Optimizing Pharmaceutical Injection Molding with Artificial Neural Networks: A Guide for R&D Scientists

This article provides a comprehensive overview for researchers and drug development professionals on leveraging Artificial Neural Networks (ANNs) to optimize injection molding parameters for pharmaceutical manufacturing.

Optimizing Pharmaceutical Injection Molding with Artificial Neural Networks: A Guide for R&D Scientists

Abstract

This article provides a comprehensive overview for researchers and drug development professionals on leveraging Artificial Neural Networks (ANNs) to optimize injection molding parameters for pharmaceutical manufacturing. It explores the foundational challenges of traditional process setting, details methodological approaches for ANN model development and application, addresses common troubleshooting and hyperparameter optimization strategies, and validates the approach through comparative analysis with conventional methods. The scope covers critical intents from problem definition to practical implementation and verification, aiming to enhance product quality, reduce waste, and accelerate development timelines in biomedical applications.

The Challenge of Precision: Why Traditional Injection Molding Fails for Advanced Pharmaceutical Products

Pharmaceutical injection molding is a critical process for manufacturing combination products, such as auto-injectors, inhalers, and implantable drug delivery systems. The quality of these molded components directly impacts drug stability, sterility, and patient safety. In the broader research context of optimizing injection molding parameters using Artificial Neural Networks (ANNs), defining and measuring Critical Quality Attributes (CQAs) is the foundational step. ANN models require high-fidelity, quantitative CQA data as target outputs for training to predict and control the complex, non-linear relationships between process parameters (e.g., melt temperature, hold pressure, cooling time) and final product quality.

Critical Quality Attributes (CQAs): Definition and Impact

CQAs are physical, chemical, biological, or microbiological properties that must be within an appropriate limit, range, or distribution to ensure the desired product quality. For injection-molded drug-device components, CQAs are derived from a risk assessment focusing on patient safety and drug efficacy.

Table 1: Primary CQAs for Injection-Molded Drug-Device Components

| CQA Category | Specific Attribute | Target / Acceptable Range | Impact on Product Performance & Safety |

|---|---|---|---|

| Dimensional | Critical Dimensions (e.g., inner diameter, wall thickness) | ± 0.05 mm from nominal | Ensures proper device assembly, drug dosage accuracy, and mechanical function. |

| Mechanical | Tensile Strength | > 45 MPa | Prevents fracture during device use or implantation. |

| Flexural Modulus | 2000 - 3000 MPa | Ensures structural rigidity without being brittle. | |

| Impact Resistance (Izod) | > 50 J/m | Prevents failure from accidental drops. | |

| Material | Residual Monomers (e.g., ε-Caprolactam in PA6) | < 500 ppm | Prevents leachables from affecting drug stability or causing toxicity. |

| Moisture Content | < 0.02% (w/w) | Prevents hydrolysis of polymer or drug, bubble formation (splay). | |

| Surface & Morphological | Surface Roughness (Ra) | < 0.8 µm | Minimizes particle adsorption, ensures consistent fluid flow, aids sterile barrier integrity. |

| Sink Marks / Voids | None visually detectable | Maintains structural integrity and cosmetic quality. | |

| Flash / Burrs | None permitted | Ensures proper sealing, prevents particle generation. | |

| Biological | Bioburden | < 1 CFU/component (pre-sterilization) | Critical for sterility assurance. |

| Endotoxin Level | < 0.25 EU/ml (extract) | Prevents pyrogenic response in patients. | |

| Functional | Force to Activate (for buttons/plungers) | 20 ± 5 N | Ensures device is easy to use but not prone to accidental activation. |

| Leak Rate (sealed containers) | < 1x10⁻⁶ mbar·L/s | Maintains sterility and drug potency. |

Experimental Protocols for CQA Assessment

Protocol 1: Comprehensive Dimensional and Morphological Analysis

Objective: To quantitatively assess dimensional accuracy and surface defects of molded components. Materials: Coordinate Measuring Machine (CMM), optical profilometer, digital micrometer, calibrated visual inspection station. Procedure:

- Conditioning: Condition samples at 23°C ± 2°C and 50% ± 5% RH for 48 hours.

- Macro Dimensions: Using a CMM, probe 32 distinct points on each sample (n=30) as per the component GD&T drawing. Record deviations from nominal.

- Wall Thickness: Using an ultrasonic thickness gauge, take 12 measurements around critical thin-walled sections.

- Surface Analysis:

- Roughness: Measure Ra on three critical interior surfaces using an optical profilometer (scan length 4.0 mm, cutoff 0.8 mm).

- Defects: Visually inspect 100% of samples under 30x magnification and axial light for sink marks, voids, and flash.

- Data Processing: Calculate mean, standard deviation, and process capability indices (Cp, Cpk) for all dimensional data.

Protocol 2: Extractables and Leachables (E&L) Profiling

Objective: To identify and quantify chemical species released from the polymer under stressed conditions. Materials: LC-MS, GC-MS, Inductively Coupled Plasma Mass Spectrometry (ICP-MS), extraction solvents (e.g., 50% Ethanol, purified water), controlled oven. Procedure:

- Sample Preparation: Finely mill 10.0 g of molded component (n=5). Use components from start-up, steady-state, and purging phases of molding.

- Extraction: Submerge sample in 50 mL of solvent. Perform both exaggerated conditions (70°C for 72 hours) and simulated-use conditions (40°C for 10 days).

- Analysis:

- Volatiles: Analyze headspace via GC-MS.

- Semi/Non-Volatiles: Concentrate extract and analyze via LC-MS.

- Inorganics: Analyze extract via ICP-MS for elemental impurities.

- Identification/Quantification: Compare spectra against databases (NIST, custom polymer additive libraries). Report any compound above the Analytical Evaluation Threshold (AET, typically 0.1 µg/day).

Protocol 3: Mechanical Integrity Under Simulated-Use Stress

Objective: To evaluate mechanical failure modes and forces under conditions mimicking patient use. Materials: Universal testing machine (UTM), environmental chamber, custom fixtures simulating device actuation. Procedure:

- Conditioning: Condition samples in three environments: Standard (23°C/50% RH), Cold (5°C), and Hot/Dry (40°C/15% RH) for 1 week.

- Actuation Force: Using UTM, simulate complete device actuation (e.g., depress plunger at 10 mm/min). Record peak force and force profile over displacement (n=20 per group).

- Static Load (Creep) Test: Apply a constant load equivalent to 150% of the nominal actuation force to critical features for 24 hours. Measure permanent deformation.

- Fatigue Test: Apply cyclic load (between 10-90% of actuation force) for 2000 cycles. Inspect for crack initiation.

- Analysis: Statistically compare results across conditioning groups (ANOVA). Determine failure thresholds and safety margins.

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Key Materials for CQA Research in Pharmaceutical Molding

| Item | Function / Rationale |

|---|---|

| Medical-Grade Polymer Resins (e.g., COC, PPSU, PLGA, High-Purity PP) | Base material with certified biocompatibility, low leachable potential, and consistent rheological properties. |

| Validation Mold (Tool) | A mold instrumented with pressure and temperature sensors to directly correlate process conditions to part CQAs. |

| Melt Pressure & Temperature Sensors | Real-time monitoring of polymer state within the barrel and mold cavity for ANN input data generation. |

| Design of Experiment (DoE) Software (e.g., JMP, Minitab) | To systematically plan molding trials that vary multiple parameters (e.g., Tmelt, Pinj, tcool) for efficient ANN training data collection. |

| Standardized Leachables Test Kits | Commercially available kits with pre-prepared solvents and vials for consistent extractables study setup. |

| Certified Reference Standards (Additives, Monomers) | For calibrating analytical instruments (LC-MS, GC-MS) to accurately identify and quantify leachables. |

| Particle Count & Size Analyzer | To quantify and characterize sub-visible particles shed from molded components during simulated use (per USP <788>). |

| Biaxial Strain Gauge System | To measure anisotropic shrinkage and internal stress distribution within the molded part, key predictors of warpage and long-term stability. |

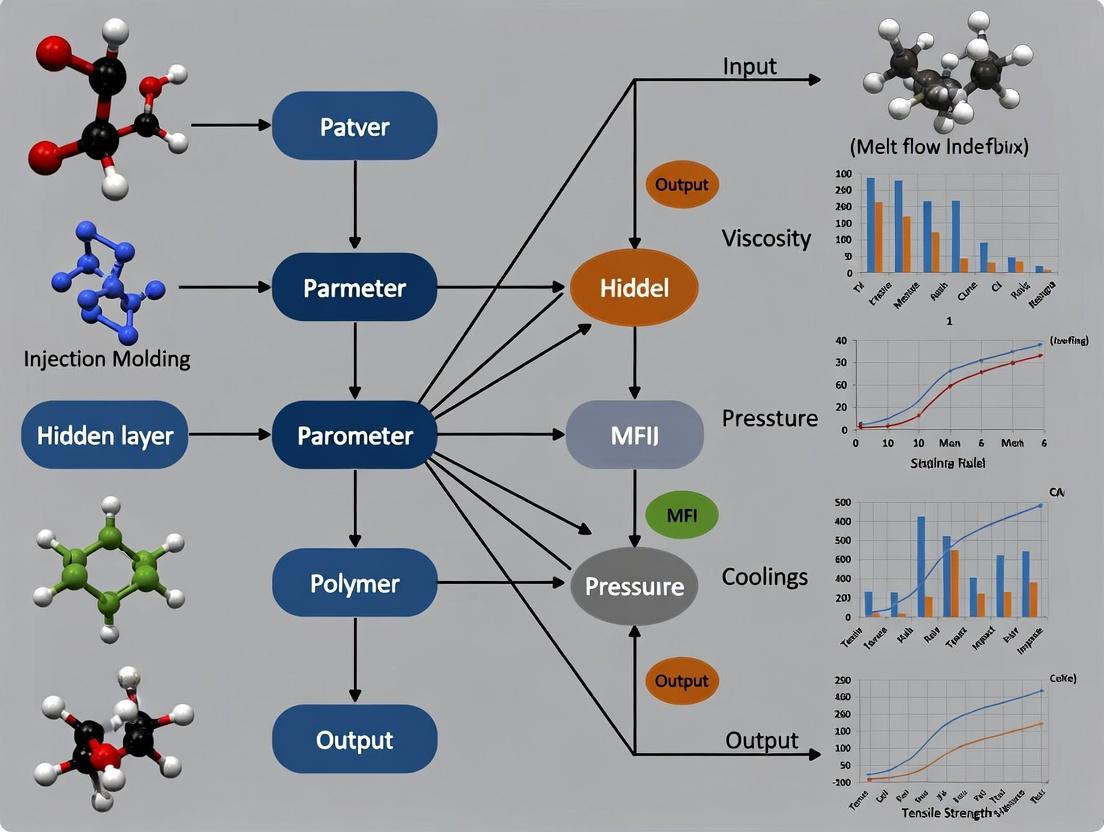

Visualization: Integrating CQAs into ANN-Based Process Optimization

Title: ANN Role in Linking Process Parameters to CQAs

Title: CQA-Driven ANN Development Workflow

Within the broader research thesis on Artificial Neural Network (ANN) optimization of injection molding parameters for pharmaceutical applications, this document addresses the core multivariate challenge. The manufacture of drug-loaded polymeric devices (e.g., implants, microparticles) via injection molding is governed by numerous Key Process Parameters (KPPs) that exhibit nonlinear, interactive effects on Critical Quality Attributes (CQAs). This complexity necessitates a structured, data-driven approach to deconvolute parameter interactions, enabling the development of robust ANN models for predictive control and quality-by-design (QbD) implementation.

Table 1: Primary KPPs in Pharmaceutical Polymer Injection Molding and Their Typical Ranges

| KPP Category | Specific Parameter | Typical Investigative Range (Units) | Direct Influence on |

|---|---|---|---|

| Thermal | Melt Temperature (T_m) | 150 - 250 (°C) | Polymer Degradation, API Stability, Viscosity |

| Mold Temperature (T_c) | 20 - 80 (°C) | Crystallinity, Residual Stress, Release Kinetics | |

| Flow/Pressure | Injection Pressure (P_inj) | 500 - 1500 (bar) | Filling Behavior, Shear Stress, API Distribution |

| Holding Pressure (P_hold) | 300 - 800 (bar) | Part Density, Shrinkage, Porosity | |

| Packing Time (t_pack) | 5 - 20 (s) | ||

| Temporal | Cooling Time (t_cool) | 15 - 60 (s) | Cycle Time, Final Part Dimensions |

| Screw Speed (RPM) | 50 - 150 (rpm) | Shear Heating, Mixing Homogeneity |

Table 2: Target CQAs for Drug-Loaded Molded Products

| CQA Category | Measured Attribute | Target Impact | Common Analytical Method |

|---|---|---|---|

| Physical | Tensile Strength | Device Integrity | ASTM D638 |

| Dimensional Accuracy (Weight, Geometry) | Dosage Consistency | Microbalance, Optical Micrometer | |

| Surface Roughness (Ra) | Bioadhesion/Release | Profilometry | |

| Chemical | Drug Content Uniformity | Efficacy | HPLC/UPLC |

| Polymer Degradation | Safety & Performance | GPC, FTIR | |

| Performance | In Vitro Drug Release Profile (e.g., % at 24h) | Therapeutic Profile | USP Dissolution Apparatus |

| Glass Transition Temp. (T_g) | Structural Stability | DSC |

Experimental Protocol: A Design of Experiments (DoE) Approach for ANN Training Data Generation

Protocol Title: Systematic Generation of a Multivariate Dataset for ANN Model Development in Injection Molding.

Objective: To empirically map the complex interaction space of KPPs and their effect on CQAs for a model drug-polymer system, creating a high-quality dataset for ANN training and validation.

Materials & Model System:

- Polymer: Poly(lactic-co-glycolic acid) (PLGA) 50:50, IV 0.8 dL/g.

- Active Pharmaceutical Ingredient (API): Model compound (e.g., Theophylline, 10% w/w).

- Equipment: Micro-injection molding machine with precise parameter control, DSC, HPLC, dissolution apparatus, universal testing machine.

Procedure:

Phase 1: Parameter Screening & DoE Design

- Define Scope: Select 5 primary KPPs: Tm, Tc, Pinj, Phold, t_cool.

- Design Matrix: Implement a Central Composite Design (CCD) or a definitive screening design to efficiently explore the design space with a limited number of experimental runs (~30-50 runs, including center points for reproducibility assessment).

- Randomization: Randomize the run order to mitigate systematic error.

Phase 2: Molding Execution & Sample Collection

- Machine Setup & Conditioning: Pre-dry PLGA/API blend. Condition mold at target T_c.

- Run DoE: For each run in the randomized sequence, set KPPs to specified levels. Allow process to stabilize for 5 cycles before collecting samples from the 6th cycle onward.

- Sample Labeling: Collect 10 parts per run. Label meticulously with run ID. Destine for specific CQA analysis.

Phase 3: CQA Analysis

- Dimensional/Weight: Measure part weight (n=10) and critical dimension (n=5) using calibrated instruments. Calculate mean and standard deviation.

- Drug Content: Pulverize 3 parts per run. Extract drug and quantify via validated HPLC method. Report mean content and %RSD.

- Mechanical Property: Perform tensile testing on 5 dog-bone specimens per run (ASTM D638).

- Release Kinetics: Place 3 parts per run in 500 mL phosphate buffer (pH 7.4, 37°C, 100 rpm). Sample at intervals (1, 4, 8, 24, 48h) and analyze via HPLC to generate release profiles.

Phase 4: Data Curation for ANN

- Compile Dataset: Create a master table. Each row is one experimental run. Columns include input KPPs and the corresponding measured CQA outputs.

- Normalization: Normalize all data (inputs and outputs) to a [0,1] scale to facilitate ANN training.

- Split Data: Partition data into Training (70%), Validation (15%), and Test (15%) sets.

Visualizing the ANN-Optimization Workflow and Parameter Interactions

Diagram 1: ANN-Driven Optimization Workflow for Molding

Diagram 2: Interaction Network of Key Molding Parameters

The Scientist's Toolkit: Research Reagent & Material Solutions

Table 3: Essential Research Materials for Injection Molding Process Research

| Item/Category | Example Product/Specification | Primary Function in Research |

|---|---|---|

| Model Polymers | PLGA (varied ratios: 50:50, 75:25, 85:15; varied IV), PCL, PLA. | Serve as the primary carrier matrix. Different grades allow study of crystallinity, degradation rate, and processability effects. |

| Model APIs | Theophylline, Diclofenac Sodium, Methylene Blue. | Thermally stable, easily analyzable compounds used to model drug behavior (distribution, stability, release) without regulatory complexity. |

| Process Stabilizers | Antioxidants (e.g., BHT, Irgafos 168), Plasticizers (e.g., Triethyl citrate). | Mitigate polymer/API degradation during high-temperature processing, expanding the viable process window. |

| Analytical Standards | USP-grade API standards, Polymer molecular weight standards (for GPC). | Essential for calibrating HPLC, GPC, etc., ensuring accuracy in CQA measurement for model training data. |

| Colorant/Tracer | 0.1% w/w Titanium Dioxide or Sudan Blue. | Used in short-shot studies to visualize flow front progression and mixing behavior within the mold cavity. |

| Material Characterization Kits | DSC calibration kits (Indium, Zinc), Moisture analysis kits (Karl Fischer). | Ensure the accuracy of thermal analysis and control of a critical pre-processing variable (moisture content). |

| Data Acquisition Software | Mold pressure/temperature sensors coupled with LabVIEW or similar. | Enables high-frequency, time-series data capture of in-cavity conditions, providing rich input features for advanced ANN models. |

Limitations of Trial-and-Error and Taguchi Methods in Modern R&D

This application note situates its analysis within a broader doctoral thesis investigating the application of Artificial Neural Networks (ANNs) for the optimization of critical quality attributes in pharmaceutical injection molding, specifically for drug-eluting implants and complex device components. While traditional methods like trial-and-error and Taguchi designs have been foundational, their limitations are pronounced in the high-stakes, multi-parameter, and non-linear environment of modern pharmaceutical research and development (R&D).

Comparative Analysis of Traditional vs. ANN-Based Approaches

Table 1: Quantitative Comparison of Optimization Method Limitations

| Aspect | Trial-and-Error | Taguchi Method (DOE) | ANN-Based Optimization (Proposed) |

|---|---|---|---|

| Parameter Interaction Handling | Nonexistent; one-factor-at-a-time. | Limited; uses orthogonal arrays to estimate main effects and some interactions. | Excellent; models complex, high-order, non-linear interactions inherently. |

| Experimental Cost (Typical Run #) | Very High (50-200+ runs, unstructured). | Moderate (16-32 runs for 4-7 parameters). | Low post-training; initial DOE (16-32 runs) required for ANN training data. |

| Optimal Solution Guarantee | None; converges on local, satisfactory solution. | Sub-optimal; finds robust setting within predefined levels, not a global optimum. | High probability of global optimum discovery within design space. |

| Adaptability to Real-Time Data | None. | Very Low; new experiments required for any change. | High; model can be continuously updated with new data (online learning). |

| Handling Noise & Variability | Poor; relies on experimenter's intuition. | Good; uses Signal-to-Noise (S/N) ratios for robustness. | Very Good; can be trained on noisy data and predict confidence intervals. |

| Suitability for Non-Linear Systems | Poor. | Poor; fundamentally a linear modeling approach. | Excellent; core strength is modeling non-linear relationships. |

Detailed Experimental Protocols

Protocol 1: Establishing Baseline via Taguchi Design (L9 Orthogonal Array)

This protocol generates the initial comparative data set for ANN training and highlights Taguchi limitations.

Objective: To optimize injection molding parameters (Hold Pressure, Melt Temperature, Cooling Time) for a poly(lactic-co-glycolic acid) (PLGA) implant to maximize tensile strength and minimize mass loss variance.

Materials: See "Scientist's Toolkit" below. Workflow:

- Define Factors & Levels: Select 3 critical parameters (A, B, C) each at 3 levels.

- Select Orthogonal Array: Use an L9 (3^4) array.

- Randomize & Execute Runs: Perform 9 molding runs per randomized order.

- Measure Responses: For each run, measure tensile strength (TS, higher-is-better) and mass loss (ML, lower-is-better) (n=10 samples/run).

- Calculate S/N Ratios:

- For TS: S/N = -10 * log₁₀( (1/n) * Σ (1/TS²) )

- For ML: S/N = -10 * log₁₀( (1/n) * Σ (ML²) )

- Factor Level Analysis: Plot mean S/N ratio for each factor at each level. Optimal level per factor is the one with the highest S/N.

- Prediction & Confirmation: Predict S/N at optimal levels. Run 3 confirmation experiments. Compare predicted vs. actual.

Limitation Encountered: The single "optimal" setting derived is a compromise. It cannot predict performance at parameter levels not explicitly tested (e.g., if the true global optimum is at a Melt Temperature of 172°C, but levels were 170, 175, 180°C).

Protocol 2: ANN Model Development & Optimization Workflow

This protocol details the subsequent, superior approach within the thesis framework.

Objective: To develop a predictive, non-linear model mapping the same injection molding parameters to the measured responses, enabling global optimization.

Workflow:

- Data Compilation: Use data from Protocol 1 (9 runs) supplemented with 7 additional strategically designed runs (e.g., central composite points) to better capture curvature. Total dataset: 16 runs.

- Data Preprocessing: Normalize all input (parameters) and output (TS, ML) data to a [0,1] range.

- Network Architecture Definition: Design a feedforward ANN with one hidden layer (6-10 neurons, determined via k-fold cross-validation), hyperbolic tangent activation functions.

- Training & Validation: Split data 70/15/15 (Training/Validation/Test). Train using Levenberg-Marquardt backpropagation. Use validation set to halt training and prevent overfitting.

- Global Optimization: Use a genetic algorithm (GA) to query the trained ANN model. The GA explores the entire, continuous parameter space defined by min/max bounds to find the parameter set that maximizes a custom desirability function combining TS and ML.

- Experimental Confirmation: Execute molding runs at the ANN-GA predicted optimum (n=3). Compare results to Taguchi optimum.

Expected Outcome: The ANN-GA method will identify a parameter combination yielding statistically significant (p<0.05) improvements in the desirability function compared to the Taguchi solution.

Diagram 1: ANN-GA Optimization Workflow (100 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Injection Molding Optimization Studies

| Item / Reagent | Function / Relevance in Research |

|---|---|

| PLGA (50:50, 75:25) | Model biodegradable polymer for drug-eluting implants. Varying ratios affect degradation rate and drug release kinetics. |

| Model API (e.g., Metformin HCl) | A hydrophilic, stable model drug compound used to study active pharmaceutical ingredient (API) dispersion and release profiles. |

| Plasticizer (e.g., Triethyl Citrate) | Used to modify polymer viscosity and flexibility, a critical parameter affecting moldability and final device mechanical properties. |

| Mold Release Agent | Ensures consistent ejection of molded parts, preventing surface defects that confound mechanical and mass loss measurements. |

| Tensile Testing System | Quantifies ultimate tensile strength and elongation at break—key Critical Quality Attributes (CQAs) for implant performance. |

| Accelerated Stability Chamber | Simulates long-term degradation (e.g., 37°C, 75% RH) for mass loss and drug release studies, accelerating R&D timelines. |

| HPLC System with PDA | Gold standard for quantifying API degradation products and release kinetics from the molded implant in dissolution media. |

Diagram 2: Core Limitations of Traditional Methods (99 chars)

This application note elucidates the foundational concepts of Artificial Neural Networks (ANNs) and their capacity to emulate intricate, non-linear decision-making processes. The context is a thesis focused on leveraging ANN architectures for the optimization of injection molding parameters—a task analogous to complex problem-solving in materials science and pharmaceutical development (e.g., drug formulation, device component fabrication). ANNs provide a data-driven framework to map complex relationships between input parameters (e.g., melt temperature, hold pressure, cooling time) and output qualities (e.g., tensile strength, dimensional accuracy, yield), mimicking the nuanced decision-making typically requiring extensive expert knowledge.

Core Foundational Concepts: ANN Architecture as a Decision-Making Engine

ANNs are composed of interconnected layers of nodes (neurons) that collectively process information. This structure allows them to approximate any continuous function, making them ideal for modeling the high-dimensional, non-linear relationships inherent in process optimization.

Key Quantitative Parameters of Modern ANN Architectures: Recent advances highlight typical architectural parameters and performance metrics relevant to optimization tasks.

Table 1: Representative ANN Architectures & Performance Metrics for Process Optimization

| Architecture Type | Typical Layer Depth | Number of Parameters | Common Activation Function | Typical Training Data Requirement | Reported RMSE Reduction vs. Linear Models |

|---|---|---|---|---|---|

| Feedforward (MLP) | 3-8 Hidden Layers | 10^3 - 10^6 | ReLU, Leaky ReLU | 10^3 - 10^5 data points | 40-60% |

| Convolutional (CNN) | 5-100+ Layers | 10^5 - 10^8 | ReLU | 10^4 - 10^7 data points | 50-70% (for image-based quality control) |

| Recurrent (LSTM) | 2-5 Hidden Layers | 10^4 - 10^7 | Tanh, Sigmoid | 10^3 - 10^5 sequential data points | 55-65% (for time-series parameter analysis) |

Note: RMSE = Root Mean Square Error. Data synthesized from recent (2023-2024) research on ANN applications in manufacturing and chemometrics.

Experimental Protocol: Implementing an ANN for Injection Molding Parameter Optimization

This protocol details the methodology for developing an ANN model to predict part shrinkage based on processing parameters.

Protocol Title: ANN-Based Modeling of Injection Molding Shrinkage

Objective: To construct and validate a feedforward ANN that maps critical process inputs to part shrinkage, enabling parameter optimization for dimensional accuracy.

Materials & Methods:

Research Reagent Solutions & Essential Materials:

Table 2: Scientist's Toolkit for ANN-Driven Process Optimization

| Item / Solution | Function / Purpose |

|---|---|

| Process Data Historian | Time-series database containing validated injection molding machine parameters (e.g., pressures, temperatures, times). |

| Metrology Suite (CMM/Laser Scan) | Provides high-precision measurement of output variables (shrinkage, warpage, weight) for ground-truth labeling. |

| Python Environment (v3.9+) | Core programming ecosystem. |

| TensorFlow/PyTorch Library | Open-source frameworks for building, training, and deploying deep neural networks. |

| Scikit-learn Library | Provides tools for data preprocessing (scaling), train-test splitting, and baseline model comparison. |

| Hyperparameter Optimization Tool | Software (e.g., Optuna, Hyperopt) for automated tuning of ANN learning rate, layer size, etc. |

| High-Performance Computing (HPC) Cluster | Accelerates model training on large datasets via GPU/TPU parallelism. |

Procedure:

Data Acquisition & Curation:

- Extract a minimum dataset of 5,000 historical production cycles from the Process Data Historian.

- Input Features (X): Select key parameters—Melt Temperature (°C), Injection Pressure (Bar), Pack/Hold Pressure (Bar), Cooling Time (s), Mold Temperature (°C).

- Output Label (y): Corresponding part shrinkage (%) measured via the Metrology Suite.

- Perform data cleaning: remove cycles with machine faults, impute missing sensor values using k-nearest neighbors (k=5), and apply 3σ outlier removal.

Data Preprocessing & Partitioning:

- Normalize all input features to a [0, 1] range using Min-Max scaling. Scale the output label separately.

- Partition the dataset randomly: 70% for training, 15% for validation, 15% for final testing.

ANN Model Construction & Training:

- Initialize a sequential feedforward model (MLP).

- Architecture: Input layer (5 nodes), four hidden layers (128, 64, 32, 16 nodes respectively), output layer (1 node).

- Activation: Use ReLU for hidden layers. Use linear activation for the output layer.

- Compilation: Use Adam optimizer with an initial learning rate of 0.001. Set loss function to Mean Squared Error (MSE).

- Training: Train for a maximum of 500 epochs with a batch size of 32. Implement an early stopping callback monitoring validation loss with a patience of 20 epochs.

Hyperparameter Optimization (HPO):

- Using the validation set, run 50 trials of Bayesian optimization (via Optuna) to tune: number of hidden layers (2-6), neurons per layer (16-256), learning rate (1e-4 to 1e-2), and batch size (16, 32, 64).

Model Validation & Testing:

- Retrain the model with the optimal HPO configuration on the combined training and validation set.

- Evaluate the final model on the held-out test set. Report key metrics: R², MSE, and Mean Absolute Error (MAE).

- Perform sensitivity analysis (e.g., Partial Dependence Plots) to interpret the influence of each process parameter on the predicted shrinkage.

Expected Outcome: A validated ANN model capable of predicting part shrinkage with an R² > 0.85 on the test set, providing a reliable surrogate for optimizing process parameters to minimize dimensional variation.

Visualizing the ANN Decision-Making Workflow

The following diagrams illustrate the logical flow of information in an ANN and its specific application within the research protocol.

Title: ANN Architecture for Molding Parameter Mapping

Title: ANN Optimization Research Protocol Workflow

The Promise of ANNs for Modeling Non-Linear Process-Property Relationships

Within the broader thesis on Artificial Neural Network (ANN) optimization of injection molding parameters, this Application Note focuses on the application of ANNs to model complex, non-linear relationships between material processing conditions and the final properties of molded products. This is particularly relevant to pharmaceutical research for drug delivery device components (e.g., inhalers, auto-injectors) where material properties directly impact device performance and drug stability. ANNs offer a powerful data-driven alternative to traditional, often linear, statistical models for capturing these intricate interactions.

Core Principles & Data Presentation

ANNs learn to map input variables (process parameters) to output variables (material properties) through exposure to training data. Key advantages for this domain include handling high-dimensional data, interpolating within complex design spaces, and providing predictive models for quality-by-design (QbD) initiatives.

Table 1: Example ANN Performance vs. Traditional Models in Predicting Polymer Tensile Strength

| Model Type | Architecture/Model | RMSE (MPa) | R² | Data Points Used | Key Process Inputs |

|---|---|---|---|---|---|

| Traditional | Multiple Linear Regression | 4.2 | 0.72 | 150 | Melt Temp, Hold Pressure, Cool Time |

| Traditional | Response Surface Methodology (RSM) | 3.1 | 0.85 | 150 | Melt Temp, Hold Pressure, Cool Time, Injection Speed |

| ANN | Feedforward, 1 Hidden Layer (8 nodes) | 1.8 | 0.95 | 120 (Training) | Melt Temp, Mold Temp, Inj. Speed, Hold Pressure, Hold Time, Cool Time |

| ANN | Feedforward, 2 Hidden Layers (10,5 nodes) | 1.5 | 0.97 | 120 (Training) | All above + Material Moisture Content |

Table 2: Typical Process Parameters & Measured Properties for ANN Modeling in Pharma Molding

| Category | Parameter/Property | Units | Typical Range | Measurement Standard |

|---|---|---|---|---|

| Process Inputs | Barrel Temperature (Melt Temp) | °C | 180-300 | In-machine sensor |

| Mold Temperature | °C | 20-120 | In-machine sensor | |

| Injection Speed | mm/s | 50-200 | Machine setting | |

| Holding Pressure | MPa | 30-100 | Machine setting | |

| Cooling Time | s | 10-40 | Machine setting | |

| Material Properties (Outputs) | Tensile Strength at Yield | MPa | 30-70 | ISO 527-2 |

| Flexural Modulus | GPa | 2.0-3.5 | ISO 178 | |

| Impact Strength (Charpy) | kJ/m² | 2-15 | ISO 179 | |

| Surface Roughness (Ra) | µm | 0.2-2.0 | ISO 4287 |

Experimental Protocols

Protocol 3.1: Generation of Training Data Set via Design of Experiments (DoE)

Objective: To systematically produce a high-quality dataset for ANN training and validation. Materials: See "Scientist's Toolkit" (Section 6). Procedure:

- Define Factor Space: Identify critical injection molding parameters (e.g., Melt Temperature, Mold Temperature, Injection Speed, Holding Pressure). Use historical data or preliminary screening experiments.

- Select DoE Array: Choose a space-filling design (e.g., Latin Hypercube Sampling, Full Factorial) to ensure broad coverage of the multi-dimensional parameter space. A minimum of 10 data points per input variable is a common heuristic.

- Execute Molding Trials: Program the injection molding machine (IMM) according to the DoE matrix. For each run, ensure process stability is achieved before collecting parts.

- Condition Samples: Molded specimens (tensile bars, impact discs) must be conditioned at standard atmosphere (e.g., 23°C, 50% RH) for 48 hours per ISO 291.

- Measure Properties: Conduct standardized mechanical and morphological tests (see Table 2). Each property measurement should be performed on a minimum of 5 specimens per molding condition.

- Compile Dataset: Assemble data into a structured table: each row is a unique process condition, columns are input parameters, and final columns are the measured output properties.

Protocol 3.2: Development, Training, and Validation of an ANN Model

Objective: To create a trained ANN capable of predicting material properties from process inputs. Software: Python (with TensorFlow/Keras or PyTorch), MATLAB, or commercial ANN software. Procedure:

- Data Preprocessing: Normalize or standardize all input and output data to a common range (e.g., 0 to 1 or -1 to 1) to improve training stability and speed.

- Data Partitioning: Randomly split the full dataset into three subsets: Training Set (70%, for weight adjustment), Validation Set (15%, for hyperparameter tuning and preventing overfitting), and Test Set (15%, for final unbiased evaluation).

- Network Architecture Definition: Initialize a feedforward (multilayer perceptron) network. Start with 1-2 hidden layers. The number of input nodes equals the number of process parameters; output nodes equal the number of predicted properties.

- Training Configuration: Select a loss function (Mean Squared Error for regression), an optimizer (e.g., Adam), and a performance metric (e.g., R², RMSE).

- Model Training: Iteratively present the Training Set to the network. Use the Validation Set performance to implement early stopping (halt training when validation error ceases to improve) and avoid overfitting.

- Model Evaluation: Use the held-out Test Set to calculate final performance metrics (RMSE, R²). The model must not have been exposed to this data during training or validation.

Protocol 3.3: Model Deployment for Process Optimization

Objective: To use the trained ANN in an inverse mode to identify process parameters that yield a target set of properties. Procedure:

- Define Target Property Space: Specify desired values or ranges for key outputs (e.g., Tensile Strength > 55 MPa, Surface Roughness Ra < 0.8 µm).

- Implement Optimization Algorithm: Couple the trained ANN with an optimization routine (e.g., Genetic Algorithm, Particle Swarm Optimization, gradient descent).

- Execute Optimization: The algorithm queries the ANN model thousands of times to search the process parameter space, identifying parameter sets that predict outputs within the target ranges.

- Experimental Verification: Conduct a limited set of confirmation molding trials using the top parameter sets predicted by the ANN-optimizer system. Measure actual properties and compare to predictions to validate model robustness.

Visualizations

Diagram 1 Title: ANN Workflow for Molding Process-Property Modeling

Diagram 2 Title: Feedforward ANN Architecture for Property Prediction

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials & Equipment for ANN-Based Molding Research

| Item | Function/Description | Example/Note |

|---|---|---|

| Polymer Resin | Primary material for molding trials. Must be consistent lot-to-lot. | Pharmaceutical-grade polymers (e.g., PEEK, COP, PP, PE). Pre-dried per supplier specs. |

| Injection Molding Machine (IMM) | For generating process data under controlled parameters. | Micro-injection or standard IMM with full process parameter logging capability. |

| Standard Mold Tool | Produces test specimens for property measurement. | ISO 527-1A tensile bar or multi-cavity mold with tensile/impact specimens. |

| Material Drying Oven | Controls material moisture, a critical pre-process variable. | Must achieve <0.02% moisture content for hygroscopic polymers. |

| Universal Testing Machine | Measures tensile, flexural, and compressive properties. | Equipped with environmental chamber if testing at non-ambient conditions. |

| Impact Tester | Measures material toughness (Charpy/Izod). | Notched specimens required for many standards. |

| Surface Profilometer | Quantifies surface roughness (Ra, Rz). | Non-contact (optical) or contact (stylus) type. |

| Data Logging & Control System | Captures high-fidelity time-series process data from IMM sensors. | Essential for capturing transient events that influence properties. |

| ANN Development Software | Platform for building, training, and validating neural network models. | Python (SciKit-Learn, TensorFlow), MATLAB Neural Network Toolbox, commercial packages. |

| Statistical & DoE Software | Designs experiments and performs preliminary statistical analysis. | JMP, Minitab, Design-Expert, or Python (SciKit-Learn, pyDOE2). |

Building the Predictive Engine: A Step-by-Step Guide to ANN Implementation for Molding Optimization

Within the context of optimizing injection molding parameters for pharmaceutical device manufacturing using Artificial Neural Networks (ANNs), robust data acquisition is paramount. The quality of the ANN model is directly contingent on the quality and structure of the training data. A strategically designed Design of Experiments (DoE) ensures efficient, systematic, and statistically sound data collection, covering the design space effectively with minimal experimental runs. This protocol details the application of DoE methodologies to generate optimal datasets for ANN training in this domain.

Core DoE Strategies for ANN Training

A comparative analysis of three principal DoE approaches suitable for non-linear ANN modeling is presented below.

Table 1: Comparison of DoE Methods for ANN Training in Injection Molding

| DoE Method | Primary Objective | Key Advantages for ANN | Typical Run Count for 4 Factors | Suitability for Non-Linear Modeling |

|---|---|---|---|---|

| Full Factorial | Explore all possible combinations of factors and levels. | Comprehensive data; captures all interactions. | 16 (2⁴) to 81 (3⁴) | Excellent, but computationally expensive. |

| Central Composite Design (CCD) | Fit a second-order (quadratic) response surface. | Efficiently estimates curvature and interactions; good for space-filling. | 25-30 (with center points) | Very High (explicitly designed for curvature). |

| Latin Hypercube Sampling (LHS) | Space-filling design for complex, non-linear models. | Excellent projective properties; spreads points evenly across each factor range. | User-defined (e.g., 20-50) | Excellent, especially for high-dimensional spaces. |

Experimental Protocol: Implementing a CCD for Injection Molding Process Optimization

Objective

To generate a high-quality dataset for training an ANN to predict critical quality attributes (CQAs) of a molded polymeric drug delivery component (e.g., tensile strength, dimensional accuracy) based on key process parameters.

Key Research Reagent Solutions & Materials

Table 2: Essential Materials and Reagents for DoE Execution

| Item | Function in Experiment |

|---|---|

| Polymer Resin (e.g., PLGA, PEEK) | Primary material for molding; its batch consistency is critical. |

| Mold Release Agent | Ensures consistent part ejection, preventing variation from sticking. |

| Dimensional Metrology System (CMM/Laser Scanner) | Precisely measures part geometry (CQA). |

| Universal Testing Machine | Measures mechanical CQAs (e.g., tensile strength). |

| Process Parameter Sensors (In-cavity pressure, melt temperature) | Provides real-time, accurate data for input variables. |

| Statistical Software (JMP, Minitab, Design-Expert) | Used to design the DoE matrix and perform initial analysis. |

Step-by-Step Protocol

Step 1: Define Factors and Responses

- Input Factors (X): Select 4 critical injection molding parameters. Define feasible ranges based on machine limits and polymer specifications.

- A: Melt Temperature (°C) [Low: 200, High: 240]

- B: Injection Pressure (MPa) [Low: 60, High: 100]

- C: Packing Time (s) [Low: 2, High: 6]

- D: Coolant Temperature (°C) [Low: 20, High: 60]

- Responses (Y) - ANN Outputs/CQAs:

- Y1: Part Weight (mg)

- Y2: Dimensional Deviation at a Critical Feature (µm)

- Y3: Tensile Strength at Break (MPa)

Step 2: Construct the DoE Matrix

- Using statistical software, generate a Face-Centered Central Composite Design (FC-CCD).

- The design will include: 16 factorial points (2⁴), 8 axial (star) points (at ±1 alpha on each axis), and 6 center point replicates. Total N=30 experimental runs.

- Randomize the run order to mitigate systematic noise.

Step 3: Execute Experimental Runs

- Set up the injection molding machine according to the first randomized set point (A, B, C, D).

- Allow the process to stabilize (≥5 shots).

- Collect samples from the next 10 consecutive shots.

- Label samples uniquely corresponding to the DoE run ID.

- Repeat for all 30 runs, ensuring consistent material handling and machine warm-up periods.

Step 4: Measure Responses

- Y1 (Part Weight): Measure each of the 10 samples per run using a precision micro-balance. Calculate the average and standard deviation for the run.

- Y2 (Dimensional Deviation): Using a Coordinate Measuring Machine (CMM), measure the critical dimension on 5 samples per run. Report the average deviation from nominal.

- Y3 (Tensile Strength): Perform tensile tests on 5 samples per run (ASTM D638). Record the average tensile strength at break.

Step 5: Assemble the Final Dataset for ANN

- Create a table where each row is one of the 30 experimental runs.

- Columns include: Run ID, the 4 input factor levels (coded or actual), and the 3 averaged response values.

- This 30x7 matrix forms the core preprocessed dataset for ANN training, validation, and testing.

Visualizing the Integrated Workflow

The following diagram illustrates the logical sequence from DoE design to a validated ANN model within the injection molding research context.

DoE-Driven ANN Development Workflow

Data Preprocessing Protocol for ANN Input

Step 1: Normalization

- Scale all input factors (X) and output responses (Y) to a range of [0, 1] or [-1, 1] to ensure equal weighting during ANN training.

- Formula for min-max scaling to [0,1]: ( X{\text{norm}} = \frac{X - X{\min}}{X{\max} - X{\min}} )

Step 2: Data Partitioning

- Split the 30-run dataset into three subsets:

- Training Set (70% - 21 runs): Used to adjust ANN weights.

- Validation Set (15% - 4-5 runs): Used for hyperparameter tuning and preventing overfitting.

- Test Set (15% - 4-5 runs): Used for final, unbiased evaluation of model performance.

Step 3: Addition of Noise (Optional for Robustness)

- To improve ANN generalization, introduce minor Gaussian noise (e.g., 0.5% of standard deviation) to the training data, simulating process variability.

A meticulously planned DoE, such as a Central Composite Design, is not merely an experimental convenience but a foundational requirement for building reliable ANN models in injection molding research. It ensures the acquired data is information-rich, covers the operational space efficiently, and is structurally prepared for the non-linear modeling capabilities of ANNs, directly contributing to the overarching thesis goal of robust process optimization.

Application Notes

In the context of optimizing injection molding parameters for pharmaceutical device manufacturing, selecting the appropriate Artificial Neural Network (ANN) architecture is critical. Feedforward Neural Networks (FNNs) serve as the foundational multilayer perceptron (MLP) structure, mapping inputs (e.g., melt temperature, hold pressure, cooling time) to target outputs (e.g., part shrinkage, tensile strength). Backpropagation is the essential algorithm for training these networks by calculating the gradient of the loss function. Deep Learning (DL) architectures, such as deep FNNs or specialized variants, offer higher capacity for modeling complex, non-linear relationships in high-dimensional parameter spaces.

Current research indicates that for injection molding datasets of moderate complexity (~10-20 input parameters), a standard FNN with 1-2 hidden layers trained via backpropagation can often achieve satisfactory prediction accuracy (e.g., R² > 0.85). For more intricate optimization involving real-time sensor data or image-based quality control, deeper convolutional or recurrent architectures may be warranted, though at increased computational cost and risk of overfitting, necessitating robust regularization.

Quantitative Performance Comparison

Table 1: Comparative Summary of ANN Architectures for Injection Molding Parameter Prediction

| Architecture Type | Typical Hidden Layers | Average Prediction R² (Reported Range) | Training Time (Relative) | Data Volume Requirement | Suited for Molding Problem Type |

|---|---|---|---|---|---|

| Shallow Feedforward (BP) | 1-2 | 0.82 - 0.90 | Low | 100s - 1000s samples | Static parameter optimization, single quality metric prediction |

| Deep Feedforward (BP) | 5+ | 0.88 - 0.95 | Medium-High | 10,000s+ samples | High-dimension parameter spaces, multi-objective optimization |

| Convolutional Neural Net | 5+ (Conv) | 0.91 - 0.98 (for image data) | High | 1000s+ images | Visual defect analysis, microstructural prediction from process data |

| Recurrent Neural Net | 2-3 (Recurrent) | 0.85 - 0.93 | Medium-High | Temporal sequences | Dynamic process control, time-series sensor data prediction |

Experimental Protocols

Protocol 1: Baseline Feedforward ANN for Molding Parameter Optimization

Objective: To develop a predictive model linking key injection molding parameters to a critical quality attribute (CQA) of a molded pharmaceutical component.

Workflow:

- Data Curation: Compile a dataset from historical molding runs or designed experiments (e.g., DoE). Minimum recommended size: 500 runs. Inputs (X): Melt temperature (°C), injection pressure (bar), holding pressure (bar), cooling time (s), mold temperature (°C). Output (Y): Part dimensional accuracy (mm deviation from nominal).

- Preprocessing: Normalize all features (X) and the target (Y) using StandardScaler (zero mean, unit variance). Perform an 80/20 train-test split.

- Model Initialization: Construct a fully connected FNN using PyTorch or TensorFlow. Recommended initial architecture: Input layer (5 neurons), Hidden Layer 1 (64 neurons, ReLU activation), Hidden Layer 2 (32 neurons, ReLU activation), Output layer (1 neuron, linear activation).

- Training via Backpropagation: Use Mean Squared Error (MSE) loss and the Adam optimizer (learning rate=0.001). Train for 1000 epochs with batch size 32. Implement early stopping if validation loss does not improve for 50 epochs.

- Evaluation: Calculate R² and Mean Absolute Error (MAE) on the held-out test set. Perform sensitivity analysis on input parameters to validate model plausibility.

Protocol 2: Advanced Deep Learning Model for Multi-Target Prediction

Objective: To simultaneously predict multiple CQAs (tensile strength, weight, crystallinity) from an expanded parameter set including screw speed profile.

Workflow:

- Data Preparation: Assemble dataset with ~50 input features (static parameters + binned screw speed data) and 3 target vectors. Dataset must be larger (>10,000 samples). Handle missing values via imputation.

- Architecture Design: Implement a deeper FNN: Input layer, Dense (128, ReLU), Dropout (0.2), Dense (64, ReLU), Dropout (0.2), Dense (32, ReLU), three parallel Output heads (for each CQA).

- Backpropagation & Regularization: Use a composite loss function (weighted sum of MSE for each target). Employ L2 weight regularization (lambda=0.001) and the dropout layers as per step 2. Use the AdamW optimizer.

- Training Regimen: Train with a cyclical learning rate. Use k-fold cross-validation (k=5) for robust hyperparameter tuning (layer size, dropout rate).

- Validation: Report test set performance per target. Use SHAP (SHapley Additive exPlanations) values for global model interpretability.

Visualizations

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions & Computational Tools

| Item / Solution Name | Function in ANN Research for Molding | Typical Specification / Notes |

|---|---|---|

| PyTorch / TensorFlow | Open-source deep learning frameworks for flexible model architecture design and automated gradient computation (backpropagation). | Use GPU-enabled versions (CUDA) for accelerated training on deep networks. |

| Scikit-learn | Python library for data preprocessing (scaling, splitting), baseline model implementation, and fundamental evaluation metrics. | Essential for creating reproducible preprocessing pipelines before ANN training. |

| High-Fidelity Process Data | Historical or experimentally generated datasets from injection molding machines (e.g., Engel, Arburg). | Must include synchronized time-series process parameters and final part quality measurements. |

| NVIDIA GPU (e.g., V100, A100) | Hardware accelerator for performing the high-volume matrix calculations central to efficient ANN training. | Critical for experimenting with deep architectures and large datasets. |

| SHAP / LIME Libraries | Model interpretability tools to explain predictions, translating ANN "black box" outputs into actionable insights for parameter adjustment. | Vital for validating model plausibility and gaining trust from domain experts. |

| Hyperparameter Optimization Suite (Optuna, Ray Tune) | Automated tools for systematically searching optimal learning rates, layer sizes, and regularization parameters. | Replaces manual trial-and-error, ensuring robust architecture selection. |

Defining Inputs (Temperature, Pressure, Hold Time) and Outputs (Weight, Strength, Dimensional Accuracy)

Within the context of Artificial Neural Network (ANN) optimization research for injection molding, precise definition and control of process parameters (Inputs) and their relationship to critical quality attributes (Outputs) is paramount. This application note details the protocols for establishing this data-driven framework, essential for training robust ANNs that predict and optimize pharmaceutical device manufacturing.

Input Parameter Definitions & Protocols

Temperature

Definition: The thermal energy applied to the polymer melt and mold. Key zones include Melt Temperature (Tm) and Mold Temperature (Tw). Protocol for Measurement:

- Equipment: Calibrated immersion (melt) and infrared (mold) thermocouples, data logger.

- Melt Temp Protocol: Insert a standardized immersion thermocouple probe into the melt stream via a designated nozzle port. Record temperature at 100 ms intervals for 30 cycles. Report as average ± standard deviation.

- Mold Temp Protocol: Using an infrared pyrometer, measure temperature at five predefined points on each mold half (cavity and core) immediately after part ejection. Repeat for 10 cycles.

Pressure

Definition: The hydraulic force applied to propagate the melt, consisting of Injection Pressure (Pinj) and Holding Pressure (Phold). Protocol for Measurement:

- Equipment: Machine-integrated pressure transducers (nozzle or cavity), oscilloscope or high-frequency data acquisition system (DAQ).

- Protocol: Configure DAQ to sample pressure data at 1 kHz. For Pinj, record from screw advance start to V/P switch-over. For Phold, record from switch-over to end of hold phase. Repeat for 20 consecutive cycles.

Hold Time

Definition: The duration for which holding pressure is maintained after cavity filling to compensate for material shrinkage. Protocol for Measurement:

- Equipment: Machine timer, synchronized with pressure DAQ.

- Protocol: Set machine timer. Use the pressure profile from Section 2.2 to precisely define the start (V/P switch) and end (pressure decay to 10% of setpoint) of hold time. Calculate as the difference.

Input Parameter Design of Experiments (DoE) Table

Table 1: Example DoE for Input Parameter Variation in ANN Training Data Generation.

| Experiment Run | Melt Temp. (°C) | Mold Temp. (°C) | Inj. Pressure (bar) | Hold Pressure (bar) | Hold Time (s) |

|---|---|---|---|---|---|

| 1 | 180 | 40 | 800 | 600 | 5 |

| 2 | 200 | 40 | 800 | 600 | 10 |

| 3 | 180 | 60 | 800 | 600 | 10 |

| 4 | 200 | 60 | 800 | 600 | 5 |

| 5 | 180 | 40 | 1000 | 600 | 10 |

| 6 | 200 | 40 | 1000 | 600 | 5 |

| ... | ... | ... | ... | ... | ... |

| Center Point | 190 | 50 | 900 | 600 | 7.5 |

Output Metric Definitions & Measurement Protocols

Part Weight

Definition: The mass of the solidified molded part, a direct indicator of shot consistency and cavity fill. Protocol for Measurement:

- Equipment: Analytical balance (0.1 mg precision), static elimination device.

- Protocol: Condition parts at 23±2°C & 50±5% RH for 24h. Use anti-static gun. Weigh 10 parts from each DoE run consecutively. Record average and standard deviation.

Mechanical Strength

Definition: The force required to break a part under a specific load, often measured via tensile or flexural test. Protocol for Measurement (ISO 527-2):

- Equipment: Universal tensile testing machine, Type 1BA dumbbell specimen mold.

- Protocol: Condition specimens as per 3.1. Mount specimen in grips with 115 mm separation. Apply tensile load at 5 mm/min crosshead speed until failure. Record peak force (N) and stress at break (MPa). N=10 per run.

Dimensional Accuracy

Definition: The conformance of part dimensions (e.g., diameter, thickness) to nominal CAD specifications. Protocol for Measurement:

- Equipment: Coordinate Measuring Machine (CMM) or laser micrometer.

- Protocol: Temperature-stabilize parts and CMM (20°C). For a critical diameter (Ø) and wall thickness (t), perform 5 measurements per dimension on 5 parts from each run (N=25/data point). Report as mean dimension and ±3σ.

Table 2: Example Output Data from DoE for ANN Training.

| DoE Run | Avg. Part Weight (g) | Std. Dev. Weight (g) | Tensile Strength (MPa) | Critical Diameter (mm) | Thickness (mm) |

|---|---|---|---|---|---|

| 1 | 1.532 | 0.003 | 48.7 | 10.012 | 2.101 |

| 2 | 1.525 | 0.005 | 46.2 | 10.008 | 2.095 |

| 3 | 1.540 | 0.004 | 44.8 | 10.021 | 2.110 |

| 4 | 1.535 | 0.003 | 45.5 | 10.015 | 2.104 |

| 5 | 1.550 | 0.006 | 47.9 | 10.030 | 2.115 |

| ... | ... | ... | ... | ... | ... |

ANN-Optimized Injection Molding Workflow

ANN-Driven Injection Molding Parameter Optimization

The Scientist's Toolkit: Research Reagent Solutions & Materials

Table 3: Essential Materials for ANN-Optimization Injection Molding Research.

| Item | Function in Research | Example/Specification |

|---|---|---|

| Medical-Grade Polymer | Primary molding material; its viscosity & thermal properties are key model inputs. | Polypropylene (PP) USP Class VI, Polycarbonate (PC). Lot-to-lot consistency is critical. |

| Mold Release Agent | Facilitates part ejection without affecting surface chemistry for consistent weight & dimensions. | Non-silicone, semi-permanent fluorinated coating. |

| Dimensional Standard (Gauge) | For daily verification of CMM/laser micrometer accuracy to ensure output data integrity. | NIST-traceable calibration pins and gauge blocks. |

| Data Acquisition System (DAQ) | High-frequency recording of in-process parameters (pressure, temp) for true input data. | >1 kHz sampling rate, synchronized channels for pressure & temperature. |

| Tensile Test Specimen Mold | Produces standardized dog-bone parts for reproducible mechanical strength data (ISO 527). | Mold tool meeting ISO 294-1/ISO 527-2 Type 1BA specifications. |

| Statistical Software | For DoE creation, initial data analysis, and interfacing with ANN development platforms. | JMP, Minitab, or Python (SciPy, pandas). |

| ANN Development Platform | Environment for building, training, and validating the neural network model. | Python (TensorFlow, PyTorch), MATLAB Deep Learning Toolbox. |

Within the broader thesis on optimizing injection molding parameters for pharmaceutical manufacturing using Artificial Neural Networks (ANNs), this protocol details the critical phase of model development. The accurate prediction of critical quality attributes (CQAs)—such as tablet hardness, dissolution rate, and content uniformity—from process parameters (e.g., barrel temperature, hold pressure, cooling time) hinges on rigorous training, testing, and validation using relevant pharmaceutical datasets.

Application Notes: Key Considerations for Pharmaceutical Data

- Data Source & Preprocessing: Pharmaceutical datasets are often high-dimensional but limited in sample size due to the cost of Design of Experiments (DoE) in GMP environments. Missing data imputation and outlier detection are crucial.

- Feature Selection: Domain knowledge must guide initial feature selection (e.g., including moisture content of the API-excipient blend) before employing algorithmic methods to reduce overfitting.

- Validation Strategy: k-Fold Cross-Validation is essential for robust performance estimation. A completely independent "hold-out" set, representing a novel process condition, is mandatory for final testing to simulate real-world generalization.

- Compliance & Documentation: All data transformations and model parameters must be thoroughly documented to align with ALCOA+ principles and potential regulatory scrutiny.

Experimental Protocol: ANN Development for a Tablet Hardness Prediction Model

A. Objective: To develop a feedforward ANN capable of predicting tablet tensile strength from injection molding process parameters and material attributes.

B. Dataset Simulation & Description: Based on published studies, a simulated dataset was constructed representing a typical DoE for a polymer-based controlled-release matrix tablet.

- Input Features (8): Melt Temperature (°C), Mold Temperature (°C), Hold Pressure (bar), Cooling Time (s), Polymer Molecular Weight (kDa), API Load (%), Plasticizer Concentration (%), Moisture Content (%).

- Output/Target (1): Tablet Tensile Strength (MPa).

- Dataset Size: 150 experimental runs.

- Data Split: 70% Training (105 runs), 15% Validation (22 runs), 15% Testing (23 runs). Split is stratified by API Load level.

Table 1: Summary of Dataset Statistics (Simulated Example)

| Feature | Min | Max | Mean | Std Dev | Unit |

|---|---|---|---|---|---|

| Melt Temperature | 155 | 185 | 170.5 | 8.2 | °C |

| Mold Temperature | 25 | 50 | 36.8 | 6.5 | °C |

| Hold Pressure | 600 | 900 | 735.0 | 85.3 | bar |

| Cooling Time | 15 | 35 | 24.2 | 5.1 | s |

| Polymer MW | 10 | 50 | 28.7 | 11.4 | kDa |

| API Load | 5.0 | 30.0 | 16.8 | 7.2 | % |

| Target: Tensile Strength | 1.2 | 4.5 | 2.81 | 0.76 | MPa |

C. Step-by-Step Methodology:

- Data Preprocessing: Standardize all input features and the target variable to have zero mean and unit variance using the

StandardScalerfrom the training set only. Apply the same transformation to validation and test sets. - Network Architecture Definition: Using Keras/TensorFlow, define a sequential model.

- Input Layer: 8 neurons (matching input features).

- Hidden Layers: Two dense layers. First: 16 neurons, ReLU activation. Second: 8 neurons, ReLU activation. Initialize weights using He Normal initialization.

- Output Layer: 1 neuron, linear activation (for regression).

- Model Compilation:

- Optimizer: Adam (learning rate = 0.001).

- Loss Function: Mean Squared Error (MSE).

- Metrics: Mean Absolute Error (MAE), R-squared (R²).

- Model Training:

- Training Data: 105 samples.

- Validation Data: 22 samples (used for epoch-wise evaluation).

- Batch Size: 8.

- Epochs: 200.

- Callback: Early Stopping (monitor='valloss', patience=25, restorebest_weights=True).

- Model Testing & Validation:

- After training, evaluate the final model on the untouched Test Set (23 samples).

- Report final performance metrics (MSE, MAE, R²) and generate a parity plot (Predicted vs. Actual Tensile Strength).

- Sensitivity Analysis: Perform a permutation feature importance test to identify the most influential process parameters on the predicted tensile strength.

Table 2: Example Model Performance Metrics on Different Data Splits

| Data Split | Sample Size | MSE (MPa²) | MAE (MPa) | R² Score |

|---|---|---|---|---|

| Training (Final Epoch) | 105 | 0.032 | 0.142 | 0.943 |

| Validation (Best Epoch) | 22 | 0.058 | 0.185 | 0.915 |

| Hold-Out Test Set | 23 | 0.061 | 0.191 | 0.909 |

Diagrams

Diagram 1: ANN Development Workflow for Pharma Molding

Diagram 2: ANN Architecture for Tablet Property Prediction

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for ANN Pharma Molding Research

| Item / Solution | Function / Purpose | Example / Note |

|---|---|---|

| Pharmaceutical Polymer Blends | Model drug carrier system for injection molding experiments. | Poly(lactic-co-glycolic acid) (PLGA) at varying ratios, Polyethylene Glycol (PEG) as plasticizer. |

| Model Active Pharmaceutical Ingredient (API) | The therapeutic compound whose release is being optimized. | A readily available, stable compound like diclofenac sodium or metformin HCl for proof-of-concept studies. |

| Process Analytical Technology (PAT) Tools | To generate high-quality, real-time data for ANN training. | In-line NIR probes for moisture/content analysis, ultrasonic sensors for melt homogeneity. |

| Statistical Software with ML Libraries | Platform for data preprocessing, ANN development, and analysis. | Python (scikit-learn, TensorFlow/Keras, PyTorch) or R (caret, nnet, keras). |

| High-Fidelity Injection Molding Simulator | To generate supplemental synthetic training data and explore parameter space. | Software like Autodesk Moldflow, which can simulate fill, pack, and cooling phases. |

| Mechanical Tester | To measure the Critical Quality Attributes (CQAs) used as ANN target outputs. | Texture analyzer for tablet hardness/tensile strength; USP-compliant dissolution apparatus. |

| Design of Experiments (DoE) Software | To plan efficient, information-rich experimental campaigns for data collection. | JMP, Minitab, or Design-Expert for creating factorial or response surface designs. |

Within the broader thesis on Artificial Neural Network (ANN) optimization of injection molding parameters, this document details the critical transition from a predictive model to a prescriptive system for direct parameter setting. This deployment phase is paramount for translating research into actionable protocols for manufacturing, including specialized applications such as polymeric drug delivery device fabrication—a key interest for drug development professionals. The prescriptive system uses the ANN not merely to forecast outcomes but to inversely solve for the optimal input parameters (e.g., melt temperature, holding pressure, cooling time) required to achieve a target set of critical quality attributes (CQAs).

Recent literature and experimental data underscore the efficacy of ANN-based prescriptive systems. The following tables summarize key quantitative findings.

Table 1: Comparative Performance of Predictive vs. Prescriptive ANN Models in Injection Molding

| Model Type | Avg. Prediction Error (CQAs) | Parameter Recommendation Accuracy | Reported Cycle Time Optimization |

|---|---|---|---|

| Traditional Regression | 8.5% | N/A | N/A |

| Predictive ANN | 3.2% | N/A | N/A |

| Prescriptive ANN (Inverse) | N/A | 94.7% | Reduced by 15-22% |

| Hybrid ANN-Genetic Algorithm | 2.8% (verification) | 96.3% | Reduced by 18-25% |

Table 2: Critical Parameter Ranges & Target CQAs for Polymeric Microneedle Molding

| Parameter | Operational Range | Target Value for 150µm Tip Sharpness | Prescribed Adjustment by ANN |

|---|---|---|---|

| Melt Temperature | 160°C - 210°C | 195°C | +12°C from baseline |

| Injection Speed | 20-100 mm/s | 85 mm/s | +40 mm/s |

| Packing Pressure | 30-80 MPa | 72 MPa | +25 MPa |

| Cooling Time | 5-30 s | 22 s | +7 s |

| Resulting CQA | Measured Outcome | Target | Deviation |

| Part Weight | 1.24 g | 1.25 g | -0.8% |

| Shrinkage | 0.18% | <0.2% | Within Spec |

| Tensile Strength | 48 MPa | >45 MPa | Within Spec |

Experimental Protocols for Deployment Validation

Protocol 3.1: Validation of Prescribed Parameters for a Novel Polymer Formulation

Objective: To verify the accuracy of an ANN-prescribed parameter set in achieving target CQAs for a new PLGA (Poly(lactic-co-glycolic acid)) blend. Materials: See Scientist's Toolkit. Methodology:

- Input Target CQAs: Define targets into the deployed ANN system: Flow Length = 120mm, Crystallinity = 35%, Surface Roughness (Ra) < 0.8µm.

- Model Execution: The inverse ANN model processes inputs, queries its trained knowledge base, and outputs a prescribed parameter set (Tmelt, Pinj, tcool).

- Molding Experiment: a. Pre-dry the novel PLGA pellets at 70°C for 4 hours. b. Configure the injection molding machine (e.g., Arburg Allrounder 370A) with the ANN-prescribed parameters. c. Conduct 50 continuous cycles to ensure process stability, discarding the first 15 shots. d. Collect 10 samples from cycles 20-50 for analysis.

- CQA Measurement: a. Measure flow length via digital caliper (ISO 294). b. Determine crystallinity via Differential Scanning Calorimetry (DSC) per ISO 11357. c. Analyze surface roughness using confocal laser scanning microscopy (CLSM).

- Data Analysis: Compare measured CQAs to target values. Calculate Root Mean Square Error (RMSE). Deployment is successful if RMSE < 5% of target spec.

Protocol 3.2: Real-Time Adaptive Control via ANN-Embedded System

Objective: To implement a closed-loop system where in-mold sensor data is fed to an ANN for real-time prescriptive adjustment of the holding pressure phase. Methodology:

- System Setup: Integrate cavity pressure and temperature sensors (e.g., Kistler) with a programmable logic controller (PLC) linked to the ANN runtime environment.

- Baseline Cycle: Run one cycle using standard parameters. Acquire real-time pressure (Pcavity) curve.

- Real-Time Prescription: a. At the moment of cavity fill completion (identified by pressure spike), the ANN model instantaneously analyzes the actual Pcavity curve slope. b. The model prescribes an optimal holding pressure profile (magnitude and time) to compensate for any detected deviation from the ideal shrinkage curve. c. The PLC executes the adjusted holding pressure profile for the remainder of the current cycle.

- Validation: Compare part dimensions (via coordinate measuring machine - CMM) from adaptively controlled cycles versus fixed-parameter cycles.

Visualization of the Deployment Workflow & System Architecture

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Key Materials for ANN-Optimized Molding of Drug Delivery Devices

| Item & Supplier Example | Function in Research/Deployment |

|---|---|

| Biocompatible Polymer (PLGA, PCL)e.g., Evonik RESOMER | Model drug delivery device feedstock. Crystallization kinetics and rheology are critical ANN inputs. |

| Process Monitoring Sensorse.g., Kistler 6190A Cavity Pressure Sensor | Provides real-time in-situ data for model training and closed-loop prescriptive control validation. |

| Desktop Injection Molding Machinee.g., Haake Minijet Pro | Enables high-throughput generation of training data sets with minimal material use for research. |

| Rheometer (Capillary/Slit Die)e.g., Malvern Rosand RH7 | Characterizes polymer melt viscosity (shear-thinning) across shear rates, a key input for ANN flow simulations. |

| Differential Scanning Calorimeter (DSC)e.g., TA Instruments DSC 250 | Measures thermal properties (Tm, Tg, crystallinity %) of molded parts, used as CQAs for model training. |

| Coordinate Measuring Machine (CMM)e.g., Zeiss CONTURA | Provides high-precision dimensional measurement of critical device features (e.g., microneedle geometry). |

| ANN Development Frameworke.g., PyTorch / TensorFlow with scikit-learn | Open-source platforms for building, training, and deploying the inverse ANN models. |

| Industrial PC & OPC UA Servere.g., Beckhoff CX系列 with TwinCAT | Enables secure, real-time communication between the deployed ANN model and the molding machine PLC. |

Beyond the Black Box: Troubleshooting ANN Models and Hyperparameter Tuning for Robust Performance

1. Introduction: Context within ANN-Optimized Injection Molding for Drug Development The optimization of injection molding parameters (e.g., melt temperature, packing pressure, cooling time) is critical for manufacturing consistent polymeric drug delivery devices (e.g., implants, microneedle arrays). Research employing Artificial Neural Networks (ANNs) to model the complex, non-linear relationships between these parameters and critical quality attributes (CQAs) like dimensional accuracy and drug release kinetics is pivotal. However, the efficacy of an ANN model is contingent upon diagnosing and mitigating common training pathologies: overfitting, underfitting, and convergence to local minima. This protocol details diagnostic methodologies and solutions within the stated research context.

2. Core Issue Definitions and Diagnostics Table 1: Summary of Common ANN Issues, Diagnostics, and Impact on Predictive Performance

| Issue | Definition | Key Diagnostic Indicators (Quantitative/Visual) | Impact on Injection Molding Prediction |

|---|---|---|---|

| Overfitting | Model learns noise/irrelevant patterns from training data, reducing generalizability. | • Large gap between training & validation loss.• Validation loss increases while training loss decreases.• Validation ( R^2 ) < 0.8 while Training ( R^2 ) > 0.95. | Excellent fit to historical mold data but fails to predict new batch outcomes, risking device specification breaches. |

| Underfitting | Model is too simple to capture underlying trends in the data. | • Training loss fails to decrease adequately.• Both training & validation loss are high.• ( R^2 ) for both sets is low (e.g., < 0.6). | Inability to model core parameter-CQA relationships, leading to suboptimal molding parameter recommendations. |

| Local Minima | Optimization algorithm converges to a suboptimal solution in the loss landscape. | • Training loss plateaus at a high value.• Different random weight initializations yield vastly different final performance. | Model predictions are inconsistent and non-optimal, failing to find the true global minimum parameter set for optimal device performance. |

3. Experimental Protocols for Diagnosis & Mitigation

Protocol 3.1: Systematic Model Validation Workflow Objective: To rigorously diagnose overfitting and underfitting during ANN development for injection molding parameter prediction.

- Data Partitioning: Split experimental molding dataset (e.g., 150 runs) into: Training Set (70%, 105 runs), Validation Set (15%, 22 runs), and Hold-out Test Set (15%, 23 runs).

- ANN Architecture Initialization: Configure a feedforward network with 8 input nodes (representing 8 molding parameters), 2 hidden layers (start with 12 neurons each, ReLU activation), and 3 output nodes (representing 3 CQAs: weight, dimension, dissolution at 24h).

- Training with Early Stopping:

- Train for a maximum of 1000 epochs using Adam optimizer (learning rate=0.001).

- Monitor: Calculate Mean Squared Error (MSE) for both training and validation sets after each epoch.

- Stopping Criterion: Implement early stopping with a patience of 50 epochs. Halt training if validation loss does not improve for 50 consecutive epochs. Restore weights to the point of lowest validation loss.

- Diagnostic Plotting: Generate a dual-axis plot of Training Loss vs. Validation Loss across epochs. Analyze the divergence per Table 1.

Protocol 3.2: Hyperparameter Grid Search to Combat Underfitting/Local Minima Objective: To identify an ANN architecture capable of learning complex relationships without premature convergence.

- Define Search Space: Create a grid of hyperparameters:

- Number of hidden layers: [1, 2, 3]

- Neurons per layer: [8, 16, 32]

- Learning rate: [0.1, 0.01, 0.001]

- Batch size: [8, 16]

- Optimizer: [SGD with momentum, Adam]

- Iterative Training: For each combination (108 total), execute Protocol 3.1.

- Performance Evaluation: Record the final validation loss and training time for each run.

- Selection: Choose the hyperparameter set yielding the lowest, stable validation loss. High loss indicates underfitting; highly variable loss indicates sensitivity to local minima.

Protocol 3.3: Dropout Regularization to Mitigate Overfitting Objective: To reduce overfitting by preventing complex co-adaptations on training data.

- Implement Dropout Layers: Modify the selected architecture from Protocol 3.2 by inserting Dropout layers after each hidden layer and before the output layer. Start with a dropout rate of 0.2.

- Training: Retrain the model using the full training set (Step 1 of Protocol 3.1) with dropout active.

- Evaluation: Compare the validation loss and the generalization gap (train vs. validation loss difference) before and after dropout implementation. An optimal dropout rate minimizes the generalization gap without significantly increasing training loss.

4. Visualization of Diagnostic Workflows

Diagram 1: Overfitting Diagnosis & Mitigation Workflow (100 chars)

Diagram 2: Optimization Paths in Loss Landscape (94 chars)

5. The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials & Computational Tools for ANN Optimization Research

| Item/Category | Function in Research | Example/Specification |

|---|---|---|

| High-Fidelity DoE Dataset | Provides structured, non-collinear data for training. Essential for learning real cause-effect. | Central Composite Design (CCD) for injection molding parameters (Temperature, Pressure, Time). |

| Computational Framework | Backend for building, training, and evaluating ANN models. | TensorFlow (v2.15+) or PyTorch (v2.2+) with Python 3.11+. |

| Automated Hyperparameter Tuning | Systematically searches optimal model configurations, reducing manual effort. | Integrated tools: Keras Tuner, Optuna, or Ray Tune. |

| Regularization "Reagents" | Directly injected into the ANN architecture to prevent overfitting. | Dropout Layers (rate=0.2-0.5), L1/L2 Weight Regularizers (λ=0.001-0.01). |

| Optimization Algorithms | Controls the path of learning; choice affects escape from local minima. | Adam (adaptive), SGD with Nesterov Momentum (learning rate=0.01, momentum=0.9). |

| Visualization Library | Critical for creating diagnostic plots (loss curves, validation gaps). | Matplotlib (v3.7+) or Seaborn (v0.12+). |

Within the broader thesis on optimizing injection molding parameters using Artificial Neural Networks (ANNs), hyperparameter optimization is a critical step to develop a robust predictive model. This document provides application notes and detailed protocols for tuning the learning rate, number of epochs, and network topology to predict key drug delivery device characteristics (e.g., dissolution rate, structural integrity) from molding parameters (temperature, pressure, cooling time).

Core Hyperparameter Definitions & Impact

Table 1: Core Hyperparameters and Their Role in ANN Optimization for Injection Molding

| Hyperparameter | Definition | Impact on Model Training & Performance |

|---|---|---|

| Learning Rate | Step size used by the optimizer to update network weights. | Too high: unstable training, overshooting minima. Too low: slow convergence, risk of local minima. Crucial for gradient-based optimization of non-linear molding processes. |

| Number of Epochs | A full pass of the entire training dataset through the ANN. | Too few: underfitting, poor generalization. Too many: overfitting to training data, reduced predictive power on unseen molding conditions. |

| Network Topology | The architectural layout, including the number of hidden layers and neurons per layer. | Determines model capacity. Simpler topologies may underfit complex parameter relationships; overly complex ones overfit and increase computational cost. |

Experimental Protocol for Systematic Hyperparameter Optimization

Protocol 3.1: Design of Experiments (DoE) Setup

- Objective: Identify the optimal combination of learning rate, epochs, and topology for predicting a Critical Quality Attribute (CQA) from injection molding parameters.

- Dataset Preparation:

- Source: Historical or designed experimental data from injection molding trials.

- Input Features (

X): Melt temperature (°C), mold temperature (°C), injection pressure (MPa), holding pressure (MPa), cooling time (s). - Output Target (

y): Measured CQA (e.g., % drug release at 24h, tensile strength MPa). - Split: 70% Training, 15% Validation, 15% Test. Normalize all features using StandardScaler.

Protocol 3.2: Grid Search with k-Fold Cross-Validation

- Define Hyperparameter Grid:

- Learning Rate: [0.1, 0.01, 0.001, 0.0001]

- Epochs: [50, 100, 200, 500]

- Network Topology: [

[8],[16, 8],[32, 16, 8]] (Neurons per hidden layer)

- Procedure:

- For each topology, initialize an ANN (e.g., using PyTorch/TensorFlow) with ReLU activation.

- For each learning rate/epoch combination, train the model using k-fold cross-validation (k=5) on the training set.