Modeling Uncertainty: How B-Spline Approximation Enhances Molecular Weight Distribution Control in Drug Development

This article provides a comprehensive overview of B-spline approximation models for controlling Molecular Weight Distribution (MWD) in polymer-based therapeutics and drug delivery systems.

Modeling Uncertainty: How B-Spline Approximation Enhances Molecular Weight Distribution Control in Drug Development

Abstract

This article provides a comprehensive overview of B-spline approximation models for controlling Molecular Weight Distribution (MWD) in polymer-based therapeutics and drug delivery systems. Targeting researchers and development professionals, it explores the mathematical foundations of B-splines for MWD representation, details practical implementation and parameter optimization strategies, addresses common fitting challenges and computational bottlenecks, and validates the approach against traditional methods through comparative case studies. The synthesis offers a robust framework for improving product consistency and regulatory outcomes in pharmaceutical development.

The Building Blocks: Understanding B-Splines and Molecular Weight Distribution Fundamentals

Within the broader research thesis on B-spline approximation models for Molecular Weight Distribution (MWD) control, the imperative for precise MWD regulation in pharmaceutical polymers is unequivocal. B-spline models offer a robust mathematical framework for representing complex, non-ideal MWD curves and enabling predictive, model-based control in polymerization reactors. This precision transcends academic interest; it is a critical determinant of drug product safety, efficacy, and quality.

The Critical Impact of MWD on Pharmaceutical Polymer Performance

Pharmaceutical polymers, used as excipients in controlled-release formulations, bioavailability enhancers, and stabilizers, exhibit performance metrics directly dictated by their MWD. Precise control is not optional for the following reasons:

- Drug Release Kinetics: The diffusion rate of an API through a polymer matrix is a function of polymer chain length. Broader MWD leads to unpredictable, multi-modal release profiles, jeopardizing therapeutic windows.

- Physical Stability & Processability: Mechanical properties (e.g., film strength in coatings, viscosity of solutions) depend on the weight-average molecular weight (Mw) and polydispersity index (Đ). High Đ can cause phase separation, cracking, or inconsistent flow during manufacturing.

- Biological Safety & Immunogenicity: Low molecular weight oligomer fractions may leach out, potentially triggering immune responses or exhibiting unanticipated toxicity.

- Batch-to-Batch Consistency: Regulatory agencies (FDA, EMA) mandate rigorous Quality by Design (QbD). Reproducible MWD is a fundamental Critical Quality Attribute (CQA) for any polymer-based drug product.

Table 1: Quantitative Impact of MWD Parameters on Drug Product CQAs

| MWD Parameter | Typical Target Range (Pharma Grade) | Impact on Critical Quality Attribute (CQA) | Consequence of Deviation |

|---|---|---|---|

| Number-Avg (Mn) | Specification-dependent (e.g., 10-100 kDa) | Drug loading capacity, polymer erosion rate. | Under-dosing or burst release. |

| Weight-Avg (Mw) | Specification-dependent (e.g., 20-200 kDa) | Matrix strength, solution viscosity, release profile. | Failed dissolution test, poor coating integrity. |

| Polydispersity (Đ) | Ideally < 1.5 (Often 1.1-1.8) | Predictability and uniformity of all above properties. | Highly variable drug release, unstable formulation. |

| Low-MW Tail | Minimized per safety assessment | Biological safety, extractables/leachables. | Potential toxicity, immunogenic response. |

| High-MW Tail | Controlled per processability need | Gelation, processing difficulties. | Non-homogeneous product, manufacturing failures. |

Application Notes: Integrating B-Spline Models for MWD Control

A B-spline model approximates the entire MWD curve as a linear combination of basis spline functions. This allows a parsimonious representation of complex distributions using a limited set of control points (de Boor points). In the thesis context, the model is defined as:

( MWD(x) = \sum{i=1}^{n} ci B{i,k}(x) ) where ( ci ) are the coefficients (control points), ( B_{i,k} ) are the k-degree B-spline basis functions, and ( x ) is the molecular weight (often log-transformed).

Application Workflow:

- Offline Characterization: Use Size Exclusion Chromatography (SEC) data from pilot batches to train an initial B-spline model, mapping reactor conditions (e.g., initiator concentration, temperature profile) to the control points ( c_i ).

- Online Estimation: Employ real-time process analytics (e.g., in-line viscosity, Raman spectroscopy) with state observers (e.g., Kalman Filter) to update the B-spline control points, estimating the evolving MWD.

- Model Predictive Control (MPC): The MPC algorithm uses the dynamic B-spline model to manipulate reactor inputs (monomer feed, temperature) to steer the predicted MWD towards the target profile defined by target control points ( c_{i, target} ).

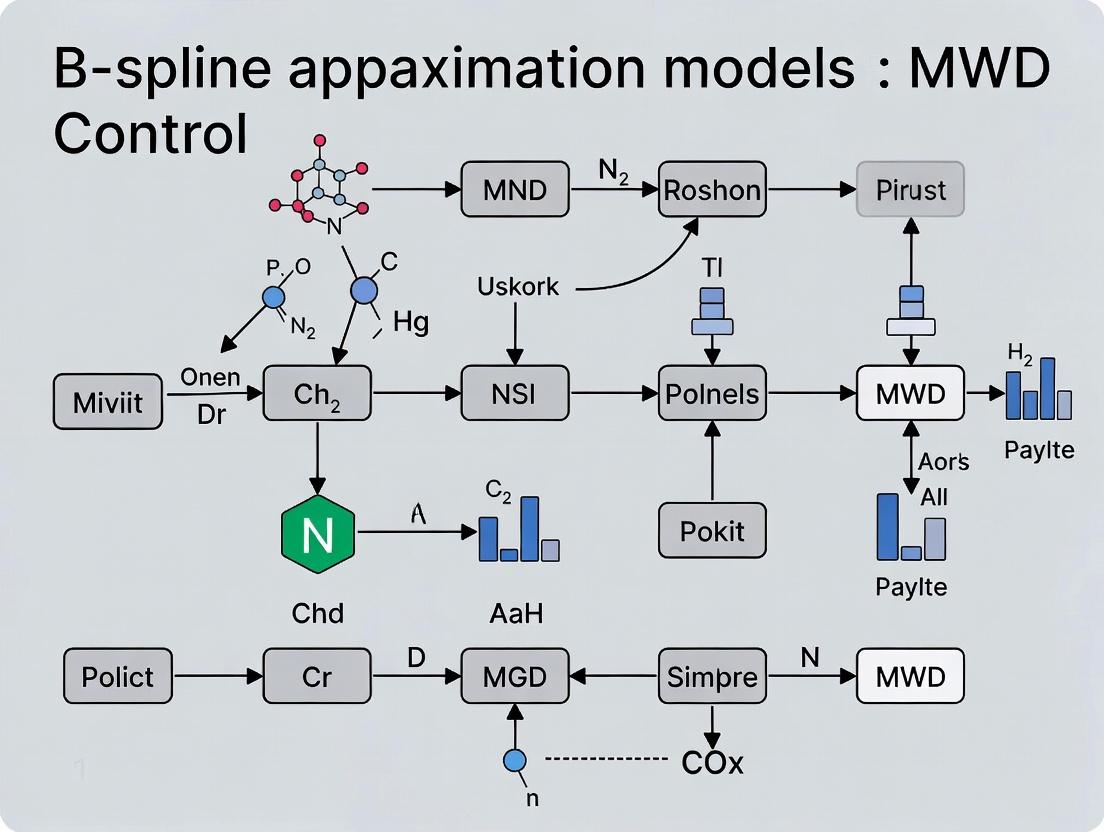

Diagram Title: B-Spline Based MWD Control Loop for Polymerization

Experimental Protocols for MWD Analysis & Model Validation

Protocol 4.1: Size Exclusion Chromatography (SEC) for MWD Benchmarking

Purpose: To obtain the definitive MWD curve for model training and validation. Materials: See Scientist's Toolkit below. Procedure:

- Sample Preparation: Precisely dissolve 2-5 mg of dried polymer in 1 mL of SEC eluent (e.g., THF with 0.1% BHT). Filter through a 0.45 µm PTFE syringe filter.

- System Calibration: Inject 100 µL of narrow polystyrene (or PEG) standard mixture. Establish a log(MW) vs. retention time calibration curve.

- Sample Analysis: Inject 100 µL of prepared sample. Use isocratic flow at 1.0 mL/min. Record differential refractive index (dRI) signal.

- Data Processing: Use SEC software to correct for band broadening. Calculate Mn, Mw, Đ, and export the full weight-fraction vs. molecular weight data for B-spline fitting.

Protocol 4.2: In-line Raman Spectroscopy for Real-Time Monomer Conversion

Purpose: To provide real-time data for the state estimator in the B-spline MPC framework. Procedure:

- Probe Installation & Calibration: Install a immersion optic Raman probe in the reactor. Develop a Partial Least Squares (PLS) regression model correlating Raman spectra (e.g., C=C bond peak at ~1640 cm⁻¹ decrease) to offline GC or NMR conversion data from calibration batches.

- Real-Time Monitoring: During polymerization, collect spectra every 30-60 seconds. Process spectra (cosmic ray removal, baseline correction) and apply the PLS model to predict instantaneous monomer conversion.

- Data Integration: Stream conversion data to the process control software where the state estimator uses it, alongside kinetic models, to update the predicted MWD (B-spline control points).

Protocol 4.3: Validation of B-Spline MWD Prediction

Purpose: To test the accuracy of the B-spline model's MWD prediction against offline SEC. Procedure:

- Run a polymerization experiment under the control of the B-spline MPC system.

- At pre-defined timepoints (e.g., 20%, 50%, 80%, 100% conversion), aseptically withdraw ~5 mL of reaction mixture.

- Immediately quench samples, precipitate, purify, and dry following standard protocols.

- Analyze each sample via SEC (Protocol 4.1) to obtain the true MWD.

- Extract the model-predicted MWD (from the B-spline control points) for the exact same timepoints.

- Compare using objective metrics: Overlay plots, and calculate the Root Mean Square Error (RMSE) between the predicted and actual weight fraction curves.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function/Application in MWD Control Research |

|---|---|

| Pharmaceutical-Grade Monomers (e.g., Lactide, Glycolide, ε-Caprolactone, NVP) | High-purity monomers are essential for reproducible kinetics and minimizing branching/transfer reactions that broaden MWD. |

| Biocompatible Initiators & Catalysts (e.g., Sn(Oct)₂, DBU, Enzymes) | Dictate the initiation efficiency and chain growth mechanism, directly influencing Đ. Choice is critical for regulatory approval. |

| SEC Columns (e.g., Agilent PLgel, Waters Styragel) | Separates polymer chains by hydrodynamic volume to measure MWD. Column pore size must match polymer MW range. |

| Narrow MWD Polymer Standards (Polystyrene, PMMA, PEG) | Essential for calibrating SEC systems to convert retention time to molecular weight. |

| Stabilized SEC Eluents (e.g., THF + 0.1% BHT) | Prevents oxidative degradation of samples and columns during analysis. |

| In-line PAT Probes (Raman, ATR-FTIR, Reactor Viscometer) | Provides real-time data on conversion and viscosity, enabling feedback for advanced control models like B-spline MPC. |

| B-spline / MPC Software Platform (e.g., MATLAB Control Toolbox, Python SciPy/Scikit-learn) | Implements the mathematical framework for modeling, state estimation, and predictive control of MWD. |

1. Introduction: The Thesis Context of B-Spline MWD Control

Within the broader thesis on B-spline approximation models for Molecular Weight Distribution (MWD) control in polymer-based drug delivery systems, the accurate characterization of the full distribution is paramount. Traditional metrics like the number-average (Mₙ) and weight-average (M_w) molecular weight are insufficient descriptors for complex, multimodal, or highly skewed distributions. This application note details the limitations of these averages and provides protocols for comprehensive MWD analysis, forming the experimental basis for high-fidelity B-spline model training.

2. Quantitative Comparison of Average Molecular Weights

Table 1: Simulated MWD Scenarios Demonstrating Identical Averages from Different Distributions

| Scenario | Distribution Type | Mₙ (kDa) | M_w (kDa) | PDI (M_w/Mₙ) | Key Descriptive Limitation |

|---|---|---|---|---|---|

| A | Narrow, Symmetric (Monodisperse) | 100.0 | 102.0 | 1.02 | Averages adequately represent the system. |

| B | Broad, Symmetric | 100.0 | 150.0 | 1.50 | Averages mask breadth; high PDI is only a hint. |

| C | Bimodal (Peaks at 50 & 150 kDa) | 100.0 | 125.0 | 1.25 | Averages completely obscure the presence of two distinct populations. |

| D | High-Weight Skewed | 100.0 | 200.0 | 2.00 | Averages fail to quantify the "tail" of high-MW species critical for viscosity. |

3. Experimental Protocols for Advanced MWD Deconvolution

Protocol 3.1: Multi-Detector Size Exclusion Chromatography (SEC-MALS/DRI/UV)

- Objective: To obtain absolute molecular weight distributions and quantify branching or composition.

- Materials: See The Scientist's Toolkit.

- Procedure:

- Prepare polymer solutions at 1-3 mg/mL in the appropriate SEC eluent (e.g., THF, DMF with LiBr, aqueous buffer). Filter through a 0.22 µm membrane.

- Calibrate the MALS detector using pure toluene. Normalize detectors using a monodisperse standard.

- Equilibrate SEC columns (guard + 2-3 analytical columns) at a constant flow rate (e.g., 1.0 mL/min).

- Inject 100 µL of sample. Data from MALS (multiple angles), DRI (concentration), and optional UV/vis detectors are collected simultaneously.

- Use dedicated software (e.g., ASTRA, Empower) to calculate M_w, Mₙ, and the full distribution via the Zimm model. Plot differential weight fraction (dw/dlogM) vs. logM.

Protocol 3.2: Asymmetric Flow Field-Flow Fractionation (AF4) with Online Viscometry

- Objective: To separate and characterize ultra-high molecular weight, supramolecular, or fragile aggregates that may be sheared in SEC columns.

- Procedure:

- Select an appropriate membrane (e.g., polyethersulfone) and spacer (350-500 µm thickness).

- Perform a focusing/injection step: Load sample (20-100 µL) with crossflow applied to focus the sample band.

- Initiate elution with a programmed decay of crossflow to separate species by hydrodynamic radius.

- The eluent flows through MALS, DRI, and an online viscometer detector.

- Data analysis yields intrinsic viscosity and hydrodynamic radius across the distribution, enabling structural (e.g., branching) analysis per slice.

4. The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Advanced MWD Analysis

| Item | Function & Relevance |

|---|---|

| Multi-Angle Light Scattering (MALS) Detector | Provides absolute molecular weight measurement for each eluting slice without reliance on column calibration standards. Critical for detecting aggregates and high-MW tails. |

| Differential Refractometer (DRI) | Measures the concentration of polymer in the eluent. Essential for calculating molecular weight when combined with MALS signal. |

| Online Viscometer Detector | Measures intrinsic viscosity across the MWD. The Mark-Houwink plot (log IV vs. log M) reveals branching and chain conformation changes. |

| AF4 System with Programmable Crossflow | Gentle separation channel for broad or fragile distributions, preventing shear degradation and extending the separation range beyond SEC. |

| Narrow Dispersity Polymer Standards (e.g., PMMA, PS) | Used for system performance verification, column calibration for conventional SEC, and detector alignment. |

| B-Spline Function Library (e.g., in Python: SciPy) | Software tools for approximating the full, high-resolution MWD curve from discrete SEC/AF4 data points for advanced process control modeling. |

5. Visualizing the Role of Full MWD in B-Spline Control Research

Diagram 1: MWD Data Path for Polymer Control

Diagram 2: Multi-Detector MWD Analysis Workflow

Application Notes

B-spline (Basis-spline) functions are polynomial functions defined piecewise over a knot vector. Within the context of a thesis on B-spline approximation models for Managed Withdrawal/Weaning (MWD) control research, these functions provide a powerful mathematical framework for modeling complex, time-dependent physiological responses during drug withdrawal or weaning from medical devices.

Core Properties:

- Flexibility: B-splines can approximate complex, non-linear response curves (e.g., hormone levels, withdrawal symptom severity scores) by adjusting the degree and number of basis functions without changing the model's fundamental form.

- Smoothness: The continuity of B-splines (C^(p-k) at knot points, where p is degree, k is knot multiplicity) is crucial for modeling biological processes that are expected to evolve smoothly over time, avoiding physiologically unrealistic abrupt transitions.

- Local Control: Modifying a single control point or coefficient affects the curve only over a limited interval, defined by the degree and knot spacing. This is critical for MWD models, as it allows refinement of the approximation for specific phases (e.g., acute withdrawal) without altering the entire model fit.

MWD Research Application: In modeling a patient's response to a tapered drug regimen, B-spline basis functions enable the creation of a smooth, flexible trajectory of a biomarker (e.g., cortisol level). The local control property permits researchers to focus model refinement on the period immediately following a dosage reduction, ensuring accurate capture of the acute response while maintaining a globally stable model.

Data Presentation

Table 1: Comparison of Approximation Methods for Time-Series Biomarker Data

| Feature | B-Spline Model | Polynomial Regression | Simple Moving Average |

|---|---|---|---|

| Underlying Flexibility | High (adjustable via knots/degree) | Low (fixed by polynomial order) | Very Low (fixed window) |

| Smoothness Guarantee | Configurable (C^(p-k) continuity) | C∞ (often overly smooth) | C⁰ (can be discontinuous) |

| Local Control | Yes | No (global influence) | Yes (within window only) |

| Parametric Efficiency | High (few parameters for complex shapes) | Low (requires high order for complexity) | N/A (non-parametric) |

| Typical Use in MWD | Primary response surface modeling | Trend line estimation | Noise reduction in raw data |

Table 2: Effect of B-Spline Degree on Model Characteristics for Simulated Withdrawal Data

| Degree (p) | Continuity at Interior Knots | Minimum # Control Points | Example MWD Application Context |

|---|---|---|---|

| 1 (Linear) | C⁰ (position continuity) | 2 | Piecewise linear approximation of symptom score. |

| 2 (Quadratic) | C¹ (tangent continuity) | 3 | Modeling smoothly changing vital sign trends. |

| 3 (Cubic) | C² (curvature continuity) | 4 | Standard for pharmacokinetic/pharmacodynamic (PK/PD) response curves. |

| 4 (Quartic) | C³ (rate of curvature change) | 5 | High-fidelity modeling of oscillatory hormonal feedback. |

Experimental Protocols

Protocol 1: Constructing a B-Spline Basis for MWD Biomarker Analysis

Objective: To generate a set of B-spline basis functions for approximating a continuous biomarker trajectory from discrete, noisy measurements.

Materials: See "The Scientist's Toolkit" below.

Software: Computational environment (e.g., Python with SciPy, R with splines package, MATLAB).

Methodology:

- Data Preparation: Compile time-series biomarker data (e.g., hourly heart rate variability). Time

tis the independent variable. - Knot Vector Definition:

- Determine the desired B-spline degree

p(typically cubic, p=3). - Define a knot vector

Ξ = [ξ₀, ξ₁, ..., ξₘ]. Forncontrol points,m = n + p + 1. - Use equally spaced knots for uniform data. For non-uniform data sampling, place more knots in regions of expected rapid change (e.g., post-dose reduction).

- Enforce

(p+1)-fold start and end knots for clamped B-splines:ξ₀ = ξ₁ = ... = ξ_pandξ_{m-p} = ... = ξ_m.

- Determine the desired B-spline degree

- Basis Function Computation:

- For each basis function

iof degree0(piecewise constant), define:N_{i,0}(t) = { 1 if ξ_i ≤ t < ξ_{i+1}, 0 otherwise }. - Recursively compute higher-degree basis functions using the Cox-de Boor recurrence relation:

N_{i,p}(t) = ((t - ξ_i) / (ξ_{i+p} - ξ_i)) * N_{i,p-1}(t) + ((ξ_{i+p+1} - t) / (ξ_{i+p+1} - ξ_{i+1})) * N_{i+1,p-1}(t). - Implement the recursion algorithmically for all

iand the desired degreep.

- For each basis function

- Validation: Plot the resulting basis functions

N_{i,p}(t)to verify they are non-negative, have local support, and form a partition of unity over the domain.

Protocol 2: Fitting a B-Spline Model to Experimental Withdrawal Data

Objective: To determine the optimal control point coefficients for a B-spline curve that approximates observed experimental data.

Methodology:

- Basis Construction: Follow Protocol 1 to generate

nbasis functionsN_{i,p}(t). - Set Up Linear System: For each observed data point

(t_j, y_j), the B-spline model isS(t_j) = Σ_{i=0}^{n-1} c_i * N_{i,p}(t_j), wherec_iare unknown coefficients. This leads to the linear systemA * c = y, whereA[j, i] = N_{i,p}(t_j). - Solve for Coefficients:

- Perform a least-squares regression:

c = (AᵀA)⁻¹Aᵀy. - For ill-conditioned systems or to prevent overfitting, employ regularization (e.g., Ridge regression:

c = (AᵀA + λI)⁻¹Aᵀy).

- Perform a least-squares regression:

- Model Evaluation:

- Calculate the fitted curve:

S(t) = Σ c_i * N_{i,p}(t). - Compute the coefficient of determination (R²) and root-mean-square error (RMSE).

- Use cross-validation to optimize hyperparameters like knot placement and regularization strength

λ.

- Calculate the fitted curve:

Mandatory Visualization

B-Spline Model Fitting Workflow

B-Spline Curve as Weighted Sum of Bases

The Scientist's Toolkit

Key Research Reagent Solutions for B-Spline Based MWD Modeling

| Item | Function in Research |

|---|---|

| High-Frequency Biometric Sensor | Captures continuous or dense time-series data (e.g., EEG, actigraphy, continuous glucose monitor) essential for defining the detailed response curve to be modeled by B-splines. |

| Computational Software (Python/R/MATLAB) | Provides libraries (SciPy, splines, Curve Fitting Toolbox) with implemented algorithms for B-spline basis computation, regression, and evaluation. |

| Optimization Algorithm Library | Enables automated knot placement optimization and regularization parameter (λ) selection to prevent model overfitting to noisy biological data. |

| Clinical Withdrawal Assessment Scale | Provides the standardized quantitative outcome variable (e.g., Clinical Opiate Withdrawal Scale score) that serves as the dependent variable y for the B-spline approximation. |

| Statistical Validation Suite | Software tools for performing k-fold cross-validation, calculating information criteria (AIC/BIC), and bootstrap analysis to confirm model robustness. |

Within the broader thesis on B-spline approximation models for Molecular Weight Distribution (MWD) control research, this document details the transformation of raw Size Exclusion Chromatography (SEC) or Gel Permeation Chromatography (GPC) data into a continuous, mathematically robust B-spline model. This representation is critical for advanced process analytics, control, and design in polymer science and biopharmaceuticals, particularly for complex therapeutics like monoclonal antibodies, ADCs, and mRNA-LNP formulations.

Table 1: Typical SEC/GPC System Parameters for MWD Analysis

| Parameter | Typical Range/Value | Function/Impact on Data |

|---|---|---|

| Column Set | 2-4 columns in series | Determines separation range (e.g., 10² - 10⁷ Da). |

| Mobile Phase | THF, DMF, HFIP, Aqueous buffer | Dissolves sample, must match detector compatibility. |

| Flow Rate | 0.5 - 1.0 mL/min | Affects resolution and analysis time. |

| Detector Types | RI, UV, LS (MALS), Viscometer | RI/UV for concentration; LS/Viscometer for absolute MW. |

| Injection Volume | 50 - 200 µL | Must be optimized for signal-to-noise. |

| Calibration Standards | Narrow polystyrene, PEG, or protein standards | Essential for relative MW calibration. |

Table 2: B-Spline Model Parameters for MWD Representation

| Parameter | Description | Typical Optimization Range |

|---|---|---|

| Knot Vector (t) | Sequence of parameter values defining spline segments. | Number of knots: 5-15 (data-dependent). |

| Control Points (P_i) | Coordinates defining spline shape (Log(MW) vs. dw/dLogM). | Equal to number of basis functions. |

| Basis Degree (p) | Polynomial degree of spline pieces. | 3 (cubic) recommended for smoothness. |

| Smoothing Factor (λ) | Penalty weight for roughness penalty in fitting. | 10⁻⁶ to 10⁻² (log-scale search). |

Experimental Protocol: From Raw Data to B-Spline Model

Protocol 1: SEC/GPC Data Acquisition and Preprocessing Objective: To obtain clean, calibrated concentration (dw/dLogM) vs. molecular weight data.

- System Calibration: Inject a series of narrow dispersity standards. Construct a calibration curve: Log(MW) vs. elution volume. Fit with a 3rd-order polynomial.

- Sample Analysis: Dissolve sample in mobile phase (2-4 mg/mL). Filter (0.2 µm). Inject in triplicate. Acquire chromatogram (Signal vs. Time/Volume).

- Baseline Correction: Subtract baseline drawn from pre-peak to post-peak baseline.

- Axis Transformation: Convert elution volume to Log(MW) using the calibration curve.

- Normalization: Normalize detector response to concentration (using dn/dc or extinction coefficient). Calculate dw/dLog(MW) and normalize area under curve to 1 (total mass).

Protocol 2: B-Spline Curve Fitting to Discrete MWD Data Objective: To fit a smooth, continuous B-spline model, S(x), to the discrete (Log(MW), dw/dLogM) data points (xi, yi).

- Define Model: Use a cubic (p=3) B-spline defined by

m+1control points and a knot vectortof lengthm+p+2. - Initial Knot Placement: Place knots at quantiles of the x_i (Log(MW)) data points to ensure sufficient data support per segment.

- Perform Penalized Least-Squares Fit: Minimize the objective function:

∑_i [y_i - S(x_i)]² + λ ∫ [S''(x)]² dxwhere λ is the smoothing parameter determined via generalized cross-validation (GCV). - Model Validation: Calculate R² and visually inspect residual plot (residuals vs. Log(MW)) for systematic bias.

Visualization of Workflows and Relationships

Title: SEC Data to B-Spline Model Workflow

Title: B-Spline Knots & Control Points Relationship

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for SEC/GPC to B-Spline Modeling

| Item | Function/Benefit | Example/Notes |

|---|---|---|

| SEC/GPC Columns | Separation of molecules by hydrodynamic volume. | TSKgel, PLgel, or UHPLC columns (e.g., Acquity). |

| Narrow MW Standards | System calibration for relative MW determination. | Polystyrene (organic), PEG/PMMA (polar), proteins (aqueous). |

| MALS Detector | Provides absolute molecular weight without calibration. | Wyatt DAWN, Heleos II. Essential for branched/unknown polymers. |

| Refractive Index (RI) Detector | Universal concentration detector. | Must be thermostatted for stability. |

| dn/dc Value | Relates RI signal to concentration for the polymer/solvent system. | Must be accurately known or measured (e.g., 0.185 mL/g for PS in THF). |

| Data Acquisition Software | Collects and exports raw chromatographic data. | Empower, Chromeleon, Astra. Must export ASCII/time-series. |

| Scientific Computing Environment | Platform for B-spline fitting and analysis. | Python (SciPy, scikit-learn), MATLAB, or R with splines package. |

| Smoothing Parameter Optimization Tool | Automates selection of optimal λ. | Implement GCV or AIC minimization routine in code. |

Within the broader thesis on B-spline approximation models for Molecular Weight Distribution (MWD) control in polymer-based drug delivery systems, this application note delineates the superior capability of B-spline models in characterizing complex, non-ideal MWDs. Traditional parametric fits (e.g., Gaussian, Log-Normal) often fail to capture multi-modality and heavy tails, critical features impacting drug release kinetics. B-splines, as flexible non-parametric estimators, provide a robust framework for accurate distribution mapping, enabling precise control over pharmaceutical product performance.

Control of MWD in polymeric excipients is paramount for predictable drug release. Traditional analytical methods rely on assumptions of distribution shape, limiting their accuracy for modern, engineered polymers with complex chain architectures. This section establishes the necessity for advanced fitting techniques within quality-by-design (QbD) paradigms.

Quantitative Comparison: B-Spline vs. Traditional Fits

Data from Size Exclusion Chromatography (SEC) analysis of a tri-modal PLGA batch was fitted using Gaussian Mixture Models (GMM) and a B-spline model. Key metrics are compared below.

Table 1: Fitting Performance Metrics for Tri-Modal PLGA SEC Data

| Metric | Gaussian Mixture Model (3 Components) | B-Spline Model (k=6, degree=3) |

|---|---|---|

| Adjusted R² | 0.942 | 0.997 |

| Akaike Information Criterion (AIC) | 125.7 | 45.2 |

| Residual Sum of Squares (RSS) | 8.34 | 0.89 |

| Tail Region (≤10% peak) Error | 32% | 5% |

| Identified Modalities | 3 (fixed) | 3 (emergent) |

Table 2: Computational and Practical Considerations

| Consideration | Traditional Parametric Fits | B-Spline Approximation |

|---|---|---|

| A Priori Shape Assumption | Required (major limitation) | Not Required |

| Sensitivity to Outliers | High | Low (configurable) |

| Local Flexibility | Poor | Excellent |

| Extrapolation Reliability | Moderate | Poor (interpolation-focused) |

| Integration into Control Loops | Straightforward | Requires knot optimization |

Experimental Protocols

Protocol 1: B-Spline Model Fitting for SEC Chromatograms

Objective: To reconstruct the true MWD from raw SEC data. Materials: See Scientist's Toolkit. Procedure:

- Data Preprocessing: Normalize SEC refractive index (RI) detector output. Correct for baseline drift. Convert elution time to Log(MW) using a calibrated standard curve.

- Knot Sequence Definition: For n data points, define a knot vector t of length m+1. For open uniform B-splines of degree k=3, use m = n + k. Place knots at data boundaries and uniformly/interquartile within the interior range.

- Basis Function Construction: Compute the i-th B-spline basis function of degree k, N_{i,k}(x), using the Cox-de Boor recursion formula.

- Linear Least Squares Regression: Solve for control point coefficients P_i by minimizing:

||D - Σ(P_i * N_{i,k}(x))||², where D is the vector of normalized SEC data. - Model Validation: Calculate residual plots and AIC. Use cross-validation to avoid overfitting.

Protocol 2: Comparative Analysis of Tail Region Fidelity

Objective: Quantify accuracy in low-probability tail regions of the MWD. Procedure:

- Sample Preparation: Use a polymer blend synthesized to produce a known asymmetric, heavy-tailed MWD.

- Data Acquisition: Perform SEC analysis in triplicate.

- Parallel Fitting: Fit Dataset A with a Log-Normal distribution via maximum likelihood estimation. Fit Dataset B with a B-spline model (degree=3, knots placed at deciles).

- Tail Extraction: Isolate data corresponding to MW values beyond ±2.5 standard deviations from the mean in the Log-Normal fit.

- Error Calculation: Compare the integrated area under the fitted curve to the integrated raw data area within the tail region. Report as percentage error.

Visualizations

Title: B-Spline MWD Analysis Workflow

Title: Model Comparison: Assumption vs. Outcome

The Scientist's Toolkit

Table 3: Essential Research Reagents & Materials for MWD Analysis

| Item | Function in Protocol | Critical Specification/Note |

|---|---|---|

| Narrow DispersityPS/PEG Standards | SEC calibration to convert elution volume to molecular weight. | Set must cover expected MW range of analyte. |

| THF or DMF (HPLC Grade) | SEC mobile phase for polymer dissolution and elution. | Must be stabilizer-free to avoid column interaction. |

| PLGA or PolymerTest Blends | Analyte for method development and validation. | Engineered to have known multi-modal or heavy-tailed distribution. |

| B-Spline Software(e.g., SciPy, MATLAB) | Computational engine for basis function generation and regression. | Must allow user-defined knot placement and degree. |

| Size ExclusionChromatography System | Primary analytical instrument for MWD separation. | Equipped with RI and multi-angle light scattering (MALS) detectors. |

| Cross-ValidationScripts | To prevent B-spline overfitting by optimizing knot number. | Custom code (Python/R) required for automated knot selection. |

From Theory to Practice: Implementing B-Spline Models for MWD Prediction and Control

Application Notes

Within the broader thesis on B-spline approximation models for Molecular Weight Distribution (MWD) control in polymer-based drug delivery systems, this protocol details the foundational steps for constructing a predictive model. Accurate MWD control is critical for optimizing drug release kinetics, nanoparticle stability, and biodistribution. This workflow transforms raw Gel Permeation Chromatography (GPC) data into a functional B-spline basis, enabling precise modeling and subsequent control of polymerization reactions.

Data Preprocessing Protocol

Objective: To clean and normalize raw chromatographic data for reliable spline approximation.

Experimental Protocol: GPC Data Acquisition and Cleaning

- Instrument Calibration: Perform GPC analysis using a polystyrene standard calibration curve. Run samples in triplicate.

- Baseline Subtraction: For each chromatogram, identify a baseline from the signal region before elution onset. Subtract this baseline value from all data points.

- Noise Filtering: Apply a Savitzky-Golay filter (2nd order polynomial, 15-point window) to smooth high-frequency instrumental noise.

- Normalization: Normalize the detector response (e.g., refractive index) so that the area under the curve (AUC) for each chromatogram equals 1, representing a normalized probability distribution of molecular weights.

- Log-Transformation: Transform the molecular weight axis (x-axis) to a logarithmic scale (log₁₀Mw) to linearize the relationship and improve spline fit across orders of magnitude.

Table 1: Representative Preprocessing Outcomes for a PLGA Batch

| Processing Step | Mean Signal Intensity (a.u.) | Standard Deviation (a.u.) | AUC |

|---|---|---|---|

| Raw Data | 0.452 | 0.187 | 1.243 |

| After Baseline Subtraction | 0.401 | 0.166 | 1.001 |

| After Smoothing | 0.399 | 0.112 | 1.000 |

| After Normalization | 0.398 | 0.111 | 1.000 |

Knot Placement Strategy

Objective: To determine the optimal number and positions of knots that define the piecewise polynomial segments of the B-spline.

Protocol: Adaptive Knot Placement

- Initial Uniform Placement: On the log-transformed Mw axis, place

kknots uniformly across the data range.k = sqrt(n)/2is a common heuristic, wherenis the number of data points. - B-spline Fit: Fit a B-spline of degree

d(typically 3 for cubic splines) to the normalized MWD data using the initial knots. - Residual Analysis: Calculate residuals (difference between fitted and actual values). Identify regions where the absolute residual exceeds a threshold (e.g., 1.5 * median absolute residual).

- Knot Insertion: In high-residual regions, insert new knots at the location of the maximum residual.

- Knot Removal/Relaxation: In regions with very low residuals over a span greater than the average knot interval, consider removing a knot to avoid overfitting.

- Iteration: Repeat steps 2-4 until the Bayesian Information Criterion (BIC) no longer improves or a maximum number of knots is reached.

Table 2: Impact of Knot Count on Model Fit for a Representative Dataset

| Number of Knots | BIC Value | Sum of Squared Residuals (SSR) | R² |

|---|---|---|---|

| 5 | -245.6 | 0.0415 | 0.972 |

| 7 | -278.9 | 0.0221 | 0.985 |

| 10 | -281.1 | 0.0188 | 0.987 |

| 15 | -275.3 | 0.0169 | 0.988 |

Basis Construction Protocol

Objective: To generate the final B-spline basis functions that will serve as the model's building blocks.

Protocol: Constructing the B-spline Basis Matrix

- Define Parameters: Using the final knot vector

tfrom Section 3 and chosen spline degreed(e.g.,d=3), define the orderp = d + 1. - Calculate Basis Functions: For each of the

mdesired basis functions (wherem = length(t) - p), compute its value across the data range using the Cox-de Boor recursion formula. - Assemble Basis Matrix

B: Create ann x mmatrixB, where each columnjcontains the values of thej-th basis function evaluated at allndata points (log Mw values). - Basis Orthogonalization (Optional): For improved numerical stability in regression, perform QR decomposition on matrix

Bto obtain an orthonormal basis matrixQ.

Visual Workflow Diagram

Title: B-spline Workflow for MWD Modeling: From GPC Data to Basis

The Scientist's Toolkit

Table 3: Essential Research Reagents and Materials for MWD Modeling Workflow

| Item | Function/Application |

|---|---|

| Polymer Standards (e.g., Polystyrene, PLGA) | Used to calibrate the Gel Permeation Chromatography (GPC) system, establishing the relationship between elution time and molecular weight. |

| Tetrahydrofuran (THF) or DMF (HPLC Grade) | Common mobile phase solvents for GPC analysis of synthetic, biodegradable polymers used in drug delivery. |

| GPC/SEC System with RI Detector | The primary instrument for obtaining raw Molecular Weight Distribution (MWD) data. Refractive Index (RI) detection is standard. |

| Savitzky-Golay Filter Algorithm | Digital signal processing tool embedded in analysis software (e.g., Python SciPy, Origin) for smoothing chromatographic noise without distorting signal. |

| B-spline Software Library (e.g., SciPy, MATLAB Curve Fitting Toolbox) | Provides core algorithms for the Cox-de Boor recursion, knot placement, and basis matrix construction. |

| Bayesian Information Criterion (BIC) Calculator | Statistical criterion (often built into fitting software) used to optimize knot count, balancing model fit and complexity to prevent overfitting. |

Within the broader thesis on B-spline approximation models for molecular weight distribution (MWD) control, this application note details the critical calibration step. Precise control over MWD is paramount in polymer science for drug delivery system development, where pharmacokinetics are directly influenced. This protocol establishes the empirical link between controllable reactor parameters and the coefficients of the B-spline functions used to model the resulting MWD.

Core Calibration Data: Parameter-Coefficient Relationships

The following tables summarize quantitative relationships derived from a designed experiment on free-radical polymerization of methyl methacrylate (MMA).

Table 1: Process Parameters and Their Experimental Ranges

| Parameter | Symbol | Unit | Low Level (-1) | High Level (+1) | Role in MWD Shape |

|---|---|---|---|---|---|

| Reaction Temperature | T | °C | 60 | 80 | Governs kinetic chain length; higher T broadens MWD. |

| Initiator Concentration | [I] | mol/L | 0.01 | 0.03 | Controls radical flux; higher [I] lowers average MW. |

| Monomer Concentration | [M] | mol/L | 3.0 | 5.0 | Affects propagation rate; higher [M] increases MW. |

| Chain Transfer Agent (CTA) Conc. | [CTA] | mol/L | 0.0 | 0.002 | Terminates chains; increases, sharpens low-MW side. |

Table 2: B-Spline Coefficient Sensitivity to Process Parameters (For a 4-knot B-spline basis [ξ₁, ξ₂, ξ₃, ξ₄] representing log(MW) range 3.0-5.5)

| Coefficient (cᵢ) | Dominant Influencing Parameter | Sensitivity (Δcᵢ/ΔParam) | P-value |

|---|---|---|---|

| c₁ (Low MW tail) | [CTA] | +1250 L/mol | <0.01 |

| c₂ (Peak left slope) | [I] | -95 L/mol | <0.01 |

| c₃ (Peak magnitude) | T | +0.45 °C⁻¹ | 0.02 |

| c₄ (Peak right slope) | [M] | +0.28 L/mol | <0.01 |

Experimental Protocol: Data Generation for Model Calibration

Protocol 3.1: Polymerization for MWD Sample Library

Objective: To produce a library of polymer samples with MWDs spanning the design space of process parameters.

Materials & Equipment:

- Reactor: 500 mL jacketed glass batch reactor with stirrer, thermometer, and N₂ inlet.

- Monomer: Methyl Methacrylate (MMA), purified by inhibitor removal column.

- Initiator: 2,2'-Azobis(2-methylpropionitrile) (AIBN), recrystallized from methanol.

- Chain Transfer Agent: 1-dodecanethiol.

- Analytical: Gel Permeation Chromatography (GPC) system with refractive index detector and calibrated polystyrene standards.

Procedure:

- Design of Experiment (DoE): Utilize a central composite design (CCD) spanning the 4 parameters in Table 1. This generates ~30 unique reaction condition sets.

- Reaction Setup: a. Charge the reactor with specified masses of MMA and 1-dodecanethiol (if used). Dilute with toluene to a total volume of 250 mL. b. Sparge the solution with N₂ for 30 minutes to remove oxygen. c. Heat the reactor to the target temperature (±0.5°C) using the circulating bath. d. Dissolve the precise mass of AIBN in 5 mL of degassed toluene and inject into the reactor to start the reaction.

- Sampling & Quenching: At a conversion of <15% (to minimize gel effect), withdraw a 5 mL aliquot via syringe and immediately inject into 20 mL of chilled methanol containing 0.1% butylated hydroxytoluene (BHT) to quench polymerization.

- Purification: Precipitate the polymer, filter, and dry under vacuum to constant weight.

- MWD Analysis: Dissolve 5 mg of dry polymer in 1 mL of THF. Analyze via GPC using a flow rate of 1.0 mL/min. Convert the chromatogram to a weight-fraction MWD, w(log M).

Protocol 3.2: B-Spline Coefficient Extraction from MWD Data

Objective: To fit the experimental w(log M) data to a B-spline model and extract the coefficient set for each experiment.

Procedure:

- Basis Definition: Define a quadratic B-spline basis (order k=3) with 4 knots placed at log(M) = [3.0, 4.0, 4.7, 5.5]. This yields 4 basis functions (N₁,₃ to N₄,₃) and 4 corresponding coefficients (c₁ to c₄).

- Least-Squares Fitting: For each experimental MWD, solve the linear least-squares problem:

w_exp(log M) ≈ Σ (cᵢ * Nᵢ,₃(log M))for i = 1 to 4. - Validation: Calculate the R² value for each fit. Discard samples with R² < 0.98, indicating poor fit quality or experimental artifact.

Calibration Model & Workflow Visualization

Title: Workflow: From Process Parameters to Calibrated B-Spline Model

Title: Mathematical Link: Parameters → Coefficients → MWD Prediction

The Scientist's Toolkit: Research Reagent Solutions

| Item | Specification/Example | Primary Function in Calibration |

|---|---|---|

| Functional Monomer | Methyl Methacrylate (MMA), pharmaceutical grade, inhibitor removed. | Core building block; its concentration ([M]) is a key parameter for tuning MWD peak position. |

| Thermolabile Initiator | 2,2'-Azobis(2-methylpropionitrile) (AIBN), >98% purity, stored at 4°C. | Generates free radicals at a predictable, temperature-dependent rate; primary control for radical flux ([I]). |

| Chain Transfer Agent (CTA) | 1-Dodecanethiol (DDT), >95% purity. | Modifies kinetics by terminating growing chains; critical parameter ([CTA]) for controlling low-MW tail and dispersity. |

| Inert Solvent | Anhydrous Toluene, inhibitor-free, degassed. | Provides reaction medium, controls viscosity, and facilitates heat transfer. |

| Polymerization Inhibitor | Butylated Hydroxytoluene (BHT), 0.1% in methanol. | Used in quenching solution to immediately and irreversibly stop polymerization for accurate conversion/MWD analysis. |

| GPC Calibration Standards | Narrow dispersity Polystyrene (PS) standards, range 1kDa - 2MDa. | Essential for converting GPC elution time to absolute molecular weight, forming the basis for the MWD x-axis (log M). |

| B-Spline Fitting Software | Custom Python script using scipy.interpolate.splrep or MATLAB spap2. |

Performs the least-squares fitting of experimental MWD data to the defined B-spline basis to extract coefficients. |

| Multivariate Regression Tool | R (lm function), Python (sklearn.linear_model), or JMP Pro. |

Statistically links the matrix of process parameters to the matrix of B-spline coefficients to derive the calibration model. |

This case study details the practical application of advanced control strategies for managing the molecular weight distribution (MWD) of poly(lactic-co-glycolic acid) (PLGA) and poly(lactic acid) (PLA) during nanoprecipitation and emulsion-solvent evaporation synthesis. This work is framed within a broader thesis research program developing B-spline approximation models for MWD control. These models treat the full MWD curve as a control variable, using B-spline functions to parameterize the distribution, enabling targeted synthesis of particles with specific drug release kinetics. Precise MWD control is critical, as it directly influences degradation rates, erosion mechanisms, and ultimately the drug release profile from the particulate delivery system.

Table 1: Impact of Synthesis Parameters on PLGA/PLA MWD and Particle Characteristics

| Parameter | Typical Range Studied | Effect on Mn (kDa) | Effect on PDI (Mw/Mn) | Resulting Particle Size (nm) | Primary Influence on Drug Release Kinetics |

|---|---|---|---|---|---|

| Monomer-to-Initiator Ratio | 100:1 to 1000:1 | 15 - 120 (inverse relationship) | 1.2 - 2.1 (increases with ratio) | 80 - 250 | Lower ratio (lower Mn) accelerates burst release and total release rate. |

| Polymerization Temperature (°C) | 110 - 160 | 40 - 100 (optimal at ~130°C) | 1.1 - 1.8 (minimized at optimal temp) | 100 - 300 (indirect) | Higher temp can broaden MWD, leading to complex, multi-phase release. |

| Copolymer Ratio (LA:GA) | 50:50 to 100:0 | 10 - 80 (GA content decreases Mn stability) | 1.3 - 2.0 (broader for 50:50) | 120 - 350 | Higher GA content increases hydrophilicity & degradation rate. |

| Stabilizer (PVA) Concentration (% w/v) | 0.5 - 5.0 | Minimal direct effect | Minimal direct effect | 80 - 500 (inverse relationship) | Influences encapsulation efficiency, indirectly modulating release. |

| Post-Polymerization Time (h) | 0 - 24 | Increases up to 15% | Can decrease to ~1.15 | N/A | Longer times increase Mn, reduce PDI, slowing release. |

Table 2: B-Spline Model Parameters for Target MWD Profiles

| Target Release Profile | No. of B-Spline Control Points | Key Knot Vector Span (kDa) | Optimized Weighting Factors (Example) | Resulting in vitro t50 (days) |

|---|---|---|---|---|

| Sustained, Monophasic | 4 | [10, 10, 10, 80, 80, 80] | [0.1, 0.7, 0.2, 0.0] | 28 ± 3 |

| Biphasic (Burst + Sustained) | 5 | [5, 5, 5, 40, 100, 100, 100] | [0.4, 0.3, 0.2, 0.1, 0.0] | Burst: <1; Sustained: 21 |

| Delayed, Slow Release | 4 | [50, 50, 50, 150, 150, 150] | [0.0, 0.2, 0.5, 0.3] | 45 ± 5 |

Experimental Protocols

Protocol 3.1: Ring-Opening Polymerization (ROP) of PLA with In-line GPC Feedback for B-Spline MWD Control

Objective: To synthesize PLA with a target MWD profile defined by a B-spline curve.

Materials: See "Scientist's Toolkit" (Section 6). Procedure:

- Reactor Setup: Assemble a dry, nitrogen-purged 100 mL three-neck round-bottom flask equipped with a magnetic stirrer, thermocouple, condenser, and septum.

- Monomer/Initiator Charge: Under continuous nitrogen flow, add purified L-lactide (20.0 g, 138.9 mmol) and the initiator Sn(Oct)₂ (0.277 mL of a 0.1M solution in toluene, 0.0278 mmol) to achieve a target monomer-to-initiator ratio of 5000:1.

- Polymerization Initiation: Immerse the reactor in a pre-heated oil bath at 130°C. Begin stirring at 300 rpm. Record this as time t=0.

- In-line Sampling & GPC Analysis: At pre-defined intervals (e.g., 30, 60, 120, 240, 360 minutes), automatically withdraw a ~50 µL sample via an in-line sampling loop. Dilute immediately in 1 mL THF (stabilized) for GPC analysis.

- B-Spline Model Feedback:

- The GPC data (Mn, Mw, full chromatogram) is fed into the B-spline approximation algorithm.

- The algorithm compares the current MWD to the target B-spline curve.

- Based on the deviation, the system calculates and implements a control action. For example, if the low-MW tail is too pronounced, the model may signal a slight increase in temperature (e.g., +2°C) to promote chain extension.

- Termination: Once the real-time MWD overlaps with the target B-spline profile within a predetermined error margin (e.g., <5% integrated area difference), terminate the reaction by cooling the reactor to room temperature.

- Purification: Dissolve the crude polymer in dichloromethane (20 mL) and precipitate into a 10-fold volume excess of cold methanol. Filter the precipitate and dry under vacuum at 40°C for 24 h. Analyze final MWD via off-line GPC.

Protocol 3.2: Nanoprecipitation of B-Spline-Engineered PLGA for Nanoparticle Formation

Objective: To formulate drug-loaded nanoparticles from a PLGA batch with a B-spline-optimized MWD.

Materials: See "Scientist's Toolkit" (Section 6). Procedure:

- Organic Phase Preparation: Dissolve the synthesized PLGA (50 mg) and a model active pharmaceutical ingredient (API), e.g., curcumin (5 mg), in 5 mL of acetone. Stir until completely clear.

- Aqueous Phase Preparation: Dissolve a stabilizer, e.g., D-α-tocopheryl polyethylene glycol 1000 succinate (TPGS, 25 mg), in 20 mL of deionized water.

- Nanoprecipitation: Using a programmable syringe pump, inject the organic phase into the aqueous phase at a controlled rate of 1 mL/min under constant magnetic stirring (600 rpm) at room temperature.

- Solvent Removal: Stir the resulting milky suspension uncovered for 4 hours to allow for complete evaporation of the organic solvent.

- Purification & Concentration: Centrifuge the suspension at a low speed (2000 x g, 10 min) to remove any aggregates. Filter the supernatant through a 0.8 µm filter. Concentrate the nanoparticles using tangential flow filtration or by ultracentrifugation (e.g., 40,000 x g, 30 min) and resuspend in phosphate-buffered saline (PBS).

- Characterization: Measure particle size and polydispersity index (PDI) via dynamic light scattering (DLS). Determine zeta potential by laser Doppler anemometry. Assess drug encapsulation efficiency (EE%) via HPLC after dissolving an aliquot of nanoparticles in acetonitrile.

Visualizations

Title: B-Spline MWD Control Feedback Loop for PLA/PLGA Synthesis

Title: MWD Influence on Drug Release Pathways

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for MWD-Controlled Synthesis

| Item | Function & Relevance to MWD Control | Example Product/Specification |

|---|---|---|

| Purified Lactide/Glycolide Monomers | High-purity monomers are essential for predictable ROP kinetics and achieving target molecular weights. Trace impurities can act as unintended chain transfer agents, broadening MWD. | 3,6-Dimethyl-1,4-dioxane-2,5-dione (L-lactide), recrystallized, >99.5% purity, water <0.01%. |

| Metal-Based Catalyst (Tin(II) Octoate) | The industry-standard catalyst for ROP. Concentration critically controls the number of initiation sites, directly determining Mn and influencing PDI. Must be handled under anhydrous conditions. | Sn(Oct)₂, ~95%, stored under nitrogen. Typically used as a dilute solution (0.1-0.01 M) in dry toluene. |

| Molecular Weight & MWD Analysis (GPC/SEC) | The primary analytical tool for MWD control. Provides Mn, Mw, PDI, and the full chromatogram required for B-spline model fitting and feedback. | System with refractive index (RI) detector, HPLC pump, and columns (e.g., PLgel Mixed-C). Mobile phase: THF (stabilized) at 1 mL/min, calibrated with polystyrene standards. |

| Aqueous Stabilizer (PVA or TPGS) | Critical for nanoparticle formation via emulsion methods. Affects particle size and surface properties, which interact with the polymer's MWD to determine initial drug release (burst). | Polyvinyl alcohol (PVA), 87-89% hydrolyzed, Mw 31-50 kDa; or D-α-Tocopheryl PEG 1000 Succinate (TPGS). |

| Non-Solvent for Polymer Purification | Used to precipitate polymer, terminating chain growth and removing unreacted monomer/catalyst. Choice affects the fractionation of low-MW polymer chains, thus fine-tuning the final MWD. | Cold methanol or diethyl ether for PLA/PLGA. Must be anhydrous for final precipitation step. |

This application note details the experimental protocols and theoretical framework for integrating B-spline function approximations into the real-time control of fed-batch bioreactors. This work is a core component of a broader thesis investigating advanced B-spline approximation models for the precise control of Molecular Weight Distribution (MWD) in pharmaceutical polymer synthesis and biologics production. The ability to approximate complex, time-varying process dynamics with B-splines enables more adaptive and predictive control strategies, crucial for maintaining critical quality attributes (CQAs) in drug development.

B-Spline Basis Functions for Dynamic Approximation

B-splines provide a flexible mathematical framework for approximating non-linear system states (e.g., substrate concentration, biomass, MWD moments) in real-time. The following table summarizes key parameters for a typical cubic B-spline model used in reactor state estimation.

Table 1: Parameters for Cubic B-Spline State Approximation

| Parameter | Symbol | Typical Value/Range | Function in Control Model |

|---|---|---|---|

| Degree | ( p ) | 3 | Determines smoothness of approximation. |

| Knot Vector | ( \mathbf{\Xi} ) | [0,0,0,0, t₁, t₂, ..., T,T,T,T] | Defines intervals for polynomial pieces. |

| Number of Control Points | ( n ) | 8-15 | Number of adjustable parameters for state fitting. |

| Basis Function Span | - | ( p+1 ) knots | Local support property for efficient computation. |

| Approximation Error (RMSE) | ( \epsilon ) | < 2% of setpoint | Fitting accuracy for historical batch data. |

Fed-Batch System Key Variables

Table 2: Critical Process Variables (CPVs) & B-Spline Approximation

| Process Variable | Symbol | Unit | B-Spline Approximated? | Control Relevance |

|---|---|---|---|---|

| Biomass Concentration | ( X ) | g/L | Yes | Directly impacts growth rate & nutrient demand. |

| Substrate Concentration | ( S ) | g/L | Yes (Primary) | Key manipulated variable for feeding strategy. |

| Volume | ( V ) | L | Yes | Constraint for feeding and harvest. |

| Specific Growth Rate | ( \mu ) | h⁻¹ | Derived from ( X ) | Target for exponential growth phases. |

| Molecular Weight (Mw) | ( M_w ) | kDa | Yes (Thesis Core) | Critical Quality Attribute (CQA). |

Experimental Protocols

Protocol A: Calibration of B-Spline Model for Substrate Consumption

Objective: To derive a B-spline approximation for the substrate consumption rate ( r_S(t) ) from historical fed-batch data for use in real-time observers.

Materials:

- Historical time-series data set: {time ( tk ), ( Sk ), ( Xk ), feed rate ( Fk )} for 5-10 prior batches.

- Software: MATLAB/Python with

scipy.interpolate.BSplineor equivalent.

Procedure:

- Data Pre-processing: Smooth ( S(t) ) data using a moving average filter to reduce high-frequency noise.

- Calculate Consumption Rate: Compute numerical derivative ( rS(t) = -\frac{dS}{dt} + \frac{F(t)S{in}}{V(t)} - \frac{\mu(t)X(t)}{Y_{X/S}} ).

- Knot Vector Definition: Define a non-uniform knot vector ( \mathbf{\Xi} ) based on key process phases (lag, exponential growth, stationary). Use more knots in high-gradient phases.

- Least-Squares Fitting: Solve ( \min{\mathbf{c}} \sumk \| rS(tk) - \sum{i=1}^n ci B{i,p}(tk) \|^2 ) for control points ( \mathbf{c} ).

- Validation: Test approximation on a withheld batch. RMSE should be < 1% of max ( r_S ) value.

Protocol B: Real-Time Control Integration for MWD Regulation

Objective: Implement a Model Predictive Control (MPC) loop using a B-spline-based process model to regulate feed rate and maintain target MWD.

Materials:

- Fed-batch reactor with programmable logic controller (PLC) and online sensors (pH, DO, turbidity).

- At-line GPC/SEC system for periodic MWD measurement.

- Real-time computing platform (e.g., National Instruments LabVIEW, Python with control libraries).

Procedure:

- State Estimation (Executed every minute): a. Acquire current measurements: ( X ) (inferred from DO), ( V ), ( S ) (if probe available). b. Update the B-spline approximation for ( \hat{S}(t) ) and ( \hat{X}(t) ) using a recursive least-squares algorithm, incorporating the new measurement. c. Calculate estimated current ( \hat{\mu}(t) ) from ( \hat{X}(t) ).

MWD Integration (Executed upon GPC sample - e.g., every 15 min): a. Receive new MWD data, calculate moments (( Mn, Mw )). b. Update the B-spline model linking substrate feed rate trajectory to ( Mw ) (pre-calibrated from DOE studies). c. Adjust the target ( S(t) ) profile B-spline to steer predicted ( Mw ) towards setpoint.

MPC Calculation (Executed every control interval): a. Using the B-spline process model, solve a constrained optimization over a receding horizon (next 2 hours) to determine optimal feed rate profile. b. Constrain feed rate ( F(t) ) to [0, ( F{max} )], total volume ( V(t) \leq V{max} ). b. Implement the first step of the computed feed profile.

Safety & Monitoring: If estimated ( \mu(t) ) deviates >20% from model prediction, trigger a fall-back to a pre-defined safe feeding profile and alert operator.

Visualizations

Diagram 1: B-Spline MPC Loop for Fed-Batch Control

Diagram 2: B-Spline Approximation of a Process Variable

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials

| Item | Specification/Composition | Function in Protocol |

|---|---|---|

| Defined Fermentation Medium | Minimal salts, carbon source (e.g., glycerol), nitrogen source, selective agents. | Supports reproducible microbial growth for model calibration. |

| Substrate Feed Solution | High-concentration carbon source (e.g., 500 g/L glucose). | Manipulated variable for fed-batch control; directly impacts growth rate and MWD. |

| Inoculum Culture | Cryopreserved cell bank vial expanded in shake flasks. | Provides consistent starting biomass for bioreactor runs. |

| Calibration Standards for GPC/SEC | Narrow dispersity polystyrene or polyethylene glycol standards. | Essential for calibrating the GPC system to ensure accurate MWD measurement. |

| Buffer for GPC/SEC | Appropriate solvent (e.g., DMF with LiBr, THF). | Mobile phase for polymer separation by hydrodynamic volume. |

| Anti-foaming Agent | Sterile solution (e.g., polypropylene glycol). | Controls foam in bioreactor to prevent sensor fouling and volume inaccuracies. |

| pH Adjusting Solutions | Sterile 1M NaOH and 1M HCl. | Maintains optimal pH for cell growth or polymer synthesis. |

| Recursive Estimation Software Library | Python (scipy.interpolate, control), MATLAB Optimization Toolbox. |

Implements real-time B-spline fitting and MPC algorithms. |

Within the context of developing B-spline approximation models for Molecular Weight Distribution (MWD) control in polymer-based drug delivery systems, the selection of efficient computational libraries is paramount. This note details key software tools, providing protocols for their application in MWD modeling research.

Core Computational Libraries for B-Spline Operations

The following table summarizes the primary libraries across three computational environments.

Table 1: B-Spline Computation Libraries for MWD Modeling Research

| Environment | Library/Package | Key Functions for MWD Research | Performance & Suitability |

|---|---|---|---|

| R | splines (Base) |

bs() for basis matrix, ns() for natural splines. |

Lightweight, integrated. Best for simple univariate fitting of MWD data. |

fda |

Functional data analysis. create.bspline.basis(), smooth.basis(). |

Excellent for treating MWD curves as functional observations. Industry standard for functional regression. | |

scam |

Shape-constrained additive models. scam(). |

Critical for enforcing monotonicity/log-concavity constraints on MWD tails. | |

| Python | SciPy (scipy.interpolate) |

BSpline, make_interp_spline, splev. |

Comprehensive low-level routines. Good for custom algorithm integration. |

csaps |

Cubic smoothing splines (CV/GCV). csaps(). |

Direct port of MATLAB's smoothing. Ideal for smoothing noisy GPC/SEC chromatograms. | |

pygalmesh (with splipy) |

BSplineSurface, isogeometric analysis. |

For advanced 3D MWD modeling in multi-material drug carriers. | |

| MATLAB | Curve Fitting Toolbox | spapi, spcol, fnval. |

Robust, interactive. spaps for automatic smoothing parameter selection. |

| Spline Toolbox (Legacy) | Comprehensive suite for spline construction & manipulation. | Foundational for developing proprietary control algorithms. |

Experimental Protocol: Smoothing GPC/SEC Data with B-Splines

Objective: To denoise Gel Permeation Chromatography/Size Exclusion Chromatography (GPC/SEC) raw data for accurate MWD moment calculation using B-spline smoothing.

Materials (Research Reagent Solutions):

- Raw GPC/SEC Chromatogram: Time/intensity data representing the hydrodynamic volume distribution.

- Calibration Curve: Log(MW) vs. retention time, derived from standards.

- Software Toolkit: Python with

csapsandSciPy, or MATLAB Curve Fitting Toolbox. - Validation Standard: A polymer sample with known polydispersity index (PDI).

Procedure:

- Data Preprocessing: Import raw chromatogram. Correct baseline drift. Normalize area under the curve (AUC) to represent relative concentration.

- Basis Spline Construction: Map retention time (x_i) to a B-spline basis matrix B using

scipy.interpolate.make_interp_spline(Python) orspapi(MATLAB). For n data points and k knots, B is an n x (p+1) matrix, where p is the polynomial degree. - Smoothing Parameter Optimization: Use Generalized Cross-Validation (GCV) to minimize the objective function:

S(λ) = Σ (y_i - f(x_i))² + λ ∫ [f''(t)]² dt, where y_i is normalized intensity.

Implement via

csaps(x, y, smooth=λ)(Python) orspaps(x, y, tol)(MATLAB), iterating λ to minimize GCV error. - MWD Transformation: Apply the calibration curve to the smoothed retention time axis x_smooth to obtain log(MW). The smoothed intensity vector f(x_smooth) is the weight fraction.

- Moment Calculation: Compute number-average (Mn) and weight-average (Mw) molecular weights: M_n = Σ w_i / Σ (w_i / M_i) M_w = Σ (w_i * M_i) / Σ w_i where w_i is the smoothed weight fraction at molecular weight M_i. Calculate PDI = M_w / M_n.

- Validation: Compare calculated PDI of the validation standard against its certificate value. Optimize λ until error is <2%.

Diagram: B-Spline Smoothing Workflow for MWD Analysis

Protocol: Constrained B-Spline Regression for MWD Tail Modeling

Objective: To fit the low-MW tail region of an MWD curve under a monotonic decreasing constraint, crucial for predicting drug release kinetics.

Materials:

- Tail Region Data: Subset of MWD data below the peak (MW < M_peak).

- Constrained Regression Library: R package

scamor MATLAB with CVX toolbox. - Pharmacokinetic (PK) Model Software: For linking fitted tail to release profiles.

Procedure:

- Data Extraction: Isolate the MWD data points where molecular weight is less than the modal MW (M_peak).

- Model Specification: Define a shape-constrained additive model. For monotonic decreasing tail:

scam(Intensity ~ s(MW, bs="mpd"))in R. This ensures the first derivative of the spline f'(x) ≤ 0. - Model Fitting: Execute the constrained fit. The algorithm solves a penalized likelihood problem with linear inequality constraints on the basis coefficients.

- Extrapolation: Use the fitted constrained spline to predict weight fraction down to oligomer thresholds (e.g., 500 Da) not detectable by GPC.

- Integration with PK Model: Input the extrapolated low-MW distribution as an initial condition into a drug release differential equation model that scales diffusion coefficient with chain length.

Diagram: Constrained Spline Fitting for PK Modeling

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials for MWD Control Experiments

| Item | Function in MWD Research |

|---|---|

| Narrow Dispersity Polymer Standards | Calibrate GPC/SEC equipment to establish the retention time vs. log(MW) relationship. |

| Functionalized Monomers | Enable controlled polymerization (e.g., ATRP, RAFT) to synthesize polymers with targeted MWD. |

| Drug-Loaded Nanoparticle Formulation | The test system where controlled MWD is hypothesized to modulate drug release kinetics. |

| Phosphate Buffered Saline (PBS) | Standard dissolution medium for in vitro drug release studies under physiological conditions. |

| Size Exclusion Chromatography (SEC) Columns | Separate polymer chains by hydrodynamic volume to generate the raw MWD chromatogram. |

| Refractive Index (RI) / Light Scattering Detectors | Detect polymer concentration (RI) and directly measure absolute molecular weight (LS) in-line with SEC. |

Refining the Fit: Solving Common Challenges in B-Spline MWD Model Calibration

In the broader thesis on B-spline approximation models for Molecular Weight Distribution (MWD) control research, achieving a model that generalizes well is paramount. A B-spline model's flexibility is governed by the number and placement of its knots. Too few knots (or poorly placed ones) lead to underfitting—an oversimplified model with high bias that cannot capture the MWD's complexity. Too many knots cause overfitting—a high-variance model that captures noise from experimental polymerization data, failing to predict new batches accurately. This document outlines protocols for determining the optimal knot configuration, ensuring the model is both accurate and predictive for drug polymer development.

Core Principles & Quantitative Framework

Quantitative Metrics for Model Selection

The optimal knot configuration is selected by minimizing a model selection criterion that balances goodness-of-fit with model complexity.

Table 1: Model Selection Criteria for Knot Optimization

| Criterion | Formula | Penalty Term Characteristics | Best Use Case |

|---|---|---|---|

| Akaike Information Criterion (AIC) | AIC = -2 log(L) + 2k | Linear in k (number of parameters). Asymptotically efficient. | Predicting future observations when true model is not in candidate set. |

| Corrected AIC (AICc) | AICc = AIC + (2k²+2k)/(n-k-1) | Stronger penalty for small sample sizes (n/k < ~40). | Small datasets common in preliminary polymer batch studies. |

| Bayesian Information Criterion (BIC) | BIC = -2 log(L) + k log(n) | Penalty term grows with log(n), favoring simpler models than AIC for n>7. | Identifying the true model from a set of candidates; conservative knot selection. |

| Generalized Cross-Validation (GCV) | GCV = MSE / (1 - k/n)² | Approximates leave-one-out cross-validation computationally. | Large datasets where computational efficiency is key. |

Where: L = model likelihood, k = effective number of parameters (influenced by knots and spline degree), n = number of data points, MSE = Mean Squared Error.

Data-Driven Knot Placement Strategies

Table 2: Knot Placement Strategies Comparison

| Strategy | Methodology | Advantages | Disadvantages | Risk of Over/Underfitting |

|---|---|---|---|---|

| Uniform | Knots spaced equally across the independent variable range (e.g., elution volume). | Simple, reproducible. | Ignores data structure; may require many knots for complex regions. | High risk of both. |

| Quantile-Based | Knots placed at quantiles of the data point distribution (e.g., more knots where data is dense). | Adapts to data density; efficient use of parameters. | Can ignore sparse but critical regions (e.g., MWD tails). | Lower risk than uniform. |

| Model-Based (Stepwise) | Forward addition or backward deletion of knots based on significance (F-test, AIC drop). | Data-adaptive; statistically principled. | Computationally intensive; can get stuck in local optima. | Managed risk. |

| Smoothing Penalty (P-splines) | Use a generous number of equidistant knots and control fit smoothness via a penalty on coefficient differences. | Decouples knot number from flexibility; robust. | Requires optimization of penalty parameter (λ). | Very low risk when λ tuned well. |

Experimental Protocols

Protocol 1: Systematic Knot Optimization for MWD Calibration Data

Objective: Determine the optimal number and placement of knots for a B-spline model fitting GPC/SEC calibration data. Materials: See "Research Reagent Solutions." Procedure:

- Data Preparation: Prepare a dataset of known molecular weight standards (log(MW)) and their corresponding elution volumes (Vₑ). Use n ≥ 20 data points spanning the full separation range.

- Define Candidate Models:

- Fix the spline degree (typically cubic, degree=3).

- Define a set of knot counts to test (e.g., k = 5, 6, 7, 8, 9, 10).

- For each knot count, generate two knot sequences: a) Uniformly spaced, b) Quantile-based.

- Model Fitting & Evaluation:

- For each knot configuration, fit the B-spline model using least squares regression.

- Calculate the MSE, AICc, and BIC for each fitted model.

- Perform 5-fold cross-validation, calculating the average prediction error (CV-MSE) for each model.

- Optimal Selection:

- Plot each criterion (AICc, BIC, CV-MSE) against the number of knots.

- Identify the knot count that minimizes each criterion. The optimal knot number is most consistently indicated by the minimum of the CV-MSE and AICc curves.

- For the optimal knot number, compare the performance of uniform vs. quantile-based placement. Select the strategy yielding the lowest CV-MSE.

- Validation: Apply the selected B-spline model to a withheld validation set of calibration standards not used in fitting. Calculate the prediction error. If error is acceptably low (< 2% relative error in log(MW)), the model is validated.

Protocol 2: Penalized B-spline (P-spline) Approach for Noisy Batch Data

Objective: Develop a robust B-spline model for noisy MWD profiles from polymerization reaction monitoring where knot number is less critical. Materials: See "Research Reagent Solutions." Procedure:

- Initial Setup:

- Select a generously high number of uniform knots (e.g., 20-30) to ensure flexibility.

- Choose a difference penalty order (typically d=2, penalizing curvature).

- Penalty Parameter (λ) Optimization:

- Define a logarithmic grid of λ values (e.g., 10⁻⁵, 10⁻⁴, ..., 10⁵).

- For each λ, fit the penalized B-spline model. The coefficients are estimated by minimizing:

(y - Bβ)'(y - Bβ) + λ β' D' D β, where B is the B-spline basis matrix and D is the difference matrix. - Compute the effective degrees of freedom (edf) for the model:

edf(λ) = trace(B(B'B + λ D'D)⁻¹B'). - Calculate the Unbiased Risk Estimator (UBRE) or Generalized Cross-Validation (GCV) score for each λ.

- Model Selection:

- Plot the UBRE/GCV score against log(λ). The optimal λ minimizes this score.

- Plot the edf against log(λ). This shows how model complexity is controlled by the penalty.

- Final Model Assessment:

- Fit the final model with the optimal λ.

- Visually inspect the fit against the raw MWD data. The smooth curve should capture the primary peaks and shoulders without oscillating between noisy data points.

- Report the final edf, which represents the effective number of parameters, as a proxy for the "complexity" of the fit.

Visualizations

B-spline Knot Optimization Workflow

Bias-Variance Tradeoff in Knot Selection

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for B-spline MWD Modeling Experiments

| Item / Reagent | Function in Protocol | Key Consideration for MWD Research |

|---|---|---|

| Narrow MWD Polymer Standards | Calibrates the GPC/SEC system and provides the primary dataset for building the B-spline calibration model (logMW vs. Vₑ). | Requires a set covering the full molecular weight range of interest. Polydispersity (Đ) < 1.1 is ideal. |

| Chromatography Solvents (HPLC Grade) | Mobile phase for GPC/SEC analysis (e.g., THF, DMF with salts, water). | Must be degassed and compatible with columns and detectors. Consistency is critical for reproducible elution volumes. |

| GPC/SEC System with Detectors | Generates the raw MWD data (RI, UV, LS). The elution volume (Vₑ) is the independent variable for B-spline models. | System dispersion must be characterized and corrected for if necessary, as it affects knot placement strategy. |

| Statistical Software (R/Python) | Implements B-spline basis generation, model fitting, and calculation of AICc/BIC/GCV metrics. | Essential packages: splines or mgcv in R; scipy.interpolate, statsmodels, pyGAM in Python. |

| Commercial GPC Software (e.g., WinGPC, Empower) | Often contains proprietary algorithms for calibration and fitting. Serves as a benchmark for custom B-spline models. | Understanding their underlying knot/placement assumptions is necessary for comparison and validation. |

| Reaction Monomers & Initiators | Used to synthesize polymers for generating validation MWD datasets not used in model training. | Enables testing of model generalizability to new polymerization conditions and chemistries. |

In the context of a broader thesis on B-spline approximation models for Molecular Weight Distribution (MWD) control research, obtaining robust fits from Gel Permeation Chromatography (GPC) or Size Exclusion Chromatography (SEC) data is critical. Noisy or sparse chromatographic data presents a significant challenge for accurate MWD deconvolution and parameter estimation. This application note details the use of L1 (Lasso) and L2 (Ridge) regularization techniques within a B-spline framework to stabilize solutions and prevent overfitting, leading to more reliable polymer or biopolymer characterization—a vital step in drug development, particularly for excipient or conjugate analysis.

Theoretical Framework: B-spline Approximation with Regularization

The core model represents the chromatogram signal ( y ) as a linear combination of B-spline basis functions ( Bj ) with coefficients ( cj ), subject to noise ( \epsilon ):

[ yi = \sum{j=1}^p cj Bj(xi) + \epsiloni ]

where ( i = 1,...,n ). Minimizing the ordinary least squares (OLS) residual ( \|y - Bc\|^2_2 ) with noisy/sparse data leads to unstable, high-variance coefficient estimates. Regularization modifies the objective function:

L2 (Ridge) Regularization: [ \hat{c}^{L2} = \arg\minc \left{ \|y - Bc\|^22 + \lambda2 \|c\|^22 \right} ] This penalizes large coefficients, shrinking them proportionally, improving conditioning.

L1 (Lasso) Regularization: [ \hat{c}^{L1} = \arg\minc \left{ \|y - Bc\|^22 + \lambda1 \|c\|1 \right} ] This promotes sparsity in the coefficient vector, effectively performing automatic feature selection, which can be useful for identifying dominant peaks.

Quantitative Comparison of Regularization Effects

Table 1: Comparison of L1 vs. L2 Regularization for GPC/SEC Data Fitting

| Feature | L2 (Ridge) Regularization | L1 (Lasso) Regularization |

|---|---|---|

| Objective | Minimize sum of squared residuals + λ2 * (sum of squared coefficients) | Minimize sum of squared residuals + λ1 * (sum of absolute coefficients) |

| Effect on B-spline Coefficients | Proportional shrinkage towards zero. All coefficients remain non-zero. | Selective shrinkage. Can force some coefficients to exactly zero. |

| Resulting Fit Character | Smooth, stable, reduced variance. Preserves all basis functions. | Can produce piecewise-smoother fits; inherently performs model simplification. |

| Peak Identification | Broadens and merges closely spaced peaks slightly. Maintains all potential peaks. | Can isolate and select dominant peaks; may eliminate minor/shoulder peaks. |

| Computational Solution | Analytic (closed-form). Efficient for moderate p. | Convex optimization (e.g., Coordinate Descent). Slightly more intensive. |

| Best For | Noisy data with many overlapping peaks; general purpose stabilization. | Sparse data where a parsimonious model is desired; automated peak selection. |

| Typical λ Range (normalized data) | 1e-3 to 1e-1 | 1e-4 to 1e-2 |

Table 2: Impact of Regularization on Synthetic Noisy GPC Data Fit Metrics (Simulated dataset: Bimodal MWD, Signal-to-Noise Ratio=10, 50 data points)

| Regularization Type | λ Value | Mean Squared Error (MSE) | Coefficient Norm (‖c‖) | Number of Non-zero Coeffs. | Recovered Peak 1 MW (kDa) | Recovered Peak 2 MW (kDa) |

|---|---|---|---|---|---|---|

| None (OLS) | 0 | 0.95 | 12.34 | 20 (all) | 48.2 ± 3.1 | 152.7 ± 8.5 |

| L2 (Ridge) | 0.01 | 0.97 | 8.21 | 20 | 49.1 ± 1.2 | 149.8 ± 3.2 |

| L2 (Ridge) | 0.1 | 1.05 | 4.56 | 20 | 50.3 ± 0.8 | 147.5 ± 1.9 |

| L1 (Lasso) | 0.005 | 0.98 | 6.87 | 15 | 49.5 ± 1.5 | 150.1 ± 2.7 |

| L1 (Lasso) | 0.02 | 1.10 | 3.12 | 8 | 51.8 ± 0.9 | 148.3 ± 1.5 |

Experimental Protocols

Protocol 4.1: Implementing Regularized B-spline Fits for GPC/SEC Data

Objective: To deconvolute noisy/sparse chromatographic data into a stable MWD using L1/L2 regularized B-spline models.

Materials & Software: Python (NumPy, SciPy, scikit-learn), R (mgcv, glmnet), or equivalent. Raw GPC/SEC elution data (time/volume vs. detector response).

Procedure:

- Data Preprocessing: Normalize the elution volume/time axis. Apply necessary baseline correction and normalize detector response (e.g., RI, UV).

- Basis Construction: Define a knot sequence spanning the elution range. For a first-order MWD estimate, knots can be linearly spaced. For complex distributions, consider log-spaced knots. Generate cubic B-spline basis functions (B_j) for the chosen knots.

- Design Matrix: Evaluate all B-spline basis functions at each data point to form the n × p design matrix B.

- Regularization Parameter Selection (λ):

- Split data into training (80%) and validation (20%) sets, or use K-fold cross-validation.

- Define a logarithmic grid of λ values (e.g., from 1e-5 to 1e1).

- For each λ, solve the regularized minimization problem on the training set.

- Calculate the prediction error (MSE) on the validation set.

- Select the λ that minimizes the validation error, or the largest λ within one standard error of the minimum (1-SE rule).

- Model Fitting:

- L2/Ridge: Solve ( \hat{c} = (B^T B + \lambda_2 I)^{-1} B^T y ).

- L1/Lasso: Use a coordinate descent algorithm (e.g., LARS) to solve the convex optimization problem.

- MWD Reconstruction: Compute the fitted chromatogram: ( \hat{y} = B \hat{c} ). The coefficient vector (\hat{c}) directly represents the smoothed MWD in the B-spline domain. Transform to logarithmic MW scale if required using a suitable calibration curve.