 1: Modulated Differential Scanning Calorimetry (mDSC)

- Objective: To accurately determine the glass transition temperature (Tg), melting temperature (Tm), and other thermal events without confounding effects from thermal history or superimposed relaxation processes.

- Methodology:

- Precisely weigh 3-10 mg of sample into a hermetic Tzero pan.

- Equilibrate at -50°C (or 50°C below the expected Tg).

- Heat at a linear rate of 2-3°C/min with a modulation amplitude of ±0.5°C every 60 seconds.

- Purge with dry nitrogen at 50 mL/min.

- Analyze the reversible heat flow signal to identify Tg (midpoint) and Tm (peak). The non-reversible flow can reveal cold crystallization or stress relaxation.

- Critical Output: The Tg is the primary lower boundary for testing temperatures in amorphous polymers. Testing below Tg can lead to physical aging effects, while testing above it accesses a different segmental mobility regime.

Protocol 2: Dynamic Mechanical Analysis (DMA)

- Objective: To characterize viscoelastic transitions (α, β relaxations) as a function of temperature and frequency, providing a mechanical perspective on Tg and sub-Tg transitions.

- Methodology (Tension or 3-Point Bending):

- Cut a sample to dimensions per fixture requirements (e.g., 20mm x 10mm x 0.2mm).

- Clamp the sample and set a static strain within the linear viscoelastic region (determined via strain sweep).

- Apply a sinusoidal oscillatory strain (e.g., 0.1% strain, 1 Hz frequency).

- Temperature ramp at 2°C/min from -100°C to 150°C or above the polymer's softening point.

- Record storage modulus (E'), loss modulus (E''), and tan delta (E''/E') as functions of temperature.

- Critical Output: The peak in tan delta or the onset of the rapid drop in E' identifies the α-relaxation (Tg). Secondary β-transitions indicate localized molecular motions that can influence low-temperature aging kinetics.

Protocol 3: Dielectric Analysis (DEA)

- Objective: To probe molecular mobility and dipole relaxations over a broad range of frequencies, identifying transitions that may not be readily apparent in DSC.

- Methodology:

- Place the polymer film (50-200 µm thick) between parallel plate electrodes.

- Apply a sinusoidal voltage (0.5-1.0 V) across the sample.

- Perform a multi-frequency temperature sweep (e.g., 0.1 Hz, 1 Hz, 10 Hz, 100 Hz).

- Monitor permittivity (ε') and loss factor (ε'') as functions of temperature and frequency.

- Critical Output: Creates an activation energy map for dipole motions. The shift of loss peaks with frequency allows calculation of activation energies for specific relaxations, directly informing Arrhenius model validity.

Data Integration and Temperature Range Selection

Data from the above protocols must be integrated to define a "safe" temperature window for accelerated testing. The following table summarizes the critical parameters and their implications.

Table 1: Critical Transition Temperatures and Their Impact on Accelerated Aging Studies

| Transition Type | Common Measurement Technique | Typical Data Output | Implication for Arrhenius Testing |

|---|---|---|---|

| Glass Transition (Tg) | mDSC, DMA (tan delta peak) | Onset, Midpoint, Endset (°C) | Primary upper bound for amorphous phase testing. Kinetics change fundamentally above Tg. |

| Melting Point (Tm) | mDSC (reversible heat flow) | Peak Temperature (°C) | Absolute upper limit for semi-crystalline polymers. Testing >Tm destroys morphology. |

| Sub-Tg (β) Relaxation | DMA, DEA | Loss Peak Temperature at 1 Hz (°C) | May govern low-temperature aging. Mechanism shift if test range spans this peak. |

| Activation Energy (Ea) | DEA, Isothermal TGA | Ea (kJ/mol) from freq. shift or multiple temps | Consistency of Ea across the proposed test range is the ultimate validity check. |

| Thermal Decomposition Onset | TGA (5% mass loss) | Temperature at 5% loss (°C) | Absolute safety limit to avoid pyrolysis-driven degradation. |

Recommended Workflow for Temperature Selection:

- Characterize: Determine Tg, Tm, and sub-Tg relaxations via mDSC and DMA.

- Define Safety Margin: Set the maximum test temperature (T_max) at least 15-20°C below the onset of Tg (for amorphous) or Tm. For highly sensitive systems, a larger margin is advised.

- Check for Mechanism Shifts: Ensure the proposed Tmax and Tmin do not bracket a known secondary relaxation (from DMA/DEA).

- Pilot Kinetic Study: Conduct short-term isothermal tests at 3-4 temperatures within the proposed range. Use a technique like HPLC (for product) or FTIR (for functional groups) to measure degradation rate constants (k).

- Validate Arrhenius Linearity: Plot ln(k) vs. 1/T (K). A statistically significant linear fit (R² > 0.98) across the pilot range confirms the absence of non-Arrhenius behavior. Any curvature indicates an invalid range.

Diagram 1: Workflow for Selecting Arrhenius-Compliant Temperatures

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for Accelerated Aging Studies

| Item | Function & Rationale |

|---|---|

| Hermetic Tzero DSC Pans & Lids | Ensures a sealed, controlled environment during mDSC to prevent moisture loss/absorption, which can plasticize the polymer and artificially shift Tg. |

| Quartz or Platinum TGA Crucibles | Inert, high-temperature stable containers for precise mass loss measurements during thermal decomposition onset studies. |

| Temperature & Humidity Calibration Standards | Certified materials (e.g., Indium, KNO₃ for T; saturated salt solutions for %RH) for rigorous instrument calibration, essential for data reliability. |

| Stabilizer-Free Polymer Resin (Control) | A reference material identical to the test formulation but without antioxidants/UV stabilizers, used to isolate base polymer kinetics from additive effects. |

| Inert Aging Atmosphere | High-purity Nitrogen or Argon cylinders with pressure regulators and oxygen scrubbers. Prevents oxidative degradation from confounding thermal-only studies. |

| Spectroscopic Grade Solvents | High-purity solvents (e.g., THF, CHCl₃) for gel permeation chromatography (GPC) sample preparation to monitor molecular weight changes without artifacts. |

| Chemical Degradation Probes | Stable radical species (e.g., TEMPO) or fluorescent tags that react with specific oxidation products (e.g., carbonyl groups), enabling precise tracking of reaction progress. |

Case Study: Amorphous Polymer Drug Delivery Device

Consider an amorphous poly(lactide-co-glycolide) (PLGA) implant. mDSC shows a Tg of 45°C. DMA indicates a β-relaxation at -10°C. The proposed use condition is 25°C.

- Incorrect Approach: Testing at 60°C, 70°C, 80°C to achieve high acceleration. This spans Tg, moving from a glassy to a rubbery state, causing a drastic, non-Arrhenius increase in degradation and drug release rates.

- Corrected Approach: Based on a 20°C safety margin below Tg, T_max = 25°C. This offers negligible acceleration. Therefore, the study must use the sub-Tg range.

- Validated Protocol: Select test temperatures of 5°C, 15°C, 25°C (use), and 35°C. This range is above the β-relaxation but safely below Tg. A pilot study measuring hydrolysis rate via GPC confirms a linear Arrhenius plot, enabling valid extrapolation.

Diagram 2: Phase State vs. Testing Range Validity

Selecting critical temperatures for accelerated polymer aging is not an arbitrary exercise in achieving high acceleration factors. It is a deliberate, data-driven process that begins with comprehensive thermal and viscoelastic characterization to map the material's landscape of phase transitions and molecular relaxations. By strictly defining test boundaries within a single physical phase and a single dominant kinetic regime—validated by a pilot Arrhenius analysis—researchers can generate reliable, predictive data. This rigorous approach upholds the scientific integrity of the Arrhenius relationship, ultimately leading to accurate shelf-life predictions and robust performance assurances for polymer-based pharmaceutical products.

Choosing Relevant Stability Indicating Methods (SIMs) for Polymer Degradation

The selection of Stability Indicating Methods (SIMs) for polymer degradation is fundamentally guided by the principles of the Arrhenius relationship in accelerated aging studies. The Arrhenius equation, k = A e^(-Ea/RT), provides the kinetic framework for extrapolating high-temperature degradation data to predict long-term stability under ambient storage conditions. The validity of these extrapolations is entirely dependent on the ability of the chosen SIMs to accurately and specifically quantify the chemical and physical changes in the polymer. This guide details the critical methodologies for monitoring polymer degradation within this kinetic framework.

Key Degradation Pathways & Corresponding Analytical Targets

Polymer degradation proceeds via distinct mechanistic pathways, each requiring specific analytical techniques for quantification.

| Degradation Pathway | Primary Chemical Changes | Key Analytical Targets |

|---|---|---|

| Hydrolysis | Scission of labile bonds (e.g., ester, amide) by water. | Increase in carboxylic acid end-groups; Decrease in molecular weight; Loss of parent polymer. |

| Oxidation | Radical-mediated reaction with oxygen. | Formation of hydroperoxides, carbonyls (e.g., aldehydes, ketones); Chain scission/cross-linking; Discoloration. |

| Thermal Degradation | Pyrolytic scission in absence of oxygen. | Volatile products; Changes in molecular weight distribution; Char formation. |

| Photodegradation | UV-induced radical formation and cleavage. | Similar to oxidation, plus specific Norrish-type cleavage products. |

Diagram 1: Primary Degradation Pathways & Measurable Products

Stability Indicating Methodologies: Protocols and Data

Chromatographic Techniques

High-Performance Liquid Chromatography (HPLC) / Size Exclusion Chromatography (SEC)

- Protocol: For SEC, use a calibrated system with refractive index (RI) and UV detectors. Columns: tandem polymeric gel columns (e.g., Phenogel, PLgel). Mobile phase: tetrahydrofuran (THF) for non-polar polymers or dimethylformamide (DMF) with LiBr for polar polymers (e.g., polyesters, polyamides). Flow rate: 1.0 mL/min. Inject polymer samples (0.1-0.5% w/v) aged under various conditions (temperature, humidity).

- Data Output: Molecular weight averages (Mn, Mw), polydispersity index (PDI). A decrease in Mn indicates chain scission; an increase in Mw/PDI suggests cross-linking.

| Polymer | Initial Mn (kDa) | Mn after 30d/60°C (kDa) | % Change | Inferred Mechanism |

|---|---|---|---|---|

| PLGA 50:50 | 25.5 | 18.2 | -28.6% | Hydrolysis |

| Polypropylene | 120.0 | 115.5 | -3.8% | Mild Oxidation |

| Polycarbonate | 32.0 | 28.1 | -12.2% | Hydrolysis/Oxidation |

Spectroscopic Techniques

Fourier-Transform Infrared Spectroscopy (FTIR)

- Protocol: Analyze polymer films via Attenuated Total Reflectance (ATR)-FTIR. Collect spectra from 4000-600 cm⁻¹ at 4 cm⁻¹ resolution (64 scans). Monitor specific peak area changes relative to an internal reference peak (e.g., C-H stretch). For oxidation, track carbonyl index (C=O stretch ~1710-1750 cm⁻¹). For hydrolysis, track hydroxyl/acid (O-H stretch ~3200-3600 cm⁻¹).

- Data Output: Carbonyl Index (CI) = (AC=O / Aref). Hydroxyl Index similarly calculated.

| Aging Condition | Carbonyl Index (CI) | Hydroxyl Index (HI) | Observation |

|---|---|---|---|

| Initial | 0.05 | 0.02 | Baseline |

| 2 weeks, 70°C/O2 | 0.42 | 0.15 | Severe Oxidation |

| 2 weeks, 70°C/75% RH | 0.11 | 0.65 | Predominant Hydrolysis |

Thermal Analysis

Thermogravimetric Analysis (TGA) & Differential Scanning Calorimetry (DSC)

- Protocol:

- TGA: Heat 5-10 mg sample from 30°C to 600°C at 10°C/min under N2 (for stability) or air (for oxidative stability). Record weight loss.

- DSC: Perform heat-cool-heat cycle (-50°C to 250°C at 10°C/min). Analyze first heat for melting temperature (Tm) and enthalpy (ΔHm), second heat for glass transition temperature (Tg).

- Data Output: Onset decomposition temperature (Td), residual mass. Changes in Tm, ΔHm (crystallinity), and Tg.

| Test | Parameter | Virgin Polymer | Aged Polymer | Degradation Indication |

|---|---|---|---|---|

| TGA | Td onset (°C) | 385.2 | 345.8 | Reduced thermal stability |

| DSC | Tm (°C) / ΔHm (J/g) | 165.5 / 85.0 | 162.1 / 72.3 | Crystal perfection loss, scission |

| DSC | Tg (°C) | 55.0 | 58.5 | Increased cross-linking |

Integrating SIMs with Arrhenius Study Design

The workflow for an accelerated aging study requires sequential analytical steps to establish a valid kinetic model.

Diagram 2: SIM Integration in Arrhenius Study Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

| Material / Reagent | Function in SIM Development |

|---|---|

| Controlled Humidity Chambers | Precisely maintain specified %RH (e.g., 25%, 60%, 75%) during accelerated aging studies for hydrolytic stability assessment. |

| Radical Initiators (e.g., AIBN) | Used in forced oxidation studies to generate radicals and accelerate oxidative degradation pathways for method development. |

| Deuterated Solvents for NMR | Essential for quantitative ¹H or ¹³C NMR analysis to identify and quantify degradation products and end-group changes. |

| Molecular Weight Standards | Narrow dispersity polystyrene or poly(methyl methacrylate) for accurate SEC calibration to monitor chain scission/cross-linking. |

| Stable Free Radical (e.g., TEMPO) | Used as a radical scavenger in control experiments to confirm oxidative mechanisms or to inhibit degradation during processing. |

| UV Light Sources (e.g., Xenon arc) | Provide simulated solar radiation for controlled photodegradation studies per ICH Q1B guidelines. |

| Headspace Vials & Septa | For sampling and analysis of volatile degradation products (e.g., monomers, formaldehyde) via GC-MS. |

This guide details methodologies for extracting chemical degradation rate constants (k) at elevated temperatures, a cornerstone for constructing Arrhenius plots within accelerated polymer aging research. The accurate determination of k across a temperature series is the critical experimental input for the Arrhenius equation, k = Aexp(-Ea/RT), enabling the extrapolation of degradation rates and material lifetimes at intended storage or use conditions. The reliability of the entire accelerated aging model hinges on the precision of these extracted k values.

Core Experimental Protocols

Forced Degradation Study Design

Objective: To induce measurable polymer or drug product degradation within a practical timeframe by exposing samples to elevated temperatures.

- Sample Preparation: Prepare identical sample units (e.g., film discs, solution aliquots, packaged dosage forms). Include at least three replicates per timepoint per temperature.

- Temperature Selection: Minimum of four elevated temperatures (e.g., 40°C, 50°C, 60°C, 70°C) plus one controlled reference condition (e.g., 25°C). Temperatures must remain below polymer phase transition points (e.g., glass transition, melting).

- Timepoint Scheduling: Schedule sampling intervals based on anticipated degradation rate. At higher temperatures, intervals may be hours/days; at lower temperatures, weeks/months.

- Control: Maintain control samples at reference temperature (e.g., -80°C or 5°C) to account for non-thermal degradation.

Quantitative Analytical Methods for Tracking Degradation

Objective: To measure the concentration of the parent compound or a specific degradation product over time.

Protocol A: Chromatographic Analysis (HPLC/UPLC)

- Sample Processing: At each predetermined timepoint, remove samples from ovens. For solid polymers, dissolve or extract in a suitable solvent. For solutions, dilute as needed.

- Analysis: Inject processed samples onto an HPLC/UPLC system equipped with a UV, PDA, or MS detector.

- Quantification: Use a validated calibration curve to determine the concentration of the target analyte (remaining parent compound or key degradant). Express results as percent remaining or percent formed.

Protocol B: Spectroscopic Analysis (FTIR, UV-Vis)

- Sample Measurement: For films, perform direct FTIR analysis, tracking changes in characteristic absorption bands (e.g., carbonyl index for oxidation). For solutions, use UV-Vis spectroscopy.

- Data Processing: Integrate peak areas or heights. Normalize data using an internal reference band (for FTIR) or path length/concentration (for UV-Vis).

Mathematical Extraction of Rate Constants (k)

Objective: To fit concentration-time data to an appropriate kinetic model and extract the rate constant k at each temperature.

- Protocol: Data Fitting to Pseudo-First-Order Kinetics

- Most polymer degradation reactions (e.g., hydrolysis, oxidative chain scission) under controlled, accelerated conditions follow apparent (pseudo) first-order kinetics.

- Model Equation:

ln(C) = ln(C₀) - kt, where C is concentration at time t, C₀ is initial concentration, k is the rate constant. - Procedure:

- Plot

ln(C)versus time t for each temperature condition. - Perform a linear regression on the data.

- The absolute value of the slope obtained from the linear fit is the degradation rate constant k (units: time⁻¹, e.g., day⁻¹, hr⁻¹).

- Plot

Data Presentation: Extracted Rate Constants

Table 1: Exemplar Degradation Rate Constants (k) for a Hypothetical Polymer

Data derived from forced hydrolysis study of Polymer X film at 95% relative humidity.

| Temperature (°C) | Rate Constant, k (day⁻¹) | R² of Linear Fit | Estimated Time for 10% Degradation (t₉₀) |

|---|---|---|---|

| 25 (Reference) | 2.15 x 10⁻⁵ | 0.992 | ~10.6 years |

| 40 | 8.72 x 10⁻⁵ | 0.998 | ~2.6 years |

| 50 | 3.41 x 10⁻⁴ | 0.996 | ~0.7 years |

| 60 | 1.24 x 10⁻³ | 0.994 | ~77 days |

| 70 | 4.96 x 10⁻³ | 0.987 | ~19 days |

Table 2: Key "Research Reagent Solutions" & Essential Materials

| Item | Function in Experiment |

|---|---|

| Stability Chambers / Ovens | Provide precise, controlled elevated temperature and humidity environments for forced degradation studies. |

| HPLC/UPLC System with Detector | High-resolution separation and quantitative analysis of polymer components/degradation products. |

| Standard Reference Material | High-purity compound used to develop calibration curves for accurate quantification. |

| Inert Atmosphere Glove Box | For sample preparation and packaging under nitrogen/argon to prevent unintended oxidative degradation prior to thermal stress. |

| Specific Chemical Reagents (e.g., radical initiators, buffered solutions) | Used to create specific degradation pathways (e.g., oxidation, hydrolysis) in a controlled manner. |

| Data Analysis Software (e.g., MATLAB, Origin, Kinetics) | For performing linear/non-linear regression to extract k values and construct Arrhenius plots. |

Visualization of Methodologies

Workflow for Extracting Degradation Rate Constant k

From Assay Data to k Value Extraction

Accelerated aging studies are fundamental to predicting the shelf-life of pharmaceutical products, where polymer-based excipients and drug delivery systems are ubiquitous. This case study is framed within a broader thesis investigating the rigorous application of the Arrhenius relationship (k = A exp(-Ea/RT)) to model the temperature-dependent degradation kinetics of common pharmaceutical polymers. The core hypothesis is that by precisely determining the activation energy (Ea) for key degradation pathways, one can extrapolate long-term stability under standard storage conditions from short-term, elevated-temperature experiments. This study focuses on Poly(lactic-co-glycolic acid) (PLGA) as a model system due to its widespread use in controlled-release formulations.

Quantitative Degradation Data for PLGA

The following tables summarize key degradation metrics for PLGA (50:50 LA:GA) under accelerated conditions, as compiled from recent literature (2022-2024).

Table 1: Hydrolytic Degradation Kinetics of PLGA (50:50) at Different pH and Temperatures

| Temperature (°C) | pH Buffer | Rate Constant, k (week⁻¹) for Mw Loss | Estimated Ea (kJ/mol) | Time to 50% Mw Loss (weeks) |

|---|---|---|---|---|

| 4 (Refrigerated) | 7.4 PBS | 0.008 ± 0.001 | - | 86.6 |

| 25 (Room Temp) | 7.4 PBS | 0.032 ± 0.003 | - | 21.7 |

| 37 (Accelerated) | 7.4 PBS | 0.154 ± 0.010 | 65.2 ± 3.5 | 4.5 |

| 50 (Accelerated) | 7.4 PBS | 0.581 ± 0.030 | - | 1.2 |

| 37 (Accelerated) | 4.0 Acetate | 0.095 ± 0.008 | 58.7 ± 4.1 | 7.3 |

| 37 (Accelerated) | 9.0 Borate | 0.210 ± 0.015 | - | 3.3 |

Table 2: Key Physical Changes During PLGA (50:50) Aging at 37°C, pH 7.4

| Time Point (Weeks) | Mass Loss (%) | Glass Transition Temp, Tg (°C) | % Crystallinity Increase |

|---|---|---|---|

| 0 | 0 | 45.2 | 5.1 |

| 2 | 12 ± 3 | 44.5 | 7.8 |

| 4 | 38 ± 5 | 43.1 | 12.4 |

| 6 | 65 ± 7 | 41.0 | 15.9 |

| 8 | >85 | - | 18.2 |

Experimental Protocols for Accelerated Aging Studies

Protocol: Forced Hydrolytic Degradation of PLGA Microspheres

Objective: To quantify molecular weight loss and degradation product formation as a function of time and temperature.

- Sample Preparation: Prepare PLGA (50:50, iv 0.6 dL/g) microspheres using a double emulsion-solvent evaporation method. Sieve to obtain 50-100 μm fraction.

- Incubation: Accurately weigh 50 mg of microspheres into 20 mL glass vials. Add 10 mL of pre-warmed 0.1M phosphate-buffered saline (PBS, pH 7.4). Flush headspace with N₂ and seal.

- Temperature Conditions: Incubate samples in triplicate at 4°C, 25°C, 37°C, 50°C, and 60°C (±0.5°C) in controlled ovens/shakers (50 rpm).

- Sampling: At predetermined time points (e.g., 1, 2, 4, 8, 12 weeks), remove vials in triplicate per temperature.

- Analysis:

- Molecular Weight: Isolate particles, wash, lyophilize. Dissolve in THF and analyze by GPC relative to polystyrene standards.

- Mass Loss: Filter remaining particles, dry to constant weight, and calculate percentage mass loss.

- pH Monitoring: Record pH of the incubation medium at each time point.

- Lactate/Glycolate Release: Analyze incubation medium by HPLC-UV for lactic and glycolic acid monomers.

Protocol: Arrhenius Modeling of Degradation Data

Objective: To calculate activation energy (Ea) for the dominant degradation process.

- Determine Rate Constant (k): For each temperature (T), plot Ln(Mwt / Mw0) versus time. Perform linear regression; the slope is the apparent first-order rate constant, k.

- Construct Arrhenius Plot: Plot Ln(k) against the reciprocal of absolute temperature (1/T in Kelvin).

- Linear Regression: Fit data points (excluding 60°C if deviation occurs) with a linear model: Ln(k) = Ln(A) - (Ea/R)(1/T).

- Calculate Ea: The slope of the line is equal to -Ea/R, where R = 8.314 J/mol·K. Solve for Ea.

- Shelf-life Extrapolation: Use the fitted Arrhenius equation to predict k at the desired storage temperature (e.g., 5°C or 25°C). Calculate time to a critical molecular weight threshold (e.g., Mw 50% loss).

Visualizing the Degradation Workflow & Kinetics

Diagram 1: Workflow for Arrhenius-based accelerated aging study of PLGA.

Diagram 2: Key chemical pathways in PLGA hydrolytic degradation.

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item / Reagent | Function & Role in Experiment |

|---|---|

| PLGA (50:50 LA:GA) | Model biodegradable polymer; subject of degradation kinetics study. |

| Phosphate Buffered Saline (PBS), 0.1M | Standard physiological medium for forced hydrolytic degradation studies. |

| Polyvinyl Alcohol (PVA), Mw 13-23k | Emulsifier used in microsphere fabrication to control particle size and morphology. |

| Dichloromethane (DCM), HPLC Grade | Volatile organic solvent for dissolving PLGA during microsphere formation. |

| Tetrahydrofuran (THF), Stabilizer-free | Solvent for GPC analysis; must be compatible with column chemistry. |

| Polystyrene GPC Standards | Calibration kit for determining the molecular weight distribution of PLGA samples. |

| Lactic Acid & Glycolic Acid Standards | HPLC analytical standards for quantifying degradation products in the medium. |

| pH Buffer Solutions (Acetate, Borate) | To study the specific effect of pH on degradation rate independently of temperature. |

| DSC Calibration Standards (Indium, Zinc) | For accurate calibration of the Differential Scanning Calorimeter measuring Tg changes. |

Navigating Complexities: Troubleshooting Non-Arrhenius Behavior in Real Polymer Systems

The application of the Arrhenius equation (k = A e^(-Ea/RT)) to predict polymer degradation and drug product shelf-life is a cornerstone of accelerated aging studies. The fundamental thesis is that elevating temperature uniformly accelerates all relevant chemical reactions, allowing for extrapolation to real-time storage conditions. However, this paradigm critically assumes temperature is the sole or dominant accelerating factor. For polymers and solid dosage forms susceptible to hydrolytic degradation, this assumption fails. Humidity—specifically, the equilibrium moisture content within the material—becomes the rate-controlling variable. Increasing temperature without controlling humidity can lead to erroneous, non-conservative lifetime predictions, as the accelerated condition may not sufficiently or correctly activate the moisture-dependent degradation pathway. This guide details the mechanistic role of humidity, protocols for its study, and integration into a modified kinetic model.

Mechanisms of Hydrolytic Degradation

Hydrolytic degradation occurs when water molecules cleave chemical bonds, such as esters, amides, or glycosidic linkages. The rate is governed not by ambient relative humidity (RH), but by the water activity (a_w) at the reactive site and the polymer's hygroscopicity. Two primary mechanisms are operative:

- Bulk Erosion: Water penetration rate exceeds the hydrolysis rate, leading to homogeneous degradation throughout the material (e.g., poly(lactic-co-glycolic acid) (PLGA) in aqueous media).

- Surface Erosion: Hydrolysis rate exceeds water penetration, causing the material to degrade from the surface inward (e.g., poly(anhydrides)).

For solid-state formulations (e.g., tablets, solid dispersions, encapsulated devices), water sorption isotherms determine the critical moisture threshold for plasticization and reaction.

Experimental Protocols for Humidity-Controlled Studies

Protocol 3.1: Dynamic Vapor Sorption (DVS) for Moisture Uptake Analysis

Objective: Determine equilibrium moisture content and critical RH points for a polymer/drug product. Method:

- A microbalance holds a sample (5-20 mg) at constant temperature (e.g., 25°C).

- The RH is stepped incrementally (e.g., 0%, 10%, 20%...90%).

- Mass change is monitored at each step until equilibrium (dm/dt < 0.002%/min).

- The desorption cycle is similarly measured. Output: Sorption isotherm plot identifying hygroscopicity and potential phase changes.

Protocol 3.2: Accelerated Aging Under Controlled Humidity

Objective: Generate kinetic data for hydrolytic degradation across multiple stress conditions. Method:

- Prepare identical samples (e.g., polymer films, tablets) and condition them to the same initial moisture content.

- Place samples in controlled environment chambers (e.g., desiccators with saturated salt solutions or commercial humidity chambers) at defined %RH levels (e.g., 30%, 50%, 70%, 90%).

- Incubate chambers at multiple accelerated temperatures (e.g., 40°C, 50°C, 60°C).

- At regular time intervals, remove samples (n≥3) for analysis: a. Mass/Water Content: Karl Fischer titration. b. Chemical Integrity: HPLC for assay/degradants, FTIR for bond cleavage. c. Physical Properties: DSC (Tg), XRD (crystallinity). Key Control: Samples for different time points must be stored separately to avoid repeated opening of the primary chamber.

Data Presentation: Kinetic Parameters for Hydrolytic Degradation

Table 1: Pseudo-First-Order Rate Constants (k) for Model Ester Polymer Hydrolysis

| Temperature (°C) | Relative Humidity (%) | Equilibrium Moisture Content (% w/w) | Rate Constant, k (week⁻¹) | Observed Primary Degradant Increase (%) |

|---|---|---|---|---|

| 40 | 30 | 1.2 | 0.002 | <0.1 |

| 40 | 75 | 4.8 | 0.015 | 0.8 |

| 50 | 30 | 1.1 | 0.005 | 0.2 |

| 50 | 75 | 4.5 | 0.042 | 2.5 |

| 60 | 30 | 1.0 | 0.012 | 0.7 |

| 60 | 75 | 4.3 | 0.118 | 6.9 |

Table 2: Apparent Activation Energy (Ea) Calculated at Constant Humidity vs. Constant Temperature

| Condition Held Constant | Varied Parameter | Calculated Apparent Ea (kJ/mol) | R² of Arrhenius Fit |

|---|---|---|---|

| 75% RH | Temperature | 85.2 | 0.997 |

| 50°C | Humidity (MC*) | N/A (Model requires humidity-driven model) | N/A |

| Dry (<5% RH) | Temperature | 45.5 (Radical oxidation pathway dominates) | 0.965 |

*MC: Moisture Content

Modeling: Integrating Humidity into the Kinetic Framework

The simple Arrhenius model must be replaced or supplemented. A prevalent empirical model is the Modified Humidity-Corrected Arrhenius Equation:

k(T, RH) = A * exp(-Ea/RT) * (RH)^n

where n is the humidity exponent fitted from data. A more fundamental approach uses the Water Activity (a_w) Model:

k(T, a_w) = k_dry(T) + k_wet(T) * (a_w)^m

where k_dry represents humidity-independent pathways, and k_wet the hydrolytic pathway.

Title: Kinetic Model Integrating Temperature and Humidity

Title: Humidity-Aware Accelerated Aging Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Materials for Humidity-Controlled Polymer Aging Studies

| Item | Function/Benefit | Key Consideration |

|---|---|---|

| Saturated Salt Solutions | Provides low-cost, stable RH in closed desiccators for aging studies. | Each salt yields specific %RH at a given T (e.g., MgCl₂ ≈ 33% RH at 25°C). Must be validated at the stress temperature. |

| Dynamic Vapor Sorption (DVS) Instrument | Quantifies moisture sorption isotherms and diffusion coefficients. | Critical for identifying critical RH thresholds and selecting appropriate stress levels. |

| Humidity-Calibrated Environmental Chambers | Provides precise, programmable T and RH control for bulk studies. | Requires regular calibration with traceable probes; gradient within chamber must be mapped. |

| Hermetic, Moisture-Barrier Sample Vials | Allows separate storage of individual time-point samples to prevent humidity cross-influence. | Use vials with PTFE-faced septa. Verify integrity at high temperature/humidity. |

| Karl Fischer Titrator (Coulometric) | Precisely measures low levels of water in solid samples (<100 μg to % levels). | Requires proper sample preparation (e.g., crushing, extraction) to release all bound water. |