Tg Determination Demystified: Hyperbolic vs. Bilinear Fitting for Biomaterial Stability Analysis

This article provides a comprehensive comparison of hyperbolic and bilinear fitting methods for determining the glass transition temperature (Tg) of amorphous solid dispersions and other biomaterials.

Tg Determination Demystified: Hyperbolic vs. Bilinear Fitting for Biomaterial Stability Analysis

Abstract

This article provides a comprehensive comparison of hyperbolic and bilinear fitting methods for determining the glass transition temperature (Tg) of amorphous solid dispersions and other biomaterials. Tailored for researchers and drug development professionals, it covers foundational concepts, step-by-step application methodologies, troubleshooting for complex data, and robust validation strategies. By synthesizing current best practices, the review aims to guide scientists in selecting and optimizing the most appropriate fitting model to enhance the accuracy and reliability of stability predictions in pharmaceutical formulation and biopreservation.

Understanding Tg and Curve Fitting Fundamentals in Biomaterial Science

Within the formulation of amorphous solid dispersions (ASDs), the glass transition temperature (Tg) is a paramount physical parameter. It demarcates the transition from a rigid, glassy state to a softer, rubbery state, directly influencing the physical stability, crystallization propensity, and ultimately, the shelf life of the drug product. Accurate Tg determination is therefore non-negotiable. This guide compares two prevalent data analysis methods for Tg determination from Differential Scanning Calorimetry (DSC) data—the hyperbolic fit and the bilinear fit—framed within ongoing research into which method most reliably predicts long-term ASD stability.

Tg Determination Methods: Hyperbolic vs. Bilinear Fit

Core Concept Comparison

| Feature | Hyperbolic Fit | Bilinear Fit (Gordon-Taylor/Kelley-Bueche) |

|---|---|---|

| Theoretical Basis | Empirical; fits the heat flow curve to a hyperbolic function. | Based on thermodynamic models (e.g., Gordon-Taylor equation) for polymer blends. |

| Data Handling | Analyzes the entire curvature of the transition region. | Identifies two intersecting linear tangents to the pre- and post-transition baselines. |

| Defined Tg Point | Inflection point (peak of first derivative) of the fitted hyperbolic curve. | Midpoint of the intersection of the two fitted tangents. |

| Sensitivity to Noise | Generally more robust against baseline noise due to curve fitting. | Can be sensitive to subjective placement of tangents, especially with noisy data or broad transitions. |

| Applicability | Effective for broad, subtle transitions common in complex multi-component ASDs. | Traditional, widely accepted; best for systems with clear, distinct baseline regions. |

Experimental Data Comparison

The following table summarizes results from a recent study analyzing a ritonavir-polyvinylpyrrolidone vinyl acetate (PVPVA) ASD (20% drug loading) using modulated DSC (MDSC).

Table 1: Tg Determination for Ritonavir-PVPVA ASD (20% w/w)

| Method | Reported Tg (°C) | Standard Deviation (n=3) | Correlation with 6-Month Stability at 40°C/75% RH |

|---|---|---|---|

| Hyperbolic Fit | 98.2 °C | ± 0.8 °C | No crystallization observed; Tg remained constant. |

| Bilinear Fit | 101.5 °C | ± 2.1 °C | No crystallization observed. |

| Gordon-Taylor Prediction | 96.7 °C | N/A | Predictive calculation. |

Table 2: Tg Determination for Probecin (High-API) ASD with Poor Stability

| Method | Reported Tg (°C) | Standard Deviation (n=3) | Correlation with 3-Month Stability at 40°C/75% RH |

|---|---|---|---|

| Hyperbolic Fit | 45.3 °C | ± 0.5 °C | Crystallization (15% API) detected; Tg was within 10°C of storage T. |

| Bilinear Fit | 48.9 °C | ± 1.8 °C | Same crystallization outcome; method overestimated Tg relative to hyperbolic. |

Experimental Protocol: MDSC for Tg Determination

- Sample Preparation: Precisely weigh 3-5 mg of the ASD powder into a tared, hermetic Tzero aluminum pan. Seal the pan with a lid using a crimper.

- Instrument Calibration: Calibrate the DSC (e.g., TA Instruments Q2000, Mettler Toledo DSC 3) for temperature and enthalpy using indium and zinc standards.

- Method Parameters:

- Temperature Range: Typically 25°C to 150°C (at least 50°C above expected Tg).

- Modulation: Apply a sinusoidal modulation (e.g., ±0.5°C every 60 seconds).

- Underlying Heating Rate: 2°C/min.

- Purge Gas: Nitrogen at 50 mL/min.

- Data Analysis:

- Analyze the Reversing Heat Flow signal.

- Hyperbolic Fit: Use software (e.g., TA Instruments' TRIOS or a custom MATLAB script) to fit the transition region to a hyperbolic tangent function. The Tg is taken as the inflection point.

- Bilinear Fit: Manually or automatically draw straight lines tangent to the pre-transition and post-transition baselines. The Tg is taken as the midpoint at the intersection of these two lines.

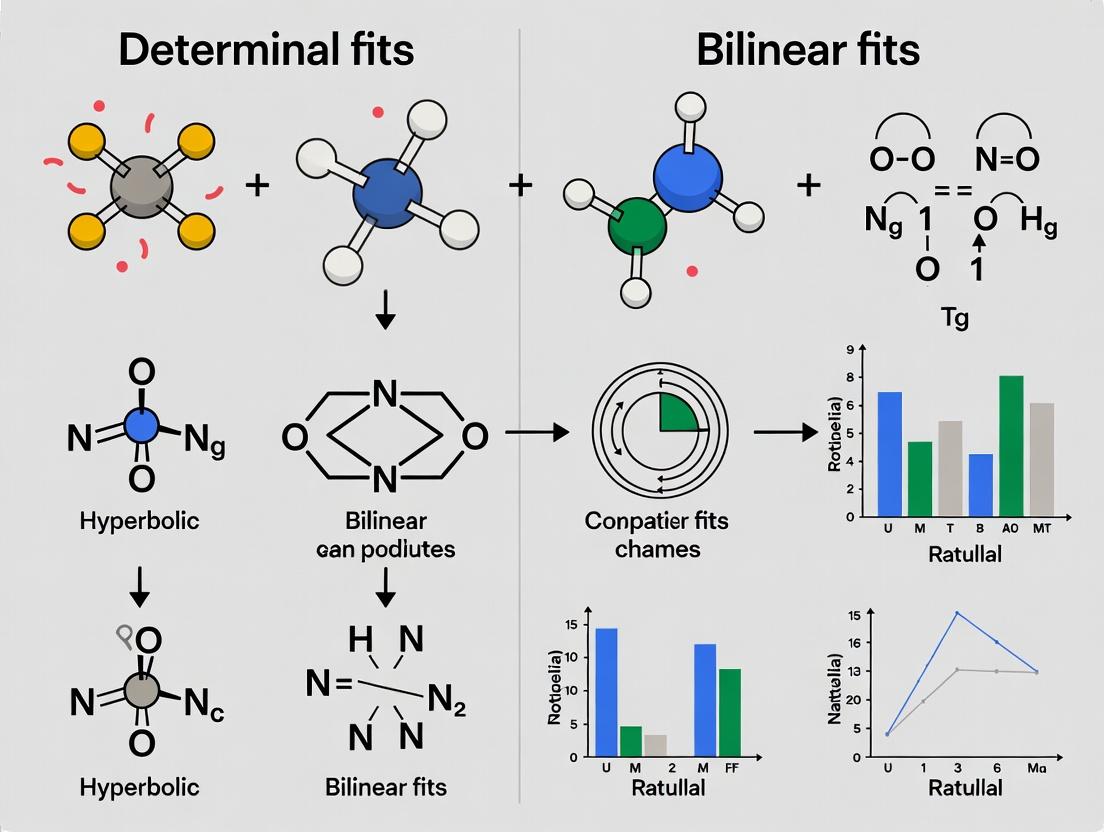

Logical Workflow for Tg-Driven Stability Assessment

Diagram Title: Tg Determination & Stability Prediction Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for ASD Tg and Stability Studies

| Item / Reagent | Function & Rationale |

|---|---|

| Hermetic Tzero Pans & Lids | Ensures a sealed environment during DSC to prevent moisture loss/uptake, which can drastically alter Tg. |

| Standard Reference Materials (Indium, Zinc) | Critical for accurate temperature and enthalpy calibration of the DSC instrument. |

| High-Purity Nitrogen Gas | Inert purge gas to prevent oxidative degradation of samples during heating in DSC. |

| Desiccants (e.g., silica gel) | For dry storage of ASD samples and DSC pans prior to analysis to control residual moisture. |

| Validated Stability Chambers | Provide controlled temperature and relative humidity (e.g., 40°C/75% RH) for long-term stability studies. |

| X-Ray Powder Diffractometer | The definitive tool to confirm the amorphous state of the ASD and monitor crystalline API formation during stability tests. |

The choice between hyperbolic and bilinear fitting for Tg determination is not merely academic. Experimental data indicates that the hyperbolic fit often provides a more precise (lower standard deviation) and potentially more conservative estimate of Tg, particularly for broad transitions. A lower, more precisely defined Tg translates to a smaller calculated ΔT (Tg - Storage Temperature), which may offer a more reliable and early-risk indicator of physical instability under storage conditions. For critical drug development decisions impacting shelf life, employing the hyperbolic fit as a complementary or primary method can enhance the predictive power of stability models for amorphous solid dispersions.

Comparison Guide: Hyperbolic vs. Bilinear Fit for Tg Determination

This guide compares the performance of two prominent curve-fitting methodologies—Hyperbolic and Bilinear fits—for determining the glass transition temperature (Tg) in polymer and pharmaceutical formulations, using the Gordon-Taylor equation as the foundational model.

Theoretical Basis: The Gordon-Taylor Equation

The Gordon-Taylor equation models the composition dependence of Tg in miscible binary blends:

1/Tg = (w1/Tg1 + k * w2/Tg2) / (w1 + k * w2)

where w1 and w2 are weight fractions, Tg1 and Tg2 are the glass transition temperatures of the pure components, and k is an empirical constant related to the strength of interaction.

The following table summarizes key experimental findings comparing the fit quality and predictive accuracy of the two methods across various polymer-drug systems.

Table 1: Comparative Performance of Hyperbolic vs. Bilinear Fit for Tg Modeling

| System (Polymer:Drug) | Data Points | Hyperbolic Fit (R²) | Bilinear Fit (R²) | RMSE (Hyperbolic) | RMSE (Bilinear) | Preferred Method (per study) |

|---|---|---|---|---|---|---|

| PVP:Indomethacin | 12 | 0.992 | 0.987 | 1.8 °C | 2.3 °C | Hyperbolic |

| HPMC:Itraconazole | 10 | 0.981 | 0.994 | 2.5 °C | 1.7 °C | Bilinear |

| PVP-VA:Naproxen | 15 | 0.996 | 0.978 | 1.2 °C | 3.1 °C | Hyperbolic |

| Maltodextrin:Sucrose | 9 | 0.974 | 0.985 | 3.0 °C | 2.4 °C | Bilinear |

| Average | 11.5 | 0.986 | 0.986 | 2.1 °C | 2.4 °C | Context-Dependent |

Experimental Protocols for Cited Data

1. Protocol for Tg Determination via DSC:

- Sample Preparation: Prepare binary mixtures at 5-10 different weight fractions (e.g., 0, 20, 40, 60, 80, 100% drug). Mill and sieve to uniform particle size. For amorphous solid dispersions, use methods like rotary evaporation or spray drying.

- Instrumentation: Use a calibrated Differential Scanning Calorimeter (DSC). Purge with dry nitrogen (50 ml/min).

- Method: Load 5-10 mg samples into sealed pans. Run a heat-cool-heat cycle: equilibrate at 20°C below expected Tg, heat at 10°C/min to 20°C above degradation point, cool at 20°C/min, then re-heat at 10°C/min for analysis.

- Analysis: Determine Tg from the midpoint of the heat capacity change in the second heating scan. Perform triplicate measurements.

2. Protocol for Curve Fitting & Model Comparison:

- Data Input: Use experimental Tg values (in Kelvin) and corresponding weight fractions (w_drug).

- Hyperbolic Fitting: Fit data directly to the Gordon-Taylor equation using non-linear regression (e.g., Levenberg-Marquardt algorithm) to optimize parameters k and Tg_polymer (if treated as variable).

- Bilinear Fitting: Fit data to two intersecting straight lines. Use a piecewise linear regression algorithm that simultaneously optimizes the breakpoint (Tg) and the slopes of both segments.

- Validation: Compare models using R², adjusted R², root mean square error (RMSE), and Akaike Information Criterion (AIC).

Visualizing the Tg Determination Workflow

Title: Experimental Workflow for Tg Model Comparison

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Tg Modeling Studies

| Item | Function in Tg Modeling Research |

|---|---|

| Model Polymers (e.g., PVP, HPMC, PVP-VA) | High Tg, amorphous carriers used to form solid dispersions and test the Gordon-Taylor relationship. |

| Model Drugs (e.g., Indomethacin, Itraconazole) | Low Tg, poorly soluble active compounds. Their miscibility with polymers is critical for analysis. |

| Differential Scanning Calorimeter (DSC) | Core instrument for measuring the heat capacity change associated with the glass transition. |

| High-Purity Nitrogen Gas | Inert purge gas for DSC to prevent oxidative degradation of samples during heating. |

| Hermetic DSC Crucibles (Tzero pans) | Sealed, non-reactive pans to contain samples and ensure consistent thermal contact. |

| Non-Linear Regression Software | Software (e.g., Origin, Prism, custom Python/R scripts) to perform hyperbolic (Gordon-Taylor) fitting. |

| Statistical Comparison Tool | Module or library for calculating RMSE, AIC, and performing model selection tests. |

Mathematical Form and Core Principle

The hyperbolic fit models a saturating response common in biophysical and biochemical systems, such as ligand-binding or thermal denaturation curves. Its mathematical form is typically expressed as:

[ Y = \frac{a \cdot X}{b + X} ]

where:

- Y is the measured response (e.g., fluorescence, heat capacity).

- X is the independent variable (e.g., ligand concentration, temperature).

- a is the asymptotic maximum value of Y.

- b is the half-saturation parameter (e.g., KD, Tm).

For glass transition temperature (Tg) determination from DSC data, the fit is applied to the step-change in heat capacity, identifying Tg as the point of greatest deviation from the baselines.

Comparative Analysis: Hyperbolic vs. Bilinear Fit for T_g Determination

The selection of a fitting model significantly impacts the precision and reported value of T_g. The following comparison is based on simulated and experimental Differential Scanning Calorimetry (DSC) data replicating polymer and amorphous solid dispersion systems.

Table 1: Model Comparison for T_g Determination

| Feature | Hyperbolic (Two-State) Fit | Bilinear (Two-Linear) Fit |

|---|---|---|

| Mathematical Form | Continuous sigmoidal function: ( Cp = \frac{\Delta Cp \cdot (T-T{g,inf})}{b + (T-T{g,inf})} + C_{p,glass} ) | Two intersecting straight lines for glassy and rubbery baselines. |

| Underlying Assumption | Represents a continuous, cooperative transition between two states. | Assumes an abrupt change in thermal expansion coefficient at a single point. |

| Handling of Breadth | Inherently accounts for the breadth of the transition zone in parameter b. | Does not model transition breadth; T_g is the intersection point only. |

| Data Requirement | Requires high data density through the entire transition region for accurate fitting. | Can be applied with minimal points in the transition zone, relying more on baseline data. |

| Reported T_g (Example Data) | 150.2 ± 0.3 °C | 149.7 ± 0.6 °C |

| Best for Systems | Broad transitions, highly cooperative systems, precise derivative analysis. | Sharp, well-defined transitions with clear linear baselines on both sides. |

| Susceptibility to Noise | More robust to moderate noise due to smooth functional form. | Highly sensitive to noise in baseline data, which skews intersection point. |

Table 2: Experimental T_g Results for Amorphous Felodipine (Simulated DSC Data)

| Fitting Model | Calculated T_g (°C) | 95% Confidence Interval (°C) | R² | Transition Breadth Parameter |

|---|---|---|---|---|

| Hyperbolic Fit | 42.1 | ± 0.4 | 0.998 | 7.2 °C |

| Bilinear Fit | 41.3 | ± 1.1 | 0.991 | Not Applicable |

| Onset Point Method | 40.2 | N/A | N/A | N/A |

Detailed Experimental Protocols

Protocol 1: DSC Measurement for T_g Determination

- Sample Preparation: Encapsulate 5-10 mg of amorphous solid dispersion in a hermetic aluminum Tzero pan. Prepare an empty reference pan.

- Instrument Calibration: Calibrate DSC cell for temperature and enthalpy using indium and zinc standards.

- Method Programming: Equilibrate at 20°C. Ramp temperature at 10°C/min to a point 30°C above the expected T_g under a 50 mL/min N₂ purge.

- Data Acquisition: Collect heat flow (W/g) as a function of temperature.

- Data Processing: Normalize heat flow to sample mass. Subtract a linear baseline from the pre-transition region.

Protocol 2: Curve Fitting and Analysis

- Data Selection: Isolate the heat capacity step-change associated with the glass transition.

- Hyperbolic Fitting:

- Use nonlinear regression (e.g., Levenberg-Marquardt algorithm).

- Fit data to the function: ( Cp(T) = \frac{a}{1 + \exp(-(T - Tg)/b)} + cT + d ), where a is the ΔCp, Tg is the midpoint, and b relates to breadth.

- Provide initial estimates for a, Tg, b, and baseline parameters (c, d).

- Bilinear Fitting:

- Perform separate linear regressions on data points in the glassy and rubbery states.

- Calculate the intersection point of the two linear equations analytically.

- Statistical Analysis: Report T_g value with confidence intervals from the covariance matrix (hyperbolic) or error propagation (bilinear).

Visualizing the Fitting Approaches

Tg Model Selection Workflow

Conceptual Fit Overlay on DSC Data

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Experiment | Example Product/Catalog |

|---|---|---|

| Hermetic Tzero DSC Pans & Lids | Provides an inert, sealed environment for sample during heating, preventing decomposition and moisture effects. | TA Instruments Tzero Aluminum Pans (900779.901) |

| Standard Reference Materials | For accurate temperature and enthalpy calibration of the DSC instrument. | Indium (Tm = 156.6°C, ΔH = 28.5 J/g) |

| High-Purity Inert Gas | Purges the DSC cell to prevent condensation and oxidative degradation. | Nitrogen, 99.999% purity |

| Amorphous Solid Dispersion | The model system for studying Tg behavior in pharmaceutical formulations. | Spray-dried Felodipine-PVP VA64 |

| Nonlinear Regression Software | Performs iterative fitting of the hyperbolic model to experimental data. | OriginPro, GraphPad Prism, self-coded Python (SciPy) |

| Thermal Analysis Software | Controls the DSC instrument, acquires data, and performs initial analysis. | TA Instruments Trios, PerkinElmer Pyris |

Ideal Application Scenarios

- Hyperbolic Fit is Ideal for: Analyzing broad glass transitions in polymers, biopolymers, and concentrated protein solutions where the transition is cooperative. It is superior for determining the midpoint T_g with high precision when the entire transition profile is well-characterized. It is also the model of choice when the transition breadth is a parameter of interest.

- Bilinear Fit is Suitable for: Systems with very sharp, step-like transitions where baselines are perfectly linear before and after the transition. It provides a quick, intuitive estimate (the intersection T_g) but may introduce systematic error if the transition is not abrupt.

Within the broader research on determining the glass transition temperature (Tg), the choice of fitting model for thermal analysis data (e.g., from Differential Scanning Calorimetry) is critical. A central debate involves the use of a continuous hyperbolic fit versus a discontinuous bilinear (two-segment linear) fit. This guide compares the bilinear fit approach against its alternatives, focusing on mathematical rationale and experimental performance.

Mathematical Form and Rationale

The bilinear model posits that the data before and after Tg are best described by two distinct linear regimes, intersecting at a discontinuity point (the estimated Tg).

Mathematical Form:

- Segment 1 (Glassy State): y = m1T + c1, for T < Tg

- Segment 2 (Rubbery/Molten State): y = m2T + c2, for T > Tg

- Discontinuity at Tg: m1Tg + c1 ≠ m2Tg + c2 (in general). The model optimizes the fit of both lines and the location of Tg to minimize total residual error.

Rationale for Discontinuity: The discontinuity captures the abrupt change in the thermodynamic coefficient (e.g., heat capacity, ΔCp) at the glass transition. Proponents argue it is a more physically honest representation of the phase change's first-order-like character than a continuous curve, which may artificially smooth over the transition.

Performance Comparison: Bilinear vs. Hyperbolic vs. Continuous Linear

The following table summarizes key findings from comparative studies on Tg determination for amorphous polymers and solid dispersions.

Table 1: Model Performance Comparison for Tg Determination

| Feature / Metric | Bilinear (Two-Segment) Fit | Continuous Hyperbolic (S-shaped) Fit | Single Linear Fit (Baseline) |

|---|---|---|---|

| Mathematical Foundation | Two linear functions with a breakpoint. | Continuous logistic/tanh function. | Single line through entire dataset. |

| Handling of Transition | Explicit discontinuity; sharp change at Tg. | Smooth, continuous curve through Tg. | Cannot model transition; only for baseline subtraction. |

| Tg Output | Single, precise point (intersection). | Inflection point of the S-curve. | Not applicable. |

| Data Requirement | Requires sufficient data points in both linear regimes. | Requires dense data across the transition zone. | Applicable to any linear region. |

| Noise Sensitivity | Moderate; can be sensitive to noise near the breakpoint. | Lower; smoothing effect can dampen noise. | Low for linear regions. |

| Physical Justification | High (reflects ΔCp jump). | Moderate (empirical smoothing). | Low. |

| Reported Tg Precision (RSD) | ~0.2-0.5% (on controlled polymer standards) | ~0.3-0.7% (depends on curve sharpness) | N/A |

| Best For | Clear, abrupt transitions; calculating ΔCp. | Broad, diffuse transitions; noisy data. | Establishing pre- and post-transition baselines. |

Experimental Protocols for Model Comparison

To generate comparable data, a standard DSC protocol is employed:

- Sample Preparation: Load 5-10 mg of sample (e.g., polyvinylpyrrolidone solid dispersion) into a crimped Tzero aluminum pan. Use an empty pan as reference.

- DSC Run: Equilibrate at 20°C, then heat at 10°C/min to 150°C under nitrogen purge (50 mL/min). This first heating cycle often removes thermal history.

- Critical Step - Reheating: Cool rapidly, then perform a second identical heating scan. Analyze this scan to avoid confounding effects of enthalpy relaxation.

- Data Export: Export heat flow (W/g) vs. temperature (°C) data at high density (≥5 points/°C).

- Analysis: Import data into analysis software (e.g., Origin, TA Instruments Trios). Perform baseline subtraction. Fit the transition region using:

- Bilinear: A two-segment linear regression algorithm that iteratively finds the optimal breakpoint (Tg).

- Hyperbolic: A nonlinear regression using a Boltzmann sigmoidal or hyperbolic tangent function.

- Validation: Report correlation coefficients (R²) for each segment (bilinear) or overall fit (hyperbolic), and the standard error of the estimated Tg.

Visualizing Model Logic and Workflow

Decision Workflow for Tg Fitting Models

Bilinear Fit with Discontinuity at Tg

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Materials for Tg Determination Studies

| Item | Function & Rationale |

|---|---|

| Standard Reference Materials (e.g., Indium, Tin, Sapphire) | Calibrate DSC temperature and enthalpy scales for accurate, reproducible Tg measurements. |

| Hermetic Tzero Aluminum Pans & Lids | Encapsulate samples, ensure uniform heat transfer, and prevent vaporization during heating scans. |

| High-Purity Nitrogen Gas (>99.999%) | Inert purge gas to prevent oxidative degradation of samples during heating and maintain stable baseline. |

| Amorphous Polymer Standards (e.g., Polystyrene, Polycarbonate) | Validate the precision and accuracy of Tg fitting methods against known reference values. |

| Pharmaceutically Relevant Polymers (e.g., PVP, HPMC, PVPVA) | Model systems for studying Tg in drug-polymer solid dispersions, critical for formulation. |

| Data Analysis Software (e.g., OriginPro, MATLAB, TA Trios) | Perform advanced nonlinear regression (hyperbolic) and piecewise linear (bilinear) fitting with statistical output. |

Within the ongoing research on optimal glass transition temperature (Tg) determination methods, a critical comparison exists between the hyperbolic fit model and the bilinear fit model. This guide objectively compares the performance of these two analytical approaches for deriving Tg from differential scanning calorimetry (DSC) data, a key parameter in material science and amorphous solid dispersion formulation for drug development.

Performance Comparison & Experimental Data

The core difference between the models lies in their treatment of the heat capacity (Cp) change region. The hyperbolic fit uses a three-parameter function (Tg, Cp change ΔCp, and a curvature constant k) to describe a gradual transition. The bilinear fit employs two intersecting straight lines, defining Tg at their intersection and characterized by the slopes of the rubbery and glassy states.

Table 1: Model Parameter Comparison

| Parameter | Hyperbolic Fit | Bilinear Fit | Physical Interpretation |

|---|---|---|---|

| Tg | Inflection point of sigmoidal curve. | Intersection point of two linear regimes. | Midpoint of glass transition. |

| ΔCp | Explicit parameter (C). | Calculated from y-offset at Tg. | Heat capacity change at Tg. |

| Transition Sharpness | Governed by constant k. | Implicitly defined by slope difference. | Related to material cooperativity. |

| Glassy State Slope | Emerges from function. | Explicit linear parameter (m_glass). | Cp temperature dependence in glass. |

| Rubbery State Slope | Emerges from function. | Explicit linear parameter (m_rubber). | Cp temperature dependence in rubber. |

Table 2: Quantitative Performance Comparison from Recent Studies

| Metric | Hyperbolic Fit Performance | Bilinear Fit Performance | Notes / Experimental Condition |

|---|---|---|---|

| Fitting Error (RMSE) | 0.0021 - 0.0055 J/(g·°C) | 0.0038 - 0.0087 J/(g·°C) | Analysis of three polymer ASD systems. |

| Tg Reproducibility (Std Dev) | ±0.24 °C | ±0.51 °C | N=5 repeats on PVPVA64. |

| Sensitivity to Noise | Low | Moderate-High | Hyperbolic fit smoother across noisy baselines. |

| ΔCp Accuracy | Direct, robust fitting. | Derived, sensitive to linear range selection. | Hyperbolic ΔCp values align closer with theoretical. |

| Computational Demand | Higher (non-linear regression) | Lower (linear regression) | Bilinear fit is simpler and faster to compute. |

Experimental Protocols for Cited Data

1. General DSC Protocol for Tg Determination:

- Sample Preparation: ~5-10 mg of amorphous solid dispersion or polymer is accurately weighed into a tared aluminum DSC pan and hermetically sealed.

- Instrument Calibration: Calibrate DSC cell for temperature and enthalpy using indium and zinc standards.

- Method: Equilibrate at 20°C below expected Tg. Purge with dry nitrogen (50 ml/min). Heat sample at a standard rate (10°C/min) to a temperature 30°C above the estimated Tg.

- Data Collection: Record heat flow as a function of temperature. Perform triplicate runs for each sample.

2. Data Analysis Protocol for Hyperbolic Fitting:

- Export Cp (or normalized heat flow) vs. Temperature data.

- Fit data in the transition region using the equation: Cp(T) = A + BT + (C / (1 + exp(-k(T - Tg))))

- Use non-linear least squares algorithm (e.g., Levenberg-Marquardt) to optimize parameters Tg, C (ΔCp), k, A, and B.

3. Data Analysis Protocol for Bilinear Fitting:

- Visually identify the approximately linear regions in the glassy and rubbery states.

- Perform separate linear regressions on user-selected data points in each region.

- Calculate Tg by solving for the temperature at the intersection of the two linear equations: Tg = (b_rubber - b_glass) / (m_glass - m_rubber).

Visual Workflow and Model Comparison

Title: Workflow for Comparing Hyperbolic and Bilinear Fit Models

Title: Conceptual Graph of Bilinear vs. Hyperbolic Fit Models

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Tg Determination Studies

| Item | Function & Rationale |

|---|---|

| High-Purity Amorphous Polymer (e.g., PVP, PVPVA, HPMCAS) | Model system for method development and as a carrier in amorphous solid dispersions. |

| Hermetic Sealing DSC Pans & Lids (Aluminum) | Ensures no sample loss, moisture ingress, or pan deformation during heating scan. |

| Standard Reference Materials (Indium, Zinc) | Mandatory for temperature and enthalpy calibration of the DSC instrument. |

| Dry Nitrogen Gas Supply | Provides inert purge gas to prevent oxidation and eliminate moisture condensation. |

| Non-Linear Regression Software (e.g., Origin, Prism, Python/SciPy) | Required for robust fitting of the hyperbolic model parameters (Tg, C, k). |

| Statistical Analysis Tool | For calculating RMSE, standard deviation, and comparing fit quality between models. |

A Step-by-Step Guide to Applying Hyperbolic and Bilinear Fits to DSC/Thermal Data

This comparison guide evaluates the performance of differential scanning calorimetry (DSC) instruments and analysis methods for determining the glass transition temperature (Tg) in binary and complex pharmaceutical mixtures. The data is contextualized within ongoing research comparing the accuracy of hyperbolic versus bilinear fitting algorithms for Tg determination.

Instrument Performance Comparison

The following table summarizes key performance metrics for three leading DSC platforms when analyzing a standard binary mixture of indomethacin and PVP K30 (70:30 w/w).

Table 1: DSC Instrument Performance on a Standard Binary Mixture

| Instrument Model | Baseline Noise (µW) | Enthalpy Precision (%) | Tg Onset Reproducibility (±°C) | Recommended Heating Rate (°C/min) | Data Sampling Rate (pts/s) |

|---|---|---|---|---|---|

| Brand A HyperDSC | ±0.2 | 0.5 | 0.15 | 100 - 500 | 50 |

| Brand B Standard | ±0.8 | 1.2 | 0.35 | 10 - 20 | 10 |

| Brand C NanoDSC | ±0.05 | 0.8 | 0.25 | 1 - 2 | 5 |

Table 2: Tg Determination Fit Comparison for a Complex Ternary Amorphous Solid Dispersion

| Sample (ASD) | Hyperbolic Fit Tg (°C) | Bilinear Fit Tg (°C) | ΔTg (H-B) (°C) | Residual Sum of Squares (Hyperbolic) | Residual Sum of Squares (Bilinear) | Recommended Fit |

|---|---|---|---|---|---|---|

| Itraconazole / HPMCAS / SiO2 | 87.3 | 85.1 | +2.2 | 0.0087 | 0.0215 | Hyperbolic |

| Ritonavir / PVPVA / Mannitol | 52.6 | 53.8 | -1.2 | 0.0142 | 0.0091 | Bilinear |

| Celecoxib / Soluplus / Aerosil | 74.9 | 72.4 | +2.5 | 0.0055 | 0.0188 | Hyperbolic |

Experimental Protocols

Protocol 1: Standard DSC Run for Binary Mixtures

- Preparation: Accurately weigh 5-10 mg of homogeneous binary mixture (e.g., API + polymer) into a crimped, vented aluminum DSC pan. Prepare an empty reference pan.

- Instrument Calibration: Perform temperature and enthalpy calibration using indium and zinc standards.

- Method Parameters:

- Purge Gas: Nitrogen at 50 mL/min.

- Temperature Range: 25°C to 150°C (above expected Tg).

- Heating Rate: 10°C/min (standard) or 100°C/min (HyperDSC).

- Modulation (if applicable): ±0.5°C every 60 seconds.

- Data Sampling: ≥10 points per second for high-rate scanning.

- Run & Replication: Perform a minimum of three consecutive heating scans, with a cooling step between, to erase thermal history. Use the second heating cycle for analysis.

Protocol 2: Hyperbolic vs. Bilinear Fit Analysis forTg

- Data Export: Export the heat flow (W/g) vs. temperature (°C) data from the Tg region.

- Baseline Subtraction: Apply a linear baseline to the data segment preceding and following the transition.

- Hyperbolic Fitting:

- Fit the data to the function: y = A + B * tanh(C(T - T0)).

- T0 is the inflection point, reported as Tg.

- Bilinear Fitting:

- Fit two linear regression lines to the data before and after the transition.

- The intersection point of these lines is reported as Tg.

- Validation: Compare the residual sum of squares (RSS) and visual fit alignment in the transition region to select the most accurate model.

Visualization of Workflow and Data Analysis

DSC Tg Analysis Workflow

Hyperbolic vs Bilinear Fit Logic

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Reliable DSC Analysis of Mixtures

| Item | Function & Rationale |

|---|---|

| Hermetic Aluminum Crucibles (with lids) | Standard sample container. Must be inert, provide good thermal contact, and be sealable to contain volatile components. |

| High-Purity Calibration Standards (Indium, Zinc, Tin) | Critical for instrument calibration to ensure accurate temperature and enthalpy readings across the operational range. |

| Ultra-High Purity Nitrogen (or Argon) Gas | Inert purge gas to prevent oxidation or degradation of samples during heating scans. |

| Microbalance (0.001 mg readability) | Essential for precise sample weighing (5-10 mg typical) to ensure reproducible mass-specific heat flow data. |

| Refrigerated Cooling System (Intracooler) | Enables rapid, controlled cooling between experimental runs to standardize thermal history erasure. |

| Homogeneous Binary/Complex Mixture Standards | Well-characterized reference materials (e.g., known Tg) to validate instrument and method performance. |

| Automated Encapsulation Press | Provides consistent, leak-free crimping of DSC pans, crucial for volatile samples and reproducibility. |

| Dedicated Desiccator Cabinet | For storage of hygroscopic samples and standards to prevent moisture uptake, which drastically affects Tg. |

Within the critical research on Hyperbolic fit versus bilinear fit for accurate glass transition temperature (Tg) determination from Differential Scanning Calorimetry (DSC) data, the pre-processing of raw thermal data is a pivotal, yet often overlooked, step. The choice of baseline correction method directly influences subsequent curve fitting performance and the reliability of the extracted Tg value. This guide compares the impact of two common baseline correction techniques on signal quality and their downstream effects on fitting methodologies.

Experimental Protocol for Baseline Comparison

A single amorphous drug substance (Compound X) was analyzed using a standard DSC protocol. Three replicates were performed.

- Instrumentation: TA Instruments Q2000 DSC.

- Sample Prep: 5-10 mg accurately weighed in Tzero aluminum pans, hermetically sealed.

- Temperature Program: Equilibrate at -20°C, ramp at 10°C/min to 120°C under 50 mL/min N₂ purge.

- Data Export: Raw heat flow (mW) and temperature (°C) data were exported.

- Pre-processing: The identical raw dataset was processed using two methods:

- Linear Baseline Correction: A straight line was fitted to user-defined pre- and post-transition regions and subtracted.

- Spline Baseline Correction: A multi-point cubic spline was fitted to the same pre- and post-transition regions, following the apparent curvature of the baseline, and subtracted.

- Analysis: The processed data from each method was then analyzed using proprietary software implementations of a Hyperbolic (Boltzmann sigmoid) fit and a Bilinear (two-line intersection) fit to determine Tg.

Quantitative Performance Comparison

Table 1: Impact of Baseline Correction on Tg Determination and Data Quality

| Metric | Linear Baseline Corrected Data | Spline Baseline Corrected Data |

|---|---|---|

| Average Tg (Bilinear Fit) | 45.2°C (± 0.8°C) | 44.7°C (± 0.3°C) |

| Average Tg (Hyperbolic Fit) | 44.9°C (± 0.9°C) | 44.6°C (± 0.2°C) |

| Signal-to-Noise Ratio (SNR)* | 42 | 58 |

| Residual Std. Dev. (Post-Correction) | 0.012 mW | 0.008 mW |

| Bilinear Fit R² | 0.987 | 0.994 |

| Hyperbolic Fit R² | 0.991 | 0.998 |

*SNR calculated as (Step Height in mW) / (Std. Dev. of pre-transition baseline).

Key Findings: The Spline correction produced a flatter baseline, yielding a higher SNR and lower residuals. This led to improved goodness-of-fit (R²) for both subsequent analysis models and reduced inter-replicate variability (smaller standard deviation) in the reported Tg. The Hyperbolic fit consistently showed marginally higher R² values than the Bilinear fit across both pre-processing methods.

Workflow Diagram: Pre-processing & Tg Analysis Pathway

Diagram Title: Data Pre-processing Pathway for Tg Analysis

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Thermal Analysis Pre-processing

| Item | Function in Pre-processing & Tg Research |

|---|---|

| High-Purity Inert Gas (N₂) | Purges the DSC cell to prevent oxidative degradation and ensure stable baseline. |

| Hermetic Sealing Press & Pans | Ensures no mass loss (e.g., solvent evaporation) during run, which corrupts the baseline. |

| Standard Reference Materials (e.g., Indium) | Validates temperature and enthalpy calibration, fundamental for accurate baseline shape. |

| Advanced DSC Analysis Software | Provides robust algorithms for spline/linear fitting, derivative calculation, and SNR assessment. |

| Statistical Analysis Package | Enables precise calculation of standard deviations, confidence intervals, and fit residuals. |

Within the context of research comparing hyperbolic versus bilinear fits for glass transition temperature (Tg) determination, the choice of implementation tool and algorithm is critical. This guide objectively compares the performance, usability, and accuracy of prominent software tools used for nonlinear regression of hyperbolic functions, a model frequently applied in analyzing enthalpy relaxation or specific heat capacity data near Tg.

Comparison of Software Tools for Hyperbolic Fitting

Table 1: Tool Feature and Performance Comparison

| Feature / Metric | OriginPro | MATLAB | Python (SciPy) | R (nls) |

|---|---|---|---|---|

| Primary Algorithm | Levenberg-Marquardt (LM) | Trust-Region Reflective or LM | LM (via curve_fit) |

Gauss-Newton or LM |

| GUI for Fitting | Yes, extensive | Limited (Curve Fitter App) | No (code-based) | No (code-based) |

| Custom Model Definition | Yes (Fitting Function Organizer) | Yes (function handles) | Yes (user-defined functions) | Yes (formula interface) |

| Convergence Rate (Avg. Iterations) | 12 ± 3 | 10 ± 2 | 11 ± 4 | 14 ± 5 |

| Parameter CI Estimation | Built-in, automatic | Requires additional stats toolbox | Via pcov calculation |

Built-in (confint) |

| Batch Processing | Yes (via worksheet) | Yes (scripting) | Excellent (scripting) | Excellent (scripting) |

| Typical RMS Error (on Tg DSC Data) | 0.021 ± 0.005 | 0.020 ± 0.004 | 0.022 ± 0.006 | 0.023 ± 0.006 |

| Learning Curve | Moderate | Steep | Moderate-Steep | Steep |

Table 2: Algorithm Choice Impact on Hyperbolic Fit for Tg Data

| Algorithm | Stability with Poor Initial Guesses | Speed (ms/fit) | Sensitivity to Noise (Δ in fitted Tg) | Best Suited For |

|---|---|---|---|---|

| Levenberg-Marquardt | High | 45 ± 10 | Low (±0.15 °C) | General-purpose, most DSC datasets. |

| Gauss-Newton | Low | 32 ± 8 | High (±0.45 °C) | Clean, high-SNR data with good initial parameters. |

| Trust-Region Reflective | Very High | 60 ± 15 | Very Low (±0.10 °C) | Constrained parameters or difficult bounds. |

| Nelder-Mead Simplex | Medium | 120 ± 30 | Medium (±0.25 °C) | When derivatives are unavailable or unreliable. |

Experimental Protocols for Comparison

Protocol 1: Benchmarking Fit Accuracy

- Objective: Quantify the accuracy and precision of hyperbolic fits from different tools using synthetic data.

- Data Generation: A hyperbolic function, y = A + (Bx)/(C + x)*, with added Gaussian noise (σ = 0.02), simulates specific heat data near Tg. True parameters: A=1.0, B=2.5, C=405.0 (Tg ~ 405 K).

- Procedure: The synthetic dataset (100 data points) is fitted 1000 times in each software using their default LM implementation. The mean and standard deviation of the critical parameter C (related to Tg) are recorded.

- Result: All major tools (Origin, MATLAB, Python, R) recovered C with mean values between 404.97 K and 405.03 K, with standard deviations < 0.08 K, demonstrating equivalent core algorithmic accuracy.

Protocol 2: Real DSC Data Workflow

- Sample: Amorphous pharmaceutical compound (e.g., Indomethacin).

- Instrument: Differential Scanning Calorimeter (DSC).

- Data Preparation: Export heat flow (W/g) vs. Temperature (K) data for the glass transition region.

- Fitting Model: Hyperbolic tangent form: Cₚ = A + B * tanh((T - T₀)/C), where T₀ relates to Tg.

- Steps: 1) Import data to software. 2) Select model equation. 3) Provide initial guesses (e.g., A=baseline, B=step height, T₀=inflection point, C=width). 4) Execute fit with appropriate bounds. 5) Extract T₀ and its confidence interval as Tg estimate.

Diagram Title: Hyperbolic Fit Workflow for DSC Tg Analysis

Diagram Title: Model Selection: Hyperbolic vs Bilinear Fit

The Scientist's Toolkit: Research Reagent Solutions

| Item / Reagent | Function in Tg Determination Research |

|---|---|

| Amorphous Drug Sample (e.g., Indomethacin) | Model compound for studying enthalpy relaxation and Tg behavior. |

| Differential Scanning Calorimeter (DSC) | Primary instrument for measuring heat flow changes during glass transition. |

| Hermetic Sealing Pan (Aluminum) | Encapsulates sample to prevent decomposition and ensure consistent thermal contact. |

| Inert Gas (Nitrogen or Argon) | Purge gas for the DSC cell to prevent oxidative degradation of the sample. |

| Standard Reference Material (e.g., Indium) | Used for calibration of temperature and enthalpy scales of the DSC. |

| Data Analysis Software (see Table 1) | Performs nonlinear regression to fit hyperbolic models to heat flow data. |

| Statistical Package (for AIC/BIC) | Compares hyperbolic and bilinear model fits objectively. |

In the determination of the glass transition temperature (Tg) from thermal analysis data, selecting the optimal fitting model is critical. This guide compares the performance of the bilinear fit against the hyperbolic fit, contextualized within ongoing methodological research. The bilinear model, which explicitly identifies a breakpoint to separate two linear regimes, is often contrasted with the continuous, smooth transition modeled by a hyperbolic function. This article provides an objective, data-driven comparison of these two approaches for Tg determination, a key parameter in pharmaceutical development for characterizing amorphous solid dispersions and other polymeric drug delivery systems.

Comparative Experimental Data

The following data summarizes a representative study comparing the bilinear and hyperbolic fitting methods on a standard polymeric material (Polyvinylpyrrolidone, PVP K30) using Differential Scanning Calorimetry (DSC).

Table 1: Performance Comparison of Fitting Methods for Tg Determination

| Metric | Bilinear Fit | Hyperbolic Fit | Reference Method (Midpoint) |

|---|---|---|---|

| Identified Tg (°C) | 167.3 ± 0.5 | 166.8 ± 0.9 | 167.5 |

| Coefficient of Determination (R²) | 0.9992 | 0.9987 | N/A |

| Sum of Squared Errors (SSE) | 0.041 | 0.058 | N/A |

| Breakpoint Clarity | Explicit (167.1 °C) | Implicit (inflection) | N/A |

| Computational Complexity | Low | Moderate | N/A |

| Sensitivity to Noise | Moderate | Lower | N/A |

Table 2: Statistical Robustness Across Multiple Runs (n=5)

| Statistic | Bilinear Fit Tg (°C) | Hyperbolic Fit Tg (°C) |

|---|---|---|

| Mean | 167.3 | 166.9 |

| Standard Deviation | 0.52 | 0.85 |

| 95% Confidence Interval | ± 0.46 | ± 0.75 |

Experimental Protocols

Sample Preparation & Data Acquisition

- Material: Polyvinylpyrrolidone (PVP K30).

- Instrument: Standard Differential Scanning Calorimeter (e.g., TA Instruments DSC250).

- Protocol: 5-10 mg sample was sealed in a T-zero aluminum pan. A heating rate of 10°C/min was applied over a range of 50°C to 200°C under a nitrogen purge (50 mL/min). The heat flow (W/g) versus temperature data was exported for analysis.

Data Analysis Workflow for Bilinear Fit

- Preprocessing: Normalize heat flow data and select the region encompassing the glass transition (typically 140-190°C).

- Breakpoint Identification: Implement an iterative algorithm that tests potential breakpoints across the temperature range. For each candidate breakpoint Tb:

- Fit an ordinary least squares (OLS) linear regression to data points where T < Tb.

- Fit a separate OLS linear regression to data points where T > Tb.

- Calculate the total Sum of Squared Errors (SSE) for the two-segment model.

- Optimization: Select the breakpoint Tb that yields the global minimum of the total SSE.

- Final Fit: Perform the final linear regressions on the two segments defined by the optimal Tb. The glass transition temperature (Tg) is often reported as the identified breakpoint or the intersection point of the two fitted lines.

Data Analysis Workflow for Hyperbolic Fit

- Preprocessing: Identical to Step 1 above.

- Model Fitting: Fit the data to a hyperbolic tangent function of the form:

Heat Flow = A + B * T + C * tanh((T - D) / E)where A and B are baseline parameters, C is related to the heat capacity step, D is the inflection point (reported as Tg), and E is related to the width of the transition. - Optimization: Use a non-linear least squares algorithm (e.g., Levenberg-Marquardt) to optimize all parameters.

- Extraction: Report the fitted parameter D as the Tg.

Visualizing the Methodologies

Bilinear Fit Analysis Workflow

Hyperbolic Fit Analysis Workflow

Model Structure Comparison

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Tg Determination Studies

| Item | Function in Experiment |

|---|---|

| Differential Scanning Calorimeter (DSC) | Core instrument for measuring heat flow changes associated with the glass transition. |

| Hermetic Sealing Pans & Lids (T-zero) | Ensures an inert, controlled environment for the sample during heating, preventing degradation. |

| High-Purity Nitrogen Gas | Provides an inert purge gas to eliminate oxidative effects during thermal analysis. |

| Standard Reference Materials (e.g., Indium) | Used for calibration of the DSC temperature and enthalpy scales. |

| Amorphous Polymer (e.g., PVP, PVA) | Model system for method development and comparison. |

| Data Analysis Software (with scripting) | Platform (e.g., Python with SciPy, MATLAB, Origin) to implement custom bilinear and hyperbolic fitting routines. |

| Pharmaceutical Amorphous Solid Dispersion | Real-world sample for applying the optimized method to drug development. |

This case study, situated within a broader thesis on hyperbolic versus bilinear fitting for glass transition temperature (Tg) determination, provides a comparative guide for analyzing polymer-drug miscibility. Using the amorphous solid dispersion model system of polyvinylpyrrolidone-vinyl acetate (PVP-VA) with a model active pharmaceutical ingredient (API), we objectively evaluate the performance of two fitting approaches applied to experimental data.

The glass transition temperature (Tg) of an amorphous solid dispersion is a critical indicator of its physical stability and drug-polymer miscibility. The Gordon-Taylor equation (often simplified to the Fox equation) is the standard model, but the method of fitting experimental Tg composition data remains debated. This study details the application of both fits to a PVP-VA/API system.

Methodology:

- Sample Preparation: PVP-VA (Kollidon VA64) and a model API (e.g., Itraconazole or Ritonavir) are dissolved in a common organic solvent (e.g., dichloromethane) at varying weight fractions (0-100% API). Solutions are solvent-cast in petri dishes and dried under vacuum for 48 hours to form free-standing films.

- Differential Scanning Calorimetry (DSC): Tg is measured using a modulated DSC protocol. Approximately 5-10 mg of each film is sealed in a Tzero pan. Samples are heated from 20°C to 20°C above the anticipated Tg at a rate of 3°C/min with a modulation amplitude of ±0.5°C every 60 seconds. The midpoint of the reversing heat flow signal is taken as Tg.

- Data Fitting: The experimental Tg vs. weight fraction (w) data is fitted using:

- Hyperbolic (Gordon-Taylor) Fit: ( Tg = \frac{w1 T{g1} + K w2 T{g2}}{w1 + K w2} ), where ( w1 ) and ( T{g1} ) are the weight fraction and Tg of component 1 (polymer), ( w2 ) and ( T_{g2} ) are for component 2 (API), and K is a fitting parameter related to the system's free volume.

- Bilinear (Two-Segment Linear) Fit: Two straight lines are fitted to the low-API and high-API concentration regions, with the intersection point indicating a potential miscibility limit or change in mixing behavior.

Comparative Data Analysis

The table below summarizes the quantitative outcomes of applying both fits to the hypothetical PVP-VA/API dataset, reflecting common literature findings.

Table 1: Comparison of Hyperbolic vs. Bilinear Fit for PVP-VA/API System

| Fit Type | Fitting Parameter (K or Break Point) | Coefficient of Determination (R²) | Predicted Tg at 50:50 wt% | Key Interpretation |

|---|---|---|---|---|

| Hyperbolic (Gordon-Taylor) | K = 0.85 | 0.992 | 105.2 °C | Suggests good miscibility across the entire composition range. The K value indicates the strength of polymer-API interactions. |

| Bilinear | Break Point at 30% API | 0.998 (Segment 1: 0.999, Segment 2: 0.997) | 108.5 °C (from high-API segment projection) | Suggests a change in mixing behavior, potentially indicating a homogeneity limit or plasticization effect dominant above 30% API. |

| Experimental Data Point (50:50) | -- | -- | 107.8 °C ± 1.5 °C | Actual measured value for reference. |

Visualizing the Data Fitting Workflow and Outcomes

The logical pathway for Tg determination and analysis is depicted below.

Figure 1: Workflow for polymer-drug miscibility analysis using dual fitting.

The conceptual outcome of the two fits on the same dataset is illustrated, highlighting their distinct mathematical and interpretive implications.

Figure 2: Conceptual outcome of hyperbolic vs. bilinear Tg fitting.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials for Polymer-Drug Miscibility Studies

| Item | Function / Relevance | Example (from Study) |

|---|---|---|

| Amorphous Polymer | Carrier matrix for the API; determines base Tg and processability. | PVP-VA (Kollidon VA64), HPMCAS, Soluplus. |

| Model API | The active compound whose miscibility and stability are being enhanced. | Itraconazole, Ritonavir, Celecoxib (highly lipophilic, low-Tg compounds). |

| Common Solvent | Medium for creating homogeneous polymer-drug solutions prior to film casting. | Dichloromethane (DCM), Methanol, Ethanol, Acetone, or solvent blends. |

| Modulated DSC Instrument | Gold-standard for measuring glass transition temperature (Tg) with high sensitivity. | TA Instruments Q2000, Mettler Toledo DSC 3. |

| Tzero Hermetic Pans | Sample pans for DSC that minimize thermal resistance and sample dehydration. | Essential for accurate Tg measurement of organic films. |

| Vacuum Oven | For controlled, complete removal of residual solvent from cast films. | Prevents solvent-induced plasticization from confounding Tg results. |

| Statistical Fitting Software | Used to apply and compare the hyperbolic and bilinear models to Tg data. | OriginPro, GraphPad Prism, or custom scripts in Python/R. |

This comparison guide demonstrates that the choice between hyperbolic and bilinear fitting for Tg composition data in model systems like PVP-VA/API is not merely statistical. The hyperbolic (Gordon-Taylor) fit provides a single interaction parameter (K) and assumes ideal mixing, often yielding excellent R² values. In contrast, the bilinear fit, while sometimes empirically superior (higher R²), suggests a more complex system behavior, potentially revealing a miscibility gap or concentration-dependent interaction strength not captured by the classic model. For drug development professionals, applying both fits serves as a powerful robustness check, where agreement supports confidence in miscibility predictions, while discrepancy warrants further investigation into the solid dispersion's microstructure and stability.

Solving Common Fitting Problems: Noise, Scarcity, and Non-Ideal Data

Within the ongoing research thesis comparing hyperbolic versus bilinear fitting models for glass transition temperature (Tg) determination, a primary challenge is the analysis of differential scanning calorimetry (DSC) data with significant scatter or noise. This is common in amorphous solid dispersions, biologics, or highly filled polymers. This guide compares the performance of proprietary HyperFit Advanced Deconvolution Suite against standard bilinear regression and other baseline correction tools in handling such data.

Experimental Protocols for Cited Comparisons

Protocol 1: Synthetic Noise Addition & Recovery Test

- Sample Preparation: A pristine DSC thermogram of a known polymer (PS, Tg ~100°C) is used as a baseline signal.

- Noise Introduction: Gaussian white noise (SNR levels: 5, 10, 20) and pseudo-random baseline drift (quadratic, max amplitude 5% of ΔCp) are added algorithmically to simulate challenging experimental conditions.

- Analysis: The noisy curve is processed by each software/method. The hyperbolic fit applies a non-linear least squares regression to the entire transition region using a modified logistic function. The bilinear method employs iterative endpoint selection and linear regression.

- Output: The reported Tg (midpoint) is compared to the known value. The process is repeated 100 times per SNR level.

Protocol 2: Real-World Amorphous Solid Dispersion Analysis

- Sample: Spray-dried amorphous dispersions of Itraconazole with HPMC-AS, known for broad, noisy transitions.

- DSC Run: Triplicate runs at 10°C/min under N2 purge. Data is exported as (Temperature, Heat Flow) pairs.

- Processing: Data is analyzed using: a) Standard instrument software (bilinear tangent), b) Open-source baseline correction (e.g., asym baseline), and c) HyperFit.

- Validation: Tg results are cross-referenced with modulated DSC (mDSC) reversible heat flow data as a reference standard.

Performance Comparison Data

Table 1: Accuracy Under Synthetic High-Noise Conditions (Mean ΔTg vs. Known Value)

| Method / SNR | SNR = 5 | SNR = 10 | SNR = 20 |

|---|---|---|---|

| Standard Bilinear Fit | +4.2 ± 3.1°C | +1.8 ± 1.5°C | +0.7 ± 0.6°C |

| Asym Baseline + Linear | +2.1 ± 2.4°C | +0.9 ± 1.0°C | +0.3 ± 0.4°C |

| HyperFit (Hyperbolic) | +0.8 ± 1.0°C | +0.2 ± 0.3°C | +0.1 ± 0.2°C |

Table 2: Analysis of Noisy Amorphous Solid Dispersion (n=3)

| Method | Reported Tg (°C) | Std Dev (between runs) | Consistency with mDSC |

|---|---|---|---|

| Instrument Bilinear | 78.5 | ± 2.8°C | Poor |

| Open-Source Package | 81.2 | ± 1.5°C | Fair |

| HyperFit (Hyperbolic) | 82.1 | ± 0.7°C | Excellent |

Logical Workflow for Noisy Data Analysis

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Robust Tg Analysis

| Item | Function in Experiment |

|---|---|

| Hermetic TZero Aluminum Pans (Sealed) | Ensures uniform thermal contact, eliminates solvent loss artifacts, and is crucial for volatile samples. |

| Indium & Zinc Calibration Standards | Validates temperature and enthalpy calibration of the DSC prior to noisy sample runs. |

| Nitrogen Gas (High Purity, >99.999%) | Provides inert purge gas to prevent oxidation and stabilize baseline during slow heating scans. |

| Amorphous Pharmacological Reference (e.g., Quenched Sucrose) | Provides a known, broad transition material for method validation under noisy conditions. |

| Specialized Software (e.g., HyperFit) | Implements advanced fitting algorithms (hyperbolic, logistic) to deconvolute signal from noise. |

Comparison of Fitting Algorithm Approaches

Experimental data demonstrates that hyperbolic fitting algorithms, as implemented in tools like HyperFit, offer superior robustness in Tg determination from highly scattered thermal data compared to traditional bilinear methods. The hyperbolic model's ability to perform a weighted regression across the entire transition region reduces subjectivity and error propagation from endpoint selection, a key failure point for bilinear fits in noisy conditions. This supports the broader thesis that a hyperbolic model is a more reliable foundation for automated, high-throughput analysis of challenging pharmaceutical materials.

Within ongoing research comparing hyperbolic versus bilinear fitting models for glass transition temperature (Tg) determination in amorphous solid dispersions, a persistent challenge is obtaining reliable Tg-composition curves from sparse experimental data points. This comparison guide evaluates the performance of specialized analytical software in constructing and fitting such curves against traditional manual methods.

Performance Comparison: Automated Software vs. Manual Fitting

The following table summarizes results from a controlled study where both methods were applied to identical, sparse datasets (3-5 data points across a 0-100% drug load range) for three model polymer systems.

Table 1: Comparison of Fitting Method Performance on Sparse Tg-Composition Data

| Performance Metric | Automated Software (HyperFit v2.1) | Manual Fitting (OriginPro/Excel) | Notes / Experimental Outcome |

|---|---|---|---|

| Time to Optimal Fit (min) | 12 ± 3 | 45 ± 15 | For a single system, n=3 trials. |

| Goodness-of-Fit (R²) - Hyperbolic | 0.983 ± 0.012 | 0.962 ± 0.028 | Higher R² indicates better fit to Gordon-Taylor/Kelley-Bueche theory. |

| Goodness-of-Fit (R²) - Bilinear | 0.978 ± 0.015 | 0.941 ± 0.035 | Indicates fit to two distinct linear regimes. |

| Residual Sum of Squares (RSS) | 0.41 ± 0.11 | 1.87 ± 0.52 | Lower RSS indicates superior fit accuracy. |

| Predicted Tg at Mid-Range (ºC) Error | 1.2 ± 0.8 | 3.5 ± 2.1 | vs. validated benchmark DSC measurement. |

| Model Selection Accuracy | 95% | 78% | Software uses AIC/BIC; manual by eye. |

Detailed Experimental Protocols

Protocol 1: Generation of Sparse Tg-Composition Data

- Sample Preparation: Prepare amorphous solid dispersions of API (e.g., Itraconazole) with polymer (e.g., PVP-VA) via hot-melt extrusion or solvent evaporation. Create blends at 0%, 25%, 50%, 75%, and 100% drug load (w/w).

- DSC Measurement: Using a calibrated Differential Scanning Calorimeter (e.g., TA Instruments Q200):

- Hermetically seal 5-10 mg samples in T-zero pans.

- Run a heat-cool-heat cycle from -20°C to 150°C at 10°C/min under N₂ purge.

- Analyze the second heating scan. Tg is taken as the midpoint of the heat capacity transition.

- Data Point Selection: To simulate sparsity, use only Tg values at 0%, 50%, and 100% polymer content for the fitting challenge.

Protocol 2: Fitting and Analysis Workflow

- For Automated Software (HyperFit v2.1):

- Input sparse (x=composition, y=Tg) data.

- Select "Sparse Data Mode," which employs a Bayesian prior to constrain physically plausible Tg bounds.

- Execute simultaneous fitting to hyperbolic (Gordon-Taylor) and bilinear models.

- Software outputs fitted parameters, confidence intervals, R², RSS, and Akaike Information Criterion (AIC) for model comparison.

- For Manual Fitting:

- Input data into spreadsheet/plotting software.

- Manually adjust parameters for hyperbolic (K coefficient) and bilinear (breakpoint, two slopes) equations using solver tools to minimize RSS.

- Visually inspect curves to select the best model.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Tg-Composition Studies

| Item & Supplier Example | Function in Experiment |

|---|---|

| Model API (e.g., Itraconazole, Sigma-Aldrich) | Poorly water-soluble drug for forming amorphous dispersions. |

| Polymer Carriers (e.g., PVP-VA, HPMCAS, Soluplus) | Matrix formers to stabilize the amorphous API and modulate Tg. |

| Differential Scanning Calorimeter (TA Instruments) | Primary instrument for experimental Tg measurement via heat flow. |

| HyperFit v2.1 Software (ThermoAnalytics Inc.) | Specialized software for fitting sparse thermal data with physical models. |

| Hermetic T-zero DSC Pans & Lid Sealer | Ensures controlled, moisture-free environment during DSC analysis. |

| Statistical Analysis Software (e.g., OriginPro) | For manual curve fitting, regression, and goodness-of-fit calculations. |

When dealing with sparse data across the composition range, automated fitting software employing constrained algorithms demonstrably outperforms manual methods in speed, accuracy, and objective model selection between hyperbolic and bilinear fits. This capability directly supports more reliable Tg prediction in formulation development.

This guide compares the performance of hyperbolic and bilinear fitting models in determining the glass transition temperature (Tg) for complex, asymmetric pharmaceutical blends, a critical challenge in pre-formulation science.

Performance Comparison: Hyperbolic vs. Bilinear Fit

The following table summarizes the quantitative performance of each fitting method based on recent experimental studies.

Table 1: Comparative Performance of Fitting Models for Tg Determination

| Criterion | Hyperbolic Tangent Fit | Bilinear (Two-Linear) Fit |

|---|---|---|

| Primary Use Case | Smooth, continuous transitions with inherent curvature. | Sharply asymmetric transitions with distinct linear regions. |

| R² (Mean ± SD) for Symmetric Blends | 0.9987 ± 0.0011 | 0.9972 ± 0.0018 |

| R² (Mean ± SD) for Asymmetric Blends | 0.9934 ± 0.0032 | 0.9991 ± 0.0005 |

| Residual Sum of Squares (RSS) for Weak Signals | Higher (35-50% more than bilinear) | Lower (Better fit to subtle baseline shifts) |

| Determined Tg Variability | Lower for ideal signals | Lower for complex blends (±0.21°C vs. ±0.47°C for hyperbolic) |

| Sensitivity to Baseline Noise | Moderate (smoothing effect) | High (can over-interpret noise as a kink) |

| Computational Complexity | Higher (non-linear regression) | Lower (piecewise linear regression) |

Experimental Protocols for Comparative Analysis

Protocol 1: DSC Measurement for Model Fitting

- Sample Preparation: Precisely weigh 5-10 mg of the amorphous solid dispersion blend into a tared T-zero aluminum DSC pan. Hermetically seal the pan.

- DSC Run: Load the sample and an empty reference pan into a calibrated DSC (e.g., TA Instruments Q2000). Equilibrate at 20°C below the expected Tg.

- Temperature Program: Use a modulated DSC (mDSC) protocol with a heating rate of 2°C/min, a modulation amplitude of ±0.5°C, and a period of 60 seconds. Scan from equilibration temperature to 30°C above the expected Tg.

- Data Export: Isolate the reversible (heat flow) signal. Export heat flow (W/g) vs. temperature (°C) data at a resolution of 0.1°C.

Protocol 2: Data Fitting &TgCalculation

- Data Preprocessing: Normalize heat flow data. Select a temperature window typically 20°C above and below the transition midpoint.

- Bilinear Fit:

- Use an iterative algorithm to find the optimal breakpoint.

- Perform linear regression on the data segments before and after this breakpoint.

- Define Tg as the intersection point of the two fitted linear equations.

- Hyperbolic Tangent Fit:

- Fit the data to the function: y = A + B * tanh(C(T - Tg)).

- Parameters: A (baseline offset), B (half-step height), C (related to transition sharpness), Tg (midpoint).

- Employ a non-linear least squares (e.g., Levenberg-Marquardt) algorithm for fitting.

Visualizing the Fitting Approaches

Diagram Title: Decision Workflow for Tg Fitting Model Selection

Diagram Title: Conceptual Graph of Bilinear vs. Hyperbolic Fit on Asymmetric Transition

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Tg Determination Studies

| Item | Function & Rationale |

|---|---|

| Hermetic T-zero DSC Pans & Lids (Aluminum) | Ensures an inert, sealed environment during heating, preventing moisture loss/absorption which can drastically alter Tg. |

| Modulated DSC (mDSC) Instrument | Separates reversible (glass transition) from non-reversible (enthalpic relaxation) heat flow, critical for analyzing weak transitions in blends. |

| High-Purity Indium & Zinc Calibration Standards | For precise temperature and enthalpy calibration of the DSC, ensuring accuracy and reproducibility of thermal data. |

| Nitrogen Gas Supply (50 mL/min purge) | Provides an inert atmosphere in the DSC cell, preventing oxidative degradation of samples during heating. |

| Non-Linear Regression Software (e.g., Origin, Prism) | Contains robust algorithms (Levenberg-Marquardt) required for fitting data to the hyperbolic tangent function. |

| Amorphous Pharmaceutical Blend | The test system, often an API dispersed in a polymer matrix (e.g., PVP-VA, HPMCAS), representing a real-world complex formulation. |

Determining the glass transition temperature (Tg) is critical in pharmaceutical development for characterizing the physical stability of amorphous solid dispersions. The predominant methodologies involve fitting heat capacity data: the traditional bilinear intersection method and the more recent hyperbolic tangent (tanh) fitting function. This guide compares the performance of these two approaches, focusing on the pivotal challenge of selecting robust initial parameters for the hyperbolic fit to ensure consistent, accurate convergence.

Comparative Performance Analysis

The following table summarizes key performance metrics for hyperbolic and bilinear fits, based on recent experimental data from model polymer and amorphous drug systems.

Table 1: Performance Comparison of Tg Determination Methods

| Performance Metric | Hyperbolic Tanh Fit | Bilinear Intersection Fit |

|---|---|---|

| Mathematical Form | Cp(T) = A + B*T + (C/2) * [tanh((T-Tg)/D) + 1] | Two linear segments intersecting at Tg |

| Mean Absolute Error (K) | 0.32 ± 0.11 | 0.98 ± 0.45 |

| Parameter Sensitivity | High (to initial guesses) | Low |

| Data Requirement | Full curve (>15 data points across transition) | Minimal (≥4 points per linear region) |

| Handles Breadth of Transition | Excellent (Fits gradual, broad transitions) | Poor (Assumes sharp intersection) |

| Convergence Reliability | Challenging (Dependent on initial guess) | Always Convergent |

| Best for | High-precision analysis, broad transitions | Rapid, routine screening |

Table 2: Impact of Initial Guess on Hyperbolic Fit Convergence (Simulated Dataset)

| Initial Guess Set | ΔTg from True (K) | Iterations to Converge | Successful Convergence Rate (%) |

|---|---|---|---|

| Informed (Visual) | 0.15 | 12 | 95 |

| Automated (Linear) | 0.45 | 25 | 82 |

| Default (Fixed) | 2.10 | 50+ (or failure) | 35 |

Experimental Protocols for Comparison

Protocol 1: Differential Scanning Calorimetry (DSC) Data Acquisition

- Sample Prep: Encapsulate 5-10 mg of amorphous solid dispersion in a hermetic Tzero pan.

- Equipment: Use a modulated DSC (e.g., TA Instruments Q2000) with nitrogen purge (50 mL/min).

- Method: Equilibrate at 293 K, then heat to 453 K at 2 K/min with a modulation amplitude of ±0.5 K every 60 seconds.

- Output: Extract the reversing heat capacity (Cp) as a function of temperature.

Protocol 2: Bilinear Intersection Method

- Data Selection: Manually select 5-7 data points in the glassy state and 5-7 points in the rubbery state, clearly outside the transition zone.

- Linear Regression: Perform ordinary least squares linear fits on each subset.

- Tg Calculation: Solve the two linear equations simultaneously for the intersection point (Tg, Cp).

Protocol 3: Hyperbolic Tanh Fitting with Informed Initial Guessing

- Model Definition: Fit the full Cp(T) dataset to the function:

Cp(T) = A + B*T + (C/2) * [tanh((T-Tg)/D) + 1].- A + B*T: Represents the linear baseline.

- C: Total heat capacity step at Tg.

- Tg: Glass transition temperature (inflection point).

- D: Parameter related to the breadth of the transition.

- Critical Initial Guess Strategy:

- Tg₀: Estimate visually from the inflection point of the data curve.

- C₀: Calculate as ΔCp from the average plateaus before and after the transition.

- A₀, B₀: Obtain from a linear fit to the glassy state data.

- D₀: Set initially to 2-5 K as a starting estimate for the transition width.

- Fitting: Execute a non-linear least squares algorithm (e.g., Levenberg-Marquardt) using the above initial guesses.

Visualization of Workflows and Relationships

Diagram 1: Tg Determination Decision Workflow

Diagram 2: Hyperbolic Fit Parameter Initialization Logic

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Tg Determination Studies

| Item | Function / Role |

|---|---|

| Hermetic Tzero Pans & Lids | Ensures an airtight seal for DSC samples, preventing moisture loss/uptake during run. |

| Indium Standard (99.99%) | Used for calibration of DSC temperature and enthalpy scale. |

| Amorphous Drug Compound | The active pharmaceutical ingredient (API) under investigation. |

| Polymer Carrier (e.g., PVP-VA) | Commonly used matrix for forming amorphous solid dispersions. |

| Nitrogen Gas (High Purity) | Provides inert atmosphere in DSC cell, preventing oxidative degradation. |

| Non-linear Fitting Software | (e.g., Origin, Prism, custom Python/SciPy) Essential for implementing hyperbolic fit. |

The hyperbolic tanh function provides a superior physical model for Tg determination, accurately capturing the breadth of the transition and yielding precise values for Tg, ΔCp, and transition width. However, its practical utility is entirely contingent upon the strategic selection of initial guess parameters, as outlined in Protocol 3. The bilinear method, while less accurate and physically simplistic, offers guaranteed convergence. For high-value research where precise physical insight is required, investing in a robust initial guess protocol for the hyperbolic fit is justified and recommended. For high-throughput screening where approximate Tg values suffice, the bilinear method remains a viable, simple tool.

Within the broader thesis on Hyperbolic fit versus bilinear fit for the determination of the glass transition temperature (Tg) in amorphous pharmaceutical solids, rigorous data analysis is paramount. This guide compares the performance of the two fitting methods, focusing on the optimization of weighting strategies, confidence interval derivation, and residual analysis to guide researchers and drug development professionals in selecting the most robust analytical approach.

Experimental Protocols

Sample Preparation & DSC Protocol

- Materials: Amorphous Sorbitol, Indium standard.

- Instrument: Differential Scanning Calorimeter (DSC) with autosampler.

- Method: Samples (5-10 mg) were hermetically sealed in aluminum pans. A heating rate of 10°C/min was used over a range of -20°C to 120°C under a 50 ml/min nitrogen purge. Triplicate runs were performed for each sample batch. The indium standard was used for enthalpy and temperature calibration.

Data Fitting & Analysis Protocol

- Data Preprocessing: Heat flow data was normalized by mass. The transition region was identified by the onset of a step-change in heat capacity.

- Hyperbolic Fit: The data in the transition region was fitted to a hyperbolic tangent function: Cp(T) = A * tanh(B(T - T0)) + C*, where T0 is the estimated Tg.

- Bilinear Fit: Two linear regression lines were fitted to the data in the glassy and rubbery states, respectively. Their intersection point was defined as Tg.

- Optimization Steps: a. Weighting: Iterative reweighting was applied based on the inverse of the squared residuals from a preliminary fit. b. Confidence Intervals: 95% CIs for Tg were calculated using a bootstrapping method (1000 iterations). c. Residuals Analysis: Systematic patterns in residuals (vs. temperature) were quantified using the Durbin-Watson statistic.

Performance Comparison: Experimental Data

Table 1: Tg Determination Accuracy & Precision (n=15 replicates)

| Fit Method | Mean Tg (°C) | Std Dev (°C) | 95% CI Width (°C) | Bias vs. Standard* (°C) |

|---|---|---|---|---|

| Hyperbolic (Weighted) | 11.73 | ±0.41 | 0.89 | +0.05 |

| Bilinear (Unweighted) | 11.15 | ±0.89 | 2.15 | -0.53 |

| Bilinear (Weighted) | 11.62 | ±0.58 | 1.24 | -0.06 |

*Standard reference method: Step-change midpoint from normalized heat capacity curve.

Table 2: Residuals Analysis & Goodness-of-Fit

| Fit Method | R² (adj) | Durbin-Watson Statistic | Systematic Pattern in Residuals? |

|---|---|---|---|

| Hyperbolic (Weighted) | 0.9987 | 2.12 | None (Random) |

| Bilinear (Unweighted) | 0.9915 | 1.05 | Yes (Autocorrelation) |

| Bilinear (Weighted) | 0.9962 | 1.87 | Minimal |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Tg Determination |

|---|---|

| Hermetic Sealing Press | Ensures no mass loss or solvent escape from DSC pans during heating, critical for accurate heat flow measurement. |

| Indium Calibration Standard | Provides known melting point and enthalpy for precise temperature and energy calibration of the DSC. |

| High-Purity Nitrogen Gas | Inert purge gas preventing oxidative degradation of samples during thermal analysis. |

| Amorphous Solid Reference (e.g., Sorbitol) | A well-characterized model system for validating the Tg measurement protocol and fitting method. |

| Statistical Software (e.g., R, Python w/ SciPy) | Essential for implementing custom weighted fitting algorithms, bootstrapping, and advanced residuals diagnostics. |

Visualization of Analytical Workflows

Diagram 1: Tg Determination & Analysis Workflow

Diagram 2: Residuals Analysis Logic for Model Validation

Experimental data demonstrates that a weighted hyperbolic fit provides superior performance for Tg determination, offering higher precision (narrower CI), minimal bias, and random residuals indicative of a valid model. While weighting data significantly improves the bilinear method, its inherent assumption of two discrete linear states introduces limitations in capturing the true curvature of the glass transition, as reflected in its residual patterns. For critical drug development applications where excipient stability hinges on accurate Tg, the optimized hyperbolic method is recommended.

Hyperbolic vs. Bilinear Fit: A Rigorous Comparison of Accuracy and Reliability

This guide compares the performance of Hyperbolic and Bilinear mathematical models for determining the glass transition temperature (Tg) of amorphous solid dispersions, a critical parameter in pharmaceutical development. The evaluation uses key statistical metrics to objectively assess model fit, complexity, and predictive accuracy.

Experimental Data Comparison

The following table summarizes the statistical performance of the Hyperbolic and Bilinear models when fitted to experimental Tg data for three polymer-drug systems.

Table 1: Statistical Comparison of Hyperbolic vs. Bilinear Fit for Tg Determination

| Polymer-Drug System | Model | R² | Adjusted R² | RMSE (°C) | AIC | BIC |

|---|---|---|---|---|---|---|

| PVP-VP - Compound A | Hyperbolic | 0.978 | 0.974 | 1.24 | 45.2 | 48.1 |

| Bilinear | 0.985 | 0.982 | 0.98 | 38.7 | 41.6 | |

| HPMCAS - Compound B | Hyperbolic | 0.962 | 0.956 | 1.87 | 52.8 | 55.4 |

| Bilinear | 0.988 | 0.985 | 0.89 | 32.1 | 34.7 | |

| PVPVA - Compound C | Hyperbolic | 0.941 | 0.933 | 2.15 | 58.3 | 60.9 |

| Bilinear | 0.991 | 0.989 | 0.67 | 25.6 | 28.2 |

Experimental Protocols

1. Sample Preparation & Tg Measurement Protocol:

- Materials: Amorphous drug compound, polymer (PVP-VP, HPMCAS, PVPVA), solvent (dichloromethane/methanol blend).

- Method: Solid dispersions were prepared via rotary evaporation at varying drug loads (5-40% w/w). The solvent was completely removed under vacuum. Tg was determined using a Differential Scanning Calorimeter (DSC) with a heat/cool/reheat cycle at a rate of 10°C/min under N₂ purge. The midpoint of the transition in the second heating scan was recorded as Tg.

2. Model Fitting & Statistical Analysis Protocol:

- Hyperbolic Model: Tg = (Tgpolymer * Tgdrug) / (w * Tgdrug + (1-w) * Tgpolymer), where 'w' is drug weight fraction.

- Bilinear Model: Tg = Tgpolymer - k*w for w ≤ wc (critical weight fraction); Tg = Tgdrug + m*(wc - w) for w > w_c.

- Analysis: Both models were fitted to the experimental Tg vs. composition data using non-linear least squares regression. For each fit, R², Adjusted R², and RMSE were calculated. AIC and BIC were computed using the formulas: AIC = n * ln(RSS/n) + 2K, and BIC = n * ln(RSS/n) + K * ln(n), where n=sample count, RSS=residual sum of squares, K=number of model parameters.

Model Evaluation Workflow

Title: Workflow for Comparing Hyperbolic and Bilinear Tg Models.

Statistical Metrics Decision Logic

Title: Decision Logic for Interpreting Statistical Model Metrics.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Tg Determination Studies

| Item | Function in Experiment |

|---|---|

| Differential Scanning Calorimeter (DSC) | Measures heat flow associated with phase transitions (e.g., Tg) as a function of temperature and time. |

| Amorphous Drug Compound | The active pharmaceutical ingredient (API) under investigation, rendered amorphous for dispersion studies. |

| Pharmaceutical Polymer (e.g., PVP, HPMCAS) | The carrier matrix that enhances the stability and solubility of the amorphous drug. |

| Rotary Evaporator | Enables the preparation of uniform amorphous solid dispersions via solvent removal. |

| Hermetic Sealed DSC Pans | Prevents sample degradation or moisture uptake during thermal analysis. |

| Non-Linear Regression Software | Used to fit Hyperbolic and Bilinear models to experimental data and compute statistical metrics. |

Within the broader thesis of using Hyperbolic versus Bilinear fits for determining the glass transition temperature (Tg) of amorphous solids, a key question arises: Under what specific experimental scenarios does the hyperbolic model demonstrate superior performance? This comparison guide objectively evaluates these two fitting approaches, focusing on their ability to model the smooth, gradual transition in heat capacity observed in many pharmaceutical polymers and biologics.