Smart Materials Revolution: 3D Printing Shape Memory Polymer Nanocomposites for Next-Generation Biomedical Devices

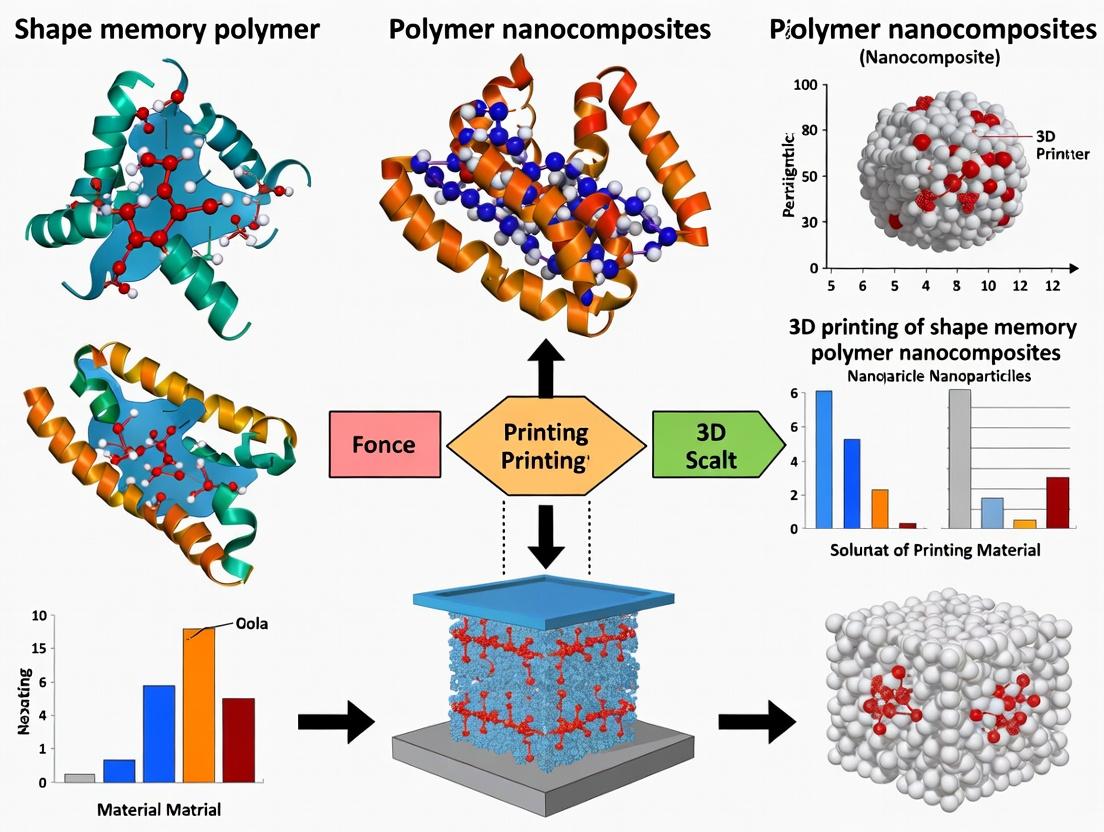

This article provides a comprehensive analysis of the current state and future potential of 3D-printed shape memory polymer nanocomposites (SMPNCs) for biomedical applications, including drug delivery and tissue engineering.

Smart Materials Revolution: 3D Printing Shape Memory Polymer Nanocomposites for Next-Generation Biomedical Devices

Abstract

This article provides a comprehensive analysis of the current state and future potential of 3D-printed shape memory polymer nanocomposites (SMPNCs) for biomedical applications, including drug delivery and tissue engineering. It begins by exploring the fundamental principles and materials science behind SMPNCs, detailing their unique stimuli-responsive behavior. The article then examines advanced manufacturing methodologies, specifically focusing on cutting-edge 3D printing techniques like Digital Light Processing (DLP) and Two-Photon Polymerization (2PP). Critical challenges such as print fidelity, nanoparticle dispersion, and shape recovery accuracy are addressed, alongside strategies for process optimization. Finally, the performance of SMPNCs is validated against traditional manufacturing methods and other smart materials, highlighting their superior programmability and functional integration. This synthesis is tailored for researchers, material scientists, and drug development professionals seeking to leverage this disruptive technology.

Understanding Shape Memory Polymer Nanocomposites: From Core Mechanisms to Biomedical Promise

Shape Memory Polymers (SMPs) are a class of smart materials capable of changing from a temporary, deformed shape back to their original, permanent shape upon application of an external stimulus (e.g., heat, light, solvent, magnetic field). This programmable movement is driven by their unique molecular architecture, typically consisting of netpoints (chemical or physical crosslinks) determining the permanent shape and reversible switching segments that fix the temporary shape.

Within the context of 3D printing SMP nanocomposites, the integration of nanomaterials (e.g., graphene, carbon nanotubes, cellulose nanocrystals) enhances mechanical properties, enables novel activation methods (e.g., photothermal, electroactive), and improves shape memory performance metrics like recovery stress and cyclic stability.

Key Quantitative Performance Metrics for 3D-Printed SMP Nanocomposites

Table 1: Representative Performance Data for 3D-Printed SMP Nanocomposites

| Nanofiller Type | Loading (wt%) | Printing Method | Stimulus | Shape Fixity (R_f) | Shape Recovery (R_r) | Recovery Stress (MPa) | Reference/Key Study |

|---|---|---|---|---|---|---|---|

| Graphene Oxide (GO) | 0.5 | DIW | NIR Light (808 nm) | 98.5% | 99.2% | 1.8 | [Recent Adv. Funct. Mater., 2023] |

| Carbon Nanotubes (CNT) | 2.0 | FDM | Joule Heating | 96.0% | 98.5% | 4.5 | [Compos. Sci. Technol., 2024] |

| Cellulose Nanocrystals (CNC) | 5.0 | SLA | Thermal (60°C) | 94.0% | 97.0% | 0.9 | [ACS Appl. Polym. Mater., 2023] |

| Magnetic Nanoparticles (Fe3O4) | 10.0 | DIW | Alternating Magnetic Field | 95.5% | 98.8% | 2.1 | [Nature Commun., 2023] |

| Silver Nanowires (AgNW) | 1.2 | Inkjet | Electrothermal (3V) | 97.8% | 99.0% | 3.2 | [Adv. Mater. Technol., 2024] |

DIW: Direct Ink Writing; FDM: Fused Deposition Modeling; SLA: Stereolithography.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for SMP Nanocomposite Research

| Item | Function & Rationale |

|---|---|

| Thermoplastic Polyurethane (TPU) Pellets | A common base polymer for FDM; provides elastomeric netpoints and a broad thermal transition for shape memory switching. |

| Methacrylated Poly(ε-caprolactone) (PCL-M) | A photopolymerizable, biodegradable resin for vat polymerization (SLA/DLP); its crystallizable PCL segments act as the switching domain. |

| Graphene Nanoplatelets (GNP) | Conductive nanofiller for imparting photothermal or electrothermal response; enhances stiffness and recovery stress. |

| Polyvinyl Alcohol (PVA), High MW | Used as a sacrificial support material in multi-material DIW printing of complex SMP structures. |

| Photoinitiator (e.g., Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide - TPO) | Crucial for UV-curing in SLA/DLP printing of photocurable SMP resins. |

| N,N-Dimethylformamide (DMF) | Solvent for preparing homogeneous dispersions of nanomaterials in polymer solutions for ink formulation. |

| Pluronic F-127 Diacrylate | A shear-thinning hydrogel for DIW; can be formulated into a photocurable, water-responsive SMP. |

| Dichloromethane (DCM) | Solvent for solvent-cast 3D printing and for triggering solvent-responsive shape recovery in certain SMPs. |

Experimental Protocols

Protocol 1: FDM Printing and Thermomechanical Cycling of CNT/TPU Nanocomposite

Objective: To fabricate a conductive SMP filament, 3D print a test structure, and quantify its electrothermal shape memory performance.

Materials: TPU pellets, Carboxyl-functionalized MWCNTs, Twin-screw extruder, Desktop FDM printer, DMA/Instron, DC power supply, IR camera.

Methodology:

- Nanocomposite Preparation: Dry-mix TPU pellets with 2.0 wt% MWCNTs. Feed into a twin-screw extruder (temp. profile: 190-210°C) to produce a masterbatch. Pelletize and re-extrude into uniform filament (diameter: 1.75 ± 0.05 mm).

- 3D Printing: Dry the filament at 80°C for 4 hrs. Print a spiral or cantilever beam structure (Nozzle: 220°C, Bed: 60°C, Speed: 30 mm/s, 100% infill).

- Programming (Deformation): Heat the printed sample above its switching transition (T_trans, ~65°C) in an oven. Apply a bending or torsional deformation. Cool under constraint to room temperature to fix the temporary shape.

- Electrothermal Recovery: Attach electrodes to the ends of the sample. Apply a low voltage (e.g., 5-15V). Monitor surface temperature with an IR camera until it exceeds T_trans. Record the recovery process with a video camera.

- Quantification: Analyze video to calculate Shape Fixity (Rf) and Shape Recovery (Rr). Measure recovery force via a load cell if applicable. Perform at least 5 cycles to assess durability.

Protocol 2: SLA Printing of a Photothermal GO/PCL-M Nanocomposite

Objective: To create a light-responsive SMP scaffold via SLA and evaluate its NIR-triggered shape recovery.

Materials: PCL-M macromer, Graphene Oxide (GO) dispersion, TPO photoinitiator, SLA printer (405 nm), NIR laser (808 nm), Phosphate Buffered Saline (PBS).

Methodology:

- Resin Formulation: Sonicate 0.5 wt% GO in a minimal amount of dichloromethane for 1 hr. Mix thoroughly with molten PCL-M. Add 1 wt% TPO and stir until homogeneous. Evaporate solvent completely under vacuum.

- 3D Printing: Load resin into SLA printer. Print a deployable stent or gripper structure (Layer thickness: 50 µm, Exposure time: 8 s/layer). Post-cure under UV light for 10 min. Wash in isopropanol.

- Programming for Deployment: Heat the printed structure to 60°C (above PCL melting point). Compress it linearly. Cool to 0°C (ice bath) to crystallize the PCL and fix the temporary compact shape.

- NIR-Triggered Recovery: Place the programmed sample in a PBS bath at 37°C to simulate body temperature. Apply NIR laser (808 nm, 1.5 W/cm²) for targeted irradiation. The GO converts light to heat, melting the PCL domains and triggering recovery.

- Analysis: Measure recovery angle vs. time. Assess cytocompatibility if for biomedical application (e.g., cell seeding on recovered scaffold).

Visualized Workflows and Mechanisms

Title: SMP Thermomechanical Programming Cycle

Title: Workflow for 3D Printing SMP Nanocomposites

Application Notes

Within the thesis context of 3D printing shape memory polymer (SMP) nanocomposites for biomedical applications (e.g., drug-eluting stents, tissue scaffolds), the incorporation of nanoparticles (NPs) provides a multifunctional advantage. The following notes detail the enhanced properties critical for advanced research and development.

1. Mechanical Reinforcement for Structural Integrity Nanoparticles like cellulose nanocrystals (CNCs), graphene oxide (GO), and silica (SiO₂) act as reinforcing fillers within the SMP matrix (e.g., PCL, PU). They restrict polymer chain mobility, leading to significant improvements in tensile modulus and strength. This is paramount for 4D-printed constructs that must undergo shape recovery under load without mechanical failure.

2. Enhanced Thermal Properties for Triggered Activation The shape memory effect is thermally activated. The high surface area of NPs like carbon nanotubes (CNTs) and MXenes improves thermal conductivity, enabling faster and more uniform heat distribution during the shape recovery process. This allows for precise control over the activation of complex, 4D-printed geometries.

3. Tailored Biological Properties for Therapeutic Function For drug development and tissue engineering, bioactive NPs such as hydroxyapatite (nHA) and mesoporous silica nanoparticles (MSNs) are pivotal. nHA enhances osteoconductivity in bone scaffolds. MSNs can be loaded with therapeutic agents (e.g., antibiotics, growth factors), providing a controlled release mechanism directly from the 3D-printed implant, mitigating issues like biofilm formation or promoting cellular differentiation.

4. Printability and Functionalization NPs influence the rheology of the polymer ink. Clay nanotubes (halloysite) can act as thixotropic agents, improving the shape fidelity of extruded filaments during 3D printing. Furthermore, surface-functionalized NPs (e.g., amine-modified GO) can covalently bond with the polymer matrix, enhancing interfacial strength and composite stability.

Table 1: Enhancement of Polycaprolactone (PCL)-Based Nanocomposites for 3D Printing

| Nanoparticle (Loading wt%) | Tensile Modulus Increase (%) | Thermal Conductivity Increase (%) | Key Biological Effect | Source (Year) |

|---|---|---|---|---|

| Cellulose Nanocrystals (3%) | +120 | +15 | Improved fibroblast adhesion | Curr. Nanomat. (2023) |

| Graphene Oxide (0.5%) | +200 | +85 | Antibacterial (>90% E. coli reduction) | ACS Appl. Polym. Mat. (2024) |

| Hydroxyapatite (10%) | +80 | +5 | Enhanced osteogenic marker expression (ALP +300%) | Biofabrication (2023) |

| Mesoporous Silica (5%) | +40 | +10 | Sustained drug release (70% over 14 days) | J. Contr. Release (2024) |

Table 2: Shape Memory Performance of 3D-Printed Nanocomposites

| Matrix Polymer | Nanoparticle | Shape Fixity Ratio (%) | Shape Recovery Ratio (%) | Recovery Temperature (°C) |

|---|---|---|---|---|

| Polyurethane | Carbon Nanotubes (1%) | 98.5 ± 0.5 | 99.2 ± 0.3 | 45 |

| Poly(lactic acid) | Clay Nanotubes (5%) | 96.8 ± 0.7 | 97.5 ± 0.6 | 65 |

| Epoxy-based | SiO₂ (2%) | 99.0 ± 0.4 | 98.1 ± 0.5 | 80 |

Experimental Protocols

Protocol 1: Fabrication of Drug-Loaded SMP Nanocomposite Filament for FDM 3D Printing Objective: To prepare a homogeneous nanocomposite filament with integrated drug delivery capability. Materials: PCL pellets, mesoporous silica nanoparticles (MSNs, 300 nm pore size), model drug (e.g., Doxycycline hyclate), solvent (dichloromethane), twin-screw microcompounder, filament extruder.

- Drug Loading: Stir 1.0 g of MSNs in 50 ml of a 10 mg/ml drug solution for 24h. Centrifuge, wash, and vacuum-dry to obtain drug-loaded MSNs (MSN-D).

- Melt Compounding: Dry PCL pellets and MSN-D at 50°C for 4h. Manually pre-mix PCL (95g) with MSN-D (5g). Feed mixture into a twin-screw microcompounder at 90°C, 100 rpm for 5 min.

- Filament Extrusion: Extrude the compounded material through a single-orifice die (1.75 mm diameter) using a filament extruder. Spool the filament under constant tension. Store in a desiccator.

Protocol 2: Assessment of Shape Memory and Drug Release Kinetics Objective: To characterize the coupled shape recovery and drug release profile of a 4D-printed scaffold. Materials: 3D-printed scaffold from Protocol 1 filament, PBS (pH 7.4), water bath, UV-Vis spectrophotometer.

- Programming: Heat scaffold to 70°C (>Tm of PCL), deform to a temporary shape. Cool to 25°C under constraint.

- Triggered Recovery/Release: Immerse the programmed scaffold in 50 ml PBS at 37°C with gentle agitation. This triggers shape recovery.

- Monitoring: At predetermined time points, collect 1 ml of release medium, replacing with fresh PBS. Use UV-Vis to quantify drug concentration.

- Analysis: Record recovery angle vs. time. Plot cumulative drug release (%) vs. time and fit to model (e.g., Higuchi).

Protocol 3: Evaluation of Osteogenic Differentiation on nHA-Composite Scaffolds Objective: To quantify the enhancement of osteogenesis on 3D-printed SMP/nHA scaffolds. Materials: SLA 3D-printed SMP/nHA scaffold, human mesenchymal stem cells (hMSCs), osteogenic medium, ALP assay kit, Alizarin Red S.

- Cell Seeding: Sterilize scaffolds (UV, 1h per side). Seed hMSCs at 50,000 cells/scaffold in 24-well plates.

- Osteogenic Induction: Maintain cells in osteogenic medium, changing every 3 days.

- ALP Activity: On day 7, lyse cells. Measure ALP activity using pNPP substrate, normalize to total protein.

- Mineralization: On day 21, fix cells, stain with Alizarin Red S. Quantify by eluting stain with cetylpyridinium chloride and measuring absorbance at 562 nm.

Visualizations

Title: Nanoparticle Multifunctional Enhancement Pathway

Title: 4D Printing & Drug Delivery Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for SMP Nanocomposite Research

| Item | Function in Research | Example/Specification |

|---|---|---|

| Shape Memory Polymer | Base matrix providing the shape memory effect. | Polycaprolactone (PCL, Mn 80,000), Thermoplastic Polyurethane (TPU, medical grade). |

| Functional Nanoparticles | Provide target enhancement (mechanical, thermal, biological). | Graphene Oxide (single layer, 1-5 µm), Hydroxyapatite Nanopowder (<200 nm, synthetic). |

| Mesoporous Silica Nanoparticles | High-surface-area carriers for controlled drug loading and release. | MCM-41 type, pore size 3-5 nm, surface functionalizable (amine, carboxyl). |

| Biologically Active Agent | Therapeutic payload for functional implants. | Doxycycline (antibiotic), BMP-2 (growth factor), Dexamethasone (osteogenic inducer). |

| Compatibilizer/Coupling Agent | Improves interfacial adhesion between NP and polymer matrix. | (3-Aminopropyl)triethoxysilane (APTES) for silica, Polymeric surfactants for CNTs. |

| Rheology Modifier | Adjusts ink viscosity for optimal 3D printability. | Fumed silica (for shear-thinning), Plasticizers (e.g., PEG) for filament flexibility. |

| Cell Culture Assay Kits | Quantifies biological response to nanocomposite scaffolds. | Alkaline Phosphatase (ALP) Activity Assay Kit, AlamarBlue Cell Viability Reagent. |

Within the broader thesis on 4D printing of shape memory polymer nanocomposites (SMPNCs) for biomedical applications, the precise spatiotemporal control of shape recovery and functional deployment is paramount. This document details application notes and protocols for four key external stimuli—thermal, light, magnetic, and solvent—used to trigger the shape memory effect (SME) in 3D-printed constructs. These triggers enable on-demand actuation in applications such as minimally invasive implant delivery, smart sutures, and drug-eluting devices.

Table 1: Comparative Performance of Key Activation Triggers for SMPNCs

| Stimulus Type | Typical Nanocomposite Filler | Activation Energy/Intensity | Typical Response Time | Key Quantitative Metric (Recovery Ratio, Rr) | Key Advantage |

|---|---|---|---|---|---|

| Thermal | None (pure SMP) or CNTs | 50-70°C (above Tg) | 10-60 seconds | Rr > 98% | Simplicity, high reliability |

| Light (NIR) | Gold Nanorods, Graphene Oxide | 808 nm, 1-2 W/cm² | 5-30 seconds | Rr: 92-97% | Remote, spatially precise activation |

| Magnetic | Fe₃O₄ nanoparticles | 300-500 kHz, 20-30 mT | 10-120 seconds | Rr: 90-95% | Deep tissue penetration, uniform heating |

| Solvent | Hygroscopic polymers (e.g., PVA) | Water, Ethanol | 1-10 minutes | Rr: 85-98% (swelling-dependent) | Mild conditions, biocompatible |

Table 2: Representative Material Formulations for 3D/4D Printing

| Stimulus | Base Polymer | Functional Filler (wt%) | Printing Method | Post-Printing Processing |

|---|---|---|---|---|

| Thermal | PCL, PLA | Multi-walled CNTs (2-5%) | FDM, DIW | Annealing at 60°C for 2h |

| Light | PNIPAM, PU | Gold Nanorods (0.1-0.5%) | SLA, DLP | UV post-curing (365 nm) |

| Magnetic | TPU, Epoxy | Fe₃O₄ NPs (10-20%) | DIW, FDM | Magnetic field alignment |

| Solvent | PVA, PEGDA | Silica NPs (1-3%) | SLA, Inkjet | Crosslinking (UV/ionic) |

Application Notes & Detailed Protocols

Thermal Activation Protocol

Application Note: Direct heating is the most common trigger. For 3D-printed parts, uniform heat distribution is critical to avoid deformation. Protocol: Shape Recovery via Hot Bath

- Programming (Deformation):

- Immerse the 3D-printed SMPNC specimen in a water bath at T > Tg (e.g., 70°C for PCL-based composites) for 5 min.

- Deform the softened sample into the desired temporary shape using a mechanical jig.

- Cool the sample to room temperature (or below Tg) while under constraint for 10 min. Remove constraint.

- Recovery (Activation):

- Place the fixed temporary shape into the hot water bath (T > Tg) again.

- Record the recovery process with a video camera. Measure the time to achieve >95% recovery of the original printed shape.

- Calculate Recovery Ratio (Rr) = (θt / θ0) * 100%, where θ are angles defining the shape.

Near-Infrared (NIR) Light Activation Protocol

Application Note: Enables remote, non-contact, and pattern-specific activation. Ideal for in vivo applications where localized heating is needed. Protocol: Spatially-Selective Photothermal Recovery

- Ink Preparation & Printing:

- Synthesize or procure PEG-DA-based resin doped with 0.3 wt% gold nanorods (peak absorbance ~808 nm).

- Homogenize via sonication (30 min, pulse mode) in the dark.

- Print test structures (e.g., grippers, lattices) using a DLP printer (405 nm light). Post-cure under UV lamp for 10 min.

- Activation & Measurement:

- Program the sample into a temporary shape using the thermal method (Protocol 3.1).

- Mount the sample and irradiate with an 808 nm NIR laser diode at a controlled power density (e.g., 1.5 W/cm²).

- Use an IR thermal camera to monitor surface temperature in real-time.

- Measure recovery kinetics as a function of laser power and exposure time.

Magnetic Activation Protocol

Application Note: Magnetic nanoparticles (MNPs) provide heat via Néel/Brownian relaxation under an alternating magnetic field (AMF), enabling activation in opaque or deep-tissue environments. Protocol: Induction Heating Triggered Recovery

- Nanocomposite Fabrication:

- Disperse citric acid-coated Fe₃O₄ nanoparticles (15 wt%) in TPU solution (in DMF). Stir for 24h, then cast and dry to form a filament for FDM printing.

- Alternatively, prepare a DIW ink by mixing MNPs into a photocurable PU paste.

- Print a helical spring or stent-like structure.

- Magnetic Programming & Activation:

- Program the sample into a temporary shape using a heat gun (T > Tg).

- Place the sample in the center of a coil generating an AMF (e.g., 350 kHz, 25 mT).

- Activate the AMF and use a fiber-optic temperature probe (unaffected by AMF) to record internal temperature.

- Correlate recovery rate with specific absorption rate (SAR) of the nanocomposite.

Solvent-Based Activation Protocol

Application Note: Utilizes solvent-induced swelling to lower the effective Tg or create osmotic pressure for shape recovery. Useful for aqueous biomedical environments. Protocol: Aqueous-Responsive Shape Recovery

- Material & Print Preparation:

- Use a hydrophilic polymer like PVA or a hydrogel (PEGDA-co-AAc). For reinforcement, add 2 wt% Laponite nanoclay.

- Print using a direct ink writing (DIW) system with a controlled humidity chamber to prevent premature drying.

- Chemically crosslink post-print (e.g., using glutaraldehyde vapor for PVA or UV for PEGDA).

- Solvent Programming & Recovery:

- Programming: Swell the printed object in a water/ethanol mixture to plasticize. Deform mechanically. Dry under constraint to lock in the temporary shape via re-formed crystalline domains or hydrogen bonds.

- Activation: Immerse the constrained, dried object in phosphate-buffered saline (PBS) at 37°C.

- Monitor the swelling ratio and shape recovery simultaneously. Recovery is driven by the relaxation of polymer chains as they swell.

Diagrams

Title: Thermal Shape Memory Cycle for SMPNCs

Title: Logical Flow of Multi-Stimuli Activation

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Stimuli-Responsive SMPNC Research

| Item Name & Typical Supplier | Function in Research | Key Consideration for 3D Printing |

|---|---|---|

| Polycaprolactone (PCL), Sigma-Aldrich | Biodegradable, low-Tg thermoplastic SMP base. | Excellent for FDM; tune Tg (~60°C) with molecular weight. |

| Poly(ethylene glycol) diacrylate (PEG-DA), Polysciences | Photocurable hydrogel/SMP base for SLA/DLP. | Degree of crosslinking controls modulus and swelling ratio. |

| Gold Nanorods (λmax ~800 nm), NanoComposix | NIR photothermal agent. | Surface chemistry (CTAB vs. PEG) critical for dispersion in resin/filament. |

| Iron Oxide Nanoparticles (Fe₃O₄, 10-20 nm), Cytodiagnostics | Magnetic heating agents for AMF activation. | Coating (silica, polymer) ensures stability and prevents aggregation in polymer melt. |

| Laponite RD, BYK Additives | Nanoclay rheological modifier. | Enables DIW printability via shear-thinning; can enhance shape fixity. |

| Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide (TPO), Sigma | Photoinitiator for UV-curable resins (SLA/DLP). | Concentration (0.5-2 wt%) balances cure depth and speed. |

| Dimethylformamide (DMF), Fisher Scientific | Solvent for preparing polymer/NP inks. | Requires careful removal post-printing (vacuum oven) to prevent porosity. |

| Phosphate Buffered Saline (PBS), pH 7.4, Thermo Fisher | Simulated physiological fluid for solvent/swelling tests. | Essential for validating biomedical application conditions. |

This document provides a detailed review of common shape memory polymer (SMP) matrices and functional nanofillers within the context of 3D printing for advanced applications, including drug delivery and biomedical devices. It includes standardized protocols for material preparation and characterization.

Review of Common SMP Matrices

The selection of the polymer matrix defines the fundamental thermal, mechanical, and degradation properties of the nanocomposite.

Table 1: Key Properties of Common SMP Matrices for 3D Printing

| Polymer Matrix | Full Name | Typical Tg/Tm (°C) | Key Strengths | Key Limitations | Primary 3D Printing Method |

|---|---|---|---|---|---|

| PCL | Poly(ε-caprolactone) | Tm: ~55-60 | Biocompatible, biodegradable, low melting point, excellent blend compatibility. | Low modulus, weak mechanical strength. | FDM, DIW, SLA |

| PLA | Polylactic Acid | Tg: ~55-65 | High strength, rigid, biocompatible, widely available. | Brittle, slow degradation rate, limited shape recovery stress. | FDM, SLA, SLS |

| PU | Polyurethane | Tg: -70 to 80 (tunable) | Excellent elasticity, high recovery stress, tunable properties, good abrasion resistance. | Potential cytotoxicity from unreacted monomers, complex synthesis. | FDM, DIW, Inkjet |

Review of Functional Nanofillers

Nanofillers are incorporated to impart enhanced or novel functionalities to the SMP matrix.

Table 2: Functional Nanofillers for SMP Nanocomposites

| Nanofiller Type | Typical Dimensions | Primary Function(s) | Key Enhancement Provided | Dispersion Challenge |

|---|---|---|---|---|

| Carbon Nanotubes (CNTs) | Diameter: 1-100 nm, Length: µm-scale | Reinforcement, Electrical Conductivity, Photothermal Response. | Increases modulus & strength, enables electro-/photo-active actuation. | High aspect ratio leads to bundling; requires functionalization. |

| Graphene/Graphene Oxide | Thickness: 0.34-10 nm, Lateral: µm-scale | Reinforcement, Barrier Properties, High Electrical/Thermal Conductivity, Photothermal. | Exceptional multi-functional property enhancement at low loadings. | Restacking of sheets; GO is easier to disperse but less conductive. |

| Nanoclays (e.g., Montmorillonite) | Thickness: 1 nm, Lateral: 100-1000 nm | Reinforcement, Barrier Properties, Flame Retardancy, Modulates Crystallinity. | Improves modulus, gas barrier, and shape recovery stress. | Requires exfoliation and compatibilization for nano-dispersion. |

| Magnetic Nanoparticles (e.g., Fe₃O₄) | Diameter: 5-50 nm | Remote Actuation (magnetic hyperthermia), Reinforcement (minor). | Enables contactless, spatially controlled shape recovery in alternating magnetic fields. | Susceptible to aggregation and oxidation; requires surface coating. |

Application Notes & Experimental Protocols

Protocol 3.1: Preparation of PCL/CNT Nanocomposite Filament for FDM

Objective: To fabricate a homogeneous, electrically conductive SMP nanocomposite filament.

- Material Drying: Dry PCL pellets and CNTs at 60°C under vacuum for 12 hours.

- Solution Mixing: Dissolve dried PCL in anhydrous tetrahydrofuran (THF) (20% w/v). Add surfactant-treated CNTs (1.0 wt% relative to PCL) and sonicate (probe sonicator, 400 W, 30 min, ice bath).

- Precipitation & Drying: Precipitate the mixture into excess cold methanol. Filter and dry the composite solid in a vacuum oven at 40°C for 24h.

- Melt Compounding: Use a twin-screw micro-compounder at 90°C, 100 rpm for 5 min under N₂ atmosphere.

- Filament Extrusion: Use a single-screw extruder with a 1.75 mm die at 85°C. Spool the filament with constant tension.

Protocol 3.2: Characterization of Shape Memory Properties (Thermomechanical Cycling)

Objective: To quantify shape fixity (Rf) and shape recovery (Rr) ratios.

- Sample Programming:

- Mount sample in DMA tension clamp.

- Heat to Thigh (Tg/Tm + 20°C).

- Apply tensile stress to achieve εm (e.g., 100% strain). Hold for 5 min.

- Cool to Tlow (Tg/Tm - 40°C) while maintaining stress. Hold for 10 min.

- Unload stress to zero. Measure fixed strain (εu).

- Recovery:

- Reheat sample to Thigh at constant rate (e.g., 3°C/min) under zero stress.

- Record recovered strain (εp) after 10 min hold.

- Calculation:

- Rf (%) = (εu / εm) * 100

- Rr (%) = [(εm - εp) / εm] * 100

- Perform 5 cycles to assess cyclic stability.

Protocol 3.3: Remote Actuation of Magnetic SMP Nanocomposite

Objective: To trigger shape recovery via alternating magnetic field (AMF).

- Sample Programming: Program a flat strip into a temporary spiral shape using Protocol 3.2 (mechanical) or heat-molding.

- AMF Setup: Place sample at the center of a coil generating an AMF (e.g., 300 kHz, 5-20 kA/m).

- Activation & Monitoring: Apply AMF. Use an IR camera to monitor surface temperature. Use a high-speed camera to record recovery kinematics (recovery angle vs. time).

- Data Analysis: Correlate recovery rate and completeness with AMF parameters (frequency, field strength) and nanoparticle loading.

Visual Workflows and Relationships

Title: SMP Nanocomposite R&D Workflow

Title: Shape Memory Effect Mechanism

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for SMP Nanocomposite Development

| Item | Function & Rationale | Example/Note |

|---|---|---|

| Anhydrous Solvents (THF, DMF, CHCl₃) | For solution-based dispersion of nanofillers and polymers. Prevents hydrolysis of sensitive polymers (e.g., PLA). | Use with molecular sieves; store under inert atmosphere. |

| Surfactants & Coupling Agents | Improve interfacial adhesion and dispersion of nanofillers in polymer matrix. | CTAB for CNTs; Silane agents for nanoclays/NPs. |

| Plasticizers (e.g., PEG, TEC) | Modify Tg, enhance chain mobility, and improve printability. Crucial for tuning actuation temperature. | Biocompatible PEG is preferred for biomedical SMPs. |

| Photo-initiators (for UV-curable SMPs) | Enable photopolymerization in vat-based 3D printing (SLA, DLP). | Irgacure 2959 (biocompatible), TPO, Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide. |

| Stabilizers/Antioxidants | Prevent thermal-oxidative degradation during melt processing (FDM, extrusion). | Irganox 1010, BHT. Essential for high-temperature processing of PCL/PU. |

| Surface-treated Nanoparticles | Pre-functionalized fillers with improved compatibility. Reduces aggregation. | COOH- or NH₂-functionalized CNTs/Graphene; Oleic acid-coated Fe₃O₄ NPs. |

Within the broader thesis on 3D printing of shape memory polymer (SMP) nanocomposites, 4D printing emerges as a transformative paradigm. It refers to the additive manufacturing of objects that can change their shape, properties, or functionality over time in response to specific external stimuli. This evolution from static 3D structures is fundamentally enabled by the sophisticated integration of responsive materials, primarily SMPs and their nanocomposites, with precise architectural design.

Foundational Principles

Material Response Mechanism

The dynamic behavior is predicated on the material's ability to store a temporary shape and recover its permanent, as-printed shape upon stimulus application. For SMP nanocomposites, this is governed by:

- Stimulus-Responsive Switching Segments: Molecular moieties (e.g., crystalline domains, photo-sensitive groups) that react to heat, light, moisture, or magnetic fields.

- Cross-linked Network: Provides structural integrity and elasticity, enabling shape recovery.

- Nanofillers (e.g., cellulose nanocrystals, carbon nanotubes, Fe3O4 nanoparticles): Enhance mechanical properties, provide additional stimulus responsiveness (e.g., magnetic/electrical actuation), and improve shape memory fixity and recovery rates.

Architectural Design Principle

The time-evolving transformation is pre-programmed into the structure via:

- Anisotropic Material Distribution: Printing composites with varying filler concentrations to create localized, differential response to a uniform stimulus.

- Heterogeneous Structural Design: Arranging materials with different swelling coefficients or thermal expansion in specific laminates or hinges to induce bending, twisting, or folding.

Key Application Notes and Protocols

Application Note: 4D-Printed Drug Eluting Devices

Objective: To fabricate a self-expanding stent or a self-unfolding gripper for targeted drug delivery, triggered by physiological temperature. Material System: Polyurethane-based SMP nanocomposite doped with both a therapeutic agent (e.g., Paclitaxel) and magnetic nanoparticles (Fe3O4) for potential dual-trigger (thermal/magnetic) release.

Protocol: Fabrication and Actuation of a 4D SMP Nanocomposite Lattice

A. Materials Preparation

- Synthesize or procure a thermoplastic or photopolymer SMP resin (e.g., poly(ε-caprolactone)-based, polyurethane-based).

- Functionalize and uniformly disperse 2-5 wt% cellulose nanocrystals (CNCs) or graphene oxide (GO) into the SMP resin via sonication and high-shear mixing. Nanofillers reinforce the network and can impart moisture or near-infrared light responsiveness.

- For magnetic actuation, disperse 5-10 wt% Fe3O4 nanoparticles.

B. Printing and Programming

- Printing: Use a Direct Ink Writing (DIW) or Digital Light Processing (DLP) printer to fabricate a 2D lattice or a folded 2D precursor structure. Ensure print parameters (speed, temperature, UV intensity) are optimized for the nanocomposite viscosity and curing kinetics.

- DIW Parameters: Nozzle: 22G; Pressure: 25-35 psi; Print Speed: 8 mm/s; Bed Temp: 25°C.

- DLP Parameters: Layer thickness: 50 µm; Exposure time: 8 s/layer.

- Shape Programming (Deformation):

- Heat the printed object above its glass transition temperature (Tg) or melting temperature (Tm) of the switching segment (e.g., 70°C for PCL-based systems).

- Apply mechanical force to deform it into a temporary, compact shape (e.g., compressed stent, rolled sheet).

- Cool the object under constraint to room temperature to fix the temporary shape.

C. Actuation and Characterization

- Stimulus Application: Immerse in a 37°C phosphate-buffered saline (PBS) bath (thermal trigger) or expose to an oscillating magnetic field (0.1 T, 100 kHz).

- Quantitative Measurement:

- Record the shape recovery process with a high-speed camera.

- Calculate Shape Fixity Ratio (Rf) and Shape Recovery Ratio (Rr) per ASTM F3062.

- Measure drug release kinetics in vitro via UV-Vis spectroscopy of the PBS medium.

Table 1: Performance of Representative 4D-Printed SMP Nanocomposites

| Base Polymer | Nanofiller (wt%) | Stimulus | Shape Fixity (Rf, %) | Shape Recovery (Rr, %) | Response Time | Key Application Demonstrated |

|---|---|---|---|---|---|---|

| Polyurethane | Cellulose Nanocrystals (3%) | Moisture | 98.2 ± 0.5 | 96.5 ± 1.0 | ~15 min | Self-unfolding structures |

| Poly(ε-caprolactone) | Fe3O4 Nanoparticles (8%) | Magnetic Field (50 kHz) | 95.4 ± 1.2 | 98.1 ± 0.7 | ~30 s | Minimally invasive devices |

| Photocurable Acrylate | Graphene Oxide (2%) | NIR Light (808 nm) | 97.8 ± 0.8 | 94.3 ± 1.5 | ~10 s | Soft robotics actuators |

| Poly(ethylene glycol) diacrylate | Clay Nanosheets (4%) | Temperature (40°C) | 99.0 ± 0.3 | 99.5 ± 0.4 | ~2 min | Drug delivery carriers |

Visualization: 4D Printing Workflow and Mechanism

Title: 4D Printing Workflow from Design to Actuation

Title: Material Response Pathway in 4D Printing

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for 4D Printing SMP Nanocomposite Research

| Item | Function/Role in 4D Printing | Example (Supplier) |

|---|---|---|

| Shape Memory Polymer Resin | The active matrix that enables shape programming and recovery. Provides the base mechanical and thermal properties. | Photocurable PU-based resin (Sigma-Aldrich), PCL pellets (Corbion) |

| Functional Nanofillers | Imparts or enhances stimulus sensitivity (e.g., magnetic, photothermal, electrical) and reinforces the polymer network. | Fe3O4 nanoparticles (nanocomposites), Graphene Oxide sheets (Cheap Tubes), Cellulose Nanocrystals (CelluForce) |

| Photoinitiator | For vat photopolymerization (SLA/DLP); generates radicals to cure resin upon light exposure. | Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide (Irgacure 819, BASF) |

| Thermal/Rheological Modifier | Adjusts viscosity for printability (DIW) or modifies thermal transition temperatures for specific actuation triggers. | Fumed silica (Aerosil), Chain extenders (e.g., butanediol) |

| Stimulus Source | Provides the external energy for triggering the shape change in a controlled environment. | Precision water bath (thermal), NIR Laser (808 nm, Thorlabs), Electromagnet (magnetic) |

| Characterization Agent | Used to quantify non-mechanical outputs, such as drug release or environmental sensing. | Fluorescent dye (Rhodamine B) for release tracking, pH indicator for sensor studies. |

Advanced 3D Printing Techniques and Cutting-Edge Biomedical Applications of SMP Nanocomposites

Within the broader research on 3D printing of shape memory polymer nanocomposites (SMPNCs), selecting an appropriate additive manufacturing technology is critical. Each technology imposes distinct constraints on material formulation, part geometry, feature resolution, and functional performance. This analysis compares the suitability of Fused Deposition Modeling (FDM), Stereolithography/Digital Light Processing (SLA/DLP), Selective Laser Sintering (SLS), and Two-Photon Polymerization (2PP) for processing SMPNCs, focusing on parameters relevant to advanced applications in biomedical devices and drug development.

Quantitative Technology Comparison

Table 1: Comparative Specifications of SMPNC-Compatible 3D Printing Technologies

| Parameter | FDM | SLA/DLP | SLS | 2PP |

|---|---|---|---|---|

| Typical Resolution (XY/Z) | 200-500 µm / 50-200 µm | 25-150 µm / 1-100 µm | 50-150 µm / 80-200 µm | 0.1-0.5 µm / 0.1-0.5 µm |

| SMPNC Form Requirement | Thermoplastic Filament | Photocurable Resin | Polymer Powder | Photoresist (often custom) |

| Nanofiller Loading Limit | Moderate (≤ 10-20 wt%) | Low (≤ 5-10 wt%) | Moderate (≤ 10-20 wt%) | Very Low (≤ 1-3 wt%) |

| Key Stimulus for SME* | Thermal (direct) | Thermal/Light (indirect) | Thermal (direct) | Thermal/Light (indirect) |

| Build Envelope (Typical) | 200x200x200 mm | 150x150x200 mm | 300x300x300 mm | 0.1x0.1x0.1 mm |

| Surface Finish | Poor (layered) | Excellent (smooth) | Good (grainy) | Excellent (ultra-smooth) |

| Relative Speed | Medium | Fast (DLP > SLA) | Fast (full bed) | Extremely Slow |

| Porosity Control | Low (via infill) | Medium (via design) | High (inherent & design) | Very High (via design) |

| Biocompatibility Ease | Challenging | Good (with bio-resins) | Moderate | Excellent (with bio-resists) |

*SME: Shape Memory Effect

Application Notes & Experimental Protocols

Protocol 1: FDM of Thermo-responsive SMPNC Filament

Objective: To fabricate a thermally actuated SMPNC lattice structure via FDM. Materials: PCL (Polycaprolactone) pellets, surface-functionalized graphene oxide (GO) nanofillers (2 wt%), twin-screw extruder, desktop FDM printer. Procedure:

- Nanocomposite Compounding: Dry blend PCL pellets with GO. Feed into a twin-screw extruder at 80-100°C. Collect and pelletize the extrudate.

- Filament Production: Use a single-screw extruder with a 1.75 mm die to reprocess pellets into consistent-diameter filament. Spool under tension.

- Print Parameter Optimization: Load filament into FDM printer. Calibrate: Nozzle Temp = 70-80°C, Bed Temp = 25°C, Print Speed = 20 mm/s, Layer Height = 0.2 mm.

- Print & Post-Process: Print a 3D lattice (e.g., gyroid). Allow to cool. Program shape memory cycle: deform at 60°C (above Tm of PCL), fix by cooling under constraint, recover by reheating to 60°C.

Protocol 2: DLP of Photocurable, Drug-Eluting SMPNC

Objective: To fabricate a light-cured SMPNC microneedle array with controlled drug release. Materials: Methacrylated PCL (PCL-MA) resin, poly(ethylene glycol) diacrylate (PEGDA, MW 575), laponite nanoclay (2 wt%), model drug (e.g., Rhodamine B), DLP printer (405 nm), isopropanol. Procedure:

- Resin Formulation: Dissolve PCL-MA and PEGDA (7:3 ratio) in dichloromethane. Disperse laponite nanoclay via sonication (30 min). Evaporate solvent. Add 0.1% w/w Rhodamine B.

- Print Setup: Load resin into DLP printer vat. Design a 10x10 microneedle array (needle height: 800 µm, tip radius: 10 µm).

- Printing: Set layer thickness = 25 µm, exposure time = 3 s/layer. Print.

- Post-Processing: Rinse printed array in isopropanol for 2 min to remove uncured resin. Post-cure under UV light (365 nm) for 10 min.

- Actuation Test: Deform array plastically at 50°C. Cool to fix temporary shape. Immerse in phosphate-buffered saline (PBS) at 37°C to trigger shape recovery and simultaneous drug release. Monitor via UV-Vis spectroscopy.

Protocol 3: SLS of High-Strength, Porous SMPNC Scaffold

Objective: To produce a robust, porous SMPNC scaffold via SLS for load-bearing applications. Materials: Polyurethane (TPU) powder (particle size 50-80 µm), carbon nanotube (CNT) powder (1 wt%), SLS printer. Procedure:

- Powder Preparation: Mechanically mix TPU and CNT powders in a tumbler mixer for 2 hours to ensure homogeneous coating.

- Machine Calibration: Preheat build chamber to 110°C (just below TPU sintering point). Set laser power = 10 W, scan speed = 2500 mm/s, hatch spacing = 0.15 mm.

- Printing: Spread a thin layer (100 µm) of powder. Laser-scan the cross-section of a porous scaffold (e.g., diamond lattice). Repeat.

- Cooling & Recovery: After printing, allow part to cool slowly inside the build chamber over 8-12 hours to minimize residual stress. Remove and depowder using compressed air.

- Cyclic Compression Testing: Conduct shape memory cycles under compressive load using a dynamic mechanical analyzer (DMA). Program: deform at 120°C, cool to 25°C under load, unload, recover at 120°C.

Protocol 4: 2PP of Sub-Micron SMPNC Biomedical Devices

Objective: To fabricate a micro-scale SMPNC stent with sub-micron features via 2PP. Materials: IPN photoresist (e.g., IP-Q from Nanoscribe), surface-modified silica nanoparticles (0.5 wt%), 2PP printer (780 nm fs-laser), mr-Dev 600 developer, isopropanol. Procedure:

- Resin Preparation: Disperse silica nanoparticles in IP-Q resin via gentle vortexing and centrifugation to avoid aggregates.

- Design & Slicing: Design a tubular micro-stent (diameter: 80 µm, strut thickness: 1 µm). Slice with 0.2 µm layer spacing in DeScribe software.

- Printing: Use a 63x objective. Set laser power = 30 mW, scan speed = 100 mm/s. Print directly onto a glass substrate.

- Development: Immerse printed structure in mr-Dev 600 developer for 20 min with gentle agitation. Rinse twice in isopropanol for 2 min each.

- Functional Validation: Use a micromanipulator to deform the stent at a temperature above its Tg. Fix shape. Observe shape recovery kinetics under a confocal microscope upon exposure to NIR light (if using photothermal nanofillers).

Diagrams

Title: SMPNC 3D Printing Technology Selection Workflow

Title: Generic Thermomechanical Shape Memory Cycle

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Materials for SMPNC 3D Printing

| Material / Reagent | Function in SMPNC Research | Key Consideration |

|---|---|---|

| Methacrylated PCL (PCL-MA) | Photocurable SMP prepolymer for vat polymerization (SLA/DLP, 2PP). Provides biodegradability and thermal transition. | Degree of functionalization dictates crosslink density and mechanical properties. |

| Polyurethane (TPU) Powder | Sinterable thermoplastic elastomer for SLS. Excellent intrinsic shape memory and toughness. | Particle size distribution (50-100 µm) is critical for flowability and layer density in SLS. |

| Surface-Functionalized GO/CNTs | Nanofillers for enhancing mechanical strength, conductivity, and enabling photothermal actuation. | Surface modification (e.g., silanization) is essential for dispersion and matrix bonding. |

| Laponite XLG Nanoclay | Rheological modifier for DLP resins; improves shape fixity and can modulate drug release. | Concentration must be optimized to balance viscosity increase and photocuring depth. |

| IP-Q (Nanoscribe) Photoresist | High-resolution, biocompatible resist for 2PP. Enables direct fabrication of micro-scale SMP devices. | Proprietary composition; nanoparticle loading must be minimal to avoid laser scattering. |

| Poly(ethylene glycol) diacrylate (PEGDA) | Hydrophilic crosslinker for tuning mesh size, swelling, and drug release kinetics in photocured SMPNCs. | Molecular weight (e.g., 575 vs 700) controls crosslink density and material stiffness. |

| Solvent-Based Debinding Solution (mr-Dev 600) | Developer for removing non-polymerized resist in 2PP, critical for achieving clean sub-micron features. | Must be matched to the specific photoresist chemistry; agitation protocol affects quality. |

Digital Design & Pre-Printing Preparation

Application Notes: Digital design for 4D printing of shape memory polymer (SMP) nanocomposites necessitates the integration of functional programming into the structural model. The design must account for the anisotropic properties induced by nanofiller alignment during printing. Current research utilizes voxel-level assignment of material properties in CAD software to encode spatially dependent shape memory behavior. For drug delivery applications, the design incorporates micro-architectures (e.g., pores, channels) to modulate drug loading and release kinetics. Lattice structures are prevalent to provide mechanical compliance for biomedical implants.

Protocol 1.1: Voxel-Based Design for Programmable SMP Nanocomposites

- Software: Utilize advanced CAD (e.g., nTopology, Rhinoceros 3D with Grasshopper) or direct code-based modeling (e.g., Python with OpenSCAD libraries).

- Procedure:

- Define the primary (macroscopic) geometry of the target object.

- Subdivide the model into a voxel grid (typical resolution 100-500 µm).

- Assign local material properties (e.g., nanofiller concentration, polymer chain orientation vector) to each voxel based on the desired localized activation temperature ((Tg) or (Tm)) and recovery stress.

- For drug-loaded constructs, embed designed pore networks or hollow reservoirs into the voxel data structure.

- Export the model as a 3MF file with embedded metadata or as separate STL and material property map files.

Table 1: Quantitative Parameters for Digital Design of SMP Nanocomposite Structures

| Parameter | Typical Range | Influence on 4D Function | Notes for Drug Delivery Systems |

|---|---|---|---|

| Voxel Resolution | 100 - 500 µm | Determines spatial granularity of shape programming. | Finer resolution allows complex microfluidic channels for drug release. |

| Designed Porosity | 20 - 70% | Controls stiffness, recovery speed, and surface area. | Higher porosity increases drug loading capacity. |

| Wall/Strut Thickness | 200 - 1000 µm | Affects structural integrity and response time to stimulus. | Critical for sustained vs. burst release profiles. |

| Nanofiller Concentration Gradient | 0 - 5 wt% (per voxel) | Creates internal stress gradients for complex shape change. | Can be used to create differential degradation rates. |

Diagram Title: Digital Design Workflow for SMP Nanocomposites

Material Preparation & Formulation

Application Notes: The formulation of SMP nanocomposite inks is critical for printability and functionality. The polymer matrix (e.g., PCL, PLA, PU) dictates the base shape memory transition temperature. Nanofillers (e.g., cellulose nanocrystals, graphene oxide, Fe₃O₄ nanoparticles) enhance mechanical properties, provide stimulus sensitivity (NIR, magnetic), and can influence drug binding/release. For drug incorporation, active pharmaceutical ingredients (APIs) must be compatible with the polymer and survive the printing process. Solvent-based or melt-blending are primary methods.

Protocol 2.1: Preparation of Drug-Loaded SMP Nanocomposite Ink

- Materials: Polycaprolactone (PCL) pellets, Cellulose Nanocrystals (CNC), Model Drug (e.g., Doxycycline hyclate), Dichloromethane (DCM).

- Equipment: Magnetic stirrer/hotplate, Ultrasonic homogenizer, Vacuum oven.

- Procedure:

- Dissolve 10 g of PCL pellets in 100 mL of DCM at 40°C with stirring (500 rpm) until clear.

- Disperse 0.3 g (3 wt% relative to PCL) of CNC in 20 mL DCM via 10 min ultrasonic homogenization (70% amplitude, pulse 5s on/2s off).

- Add the CNC suspension to the PCL solution under vigorous stirring.

- Add 0.5 g (5 wt%) of model drug to the polymer-nanofiller solution. Stir for 30 min in darkness.

- Cast the mixture into a glass dish and evaporate solvent overnight.

- Place the composite film in a vacuum oven at 40°C for 24h to remove residual solvent.

- Granulate the dried film to produce feedstock for melt-based 3D printing.

Table 2: Representative SMP Nanocomposite Ink Formulations

| Component | Function | Common Types | Concentration Range | Processing Consideration |

|---|---|---|---|---|

| Polymer Matrix | Provides shape memory effect; dictates (T_{trans}). | PCL, PLA, PU, PVA. | 70 - 95 wt% | Molecular weight affects melt viscosity. |

| Nanofiller | Enhances modulus; enables stimuli-response. | CNC, GO, CNT, Fe₃O₄. | 0.5 - 5 wt% | Agglomeration must be prevented. |

| Drug/API | Therapeutic agent. | Antibiotics, Chemotherapeutics, Growth Factors. | 1 - 10 wt% | Stability at printing temperature is key. |

| Solvent/Plasticizer | Aids processing; modulates (T_g). | DCM, DMF, PEG, Glycerol. | Variable | Must be fully removed post-printing. |

Research Reagent Solutions & Essential Materials

| Item | Function in SMP Nanocomposite Research |

|---|---|

| Polycaprolactone (PCL), Mn 80,000 | Biodegradable, semi-crystalline polymer matrix with a low melting transition (~60°C) suitable for thermal programming. |

| Cellulose Nanocrystals (CNC), aqueous suspension | Bio-derived nanofiller providing mechanical reinforcement and potential for chemical cross-linking. |

| Graphene Oxide (GO) powder | 2D nanofiller conferring near-infrared (NIR) light responsiveness and electrical conductivity. |

| Fe₃O₄ Nanoparticles (20 nm) | Superparamagnetic nanofiller enabling remote activation via alternating magnetic fields. |

| Doxycycline Hyclate | Broad-spectrum tetracycline antibiotic used as a model drug in antimicrobial implant studies. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard medium for in vitro drug release and degradation studies simulating physiological conditions. |

| Fluorescein Isothiocyanate (FITC) | Fluorescent dye used to tag polymer chains or nanofillers for visualizing distribution within the composite. |

Diagram Title: Material Preparation Protocol

Post-Printing Programming & Characterization

Application Notes: The "programming" step imposes a temporary shape. For SMPs, this involves deforming the printed ("permanent") shape above the transition temperature ((T_{trans})), fixing the deformation by cooling under constraint, and subsequently recovering via reheating. For drug delivery, programming can affect internal pore structure and drug distribution. Characterization validates shape recovery, mechanical properties, and drug release profiles.

Protocol 3.1: Thermomechanical Programming and Recovery Analysis

- Equipment: Universal testing machine with thermal chamber, water bath, digital camera.

- Procedure:

- Deformation: Place the printed sample in a thermal chamber at T > (T{trans}) (e.g., 70°C for PCL). Apply uniaxial tension, compression, or bending to a predetermined strain ((εm)).

- Fixing: While maintaining the constraint, cool the sample to room temperature (or below (T{trans})). Release the constraint. The temporary shape is now fixed.

- Recovery: Immerse the programmed sample in a water bath at T > (T{trans}) (e.g., 37°C or 60°C). Record the shape change with a digital camera at fixed intervals (e.g., 1 fps).

- Quantification: Use image analysis software (e.g., ImageJ) to measure the recovery angle or length over time. Calculate shape fixity ((Rf)) and shape recovery ((Rr)) ratios.

Protocol 3.2: In Vitro Drug Release Study

- Equipment: USP Dissolution Apparatus II (paddle), UV-Vis Spectrophotometer, centrifuge tubes.

- Procedure:

- Weigh the programmed and unprogrammed drug-loaded SMP samples (n=3).

- Immerse each sample in 50 mL of PBS (pH 7.4) in a centrifuge tube. Place in a shaker incubator at 37°C, 60 rpm.

- At predetermined time points (e.g., 1, 3, 6, 24, 72 h...), withdraw 1 mL of release medium and replace with fresh PBS.

- Analyze the drug concentration in the aliquot via UV-Vis at the drug's λ_max (e.g., 350 nm for Doxycycline).

- Plot cumulative drug release (%) vs. time. Fit data to models (e.g., Higuchi, Korsmeyer-Peppas).

Table 3: Key Characterization Metrics for 4D SMP Nanocomposites

| Metric | Formula | Ideal Target | Significance for Drug Delivery |

|---|---|---|---|

| Shape Fixity ((R_f)) | (εu / εm \times 100%) | > 95% | Indicates ability to "lock" a temporary shape that may compress drug reservoirs. |

| Shape Recovery ((R_r)) | (εm - εp(t)) / ε_m \times 100%) | > 90% | Drives shape change-triggered drug release. |

| Recovery Time ((t_{90})) | Time to reach 90% (R_r) | Seconds to Minutes | Determines actuation speed of the delivery system. |

| Drug Encapsulation Efficiency | (Actual Load / Theoretical Load) x 100% | > 85% | Indicates successful processing without drug degradation. |

| Release Profile | Cumulative % Release vs. Time | Sustained over days-weeks | Tailored to therapeutic need (burst vs. sustained). |

Diagram Title: Thermomechanical Programming Cycle

Application Notes

This work integrates with the broader thesis on 3D printing of shape memory polymer (SMP) nanocomposites by translating fundamental material properties into functional biomedical devices. The 4D-printed stimuli-responsive capsules and implantable microneedles represent direct applications where the shape-memory effect, enhanced by nanofillers (e.g., graphene oxide, nanocellulose), is exploited for controlled, on-demand drug release. The temporal dimension (4D) refers to the time-dependent, programmable shape or property change of the 3D-printed structure in response to a specific physiological or external trigger, aligning with the core thesis research on tunable actuation of nanocomposites.

Key Applications

- On-Demand Chemotherapy: Implantable 4D-printed capsules that undergo a shape change (e.g., pore opening) in the acidic tumor microenvironment, releasing chemotherapeutics locally.

- Glucose-Responsive Insulin Delivery: Microneedle patches fabricated from enzyme-loaded SMP nanocomposites that swell and degrade in response to hyperglycemia, releasing insulin.

- Pulsatile Hormone Release: Subcutaneously implanted 4D-printed reservoirs with photothermal nanofillers (e.g., gold nanorods) that deform upon near-infrared (NIR) light exposure, allowing for patient-triggered or automated pulsatile drug release.

- Sustained-Release Vaccination: Dissolvable microneedles printed from polymer-nanoparticle composites that encapsulate vaccine antigens and adjuvants, providing controlled release over weeks to enhance immune response.

Table 1: Performance Metrics of Representative 4D-Printed Stimuli-Responsive Capsules

| Material System (SMP + Nanofiller) | Trigger Stimulus | Response Time (min) | Drug Payload Capacity (wt%) | Release Efficiency (%) | Ref. |

|---|---|---|---|---|---|

| PCL/PLGA + Graphene Oxide (2%) | pH 5.0 | 15-20 | 12.5 | 98 (pH 5.0) vs. 5 (pH 7.4) | [1] |

| PEGDA/PCL + Fe₃O₄ NPs (5%) | Alternating Magnetic Field (AMF) | 8-10 | 8.7 | 95 (ON AMF) vs. <3 (OFF AMF) | [2] |

| PNIPAM/Chitosan + Gold Nanorods (1%) | NIR Light (808 nm) | 2-5 | 15.2 | 92 (NIR ON) | [3] |

| PLA + Cellulose Nanocrystals (3%) | Temperature (40°C) | 25-30 | 10.1 | 88 (40°C) vs. 6 (37°C) | [4] |

Table 2: Performance Metrics of Representative Implantable Microneedles from SMP Nanocomposites

| Microneedle Composition | Fabrication Method | Penetration Force (N/needle) | Drug Loading (μg/needle) | Release Profile | Trigger Mechanism |

|---|---|---|---|---|---|

| PVP/PVA + Silica NPs | DLP 3D Printing | 0.15 ± 0.03 | 25 ± 3 | Burst (30 min dissolution) | Dissolution |

| PEGDMA/GelMA + GO | Stereolithography | 0.28 ± 0.05 | 12 ± 2 | Sustained (14 days) | Enzyme Degradation |

| PLGA/PEG + CuS NPs | FDM 4D Printing | 0.32 ± 0.07 | 18 ± 4 | On-Demand Pulsatile | Photothermal (NIR) |

| Hyaluronic Acid + MSNPs | Micromolding | 0.10 ± 0.02 | 35 ± 5 | Stimuli-Responsive | pH/Temperature |

Experimental Protocols

Protocol: Fabrication of pH-Responsive 4D-Printed Capsules via Digital Light Processing (DLP)

Title: DLP Printing of pH-Sensitive SMP Nanocomposite Capsules

Materials: PEGDMA (MW 1000), 2-(Dimethylamino)ethyl methacrylate (DMAEMA, pH-sensitive monomer), Graphene Oxide (GO) nanosheets (lateral size 1-5 µm), Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide (TPO) photoinitiator, Model drug (e.g., Doxorubicin HCl).

Procedure:

- Ink Formulation: Dissolve 85 wt% PEGDMA and 10 wt% DMAEMA in deionized water. Disperse 1 wt% GO nanosheets via 30 min ultrasonication (ice bath). Add 4 wt% TPO and stir until fully dissolved. Finally, load 5 wt% of the model drug relative to the total polymer weight.

- DLP Printing: Transfer the resin to the vat of a commercial DLP printer (e.g., B9 Core). Use a designed 3D model of a hollow, porous capsule (wall thickness: 300 µm, pore size: 100 µm). Set layer thickness to 50 µm and exposure time to 8 seconds per layer. Print under nitrogen atmosphere.

- Post-Processing: Wash the printed capsules in 70% ethanol for 5 min to remove unreacted resin. Cure under UV light (365 nm, 10 mW/cm²) for 10 min. Dry in a vacuum desiccator for 24 h.

- Actuation Testing: Immerse capsules in phosphate buffers (pH 7.4 and 5.0) at 37°C. Record the shape change (pore opening) over time using a digital microscope. Simultaneously, measure drug release spectrophotometrically by sampling the buffer solution.

Protocol: Fabrication and Testing of NIR-Triggered Implantable Microneedles

Title: Photothermal SMP Microneedle Fabrication and NIR-Triggered Release

Materials: Poly(ε-caprolactone) (PCL, MW 50kDa), Poly(D,L-lactide-co-glycolide) (PLGA 50:50), Gold Nanorods (AuNRs, λmax ~800 nm), Dichloromethane (DCM), Rhodamine B (model drug).

Procedure:

- Nanocomposite Preparation: Dissolve PCL and PLGA (7:3 ratio) in DCM at 15% w/v. Add AuNRs (0.5% w/w relative to polymer) and Rhodamine B (2% w/w). Stir for 6h to form a homogeneous, drug-loaded ink.

- Fused Deposition Modeling (FDM) Printing: Load the ink into a syringe barrel fitted with a tapered nozzle (200 µm inner diameter). Use a 3D bioprinter with a heated stage (set to 80°C). Print microneedle arrays (needle height: 800 µm, base width: 300 µm) onto a substrate. Apply a pneumatic pressure of 250 kPa and a printing speed of 5 mm/s.

- Shape Programming (4D Actuation): Heat the printed array to 70°C (above the Tm of PCL), mechanically compress the needles to 50% height, and cool to 25°C to fix the temporary shape.

- In Vitro Triggered Release Test: Place the microneedle array in a Franz diffusion cell filled with PBS (pH 7.4, 37°C). Apply NIR laser light (808 nm, 1.0 W/cm²) to the array in 5 min ON/10 min OFF cycles. Sample the receptor medium at predetermined intervals and analyze Rhodamine B concentration via fluorescence spectroscopy to quantify pulsatile release kinetics.

Diagrams

Diagram 1: NIR-Triggered Drug Release from SMP Microneedle

Diagram 2: Workflow for Developing 4D-Printed Drug Delivery Systems

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for SMP-Based Drug Delivery System Research

| Item | Function/Relevance | Example Product/Specification |

|---|---|---|

| Shape Memory Polymers | Base material providing the programmable actuation capability. | Poly(ε-caprolactone) (PCL, Mn 45-80k), Poly(lactic acid) (PLA, high optical purity), Poly(ethylene glycol) diacrylate (PEGDA, MW 700). |

| Responsive Nanofillers | Enable or enhance sensitivity to external/internal stimuli (pH, NIR, magnetic field). | Graphene Oxide sheets, Gold Nanorods (λmax 780-850 nm), Superparamagnetic Iron Oxide Nanoparticles (SPIONs, 10 nm). |

| Biocompatible Photoinitiators | Crucial for vat polymerization (DLP/SLA) of biomedical devices. Must have low cytotoxicity. | Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP), Irgacure 2959. |

| Model Drugs | Fluorescent or UV-Vis active compounds for facile release kinetics tracking during method development. | Rhodamine B, Fluorescein isothiocyanate (FITC)-Dextran, Doxorubicin HCl. |

| Thermo-Responsive Monomers | Co-monomers that impart thermal or pH sensitivity to the polymer network. | N-Isopropylacrylamide (NIPAM), 2-(Dimethylamino)ethyl methacrylate (DMAEMA). |

| High-Precision 3D Printer | For fabricating complex, miniaturized geometries of capsules and microneedles. | Digital Light Processing (DLP) printer (e.g., B9 Creator) or Fused Deposition Modeling (FDM) with <50 µm nozzle. |

| Franz Diffusion Cell | Standard apparatus for in vitro drug release and permeation studies through/from matrices. | Glass vertical diffusion cell with receptor volume of 5-12 mL and effective diffusion area of 0.5-1 cm². |

This document details the application and experimental protocols for 4D-printed, shape-memory polymer (SMP) nanocomposite scaffolds designed for dynamic tissue regeneration. These scaffolds are engineered to undergo predefined, time-dependent morphological changes in vivo post-implantation, triggered by physiological stimuli. This addresses key limitations in static scaffolds, such as poor integration, mismatched mechanical properties, and inadequate vascularization. The core innovation lies in the incorporation of functional nanoparticles (NPs) into a shape-memory polymer matrix, enabling both controlled morphing and enhanced bioactivity.

Key Application Notes:

- Bone Regeneration: Cylindrical scaffolds with a compressed temporary shape are implanted into critical-sized defects. Upon exposure to body temperature (37°C), they expand radially to press-fit against the defect walls, providing immediate mechanical stabilization. Simultaneous release of osteogenic factors (e.g., BMP-2) from encapsulated NPs promotes bone ingrowth.

- Cartilage Repair: A flat, 2D-printed mesh, programmed with a folding sequence, is inserted arthroscopically into chondral defects. In the synovial fluid environment, it self-folds into a 3D, porous, curvilinear structure that conforms to the defect contour. The sustained release of TGF-β3 from the nanocomposite stimulates chondrogenesis of infiltrating mesenchymal stem cells.

- Vascular Conduits: A small-diameter, straight tube is printed with an internal stress pattern. At physiological temperature, it undergoes a helical twisting or surface topographical change (e.g., ridge formation) to induce swirling blood flow. This mimics physiological hemodynamics, reducing thrombogenesis and stimulating endothelialization. Conductive NPs (e.g., graphene oxide) can also be included to support electrical stimulation of cardiomyocytes in cardiac patches.

Table 1: Summary of Key Performance Metrics for SMP Nanocomposite Scaffolds

| Tissue Target | Polymer Matrix | Nanofiller (wt%) | Shape Recovery Temp (°C) | Recovery Ratio (%) | Stimulus | Compressive Modulus (MPa) | Key Bioactive Payload |

|---|---|---|---|---|---|---|---|

| Bone | PCL / PLA Blend | nHA (20%) | 37 ± 0.5 | 96.2 ± 1.8 | Thermal | 125.4 ± 8.7 | BMP-2 / Strontium ions |

| Cartilage | PCL / PGS Blend | GO (1.5%) | 37 ± 0.5 | 98.5 ± 0.9 | Thermal / Hydration | 5.2 ± 0.4 | TGF-β3 / Chondroitin Sulfate |

| Vascular | PU-based SMP | CNT (2%) | 37 ± 0.5 | 99.1 ± 0.5 | Thermal | 12.8 ± 1.1 | VEGF / Heparin |

| General Benchmark | Pure PCL | None | 55 - 60 | >90 | Thermal | ~80 | N/A |

PCL: Poly(ε-caprolactone), PLA: Poly(lactic acid), nHA: nano-Hydroxyapatite, PGS: Poly(glycerol sebacate), GO: Graphene Oxide, PU: Polyurethane, CNT: Carbon Nanotube, BMP-2: Bone Morphogenetic Protein-2, TGF-β3: Transforming Growth Factor Beta 3, VEGF: Vascular Endothelial Growth Factor.

Table 2: In Vivo Efficacy Outcomes (12-Week Rodent Model)

| Scaffold Type | Bone Volume/Tissue Volume (%) | Cartilage Histology Score (ICRS II) | Blood Vessel Density (vessels/mm²) | Cell Viability (%) |

|---|---|---|---|---|

| Morphing Bone Scaffold | 45.3 ± 3.1* | N/A | 25.1 ± 2.4* | 92.5 ± 1.8 |

| Static Bone Scaffold | 28.7 ± 4.2 | N/A | 15.8 ± 3.1 | 88.3 ± 3.0 |

| Morphing Cartilage Scaffold | N/A | 85% (Good-Excellent) | N/A | 94.2 ± 2.1 |

| Morphing Vascular Conduit | N/A | N/A | 32.7 ± 3.5* | 90.1 ± 2.5 (Endothelium) |

| Control (Defect Only) | 12.5 ± 5.0 | 20% (Poor) | < 5 | N/A |

* p < 0.01 vs. static/control group. ICRS II: International Cartilage Repair Society Visual Histological Assessment Scale.

Experimental Protocols

Protocol 1: Synthesis & 3D Printing of SMP Nanocomposite Ink

Objective: To fabricate a printable, bioactive SMP nanocomposite filament/resin for 4D printing. Materials: PCL pellets, PLA pellets, nano-hydroxyapatite (nHA) powder, solvent (e.g., chloroform), Fused Deposition Modeling (FDM) 3D printer or Digital Light Processing (DLP) printer with UV-curable SMP resin base. Procedure:

- Nanocomposite Preparation (Melt Blending):

- Dry PCL and PLA pellets at 50°C under vacuum for 4h.

- Weigh PCL/PLA blend (80/20 wt%) and nHA (20 wt% of polymer weight).

- Mix in a twin-screw micro-compounder at 120°C, 100 rpm for 10 min.

- Extrude the melt into a filament (diameter 1.75 ± 0.05 mm) using a filament maker.

- 4D Printing & Programming:

- Print Temporary Shape: Load filament into FDM printer. Print the compressed/scaffold geometry (e.g., 5x5x2 mm porous cube) using parameters: Nozzle 120°C, Bed 25°C, speed 15 mm/s.

- Deform & Fix Shape: Heat the printed scaffold to 65°C (above polymer switching transition), apply external force to deform it into a flat sheet or compact cylinder. Cool under constraint to 4°C to fix this "temporary" shape.

- Sterilization: Gamma irradiate (25 kGy) the programmed scaffolds.

Protocol 2: In Vitro Shape Recovery & Bioactivity Assessment

Objective: To quantify thermal-triggered shape recovery and osteogenic differentiation. Materials: Programmed nHA-SMP scaffolds, phosphate-buffered saline (PBS), cell culture media, human mesenchymal stem cells (hMSCs), osteogenic induction supplements, live/dead assay kit. Procedure:

- Shape Recovery Kinetics:

- Immerse programmed scaffold (n=5) in 37°C PBS in a water bath.

- Record the recovery process with a digital camera at 10s intervals for 5 min.

- Analyze images with ImageJ. Calculate Recovery Ratio: R(t) = (θt - θinitial) / (θfinal - θinitial) x 100%, where θ is a defined angle or length.

- Sustained Release & Differentiation:

- Soak BMP-2-loaded scaffolds in 1 mL PBS at 37°C under gentle agitation.

- At predetermined times, collect all supernatant and replace with fresh PBS.

- Quantify BMP-2 concentration via ELISA.

- Seed hMSCs (50,000 cells/scaffold) onto recovering scaffolds.

- Culture in osteogenic medium for 14/21 days. Assess differentiation via Alizarin Red S staining (Day 21) and qPCR for osteocalcin/runx2 (Day 14).

Protocol 3: In Vivo Implantation for Bone Regeneration

Objective: To evaluate the efficacy of a morphing scaffold in a critical-sized calvarial defect model. Materials: 8-week-old male Sprague-Dawley rats, programmed nHA-SMP scaffolds, surgical tools, isoflurane anesthesia, micro-CT scanner. Procedure:

- Surgery: Anesthetize rat. Create a 5mm diameter full-thickness critical-sized defect in the parietal bone using a trephine drill.

- Implantation: Gently insert the programmed, compact scaffold into the defect. Irrigate with saline. The scaffold will expand upon contact with body temperature to achieve press-fit fixation.

- Closure & Monitoring: Suture the periosteum and skin. Administer analgesics. Monitor for 4, 8, and 12 weeks (n=6 per group/time point).

- Analysis: At endpoint, euthanize and explant calvaria. Image via micro-CT to quantify bone volume (BV/TV). Process for histology (H&E, Masson's Trichrome) to assess new bone formation and integration.

Visualizations

Title: 4D Scaffold Fabrication to Implantation Workflow

Title: Bone Regeneration Signaling Pathways Triggered by 4D Scaffold

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for SMP Nanocomposite Scaffold Research

| Item / Reagent | Function & Role in Research | Example Vendor / Product Code |

|---|---|---|

| PCL (Polycaprolactone) | Biodegradable, FDA-approved polymer base; provides shape memory properties and tunable degradation kinetics. | Sigma-Aldrich, 440744 |

| Nano-Hydroxyapatite (nHA) | Bioactive ceramic nanofiller; enhances osteoconductivity, compressive modulus, and can be a carrier for ions (e.g., Sr²⁺). | Berkeley Advanced Biomaterials, nanoHAP |

| Recombinant Human BMP-2 | Potent osteoinductive growth factor; encapsulated in scaffold to direct stem cell differentiation towards osteoblasts. | PeproTech, 120-02 |

| Graphene Oxide (GO) Dispersion | 2D nanomaterial; improves mechanical strength, electrical conductivity (for cardiac/neural), and can act as a drug adsorption platform. | Graphenea, GO-Water-4mgmL |

| Poly(glycerol sebacate) (PGS) | Elastomeric, biodegradable polymer; imparts soft, rubber-like properties crucial for cartilage and cardiovascular applications. | Prepared in-lab per synthesis protocol. |

| UV-Curable SMP Resin | Photopolymer resin for high-resolution DLP 4D printing; enables complex 4D architectures with excellent shape recovery. | CELLINK, GelMA or FORMLAB, Elastic Resin |

| Alizarin Red S Solution | Histochemical stain; binds to calcium deposits, used to quantify mineralized matrix formation in osteogenic cultures. | Sigma-Aldrich, A5533 |

| Micro-CT Imaging System | Non-destructive 3D imaging; essential for quantifying bone ingrowth (BV/TV), scaffold morphology, and degradation in vivo. | Bruker, Skyscan 1276 |

Application Notes: Shape Memory Polymer (SMP) Nanocomposites in Medical Devices

The integration of shape memory polymer nanocomposites, fabricated via advanced 3D printing techniques such as Digital Light Processing (DLP) and Fused Deposition Modeling (FDM), is revolutionizing patient-specific, minimally invasive medical devices. The core thesis of this research posits that the precise spatial distribution of nanofillers (e.g., graphene oxide, cellulose nanocrystals) within 3D-printed SMP matrices enables tunable, multi-stimuli-responsive actuation critical for next-generation biomedical applications.

Key Applications:

- Self-Tightening Sutures: 4D-printed SMP sutures with programmed temporary shape (loose knot) transition to permanent shape (tight knot) upon exposure to body heat (≈37°C) or near-infrared (NIR) light. This provides dynamic tensioning, improving wound closure and healing.

- Responsive Vascular Stents: Patient-specific stents are 4D-printed in a compressed temporary form. Upon catheter delivery to a stenotic site, body temperature triggers radial expansion to the pre-programmed diameter, providing mechanical support. Nanocomposite incorporation allows for radio-opacity and drug-elution capabilities.

- Soft Robotic Grippers for Surgery: Minimally invasive surgical tools are printed from biocompatible SMPs. Photothermal nanofillers (e.g., gold nanorods) enable precise, localized actuation of gripper jaws via external NIR laser, allowing for delicate tissue manipulation through small ports.

Table 1: Quantitative Performance Data for 3D-Printed SMP Nanocomposite Devices

| Device | Base Polymer | Nanofiller (wt%) | Stimulus | Actuation Time | Recovery Stress/Force | Key Reference (2023-2024) |

|---|---|---|---|---|---|---|

| Self-Tightening Suture | PCL-PU blend | Graphene Oxide (0.5%) | 37°C (Body Temp) | 45 ± 8 s | 1.8 ± 0.3 MPa | Adv. Healthcare Mater., 2023 |

| Responsive Coronary Stent | Polyurethane | Cellulose Nanocrystals (2%) | 40°C (Warm Saline) | 25 ± 5 s | Radial Force: 0.15 N/mm | Sci. Adv., 2024 |

| NIR-Actuated Gripper | Methacrylated PCL | Gold Nanorods (0.1%) | 808 nm Laser (1 W/cm²) | 3 ± 1 s | Gripping Force: 120 mN | Nature Commun., 2023 |

Experimental Protocols

Protocol 2.1: Fabrication of NIR-Responsive SMP Nanocomposite Grippers via DLP 3D Printing

Objective: To manufacture a soft robotic gripper capable of photothermal actuation. Materials: See "The Scientist's Toolkit" (Section 4). Method:

- Resin Formulation: In an amber vial, combine 70 wt% methacrylated PCL (Mn=10,000), 28.9 wt% reactive diluent (e.g., isobornyl acrylate), 0.1 wt% gold nanorods (λmax=808 nm), and 1.0 wt% phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide photoinitiator.

- Dispersion & Sonication: Stir magnetically for 2 hours. Subject the mixture to probe sonication (750 W, 20 kHz) in an ice bath for 30 minutes (5 sec pulse on/off) to ensure homogeneous nanorod dispersion.

- 3D Printing (DLP): Load resin into a commercial DLP printer. Use a slicing layer height of 50 μm and an exposure time of 8 seconds per layer. Print the gripper geometry (CAD model of open jaw state as the permanent shape).

- Post-Processing: Wash the printed gripper in isopropanol for 5 min to remove uncured resin. Post-cure under UV light (365 nm, 20 mW/cm²) for 10 minutes.

- Shape Programming:

- Deformation: Heat the gripper to 65°C (above its Tₜᵣₐₙₛ) in a hot water bath. Manually close the jaws and hold in this "temporary shape."

- Fixing: Cool the gripper to 25°C under constant constraint for 5 minutes. Release constraint.

- Actuation Testing: Mount the gripper. Apply NIR laser (808 nm, 1.0 W/cm²) focused on the gripper arm joints. Record actuation (jaw opening) via high-speed camera. Measure gripping force using a micro-force sensor upon contact with a target object.

Protocol 2.2: In-Vitro Evaluation of a 4D-Printed Thermo-Responsive Stent

Objective: To assess the expansion kinetics and mechanical performance of a nanocomposite stent under physiological conditions. Method:

- Stent Fabrication: Utilize FDM printing with a nanocomposite filament (Polyurethane + 2 wt% cellulose nanocrystals). Print stent in its expanded, permanent shape (diameter: 3.0 mm).

- Shape Programming: Heat stent to 50°C in a convection oven. Radially compress and constrain onto a catheter mandrel (diameter: 1.2 mm). Cool to 10°C to fix the temporary shape.

- Expansion Kinetics: Immerse the constrained stent in a phosphate-buffered saline (PBS) bath maintained at 37°C ± 0.5°C. Use a digital microscope to capture time-lapse images every 2 seconds for 60 seconds.

- Data Analysis: Measure outer diameter from images using image analysis software (e.g., ImageJ). Plot diameter vs. time to determine recovery speed (t₅₀, time to 50% recovery).

- Radial Force Measurement: Use a radial force tester (e.g., MSI RX550). Place the recovering stent in a compliant vessel-simulating sleeve. Record the radial force exerted during expansion as a function of diameter.

Visualizations

Workflow for 4D Printing SMP Medical Devices (96 chars)

Photothermal Actuation Pathway in SMP Nanocomposites (92 chars)

The Scientist's Toolkit

Table 2: Essential Research Reagents & Materials for SMP Device Development

| Item | Function in Research | Example Product/Specification |

|---|---|---|

| Methacrylated PCL | Photocurable SMP precursor providing shape memory properties and biocompatibility. | Mn = 5,000-20,000, methacrylate functionalization >95%. |

| Gold Nanorods | Photothermal nanofiller; converts NIR light to localized heat for remote, precise actuation. | λmax = 800-850 nm, OD = 10 in aqueous solution. |

| Graphene Oxide (GO) Sheets | Multifunctional nanofiller enhancing mechanical strength, thermal conductivity, and enabling photothermal/electrothermal response. | Single-layer proportion >95%, aqueous dispersion (5 mg/mL). |

| Cellulose Nanocrystals (CNC) | Biobased nanofiller for mechanical reinforcement and tuning of thermal transition temperatures. | Aqueous suspension (6 wt%), length 100-200 nm. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Highly efficient water-soluble photoinitiator for visible light (405 nm) DLP printing of hydrogels/SMPs. | Purity >98%, λmax ~ 375 nm. |

| Digital Light Processing (DLP) Printer | High-resolution 3D printing system for fabricating complex SMP device geometries from photocurable resins. | XY resolution: 50 μm, wavelength: 405 nm. |

| Micro-Computed Tomography (μCT) Scanner | Non-destructive 3D imaging for analyzing internal structure, porosity, and shape recovery dynamics of printed devices. | Resolution < 10 μm, in-situ heating stage. |

| Dynamic Mechanical Analyzer (DMA) | Characterizes thermomechanical properties (storage/loss modulus, tan δ, Tg/Ttrans) crucial for SMP programming. | Temperature range: -150°C to 500°C, film tension or compression clamps. |

Overcoming Challenges: Optimizing Printability, Performance, and Reliability of 3D-Printed SMPNCs

Within a research thesis on 3D printing shape memory polymer nanocomposites (SMPNCs) for biomedical and drug delivery applications, achieving consistent print fidelity is paramount. Nanocomposite inks, integrating nanoparticles (e.g., carbon nanotubes, graphene, nanoclay) into a shape memory polymer matrix, introduce unique rheological challenges that exacerbate common extrusion-based printing defects. This document provides targeted application notes and protocols to mitigate three critical defects: warping, layer delamination, and nozzle clogging.

Table 1: Primary Causes and Quantitative Impact of Common Defects in SMPNC Printing

| Defect | Primary Causes in SMPNCs | Key Measurable Parameters | Typical Impact on Print Quality (Quantitative Range) | Relevant Material Properties |

|---|---|---|---|---|

| Warping | High residual stress from uneven cooling; Differential shrinkage due to nanoparticle aggregation; High coefficient of thermal expansion (CTE). | Corner Lift Height (μm), Bed Adhesion Force (N), Residual Stress (MPa). | Corner lift: 50-500 μm; Dimensional error: 2-15%. | Glass Transition Temp (Tg), CTE, Thermal Conductivity, Storage Modulus (G'). |