The Complete Guide to Measuring Tg in Epoxy Resins and Composites: Methods, Best Practices, and Interpretation

This comprehensive guide provides researchers and materials scientists with an in-depth analysis of glass transition temperature (Tg) measurement in epoxy systems.

The Complete Guide to Measuring Tg in Epoxy Resins and Composites: Methods, Best Practices, and Interpretation

Abstract

This comprehensive guide provides researchers and materials scientists with an in-depth analysis of glass transition temperature (Tg) measurement in epoxy systems. Covering foundational concepts from molecular mobility to network structure, it details practical methodologies including DMA, DSC, and TMA. The article addresses common pitfalls, data interpretation challenges, and optimization strategies for accurate measurement. A comparative analysis of techniques guides selection based on material type and application needs, with specific emphasis on implications for performance and durability in advanced composites and biomedical applications.

Understanding Tg: The Science Behind the Glass Transition in Epoxy Networks

What is Tg? Defining the Glass Transition Temperature in Polymer Science

The glass transition temperature (Tg) is a fundamental thermodynamic and kinetic property of amorphous materials, including polymers, glasses, and some pharmaceuticals. It is defined as the temperature range at which a polymer transitions from a hard, glassy, and often brittle state to a soft, rubbery, and ductile state upon heating. This is not a first-order phase transition like melting but a second-order transition characterized by a change in the slope of thermodynamic properties (e.g., volume, enthalpy) versus temperature.

In the context of epoxy resins and composites research, Tg is a critical performance indicator. It defines the upper-use temperature for the material, influences its mechanical properties (modulus, toughness), dimensional stability, and long-term durability. Accurate measurement and interpretation of Tg are essential for formulating resins, optimizing cure cycles, and predicting composite performance in aerospace, automotive, and electronics applications.

Key Measurement Techniques: Application Notes

The following table summarizes the primary techniques used to measure Tg in epoxy resins and composites, along with their key characteristics.

Table 1: Comparative Overview of Primary Tg Measurement Techniques

| Technique | Abbreviation | Measured Property | Sample Form | Key Advantage for Epoxy/Composites | Estimated Precision (°C) |

|---|---|---|---|---|---|

| Differential Scanning Calorimetry | DSC | Heat Flow (Cp) | 5-20 mg powder/film | Rapid, standardized, detects cure exotherm | ± 1-2 |

| Dynamic Mechanical Analysis | DMA | Storage/Loss Modulus, Tan δ | Solid bar, film, fiber | Sensitive, provides viscoelastic spectrum, detects sub-Tg relaxations | ± 1-2 |

| Thermomechanical Analysis | TMA | Coefficient of Thermal Expansion | Solid bar, film | Direct measurement of dimensional change, good for layered composites | ± 2-3 |

| Dielectric Analysis | DEA | Permittivity/Loss Factor | Film, between electrodes | In-situ cure monitoring, frequency sweeps, sensitive to ionic mobility | ± 2-5 |

Detailed Experimental Protocols

Protocol 3.1: Tg Measurement by Differential Scanning Calorimetry (DSC)

Objective: To determine the glass transition temperature of an epoxy resin sample via the change in specific heat capacity (Cp).

Research Reagent Solutions & Essential Materials:

- Epoxy Resin Sample: Fully cured, post-cured, or in-situ curing sample (5-20 mg).

- DSC Instrument: Calibrated for temperature and enthalpy using indium and zinc standards.

- Sample Pan: Hermetically sealed aluminum crucibles (standard or high-pressure for curing studies).

- Reference Pan: Empty, identical aluminum crucible.

- Purge Gas: High-purity nitrogen or argon at 50 mL/min flow rate.

- Liquid Nitrogen Cooling System (Optional): For sub-ambient temperature ramps.

Procedure:

- Sample Preparation: Precisely weigh 5-20 mg of sample using a microbalance. For cured samples, ensure a flat, thin piece to maximize thermal contact. Place sample in pan and hermetically seal.

- Instrument Setup: Load the sample pan and an empty reference pan into the DSC furnace. Purge with inert gas (N2) at 50 mL/min.

- Temperature Program:

- Equilibrate at 25°C.

- First Heat: Ramp from 25°C to 50°C above the expected Tg at a rate of 10-20°C/min. This first scan removes thermal history (e.g., residual stresses, physical aging).

- Cooling: Rapidly cool back to 25°C at 20-50°C/min.

- Second Heat: Repeat the heating ramp (25°C to 50°C above Tg). The Tg is measured from this second heating curve to obtain a reproducible, history-free value.

- Data Analysis: Plot heat flow vs. temperature. Tg is reported as the midpoint of the step-change in heat flow (ASTM E1356). Determine the onset and endpoint tangentially. For a curing sample, the residual heat of reaction can also be quantified.

Visualization: DSC Tg Determination Workflow

Title: DSC Protocol Workflow for Tg Measurement

Protocol 3.2: Tg Measurement by Dynamic Mechanical Analysis (DMA)

Objective: To determine Tg and the viscoelastic properties of an epoxy composite via the temperature dependence of the storage (E') and loss (E") moduli.

Research Reagent Solutions & Essential Materials:

- Composite Sample: Rectangular bar (typical: 30 x 10 x 2 mm) or film, precisely dimensioned.

- DMA Instrument: Calibrated for force, displacement, and temperature.

- Clamping Assembly: Dual/single cantilever, 3-point bend, or shear fixtures depending on sample stiffness.

- Strain-Amplitude Calibration Standard: Low-expansion metal bar.

- Purge Gas: Nitrogen for temperature control and sample protection.

Procedure:

- Sample Preparation: Machine a rectangular specimen with parallel, flat faces. Accurately measure dimensions (length, width, thickness) for modulus calculation.

- Mounting: Securely clamp the sample in the chosen fixture, ensuring good contact but avoiding over-torquing. Set the exact gauge length.

- Method Setup:

- Deformation Mode: Select (e.g., 3-point bend for stiff composites).

- Frequency: Set to 1 Hz (standard) or perform multi-frequency sweep.

- Strain/Amplitude: Set within the linear viscoelastic region (typically 0.01-0.1% strain).

- Temperature Program: Ramp from 25°C to 150-250°C (exceeding Tg) at 2-5°C/min.

- Data Collection: Monitor storage modulus (E'), loss modulus (E"), and tan δ (E"/E') versus temperature.

- Data Analysis: Identify Tg via multiple metrics: (i) Onset of E' Drop: The temperature where E' begins to decline sharply. (ii) Peak of E": The temperature of the loss modulus peak. (iii) Peak of Tan δ: The most commonly reported value, representing the maximum damping.

Visualization: DMA Tg Determination Metrics

Title: Three Metrics for Determining Tg from DMA

Factors Influencing Tg in Epoxy Composites

Tg is not an intrinsic material constant but is influenced by molecular structure and processing history.

Table 2: Key Factors Affecting Tg in Epoxy Resins and Composites

| Factor | Effect on Tg | Molecular/Physical Rationale |

|---|---|---|

| Crosslink Density | Increases Tg | Reduced chain segment mobility between network junctions. |

| Curing Agent & Stoichiometry | Varies Significantly | Affects final network structure, free volume, and crosslink density. |

| Degree of Cure | Increases with cure | Reduction in free volume and chain ends as reaction proceeds. |

| Post-Cure Cycle | Increases Tg | Drives reaction to completion, maximizes crosslink density. |

| Plasticizers/Moisture | Decreases Tg | Increases free volume, enhances chain lubricity and mobility. |

| Reinforcing Fibers/Fillers | Complex Effect | Can restrict polymer mobility (↑Tg) or introduce interfaces/defects (↓Tg). |

| Physical Aging | Increases apparent Tg | Annealing below Tg reduces free volume, sharpens the transition. |

Advanced Considerations in Composite Research

For fiber-reinforced composites (e.g., carbon/epoxy), interfacial adhesion and fiber constraint can lead to broadened or multi-step Tg transitions. Dielectric Analysis (DEA) is invaluable for in-situ monitoring of Tg development during the cure process in an autoclave or oven. Correlating results from multiple techniques (DSC, DMA, TMA) provides the most robust understanding of the material's thermal and mechanical transition.

The glass transition temperature (Tg) is a fundamental property dictating the thermomechanical behavior and long-term durability of epoxy resins and composites. This application note details the critical role of Tg in performance prediction and outlines standardized protocols for its measurement, framed within ongoing research to establish robust structure-property relationships.

In epoxy systems, Tg marks the transition from a rigid, glassy state to a flexible, rubbery state. This transition profoundly influences key performance metrics:

- Thermal Stability: Maximum service temperature.

- Mechanical Properties: Modulus, toughness, and creep resistance.

- Chemical & Environmental Resistance: Susceptibility to solvent ingress and hydrolytic degradation.

- Long-Term Durability: Resistance to physical aging and microcracking.

A higher Tg generally indicates a more crosslinked, thermally stable network, but optimal performance often requires balancing Tg with toughness.

Quantitative Correlation Data

The following tables summarize key relationships between Tg and epoxy performance, based on current research findings.

Table 1: Tg Correlation with Thermo-Mechanical Properties

| Epoxy System Formulation | Tg (ºC) by DMA (tan δ peak) | Storage Modulus (E') at 25ºC (GPa) | Coefficient of Thermal Expansion (CTE) Below Tg (ppm/ºC) | Reference Standard |

|---|---|---|---|---|

| DGEBA / DDA (Neat) | 125 ± 3 | 2.9 ± 0.1 | 65 ± 5 | ASTM D7028 |

| DGEBA / DDA + 15% Rubber | 110 ± 4 | 2.4 ± 0.2 | 78 ± 6 | ASTM D7028, D4065 |

| DGEBA / High-Functionality Amine | 165 ± 2 | 3.3 ± 0.1 | 55 ± 3 | ASTM D7028 |

| Tetrafunctional Epoxy / Aromatic Hardener | >200 | 3.8 ± 0.2 | 48 ± 4 | ASTM D7028 |

Table 2: Tg Correlation with Durability Metrics

| Performance Metric | Test Method | High Tg Epoxy (>150ºC) | Moderate Tg Epoxy (100-125ºC) | Key Correlation Finding |

|---|---|---|---|---|

| Wet Tg Retention | DMA after 48h water immersion at 85ºC | >90% | 75-85% | Higher initial crosslink density (indicated by higher Tg) reduces hydroplasticization. |

| Fracture Toughness (K₁c) | ASTM D5045 | 0.6 - 0.8 MPa√m | 1.2 - 2.0 MPa√m | Inverse relationship common; increased Tg from higher crosslinking can reduce toughness. |

| Time to Microcrack Onset | Thermal Cycling (-55 to Tg-20ºC) | >5000 cycles | <2000 cycles | Service temperature relative to Tg is critical. Closer to Tg accelerates damage. |

Experimental Protocols for Tg Measurement and Performance Correlation

Protocol 3.1: Dynamic Mechanical Analysis (DMA) for Tg Determination

Principle: Measures viscoelastic properties (storage modulus E', loss modulus E'', tan δ) as a function of temperature. Tg is typically identified from the peak of the tan δ curve or the onset of the drop in E'.

Materials & Equipment:

- DMA instrument (e.g., TA Instruments Q800, Netzsch 242)

- Specimens: Rectangular bars (typical: 35 x 12 x 3 mm) or tensile strips.

- Liquid Nitrogen or integrated cooling system.

- Calibration standards (for temperature, force, and compliance).

Procedure:

- Sample Preparation: Cut and dimension samples precisely. Anneal if necessary to relieve internal stresses.

- Mounting: Secure sample in dual/single cantilever, 3-point bend, or tensile clamp per material stiffness.

- Method Setup:

- Mode: Strain-controlled oscillation (recommended amplitude: 10-20 µm).

- Frequency: 1 Hz (standard).

- Temperature Ramp: 2-3°C/min from at least 50°C below expected Tg to 50°C above.

- Atmosphere: Nitrogen purge (50 mL/min).

- Data Collection: Run method, monitoring force to ensure it remains within linear viscoelastic range.

- Analysis: Identify Tg as:

- Tan δ Peak: Most sensitive, reflects molecular mobility peak.

- E' Onset: Intersection of tangents from glassy and transition regions; often correlates with "practical" service limit.

Protocol 3.2: Accelerated Hydrothermal Aging & Tg Retention Study

Objective: Quantify the plasticizing effect of moisture absorption on Tg and modulus.

Procedure:

- Baseline DMA: Perform DMA (as per Protocol 3.1) on dry samples (conditioned at 50°C in desiccator for 24h). Record dry Tg and E' at 25°C.

- Immersion: Immerse duplicate samples in deionized water at 85°C (±2°C) for 48 hours.

- Surface Drying: Remove samples, blot off surface water with lint-free cloth.

- Wet Weighing: Immediately weigh to determine moisture uptake (% weight gain).

- Wet DMA: Within 10 minutes of removal, perform DMA on the wet sample using identical method parameters.

- Calculation: Calculate % Tg retention = (Wet Tg / Dry Tg) x 100%. Correlate with % moisture uptake and crosslink density.

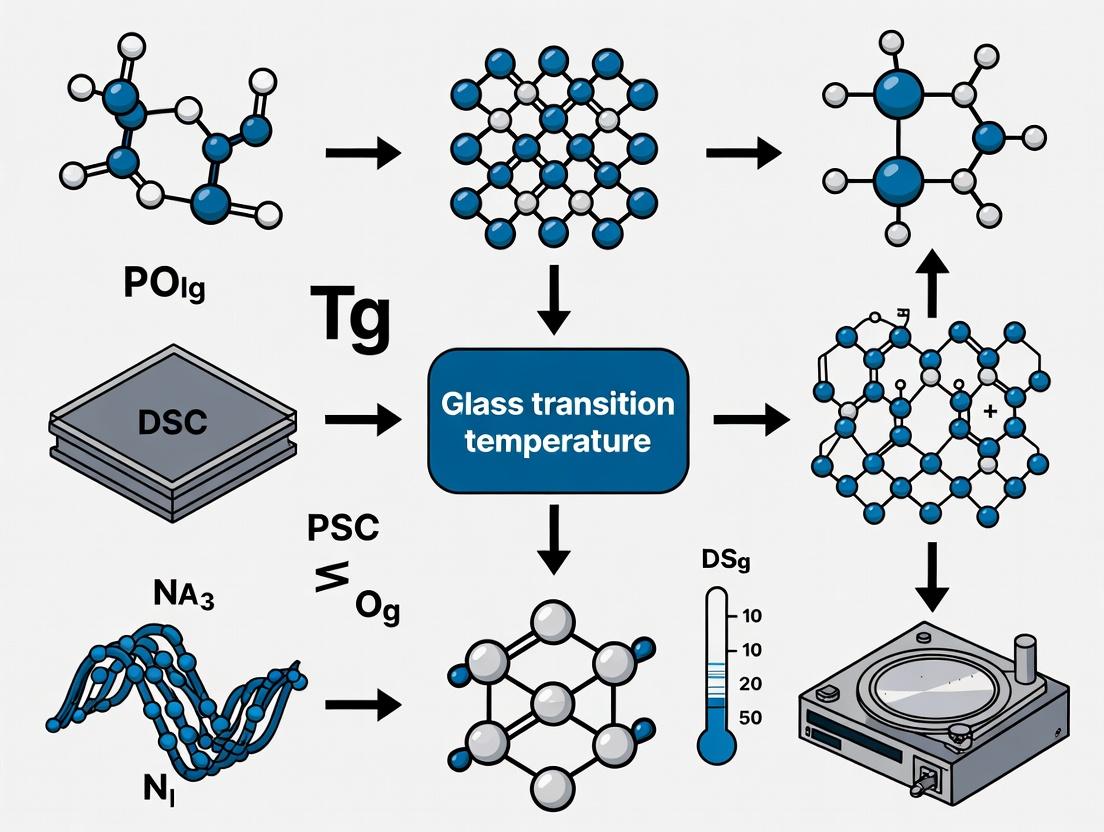

Visualizing Relationships and Workflows

Tg as Central Performance Determinant

Standard DMA Protocol Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Epoxy Tg Research

| Item / Reagent | Function & Relevance to Tg Studies | Example Product/Chemical |

|---|---|---|

| Diglycidyl Ether of Bisphenol A (DGEBA) | Standard epoxy resin backbone; baseline for formulation studies. | EPON 828, DER 331 |

| 4,4'-Diaminodiphenyl Sulfone (DDS) | High-Tg aromatic amine hardener; produces high-performance networks. | Aradur 976-1 |

| Polyetheramine Hardeners | Flexible, toughening hardeners; used to study Tg-toughness trade-offs. | Jeffamine D-230, T-403 |

| Reactive Diluents | Reduces viscosity and crosslink density; model for Tg depression studies. | Butyl glycidyl ether (BGE) |

| Core-Shell Rubber Particles | Toughening additive; study impact on Tg and fracture toughness. | Kane Ace MX 120 |

| Calorimetry Standards | For DSC temperature and enthalpy calibration. | Indium, Tin, Zinc |

| DMA Calibration Kit | Verifies instrument's force, displacement, and temperature accuracy. | TA Instruments DMA-K1 |

| Anhydrous Solvents | For sample cleaning/preparation without inducing plasticization. | Anhydrous Acetone, Isopropanol |

Within the broader thesis on measuring the glass transition temperature (Tg) in epoxy resins and composites, understanding the fundamental molecular principles governing Tg is paramount. Tg is not an intrinsic material property but a manifestation of underlying molecular dynamics. Three interlinked concepts form the core of this understanding: chain mobility, free volume, and crosslink density. The measurement of Tg is, in essence, an experimental probe of the balance between these factors. This Application Note details protocols to quantitatively assess these parameters and their direct impact on Tg, providing researchers with a toolkit to design materials with tailored thermal properties.

Key Concepts and Quantitative Relationships

The following table summarizes the direct quantitative impact of molecular parameters on Tg and key material properties.

Table 1: Molecular Parameters and Their Impact on Epoxy Properties

| Molecular Parameter | Effect on Chain Mobility | Effect on Free Volume | Effect on Crosslink Density | Result on Tg | Impact on Key Material Properties |

|---|---|---|---|---|---|

| Increased Molecular Weight between Crosslinks (M~c~) | Increases | Increases | Decreases | Decreases | Increased toughness, ductility; Reduced modulus, hardness. |

| Higher Curing Temperature | Increases during cure | Increases (final frozen-in free volume) | Can increase or decrease (kinetics vs. thermodynamics) | Can decrease (if vitrification is delayed, leading to higher conversion) | More complete conversion, potentially higher modulus. |

| Longer Cure Time / Post-Cure | Decreases (chains become restricted) | Decreases | Increases | Increases | Increased modulus, chemical resistance; Reduced creep. |

| Addition of Flexible Spacers / Diluents | Increases | Increases | Decreases (if diluent is non-reactive) | Decreases | Reduced viscosity during processing, lowered modulus. |

| Increased Stoichiometric Hardener Ratio | Decreases | Decreases | Increases (up to a point) | Increases | Increased modulus, brittleness; Optimal properties usually at ~1:1. |

Experimental Protocols

Protocol 3.1: Determination of Crosslink Density (ν) from Rubber Elasticity Theory

Principle: Above its Tg, a crosslinked polymer behaves as an elastomer. The shear storage modulus (G') in the rubbery plateau region is related to the crosslink density by the kinetic theory of rubber elasticity. Materials: DMA instrument, fully cured epoxy sample (dimensions per DMA fixture requirements). Procedure:

- Perform a temperature ramp DMA test (e.g., 30°C to Tg+50°C) in shear or tension mode at a fixed frequency (1 Hz).

- Identify the temperature region well above Tg where G' is relatively constant (rubbery plateau).

- Calculate the crosslink density (ν, mol/m³) using the formula: ν = G' / (φRT), where G' is the plateau modulus (Pa), φ is a front factor (~1 for ideal networks), R is the gas constant (8.314 J·mol⁻¹·K⁻¹), and T is the absolute temperature (K) in the plateau region.

- The average molecular weight between crosslinks (M~c~) can be approximated by M~c~ = ρ / ν, where ρ is the polymer density (kg/m³).

Protocol 3.2: Estimating Free Volume via Positron Annihilation Lifetime Spectroscopy (PALS)

Principle: A positron injected into matter can form a metastable state (ortho-positronium, o-Ps) localized in free volume holes. The annihilation lifetime of o-Ps is directly related to the free volume hole size. Materials: PALS spectrometer, thin, uniform epoxy disc samples (~1-2 mm thick, 10 mm diameter). Procedure:

- Place a ²²Na positron source sandwiched between two identical epoxy samples.

- Acquire the positron lifetime spectrum for at least 1-2 million counts to ensure good statistics.

- Analyze the spectrum using a fitting program (e.g., PATFIT, LT) to resolve lifetime components. The longest-lived component (τ~3~, 1-4 ns) corresponds to o-Ps pick-off annihilation.

- Calculate the average free volume hole radius (R, Å) using the Tao-Eldrup model: τ~3~ = 0.5 [1 - R/R~0~ + (1/2π) sin(2πR/R~0~)]⁻¹, where R~0~ = R + ΔR (ΔR = 1.656 Å).

- Monitor τ~3~ and R as a function of temperature through Tg; a distinct increase in slope at Tg indicates the onset of increased free volume.

Protocol 3.3: Probing Chain Mobility via Dielectric Spectroscopy (DES)

Principle: Dielectric spectroscopy measures the reorientation of molecular dipoles in an alternating electric field, directly probing molecular mobility. Materials: Dielectric analyzer with parallel plate cell, gold-coated or electrode-equipped epoxy sample. Procedure:

- Prepare a sample with parallel, flat surfaces. Apply conductive electrodes (sputtered gold or conductive adhesive).

- Mount the sample in the dielectric cell. Run a combined temperature/frequency sweep (e.g., -50°C to 250°C, frequency range 0.1 Hz to 1 MHz).

- Analyze the complex permittivity (ε* = ε' - iε'') data. The α-relaxation peak, visible in the loss factor (ε'' or tan δ) vs. frequency plot, corresponds to segmental chain motion.

- The frequency of the α-peak maximum (f~max~) follows the Vogel-Fulcher-Tammann relationship. The temperature at which f~max~ equals a conventional frequency (e.g., 10 mHz or 1 Hz from DSC heating rates) is defined as the dielectric Tg.

- Compare the breadth and strength of the α-peak to infer changes in network heterogeneity and dipolar density.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Epoxy Tg and Network Research

| Item | Function & Relevance |

|---|---|

| Diglycidyl Ether of Bisphenol-A (DGEBA) | Standard epoxy resin monomer; model system for studying effects of crosslink density variations. |

| Tetraglycidyl-4,4'-diaminodiphenylmethane (TGDDM) | High functionality epoxy resin for aerospace composites; enables high Tg, dense networks. |

| 4,4'-Diaminodiphenyl Sulfone (DDS) | Aromatic diamine hardener; provides high Tg, thermal stability, and controlled reactivity. |

| Poly(propylene glycol) bis(2-aminopropyl ether) (Jeffamine D-230) | Aliphatic polyetheramine hardener; introduces flexible spacers to study chain mobility/free volume. |

| Dynamic Mechanical Analyzer (DMA) | Primary instrument for measuring Tg (tan δ peak) and quantifying rubbery plateau modulus for crosslink density. |

| Differential Scanning Calorimeter (DSC) | Standard for determining Tg (midpoint/onset) and curing exotherm/degree of conversion. |

| Positron Annihilation Lifetime Spectrometer (PALS) | Directly probes nanoscale free volume holes and their size distribution as a function of temperature. |

| Broadband Dielectric Spectrometer (BDS) | Directly measures molecular dipole mobility (α, β relaxations) across wide frequency/temperature ranges. |

Visualizations

Molecular Basis of Glass Transition Relationship Map

Multi-Technique Workflow for Molecular Parameter Analysis

Key Factors Influencing Tg in Epoxy Resins and Composites

Within the broader thesis on measuring the glass transition temperature (Tg) in epoxy resins and composites, understanding the key factors that influence Tg is paramount. Tg is not an intrinsic material property but a response measured under specific conditions, heavily dependent on the material's chemical and physical architecture. This application note details the primary factors, measurement protocols, and essential tools for researchers and scientists.

The following table summarizes the major factors influencing Tg in epoxy systems, along with representative quantitative effects.

Table 1: Key Factors Influencing Tg in Epoxy Resins and Composites

| Factor Category | Specific Factor | Direction of Effect on Tg | Typical Magnitude of Change | Mechanism / Notes |

|---|---|---|---|---|

| Network Structure | Crosslink Density | Increases with higher density | +10°C to +50°C per 0.1 mol/kg increase | Higher density restricts chain mobility. Excessive density can lead to embrittlement. |

| Molecular Weight Between Crosslinks (Mc) | Decreases with lower Mc | Tg ∝ 1/Mc (per Fox-Flory equation) | Shorter chain segments between nodes reduce free volume. | |

| Cure Chemistry | Cure Agent Type (Aromatic vs. Aliphatic) | Aromatic > Cycloaliphatic > Aliphatic | Aromatic amines can yield Tg > 150°C; Aliphatic ~50-80°C | Aromatic structures impart rigidity and higher crosslink density. |

| Stoichiometry (Ratio of Hardener to Epoxy) | Maximum Tg at optimal stoichiometry | Deviation of ±10% can reduce Tg by 20-40°C | Off-ratio leads to unreacted ends or incomplete network. | |

| Cure Cycle (Time & Temperature) | Increases with post-cure | Post-cure can increase Tg by 20-80°C | Drives reaction to completion, increases conversion and density. | |

| Formulation Additives | Plasticizers / Flexibilizers | Decreases Tg | Can depress Tg by 30-100°C | Increase free volume and chain segment mobility. |

| Reinforcements (Fibers, Fillers) | Usually increases Tg (constrained) | +5°C to +30°C for well-bonded systems | Restrains polymer chain motion via interfacial adhesion. | |

| Toughening Agents (Rubber, Thermoplastics) | Often decreases Tg | -5°C to -30°C for dispersed phases | Introduces softer, lower-Tg domains. | |

| Environmental | Moisture Absorption (Plasticization) | Significantly decreases Tg | ~20°C depression per 1% absorbed water | Water acts as a plasticizer, increasing free volume. |

| Thermal/Oxidative Aging | Can increase or decrease | Complex; chemical aging may raise Tg, physical aging lowers it | Post-curing vs. chain scission/volatilization effects. |

Experimental Protocols for Tg Measurement in Research

Protocol 1: Differential Scanning Calorimetry (DSC) for Neat Epoxy Resins

- Objective: Determine the Tg of a cured epoxy resin sample via the change in heat capacity.

- Materials: DSC instrument (e.g., TA Instruments, Mettler Toledo), calibrated with indium and zinc standards, hermetic aluminum pans and lids, microbalance, cured epoxy sample (5-15 mg), inert gas (N₂ or Ar).

- Procedure:

- Sample Preparation: Precisely weigh 5-15 mg of sample. Place in a hermetic aluminum pan and crimp the lid. Prepare an empty reference pan.

- Instrument Calibration: Perform temperature and enthalpy calibration using pure metal standards.

- Method Setup: Create a temperature ramp method. Typical parameters:

- Equilibrium at 25°C.

- Ramp from 25°C to 50°C above expected Tg at 10°C/min.

- Isotherm for 2-5 minutes.

- Cool to 25°C at 20°C/min.

- Second ramp identical to the first.

- Experiment: Load sample and reference pans. Purge cell with inert gas at 50 mL/min. Run method.

- Data Analysis: Analyze the second heating ramp to erase thermal history. Tg is determined as the midpoint of the step transition in heat flow.

- Key Notes: Use small sample mass for good thermal conductivity. The second heat provides the most reliable, history-independent Tg.

Protocol 2: Dynamic Mechanical Analysis (DMA) for Epoxy Composites

- Objective: Measure the Tg of a composite material via the peak in loss factor (tan δ) or the onset of drop in storage modulus (E').

- Materials: DMA instrument (e.g., TA Instruments, Netzsch), appropriate clamp (dual/single cantilever or 3-point bend for composites), calibrated temperature sensor, sample of precise dimensions (e.g., 50 x 10 x 2 mm), liquid N₂ for sub-ambient cooling (if needed).

- Procedure:

- Sample Preparation: Cut composite to fit clamp geometry. Measure dimensions precisely (length, width, thickness).

- Clamp Installation: Install correct clamps. Insert sample, ensuring proper torque and contact. Set strain amplitude within linear viscoelastic region (e.g., 0.01% strain).

- Method Setup: Create a temperature ramp method. Typical parameters:

- Frequency: 1 Hz (fixed).

- Oscillation Amplitude: As determined in step 2.

- Temperature Ramp: from 30°C to 250°C (or as required) at 3°C/min.

- Experiment: Initiate temperature ramp.

- Data Analysis: Plot storage modulus (E'), loss modulus (E''), and tan δ (E''/E') vs. temperature. Record Tg as the peak temperature of the tan δ curve. Also note the onset of the E' drop.

- Key Notes: Clamp selection is critical. Tan δ peak Tg is often 10-20°C higher than DSC midpoint Tg. DMA is sensitive to reinforcement and interface quality.

Visualization of Key Relationships and Workflows

Diagram Title: Primary Factors Affecting Epoxy Tg

Diagram Title: Standard DSC Protocol Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Epoxy Tg Research

| Item / Reagent | Function / Role in Tg Research | Key Considerations |

|---|---|---|

| Epoxy Resin (DGEBA) | Base monomer providing epoxide groups for network formation. Standard model system (e.g., DER 332). | Purity, epoxide equivalent weight (EEW) for stoichiometry. |

| Aromatic Amine Hardener (DDS) | High-performance curing agent (4,4'-Diaminodiphenyl sulfone). Imparts high Tg and thermal stability. | Requires high cure temperature (>180°C). Hygroscopic—must be dried. |

| Aliphatic Amine Hardener (DETA) | Room-temperature curing agent (Diethylenetriamine). Useful for baseline or low-Tg systems. | Fast exotherm, sensitive to stoichiometry, prone to moisture absorption. |

| Flexibilizer (CTBN Rubber) | Carboxy-terminated butadiene-acrylonitrile. Used to study Tg depression and toughness. | Phase-separates during cure, forming dispersed rubber particles. |

| Hermetic DSC Pans & Lids | Encapsulate sample for reliable DSC, preventing volatile loss and oxidative degradation. | Must be inert and seal perfectly. Aluminum is standard. |

| DMA Clamp Set (3-Point Bend) | Holds composite samples for dynamic mechanical analysis under controlled strain. | Correct geometry and torque are critical for modulus accuracy. |

| Desiccant (Molecular Sieve) | To dry resins, hardeners, and cured samples, eliminating plasticization from ambient moisture. | Essential for reproducible baseline Tg measurements. |

| Inert Purge Gas (N₂) | Provides inert atmosphere in thermal analyzers to prevent oxidative degradation during heating. | High purity (≥99.99%) and constant flow rate required. |

In epoxy resin and composite research, accurate determination of the glass transition temperature (Tg) is critical for predicting material performance. However, interpreting thermal analysis data can be confounded by overlapping transitions such as melting (Tm) or degradation (Td). This Application Note provides protocols to distinguish Tg from these other events using Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA).

Key Thermal Transitions: Definitions & Signatures

Glass Transition (Tg): A reversible change in an amorphous material from a hard, glassy state to a soft, rubbery state. It is a second-order transition marked by a step change in heat capacity. Melting (Tm): A first-order transition where a crystalline phase changes to an isotropic liquid, characterized by an endothermic peak. Degradation (Td): An irreversible chemical decomposition (e.g., pyrolysis, oxidation) resulting in mass loss, detected by TGA.

Table 1: Characteristic Signatures of Thermal Transitions in DSC & TGA

| Transition | DSC Signature | TGA Signature | Typical Epoxy Range | Reversibility |

|---|---|---|---|---|

| Glass Transition (Tg) | Step change in baseline (endothermic shift) | No mass loss | 50°C - 300°C | Reversible |

| Melting (Tm) | Sharp endothermic peak | No mass loss | Not typical for cured epoxies | Reversible (phase) |

| Crosslinking (Cure) | Broad exothermic peak | No mass loss | Varies by system | Irreversible |

| Thermal Degradation (Td) | May show exo/endo peak | Significant mass loss (>5%) | ~300°C - 500°C | Irreversible |

Table 2: Key Experimental Parameters for Distinguishing Transitions

| Method | Recommended Heating Rate | Sample Mass | Atmosphere | Key Measurand |

|---|---|---|---|---|

| DSC (for Tg/Tm) | 10°C/min | 5-20 mg | N₂ | Heat Flow (mW) |

| TGA (for Td) | 10-20°C/min | 10-20 mg | N₂ or Air | Mass (%) |

| Modulated DSC (MDSC) | 2-5°C/min (with modulation) | 5-15 mg | N₂ | Reversing/Non-Reversing Heat Flow |

Experimental Protocols

Protocol 1: Distinguishing Tg from Residual Cure Exotherm via DSC

Objective: To isolate the reversible Tg signal from an overlapping residual curing reaction. Materials:

- PerkinElmer DSC 8500 or equivalent

- Hermetic aluminum pans with lids

- Nitrogen purge gas (50 mL/min)

- Partially cured epoxy sample (5-10 mg).

Procedure:

- First Heat (20°C to 250°C): Heat at 10°C/min. Observe for a broad exothermic peak (cure) preceding or overlapping the Tg step.

- Quench Cooling: Rapidly cool the sample from 250°C to -50°C at 50°C/min.

- Second Heat (Identical Parameters): Re-run the identical heating profile. The cure exotherm will be absent if the sample is fully cured.

- Analysis: The Tg is taken as the midpoint of the heat capacity step from the second heating scan, ensuring it is free of curing artifacts.

Protocol 2: Isolating Tg from Degradation using TGA-DSC Coupling

Objective: To correlate mass loss (degradation) with thermal events. Materials:

- Simultaneous TGA-DSC instrument (e.g., Netzsch STA 449)

- Alumina crucibles

- Sample (15 mg epoxy composite).

Procedure:

- Calibrate both TGA and DSC signals using standard references.

- Heat sample from 30°C to 600°C at 10°C/min under N₂.

- Simultaneously record mass change (TGA) and heat flow (DSC).

- Analysis: Overlay the curves. Any endothermic or exothermic event in the DSC trace without concurrent mass loss in TGA is not degradation. The onset of rapid mass loss (typically >5%) is recorded as Td. The Tg should be observed well below this onset.

Protocol 3: Confirming Amorphous Nature vs. Melting via Modulated DSC (MDSC)

Objective: To separate reversing (heat capacity) events from non-reversing (kinetic) events. Materials:

- TA Instruments MDSC Q2000

- Hermetic aluminum pans

- Epoxy sample (8 mg).

Procedure:

- Set underlying heating rate to 2°C/min, modulation amplitude ±0.5°C, period 60 seconds.

- Heat from -30°C to 300°C.

- Analysis: The Reversing Heat Flow signal will show the Tg as a step change. Any melting (unlikely in cured epoxies) would appear as a peak in the Non-Reversing Heat Flow signal. This cleanly separates Tg from other kinetic events.

Visualization of Experimental Logic & Workflows

Diagram 1: DSC Transition Identification Logic (100 chars)

Diagram 2: Three-Pronged Experimental Strategy (100 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Tg Analysis in Epoxies

| Item | Function & Importance | Example Product/Specification |

|---|---|---|

| Hermetic Aluminum DSC Pans | Ensures no mass loss from volatile evaporation during Tg run, critical for baseline stability. | TA Instruments Tzero Pan/Lid (Part# 901683.901) |

| Nitrogen Gas (High Purity) | Inert purge gas for DSC/TGA prevents oxidative degradation during analysis, isolating thermal stability. | Grade 5.0 (99.999% purity), flow rate 50 mL/min. |

| Indium Standard | Calibration standard for DSC temperature and enthalpy; validates instrument performance. | 99.99% purity, Tm = 156.6°C, ΔH ≈ 28.45 J/g. |

| Alumina Crucibles (TGA) | Inert, high-temperature resistant sample holders for TGA with minimal baseline drift. | Netzsch Al₂O₃ Crucibles (Type 709.929) |

| Reference Material (Sapphire) | Used for calibration of DSC heat capacity signal, crucial for accurate Tg step height measurement. | NIST SRM 720 (Synthetic Sapphire Disk) |

| Modulated DSC Software Module | Enables separation of complex thermal events into reversing and non-reversing components. | TA Instruments TRIOS Software MDSC package. |

A Practical Guide to Tg Measurement Techniques: From DMA to DSC

Within a thesis investigating the measurement of glass transition temperature (Tg) in epoxy resins and composites, selecting a robust and sensitive method is paramount. Dynamic Mechanical Analysis (DMA) is widely regarded as the gold standard for Tg determination in these materials. Unlike differential scanning calorimetry (DSC), which measures thermal transitions, DMA assesses viscoelastic properties—storage modulus (E'), loss modulus (E''), and tan delta (E''/E')—as a function of temperature, frequency, or time. The Tg, indicating the transition from a glassy to a rubbery state, is identified by a significant drop in E' and peaks in E'' and tan delta. This application note details protocols and considerations for using DMA to characterize Tg in epoxy-based systems, providing critical insights into network structure, crosslink density, and the effects of fillers or additives.

Key Quantitative Parameters from DMA

DMA provides several metrics for Tg determination. The following table summarizes the primary data obtained and their typical correlations for epoxy resins.

Table 1: Quantitative Data from DMA for Epoxy Resin Tg Analysis

| Parameter | Symbol | Typical Value Range (Epoxy) | Physical Significance | Common Tg Identification Point |

|---|---|---|---|---|

| Storage Modulus (Glassy) | E' | 2.0 - 4.0 GPa | Elastic stiffness; energy stored | Onset of rapid decrease |

| Storage Modulus (Rubbery) | E' | 10 - 50 MPa | Elasticity post-transition | Plateau region after transition |

| Loss Modulus Peak | E'' | - | Viscous dissipation; mechanical damping | Peak Temperature (Tg_E'') |

| Tan Delta Peak | tan δ | 0.3 - 1.2 (height) | Damping efficiency; ratio of loss to storage | Peak Temperature (Tg_tan δ) |

| Glass Transition Temp. (E'' peak) | Tg_E'' | 80 - 220 °C | Molecular mobility onset | Most sensitive to molecular motions |

| Glass Transition Temp. (tan δ peak) | Tg_tan δ | 5 - 20 °C > Tg_E'' | Macroscopic damping peak | Most common reported value |

| Onset Temperature (E' drop) | Tg_onset | 5 - 15 °C < Tg_E'' | Initial deviation from glassy state | Conservative estimate |

| Crosslink Density (ν) | ν | Calculated from rubbery modulus | Network density; mol/m³ | ν = E'_rubbery / (3RT) |

Experimental Protocols

Protocol 1: Sample Preparation for Epoxy Resin DMA

Objective: To prepare standardized rectangular bars for DMA three-point bending mode.

- Mixing & Casting: Precisely weigh epoxy resin and curing agent as per supplier's stoichiometric ratio. Mix thoroughly, degas under vacuum. Pour into a pre-leveled silicone rubber mold (typical cavity: 60mm x 12mm x 3mm).

- Curing Cycle: Cure according to the prescribed thermal schedule (e.g., 2 hrs at 80°C followed by 2 hrs at 120°C). This must be optimized for the specific resin system.

- Demolding & Post-Cure (if required): Gently demold cured sample. Perform any specified post-cure (e.g., 4 hrs at 150°C).

- Finishing: Lightly sand edges to remove flash. Ensure parallel faces. Measure final dimensions (length, width, thickness) accurately at multiple points.

Protocol 2: Standard DMA Temperature Ramp Experiment

Objective: To determine the Tg and viscoelastic profile of an epoxy resin sample.

- Instrument Setup: Calibrate DMA according to manufacturer instructions. Install a dual/single cantilever or three-point bending clamp system appropriate for the sample stiffness.

- Mounting: Insert sample securely. Adjust clamp torque to specification to avoid slippage or excessive stress.

- Method Parameters:

- Mode: Strain-controlled (recommended).

- Frequency: 1 Hz (standard for Tg screening). Multi-frequency runs add depth.

- Strain Amplitude: 0.01-0.05% (within linear viscoelastic region, confirm via strain sweep).

- Temperature Range: Start 30°C below expected Tg, end 50°C above.

- Heating Rate: 3°C/min (standard compromise between resolution and time).

- Atmosphere: Nitrogen purge at 50 mL/min to prevent oxidative degradation.

- Execution: Start method. Monitor force and displacement graphs for stability.

- Data Analysis: Plot E', E'', and tan δ vs. Temperature. Identify Tg from:

- Tg (tan δ peak): The maximum of the tan δ curve.

- Tg (E'' peak): The maximum of the loss modulus curve.

- Tg (onset): The intersection of tangents from the glassy plateau and the steep drop in E'.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for DMA of Epoxy Resins and Composites

| Item | Function & Rationale |

|---|---|

| High-Purity Epoxy Resin (e.g., DGEBA) | Base polymer; defines network chemistry and ultimate properties. Must be characterized for epoxide equivalent weight (EEW). |

| Stoichiometric Curing Agent (e.g., amine, anhydride) | Initiates crosslinking; type and ratio critically determine Tg, modulus, and crosslink density. |

| Silicone Rubber Molds | For creating samples with precise, reproducible geometry required for clamp fixtures. |

| Release Agent | Facilitates demolding without damaging the sample surface. |

| Liquid Nitrogen or Intracooler | For cooling the DMA furnace to start temperatures below ambient. |

| Calibration Standards (Modulus & Temperature) | Verifies instrument accuracy for force/displacement and temperature sensors. |

| Sandpaper (Fine Grit, e.g., 400 grit) | For finishing sample edges to precise dimensions and smooth surfaces. |

| Precision Micrometer | To measure sample dimensions (thickness, width) accurately, critical for modulus calculation. |

| Nitrogen Gas Cylinder | Provides inert purge gas to the sample chamber, preventing thermal-oxidative artifacts during heating. |

Diagrams

DMA Workflow for Epoxy Tg Measurement

Tg Identification Points on DMA Thermogram

Thesis Context: This document provides detailed protocols for Differential Scanning Calorimetry (DSC) within the broader research objective of accurately measuring the glass transition temperature (Tg) in epoxy resins and composite materials. Determining Tg is critical for understanding the thermal and mechanical performance boundaries of these materials in applications ranging from aerospace to electronics.

Fundamental Principles and Key Transitions

DSC measures the difference in heat flow rate between a sample and an inert reference as a function of temperature or time under controlled atmosphere. For epoxy resins and composites, key thermal transitions detectable by DSC include:

- Glass Transition (Tg): A reversible change in the material from a hard, glassy state to a soft, rubbery state. It appears as a step change in the heat flow curve.

- Curing (Exothermic) Peak: For uncured or partially cured resins, the heat released during cross-linking polymerization.

- Melting (Endothermic) Peak: For semi-crystalline polymers or composite constituents.

- Thermal Decomposition/Oxidation (Exothermic): High-temperature exothermic events indicating material degradation.

Experimental Protocols

Protocol A: Standard Tg Measurement for Cured Epoxy Resins

Objective: To determine the glass transition temperature of a fully cured epoxy resin sample.

Sample Preparation:

- Cut a small, flat disc (5-10 mg) from the cured epoxy/composite using a precision saw or punch.

- Ensure the sample fits neatly into the bottom of a standard DSC aluminum crucible.

- Weigh the sample to an accuracy of ±0.01 mg using a microbalance.

- Place the sample in an aluminum crucible and seal it with a lid using a crucible press. Ensure a hermetic but not overly compressed seal.

- Prepare an identical reference crucible that is empty or contains an inert material (e.g., alumina).

Instrument Calibration:

- Calibrate the DSC for temperature and enthalpy using high-purity indium (Tm = 156.6 °C, ΔHfus = 28.4 J/g) and zinc (Tm = 419.5 °C) at the same heating rate to be used for the experiment.

Experimental Parameters:

- Temperature Range: Start 50 °C below the expected Tg to 50 °C above it. (e.g., 30 °C to 200 °C for a Tg ~120 °C).

- Heating Rate: 10 °C/min (Standard). Higher rates (20 °C/min) shift Tg to higher temperatures; lower rates (5 °C/min) provide higher resolution.

- Atmosphere: Inert nitrogen purge at 50 mL/min to prevent oxidative degradation.

- Data Acquisition Rate: ≥5 pts/°C.

Run Procedure:

- Load the sample and reference crucibles.

- Equilibrate at the starting temperature for 2 minutes.

- Execute the heating scan.

- Cool rapidly after the scan.

Data Analysis (Tg Determination):

- Plot heat flow (W/g) vs. Temperature.

- Identify the step change associated with the glass transition.

- Use the instrument software to determine:

- Onset Tg: Intersection of the extrapolated baseline before the transition and the tangent at the point of maximum slope.

- Midpoint Tg: Temperature at half-height of the heat capacity step.

- Endpoint Tg: Intersection of the extrapolated baseline after the transition and the tangent.

- Report the midpoint Tg as per common practice in polymer science.

Protocol B: Residual Enthalpy and Degree of Cure Measurement

Objective: To determine the degree of cure (α) of a partially cured epoxy or composite and estimate its final Tg.

Sample Preparation: Follow Protocol A for an uncured or partially cured sample (5-10 mg). Hermetic sealing is critical to prevent volatile loss.

Experimental Parameters (Multi-Step Method):

- Step 1: Heat from 30 °C to 100 °C at 20 °C/min (remove thermal history, dry).

- Step 2: Cool to 30 °C at 50 °C/min.

- Step 3: Heat from 30 °C to 300 °C at 10 °C/min. Record this first heating scan. The exothermic peak area corresponds to the Residual Enthalpy of Reaction (ΔHresidual).

- Step 4: Cool to 30 °C.

- Step 5: Re-heat from 30 °C to 300 °C at 10 °C/min. Record this second heating scan. This shows the Tg of the fully cured material (Tg∞) and the absence of a residual reaction peak.

Data Analysis:

- Integrate the exothermic peak area from the first heating scan (Step 3) to obtain ΔHresidual (J/g).

- The Degree of Cure (α) is calculated as:

α = 1 - (ΔHresidual / ΔHtotal)where ΔHtotal is the total enthalpy of reaction for the fully uncured resin, obtained from a separate DSC scan of a fresh, uncured sample. - The Tg from the second heating scan (Step 5) is reported as the ultimate Tg (Tg∞).

Peak Interpretation and Data Presentation

Table 1: Interpretation of Key DSC Events in Epoxy/Composite Analysis

| Event | Direction of Heat Flow | Typical Appearance | Physical Meaning | Notes for Epoxy Systems |

|---|---|---|---|---|

| Glass Transition (Tg) | Endothermic Step | Reversible step change in baseline | Onset of molecular segmental motion | Primary metric. Width of step relates to heterogeneity. Affected by cure, moisture, filler content. |

| Curing Reaction | Exothermic Peak | Large, broad peak | Heat released from cross-linking | Peak temperature indicates reactivity. Area = ΔHtotal. Disappears upon full cure. |

| Residual Cure | Small Exothermic Peak | Small peak preceding or overlapping Tg step | Completion of incomplete cure | Present in poorly cured samples. Must be accounted for in Tg measurement. |

| Enthalpic Relaxation | Endothermic Peak | Sharp peak superimposed on Tg step | Recovery of enthalpy lost during physical aging | Occurs in aged samples. Annealing below Tg creates this peak. |

| Moisture Loss | Endothermic Broad Peak | Very broad, low peak ~100°C | Evaporation of absorbed water | Can obscure Tg. Pre-drying scans (Protocol B, Step 1) are essential. |

| Decomposition | Exothermic or Endothermic | Sharp or broad peak at high T (>300°C) | Chemical breakdown of polymer | Indicates thermal stability limit. Often seen in TGA-DSC. |

Table 2: Impact of Experimental Variables on Measured Tg

| Variable | Typical Standard Value | Effect on Measured Tg | Recommendation for Tg Precision |

|---|---|---|---|

| Heating Rate (β) | 10 °C/min | Increased β increases apparent Tg (kinetic effect). | Use consistent rate (10°C/min) for all comparative studies. Report rate used. |

| Sample Mass | 5-10 mg | Larger mass can broaden transition and reduce resolution. | Use minimal, consistent mass (5±1 mg). |

| Sample Geometry | Thin disc/powder | Poor contact (thick piece) creates thermal lag. | Ensure flat, thin sample for good crucible contact. |

| Atmosphere | N2 (50 mL/min) | Oxidative atmosphere (Air) can lower degradation temperature. | Always use inert N2 purge for stability. |

| Pan Type | Hermetic, sealed | Open pans allow moisture loss, altering Tg. | Always use hermetically sealed pans for polymers. |

| Thermal History | --- | Prior cooling rate/annealing affects enthalpy state. | Erase thermal history with a pre-heat cycle (Protocol B). |

Visualization of Workflows

Title: DSC Analysis Workflow for Epoxy Tg

Title: DSC Peak Identification and Interpretation Logic

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for DSC Analysis of Epoxies

| Item | Function/Benefit | Critical Notes for Tg Measurement |

|---|---|---|

| High-Purity Indium Calibration Standard | Calibrates temperature and enthalpy scale of DSC. Melting point: 156.6°C. | Must be >99.999% pure. Flatten piece to ensure good thermal contact. |

| Hermetic Aluminum Crucibles with Lids | Seals sample in a controlled, constant-volume environment. | Prevents loss of volatiles (moisture, residual solvent) which drastically affects Tg. Essential for polymers. |

| Crucible Press (Sealing Tool) | Creates a consistent, hermetic seal on aluminum DSC pans. | Over-compression can strain the pan, creating artifact peaks. |

| Ultra-High Purity Nitrogen Gas | Inert purge gas to prevent oxidation during heating scans. | Standard flow rate is 50 mL/min. Ensure moisture traps are in place. |

| Microbalance (±0.01 mg) | Precisely measures sample mass (5-10 mg). | Accurate mass is critical for quantitative enthalpy (J/g) calculations. |

| Liquid Nitrogen Cooling Accessory | Enables rapid cooling and sub-ambient temperature operation. | Required for running "heat-cool-heat" cycles to erase thermal history. |

| Calibrated Temperature Standards (e.g., Zn, Pb, Ga) | Multi-point temperature calibration across a wide range. | Use at least two standards bracketing your Tg region for accurate temperature reporting. |

| Flat-Bottom Sample Punch/Cutter | Creates uniform, disc-shaped samples from epoxy/composite sheets. | Ensures consistent, reproducible contact with the crucible base for optimal heat transfer. |

Within a comprehensive thesis on measuring the glass transition temperature (Tg) of epoxy resins and composites, Thermomechanical Analysis (TMA) provides a critical dimension-specific perspective. Unlike DSC, which measures heat flow, TMA quantifies the change in a sample's physical dimensions (expansion, contraction, softening) as a function of temperature under a defined static force. For epoxy networks and composite materials, the coefficient of thermal expansion (CTE) undergoes a distinct, measurable change at Tg, offering a direct method for its determination. This application note details the protocols and considerations for employing TMA to accurately measure Tg in these material systems.

Fundamental Principle and Data Output

TMA applies a minimal, non-deforming force to a sample while subjecting it to a controlled temperature program. The probe displacement is monitored with high sensitivity. For a rigid epoxy or composite below Tg (in the glassy state), the CTE is relatively low. As the material transitions through Tg into the rubbery state, molecular mobility increases dramatically, leading to a significant increase in CTE (for free expansion mode) or a penetration/softening event (under a compressive load). The Tg is identified from the plot of dimension change (ΔL) vs. Temperature as the onset or intersection point of the extrapolated glassy and rubbery state expansion lines.

Table 1: Typical TMA Data for Epoxy Resin Systems

| Material System | Sample Geometry | Load (N) | Mode | Tg (Onset) [°C] | CTE Below Tg [µm/(m·°C)] | CTE Above Tg [µm/(m·°C)] |

|---|---|---|---|---|---|---|

| Neat DGEBA/Amine Epoxy | Cylinder (5mm height) | 0.05 | Expansion | 125 ± 2 | 65 ± 5 | 195 ± 10 |

| Silica-Filled Epoxy Composite | Cylinder (5mm height) | 0.05 | Expansion | 128 ± 2 | 55 ± 5 | 180 ± 10 |

| Carbon Fiber/Epoxy Laminate (in-plane) | Rectangular (10mm length) | 0.02 | Expansion | 132 ± 3 | 12 ± 2 | 35 ± 5 |

| Neat Epoxy Film | Film (~100µm) | 0.1 | Penetration | 122 ± 1 | (Not Applicable) | (Not Applicable) |

Detailed Experimental Protocols

Protocol 3.1: TMA Sample Preparation for Epoxy Resins and Composites

Objective: To prepare uniform, parallel-faced specimens suitable for TMA expansion measurements. Materials: Cured epoxy plaque or composite laminate, low-speed diamond saw, polishing paper (P400, P800 grit), micrometer, isopropyl alcohol. Procedure:

- Sectioning: Using a water-cooled low-speed saw, cut a small specimen from the cured material. Target dimensions: 3-5mm in both diameter/width and length/height.

- Facing: Carefully polish the two faces intended for contact with the TMA probe and sample holder to be flat and parallel. Sequential polishing with P400 then P800 grit paper is typical.

- Cleaning: Ultricate the specimen in isopropyl alcohol for 5 minutes to remove debris. Dry thoroughly in a dust-free environment.

- Measurement: Precisely measure and record the initial sample height (L0) at room temperature using a micrometer at multiple points. Average the values.

- Conditioning: Store the sample in a desiccator until analysis to prevent moisture uptake.

Protocol 3.2: Standard TMA Operation for Tg Determination (Expansion Mode)

Objective: To determine Tg from the change in the coefficient of thermal expansion (CTE). Instrument Calibration: Perform temperature and probe displacement calibration using a certified standard (e.g., high-purity aluminum, indium, or quartz). Method:

- Instrument Setup: Select a flat quartz expansion probe (2-5mm diameter). Choose the expansion or linear thermal expansion measurement mode.

- Force Selection: Apply a minimal static force (typically 0.01N to 0.1N) to ensure consistent contact without compressing the sample. For films, a lower force is used.

- Loading: Place the prepared sample centrally on the sample holder stage. Lower the probe gently onto the sample surface.

- Temperature Program:

- Equilibrate at 30°C.

- Isotherm for 5 min to stabilize.

- Ramp temperature from 30°C to 200°C at a rate of 5°C/min.

- Purge Gas: Nitrogen at 50 mL/min.

- Data Collection: Record probe displacement (ΔL) as a function of temperature (T) and sample temperature (T).

- Data Analysis: Plot ΔL/L0 vs. T. Perform a tangent fit on the linear regions well below and well above the transition. The Tg is reported as the onset temperature, defined as the intersection point of the two extrapolated tangents. The CTE is calculated from the slope of these linear regions (ΔL/(L0·ΔT)).

Protocol 3.3: TMA in Penetration Mode for Softening Point

Objective: To determine the softening temperature, often correlated with Tg, for thin films or coatings. Method:

- Setup: Replace the flat probe with a hemispherical or pointed tip probe. Select penetration or tension/compression mode.

- Force Selection: Apply a higher force (e.g., 0.1N to 0.5N) to enable probe penetration upon softening.

- Loading: Place the film/substrate sample on the stage. Ensure the probe tip contacts the material surface.

- Temperature Program: Identical to Protocol 3.2.

- Data Analysis: The onset of a rapid downward displacement (probe penetration) indicates softening. Tg is typically taken as the extrapolated onset of this deviation from the baseline expansion.

The Scientist's Toolkit: Key Reagent Solutions & Materials

Table 2: Essential Materials for TMA Sample Preparation and Analysis

| Item | Function/Description |

|---|---|

| High-Purity Cured Epoxy Reference (e.g., NIST SRM) | Provides a known Tg and CTE for method validation and instrument performance checks. |

| Flat Quartz Expansion Probes (Various Diameters) | The primary contact for expansion measurements; inert, low thermal expansion. |

| Quartz Penetration Probes (Hemispherical Tip) | Used in softening point/penetration measurements on films or soft materials. |

| Standard Calibration Materials (Al, In, Quartz) | For accurate temperature and dimensional change calibration of the TMA. |

| Low-Speed Diamond Wafering Saw with Water Cooling | Enables precise, low-stress sectioning of rigid epoxy composites. |

| Parallel Polishing Fixture and Abrasive Papers | Ensures production of flat, parallel sample faces critical for accurate ΔL measurement. |

| High-Precision Micrometer (1µm resolution) | Measures initial sample dimension (L0) for accurate CTE and strain calculation. |

| Ultra-High Purity Nitrogen Gas (>99.998%) | Inert purge gas to prevent oxidative degradation of the sample during heating. |

| Temperature-Platform Calibration Kit | Independent verification of the instrument's furnace temperature profile. |

Visualization of TMA Workflow and Data Analysis

Title: TMA Experimental Workflow for Tg Measurement

Title: Interpretation of TMA Thermal Expansion Data

Dielectric Analysis (DEA) and Emerging Techniques

Application Notes

Dielectric Analysis (DEA) is a pivotal technique for characterizing the molecular mobility and phase transitions in epoxy resins and composites, directly applicable to determining the glass transition temperature (Tg). DEA measures the dielectric permittivity (ε') and loss factor (ε'') of a material as a function of temperature, time, and frequency. The peak in the loss factor (tan δ) or the inflection point in the permittivity curve is commonly used to identify Tg. The technique is highly sensitive to the onset of segmental mobility in polymer chains, making it complementary to DSC, especially for detecting early mobility in highly crosslinked or filled systems.

Recent emerging techniques enhance DEA's capabilities. Broadband Dielectric Spectroscopy (BDS) expands the frequency range (typically 10^-6 to 10^9 Hz), providing a detailed map of relaxation processes (α, β, γ) and enabling the construction of master curves via time-temperature superposition. Microdielectric Sensors allow for in-situ, real-time cure monitoring and Tg determination directly in process environments like autoclaves or molds. Impedance Spectroscopy is increasingly used to correlate dielectric properties with microstructural features in composites, such as fiber-matrix interphase quality.

Key Advantages for Epoxy/Composites Research:

- High Sensitivity: Detects subtle changes in mobility before macroscopic Tg.

- Cure Monitoring: Tracks viscosity, gel point, vitrification, and final Tg development.

- Multi-Scale Insight: Probes localized (dipole) and large-scale (ionic) motions.

- In-situ Potential: Miniaturized sensors enable measurement under processing conditions.

Quantitative Data Summary: Comparison of Tg Determination Techniques

Table 1: Comparison of Thermal & Dielectric Techniques for Tg Measurement

| Technique | Measured Parameter | Typical Sample Size | Key Advantage for Epoxies | Key Limitation |

|---|---|---|---|---|

| DSC (Standard) | Heat Flow | 5-20 mg | Direct, standardized, quantitative (ΔCp). | Insensitive to subtle mobility; bulk measurement. |

| DMA (Mechanical) | Storage/Loss Modulus | 10-50 mm³ | High sensitivity to Tg; measures modulus. | Clamping can affect soft samples. |

| DEA (Dielectric) | Permittivity (ε''), Tan δ | ~1 cm² (surface) | Extremely sensitive to early mobility; in-situ cure monitoring. | Requires conductive electrodes; data interpretation complex. |

| BDS (Broadband) | Full spectra of ε' & ε'' | ~1 cm² (surface) | Maps all molecular relaxations; defines activation energy. | Time-intensive; complex analysis. |

Table 2: Typical Dielectric Signatures for Epoxy Resin States

| Material State | Dielectric Loss (ε'') Peak Character | Tan δ Peak Temperature | Ionic Conductivity (σ) |

|---|---|---|---|

| Uncured Liquid | Very high, dominated by ionic flow. | Not defined. | Very high, decreases with viscosity. |

| During Cure | β-relaxation visible; α-relaxation shifts. | Shifts to higher T as cure progresses. | Drops sharply at gelation/vitrification. |

| Glass (Below Tg) | Low, only local β-relaxations. | Lower temp peak (β-relaxation). | Very low, Arrhenius behavior. |

| Rubber (Above Tg) | Sharp α-relaxation peak (Tg). | Clear peak defining Tg. | Increases dramatically. |

Experimental Protocols

Protocol 1: Standard DEA for Tg Determination of Cured Epoxy Resin

Objective: To determine the glass transition temperature (Tg) of a fully cured epoxy resin sample via the α-relaxation peak.

Materials & Equipment:

- Dielectric analyzer with parallel plate sensor or single-surface interdigitated electrode (IDE).

- Temperature-controlled oven or environmental chamber.

- Nitrogen purge gas supply (optional, to reduce moisture effects).

- Cured epoxy resin sample (flat, ~1-3 mm thick, surface smooth).

Procedure:

- Electrode Preparation: Clean the parallel plate electrodes or IDE sensor with isopropanol and dry. For parallel plates, apply a thin, uniform layer of silicone grease or gold sputtering to the sample surfaces to ensure good electrode contact.

- Sample Mounting:

- Parallel Plate: Place the sample between the two plates, ensuring full coverage of the electrode area. Apply minimal, consistent pressure.

- IDE Sensor: Place the flat sample directly onto the sensor surface. Use a spring-loaded fixture to apply gentle, uniform pressure.

- Connection: Secure the sensor/cell in the analyzer and connect to the temperature chamber.

- Parameter Setup:

- Frequency: Set a multi-frequency sweep (e.g., 0.1 Hz, 1 Hz, 10 Hz, 100 Hz, 1000 Hz).

- Temperature Program: Set a heating rate of 2°C/min from at least 50°C below the expected Tg to 50°C above it.

- Measurement: Set to track capacitance (C) and conductance (G) or directly output ε' and ε''.

- Execution: Start the temperature program and data acquisition. If available, use a nitrogen purge (50 mL/min) to minimize atmospheric effects.

- Data Analysis:

- Plot tan δ (ε''/ε') or ε'' vs. Temperature for each frequency.

- Identify the peak maximum of the α-relaxation process. The temperature at the peak at a standard frequency (commonly 1 or 10 Hz) is reported as TgDEA.

- Note the frequency dependence; the activation energy can be calculated from an Arrhenius plot of log(frequency) vs. 1/Tpeak.

Protocol 2: In-situ DEA for Cure Monitoring and Tg Development

Objective: To monitor the isothermal cure of an epoxy-amine system and determine the evolution of the glass transition temperature in real-time.

Materials & Equipment:

- DEA with micro-IDE sensor capable of high-temperature measurements.

- Programmable hot plate or oven.

- Epoxy resin and hardener (pre-mixed, degassed).

- Disposable sensor carriers or high-temperature tape.

Procedure:

- Sensor Setup: Affix the micro-IDE sensor to a glass slide or into a disposable frame. Connect cables to the analyzer.

- Sample Application: Apply a small amount (≈0.1-0.2 mL) of the mixed, uncured resin directly onto the active area of the sensor, covering the electrodes completely.

- Isothermal Cure: Place the sensor/sample into the pre-heated oven or on the hot plate at the desired cure temperature (e.g., 80°C, 120°C). Start data acquisition immediately.

- Parameter Setup:

- Frequency: Use a single low frequency (e.g., 10 Hz or 100 Hz) for optimal sensitivity to ionic viscosity and the α-relaxation.

- Time: Measure continuously for the duration of the cure (e.g., 4-24 hours).

- Monitoring: Track the ionic conductivity (σ) and permittivity (ε') or loss factor (ε'').

- Data Analysis:

- Gel Point: Identify as the time/temperature where the conductivity plateaus or the loss factor shows an inflection (crossover of storage/loss permittivity in time).

- Vitrification: Identified as a sharp minimum in the ionic conductivity or a distinct maximum in ε'' as the material's mobility decreases.

- Tg Development: During cure, the material's Tg rises from below to above the cure temperature. The time to vitrification corresponds to the point where Tg equals the cure temperature. Post-cure, a temperature ramp can be used to find the final Tg.

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for DEA of Epoxy Resins

| Item | Function/Description |

|---|---|

| Interdigitated Electrode (IDE) Sensors | Single-surface sensors for liquid or solid samples. Enable in-situ cure monitoring and minimal sample preparation. |

| Parallel Plate Ceramic Cells | Rigid capacitors for solid, film, or liquid samples. Provide defined geometry for precise permittivity calculation. |

| Conductive Silver Paste/Grease | Ensures ohmic contact between sample and electrode, reducing interfacial polarization artifacts. |

| Temperature Chamber with N₂ Purge | Provides controlled thermal environment; N₂ purge reduces moisture condensation and oxidation at high T. |

| Standard Reference Materials (e.g., PMMA, PS) | Materials with known dielectric relaxation properties for calibration and validation of instrument response. |

| Frequency Response Analyzer (FRA) | Core instrument for BDS, applying AC voltage and measuring phase-sensitive material response. |

Visualizations

Diagram Title: DEA Experiment & Tg Analysis Workflow

Diagram Title: Dielectric Relaxations Linked to Tg

Within a broader thesis on How to measure Tg in epoxy resins and composites research, the accuracy of the Glass Transition Temperature (Tg) determination is critically dependent on meticulous sample preparation and experimental setup. Inconsistent preparation leads to data scatter, unreliable comparisons, and flawed conclusions regarding network structure, degree of cure, and composite integrity. This protocol details the standardized steps essential for generating reproducible and accurate Tg data via Differential Scanning Calorimetry (DSC), the most prevalent method.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 1: Key Materials and Equipment for Tg Measurement in Epoxy/Composites

| Item | Function & Rationale |

|---|---|

| High-Purity Indium Standard | Calibration standard for temperature and enthalpy. Its sharp melting point (156.6°C) verifies instrument calibration. |

| Hermetic Aluminum DSC Pans & Lids | Sealed, volatile-retaining pans prevent oxidation and solvent loss during cure cycles or Tg measurement, ensuring data integrity. |

| Encapsulation Press | Ensures a hermetic, consistent seal of DSC pans, crucial for obtaining flat baselines and preventing sample contamination. |

| Microbalance (0.01 mg sensitivity) | Allows precise sample mass measurement (5-10 mg typical). Accurate mass is vital for quantitative heat flow analysis. |

| Desiccator | Stores pre-dried samples and pans to prevent moisture absorption, which plasticizes epoxies and artificially lowers Tg. |

| Solvents (e.g., Acetone, Isopropanol) | For cleaning DSC pans and tools to prevent cross-contamination between samples. |

| Cryogenic Mill or Precision Saw | For composite samples, enables creation of a representative, small mass sample from a larger, heterogeneous composite. |

| Temperature-Controlled Oven/Furnace | For performing precise post-cure or annealing protocols prior to Tg analysis, ensuring a defined thermal history. |

Detailed Experimental Protocols

Protocol 3.1: Sample Preparation for Neat Epoxy Resins

Objective: To obtain a homogeneous, moisture-free, and reproducibly sized sample for DSC analysis.

- Material Conditioning: Store the uncured resin/hardener components and cured samples in a desiccator for ≥24 hours prior to preparation.

- Mixing & Degassing: For uncured systems, mix components at the prescribed stoichiometric ratio. Mix thoroughly and degas under vacuum to remove entrapped air bubbles.

- Cure Cycle (Pre-treatment): Cure the sample in a controlled oven using the manufacturer-specified time/temperature profile. Use a mold to create a thin film (~0.5-1 mm thick) to ensure uniform cure.

- Sample Sectioning: From the fully cured film, use a clean razor blade or punch to cut a small, flat disc (~1-2 mm diameter) fitting the DSC pan.

- Weighing & Encapsulation: Pre-weigh an empty, clean hermetic pan. Using tweezers, place the sample disc inside. Weigh the pan+sample to obtain exact mass (target 5.0 ± 2.0 mg). Seal the pan using the encapsulation press.

- Labeling & Documentation: Label the sealed pan with a unique identifier and record the exact mass.

Protocol 3.2: Sample Preparation for Epoxy-Based Composites

Objective: To obtain a small, representative sample that reflects the bulk composite's fiber/matrix distribution.

- Bulk Sectioning: Cut a small subsection from the composite laminate using a low-speed diamond saw or cryogenic mill to avoid thermal degradation.

- Size Reduction: For fiber-reinforced composites (e.g., carbon/epoxy), use a cryogenic mill to pulverize the subsection under liquid nitrogen. This creates a powder where resin is exposed on particle surfaces.

- Matrix-Rich Selection: If milling is not possible, carefully slice or grind to obtain fine shavings. Visually select shavings that appear resin-rich, but note this biases the measurement towards the matrix Tg.

- Drying: Place the composite powder/shavings in a desiccator for ≥48 hours due to increased surface area for moisture absorption.

- Weighing & Encapsulation: Follow steps 5-6 from Protocol 3.1. A slightly larger mass (8-12 mg) may be used to improve the signal-to-noise ratio for the often-smaller polymer fraction.

Protocol 3.3: DSC Experimental Setup for Tg Measurement (ASTM E1356)

Objective: To configure the DSC instrument for accurate Tg measurement via the midpoint or inflection point method.

- Instrument Calibration: Calibrate the DSC for temperature and enthalpy using high-purity indium. Perform baseline calibration with two empty, sealed pans.

- Sample Loading: Load the sealed sample pan into the DSC sample furnace. Place an identical, empty sealed reference pan in the reference position.

- Method Programming:

- Equilibration: Hold at 0°C for 2 min.

- Heating Scan: Heat from 0°C to a temperature ≥Tg + 30°C at a standard rate of 10°C/min. For highly cured systems, 20°C/min may be used.

- Cooling: Cool back to 0°C at 40°C/min.

- Second Heating Scan: Repeat the heating scan (0°C to Tfinal at 10°C/min). The Tg is reported from this second heating scan to erase individual thermal history.

- Atmosphere: Use a nitrogen purge gas at a flow rate of 50 mL/min to prevent oxidative degradation.

- Data Acquisition: Ensure sufficient data point density (≥1 point per second).

Data Presentation and Analysis

Table 2: Quantitative DSC Data Analysis for Tg Determination

| Sample ID | Sample Mass (mg) | 1st Heat Tg (°C) | 2nd Heat Tg (°C) | ΔCp (J/g·°C) | Notes |

|---|---|---|---|---|---|

| Neat Epoxy, Cure Cycle A | 5.21 | 125.4 | 127.2 | 0.38 | Residual cure exotherm in 1st heat |

| Neat Epoxy, Cure Cycle B | 5.05 | 138.7 | 139.1 | 0.35 | Higher cure state |

| Carbon/Epoxy Composite | 10.12 | 132.5 | 134.8 | 0.22 | Reduced ΔCp due to filler |

| Indium Std (Calibration) | 8.75 | - | Onset: 156.5°C | ΔH: 28.45 J/g | Meets ASTM criteria |

Analysis Workflow: 1) Plot heat flow (W/g) vs. temperature. 2) On the second heating curve, draw tangents to the pre- and post-transition baselines. 3) Identify the midpoint (Tg midpoint) as the temperature at half-height of the heat capacity step or the inflection point from the derivative curve.

Visualization of Critical Workflows

Sample Preparation and DSC Analysis Workflow

Tg Data Analysis Pathway

Solving Common Tg Measurement Problems: Artifacts, Accuracy, and Reproducibility

Identifying and Avoiding Measurement Artifacts (e.g., Residual Stress, Moisture)

Within the broader thesis on measuring the glass transition temperature (Tg) in epoxy resins and composites, accurate determination is paramount for predicting material performance. A significant challenge arises from measurement artifacts, primarily residual stress and moisture absorption, which can distort thermal analysis results, notably those from Differential Scanning Calorimetry (DSC). This Application Note details protocols for identifying and mitigating these artifacts to ensure data fidelity.

Common Artifacts and Their Impact on Tg

Artifacts can shift the observed Tg, leading to incorrect conclusions about cure degree, thermal stability, and service temperature limits.

Table 1: Impact of Common Artifacts on Measured Tg in Epoxy Systems

| Artifact | Typical Effect on DSC Tg Signal | Potential Magnitude of Tg Shift | Common Source |

|---|---|---|---|

| Residual Stress (Physical Aging) | Endothermic peak before Tg | +5°C to +15°C | Rapid quenching, post-cure cooling, machining |

| Moisture (Plasticization) | Tg depression, broadened transition | -10°C to -50°C | Ambient storage, inadequate drying |

| Incomplete Cure | Broader Tg step, lower enthalpy | Lower than theoretical max | Insufficient time/temperature during cure |

| Residual Solvent | Tg depression, volatile evolution | Variable | Inadequate solvent removal post-processing |

Experimental Protocols for Artifact Mitigation

Protocol 1: Standardized Sample Preparation & Conditioning for DSC

Objective: To prepare epoxy/composite specimens for Tg analysis, minimizing the introduction of moisture and stress artifacts. Materials: DSC pans (hermetic, aluminum), micro-balance, desiccator, drying oven, diamond saw/ultra-microtome. Procedure:

- Sectioning: Cut a small sample (5-10 mg) using a low-speed diamond saw or microtome under minimal mechanical stress. Avoid crushing or sanding.

- Drying:

- Place sample in an open DSC pan.

- Condition in a vacuum oven at 40°C (above typical boiling point of water, below Tg of most epoxies) for 24-48 hours.

- Transfer samples directly to a desiccator containing anhydrous silica gel to cool.

- Encapsulation:

- Weigh the dried sample in a hermetic DSC pan within the desiccator environment.

- Seal the pan immediately using a crimper to prevent moisture reabsorption.

- Pre-DSC Conditioning: Store sealed pans in a desiccator until the moment of DSC analysis.

Protocol 2: DSC Method for Detecting Residual Stress (Physical Aging)

Objective: To identify and separate the endothermic relaxation peak of physical aging from the glass transition. DSC Instrument Calibration: Calibrate for temperature and enthalpy using indium and zinc standards. Method:

- Load the sealed, dried sample.

- First Heat: Run from 25°C to a temperature 30°C above the expected Tg at a standard rate (e.g., 10°C/min). This heat cycle erases the thermal history, including residual stresses.

- Cool: Cool the sample rapidly (e.g., 50°C/min) to the aging temperature (often Tg - 20°C) and hold isothermally for a defined period (t_aging) to reintroduce controlled aging.

- Second Heat: Reheat through the Tg region at the same rate (10°C/min). The endothermic relaxation peak will appear just prior to the Tg step.

- Analysis: On the second heat curve, integrate the relaxation peak enthalpy separately from the heat capacity step change at Tg.

Table 2: Typical DSC Parameters for Stress/Moisture Analysis

| Parameter | Value for Stress Analysis | Value for Moisture Screening | Rationale |

|---|---|---|---|

| Sample Mass | 5-10 mg | 5-10 mg | Ensures uniform thermal gradient |

| Pan Type | Hermetic, sealed | Hermetic, pinhole lid or Tzero pressurizable | Sealed for dryness; vented to observe evaporation |

| Purge Gas | N₂ at 50 ml/min | N₂ at 50 ml/min | Inert atmosphere |

| First Heat Rate | 10°C/min | 5°C/min | Standard; Slower rate can help separate moisture loss events |

| Upper Temperature | Tg + 30°C | 120-150°C (or Tg+30°C) | Erases history; Removes moisture, observes boiling |

| Isothermal Hold | Yes (at Tg-20°C) | Optional (e.g., 5 min at 120°C) | Induces controlled aging; Allows solvent/moisture evaporation |

| Second Heat Rate | 10°C/min | 10°C/min | Analyzes "dry" sample state |

Protocol 3: Distinguishing Moisture Plasticization from Incomplete Cure

Objective: To differentiate between a Tg lowered by plasticization vs. one lowered by insufficient crosslinking. Procedure:

- Perform Protocol 1 for drying and encapsulation.

- Run a standard DSC heat (10°C/min) on the dried sample to obtain Tg(dry).

- Re-cool the sample and perform a modulated DSC (MDSC) run with a slow underlying heat rate (2°C/min) and a small modulation amplitude (±0.5°C) over a 60-second period.

- Analyze the reversing heat flow signal. A broad Tg in the reversing signal is indicative of a heterogeneous network (incomplete cure), while a sharp Tg that was initially depressed by moisture will appear normal in the dry, reversing signal.

- Optional: Perform FTIR spectroscopy on dried vs. undried samples to monitor the change in -OH absorption bands relative to aromatic or C-H bands.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Tg Measurement in Epoxies

| Item | Function/Benefit | Example (Non-branded) |

|---|---|---|

| Hermetic DSC Pan & Lid | Prevents moisture ingress/loss during analysis, crucial for baseline stability. | Sealed aluminum crucibles with O-ring. |

| Tzero Pressurized Pan | Allows controlled venting of volatiles (water, solvents) during analysis to prevent pan rupture. | Aluminum pans with a ventable lid system. |

| Ultra-Microtome Diamond Knife | Produces thin, stress-free sections from composite materials for uniform DSC sampling. | Diamond-coated knife for polymer sections. |

| High-Precision Microbalance | Accurate weighing of sub-10mg samples is critical for quantitative DSC enthalpy analysis. | Balance with 0.001 mg readability. |

| Vacuum Oven with Inert Gas Port | Enables low-temperature, oxygen-free drying to prevent oxidative degradation during moisture removal. | Oven capable of <1 mbar vacuum. |

| Desiccator Cabinet with Dry Gas Purge | Provides a dry storage environment for samples and pans before/after sealing. | Cabinet with anhydrous silica gel or Drierite. |

| Standard Reference Materials (Indium, Zinc) | Mandatory for temperature and enthalpy calibration of the DSC instrument. | High-purity metal standards. |

Visualized Workflows